Preparation method of wood fiber oil-absorption material

A wood fiber and oil-absorbing material technology, applied in the field of biomass refining, can solve the problems of unsuitability for industrial production, high amount of organic solvent, high price, etc., and achieve good oil-absorbing effect, high reaction degree, and short modification time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a preparation method of lignocellulosic oil-absorbing material, comprising the following steps:

[0028] The wood fiber and the esterification reagent are subjected to esterification reaction under pyridine catalysis and ball milling conditions to obtain the wood fiber oil-absorbing material.

[0029] The present invention does not have any special limitation on the source of the lignocellulosic fiber, and the source of the lignocellulosic fiber well known to those skilled in the art or commercial products can be used; in the embodiment of the present invention, the lignocellulosic biomass raw material is preferably extracted to obtain the lignocellulosic For wood fiber, the solvent used in the extraction is a mixed solvent of toluene and ethanol, and the volume ratio of the toluene and ethanol is 2:1.

[0030] In the present invention, the extraction time is preferably 10-12 hours, more preferably 11-11.5 hours; the extraction temperature is pref...

Embodiment 1

[0051] Extract bagasse with a mixed solution of toluene and ethanol at a volume ratio of 2:1 to obtain bagasse raw material, take 3 mL of acetic anhydride, 3 mL of pyridine and 1 g of pulverized bagasse raw material in a ball mill jar, set the ball mill speed to 1200 rpm , ball milled in a continuous manner for 4 hours, washed with deionized water for several times, dried in an oven at 70°C for 12 hours, and then transferred to an oven at 105°C for 12 hours to obtain bagasse acetate oil-absorbing material.

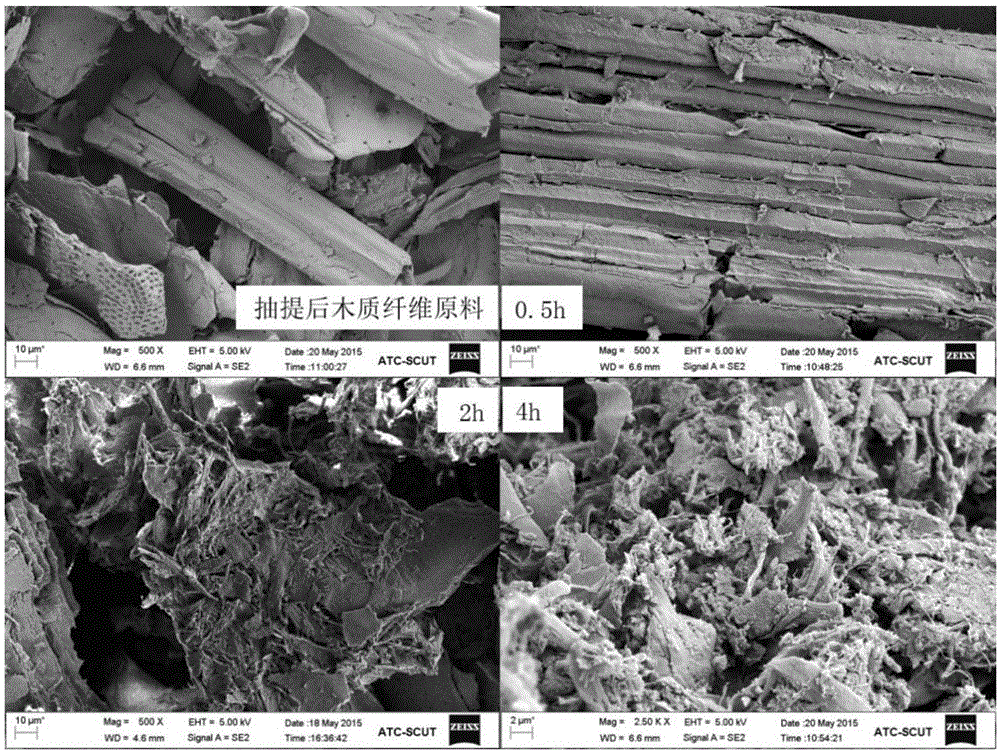

[0052] Bagasse after extraction, bagasse after reaction for 0.5h, bagasse after reaction for 2h, and bagasse after reaction for 4h were analyzed by scanning electron microscope, the results are as follows: figure 1 As shown, after ball milling modification, the surface morphology of the bagasse changed, and the bagasse was completely pulverized, which fully increased the surface area of the bagasse.

