Production method and application of super-hydrophobic surface polypropylene nonwoven fabric

A technology of polypropylene non-woven fabric and super-hydrophobic surface, which can be used in separation methods, chemical instruments and methods, textiles and papermaking, etc., and can solve the problems of large consumption of organic solvents, high requirements for surface grafting equipment, and complex processes. Achieve the effects of low equipment requirements, short modification time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

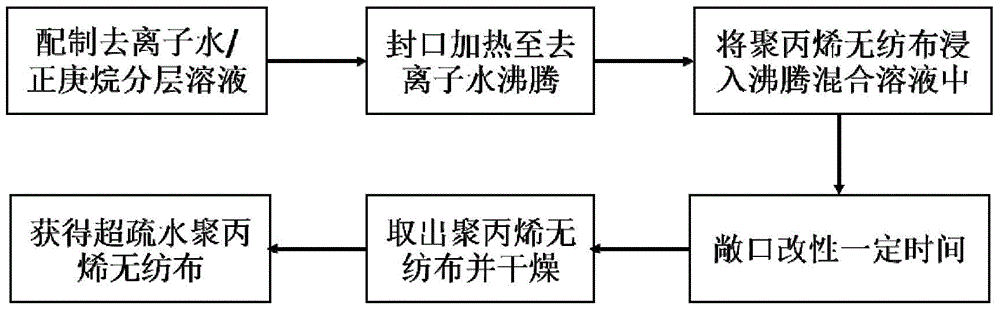

Method used

Image

Examples

Embodiment 1

[0029] Add 5mL of deionized water and 10mL of n-heptane into a 250mL beaker, heat it on an electric stove until the deionized water boils after sealing, and put 0.048g of 30# polypropylene non-woven fabric (30g / m 2 ) was immersed in the boiling solution for 30 s, and was taken out to dry to obtain a superhydrophobic polypropylene nonwoven fabric with a contact angle of 164°.

Embodiment 2

[0033] Add 9mL of deionized water and 9mL of n-heptane into a 250mL beaker, heat it on an electric stove until the deionized water boils after sealing, and put 0.064g of 40# polypropylene non-woven fabric (40g / m 2 ) was immersed in the boiling solution for 40 s, and was taken out to dry to obtain a superhydrophobic polypropylene nonwoven fabric with a contact angle of 160°.

Embodiment 3

[0035] Add 60mL of deionized water and 15mL of n-heptane into a 250mL beaker, heat it on an electric stove until the deionized water boils after sealing, and put 0.216g of 60# polypropylene non-woven fabric (60g / m 2 ) was immersed in the boiling solution for 60 seconds, and was taken out to dry to obtain a superhydrophobic polypropylene nonwoven fabric with a contact angle of 159°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com