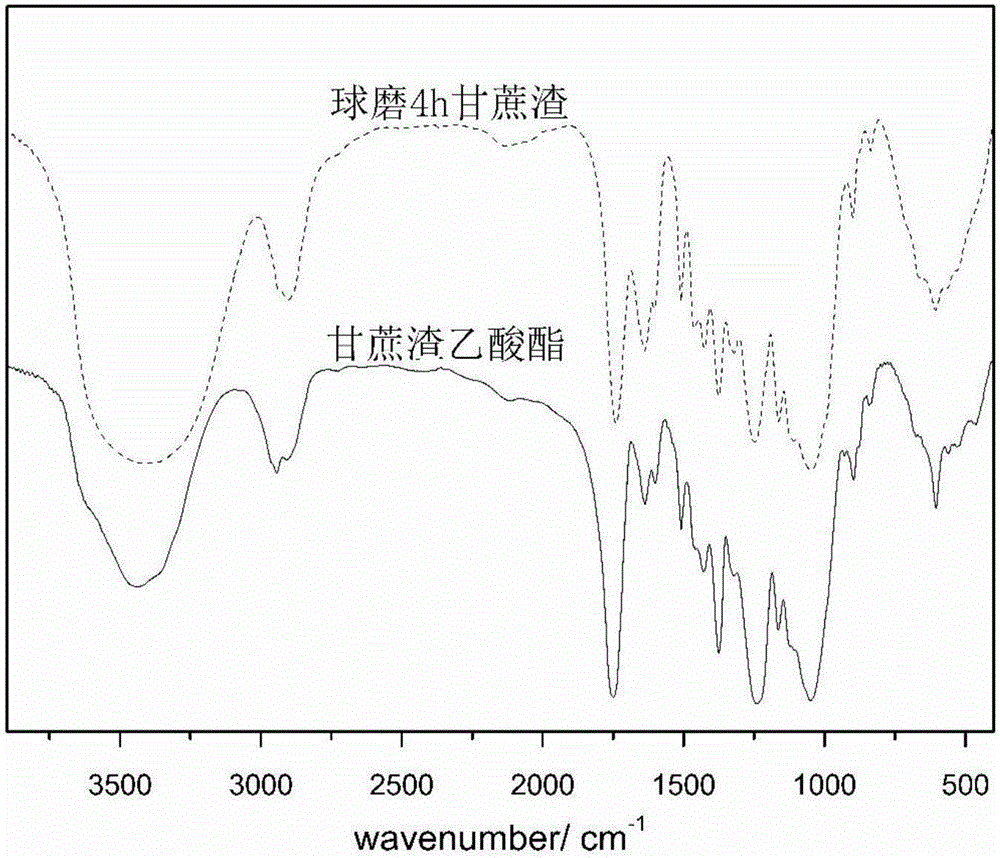

[0053] After weighing, the weight gain rate of bagasse acetate oil-abs...

Embodiment 2

[0055] Extract bagasse with a mixed solution of toluene and ethanol with a volume ratio of 2:1 to obtain bagasse raw material, take 3.5mL propionic anhydride, 2.1mL pyridine and 1g pulverized bagasse raw material and place them in a ball mill jar, set the ball mill speed 800rpm, ball milled continuously for 2h, the product was washed several times with methanol, dried in an oven at 90°C for 12h, and then transferred to an oven at 110°C for 24h to obtain bagasse propionate oil-absorbing material.

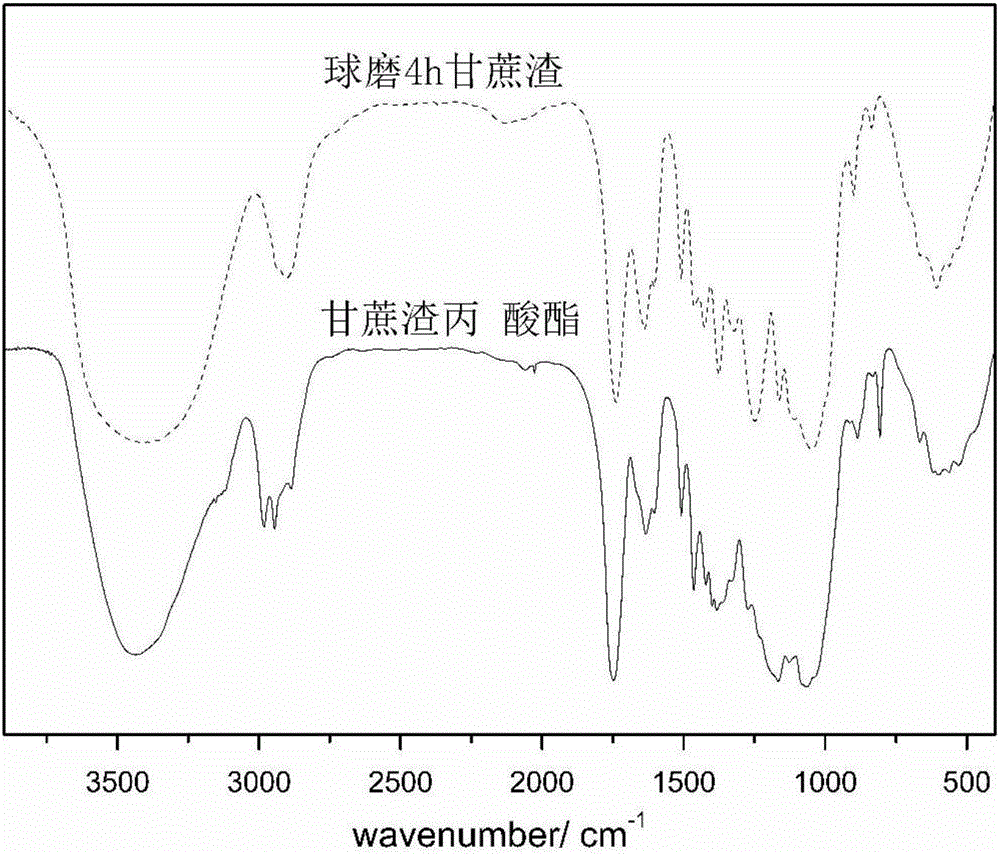

[0056] After weighing, the weight gain rate of bagasse propionate oil-absorbing material is 33.6%, the adsorption rate to diesel oil is 9.35g / g, and the adsorption rate to soybean oil is 9.72g / g. It is detected by infrared spectroscopy, and the obtained results Such as image 3 shown. 1745cm -1 The C=O stretching vibration absorption peak in the ester bond at 1462cm -1 The characteristic absorption peak of propionyl, and 2985~2888cm -1 Two saturated C-H bond absorption peaks appe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com