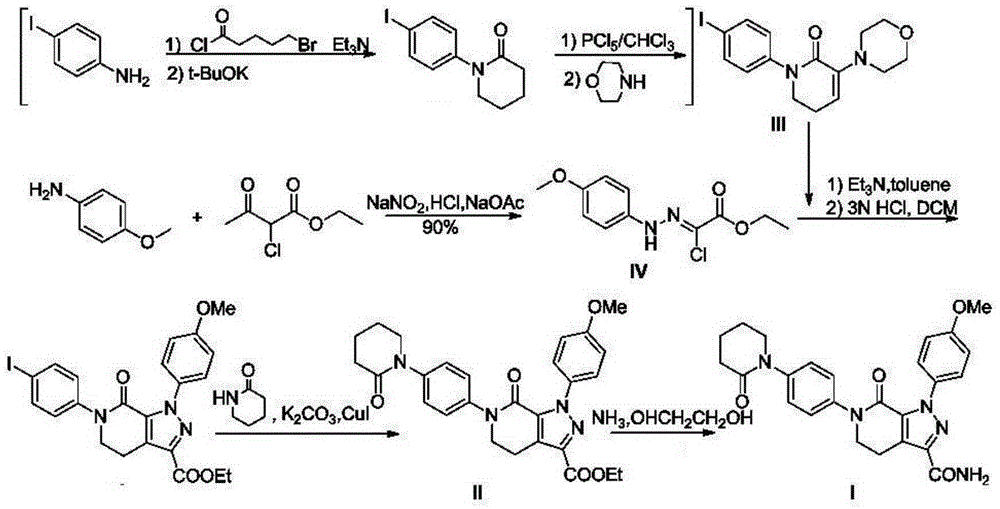

A kind of synthetic method of Apixaban

A synthetic method and technology of apixaban, applied in the field of drug synthesis, can solve the problems of only reaching 29%, high price, unfavorable cost, etc., and achieve the effects of simplifying separation and purification operations, reducing synthesis costs, and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

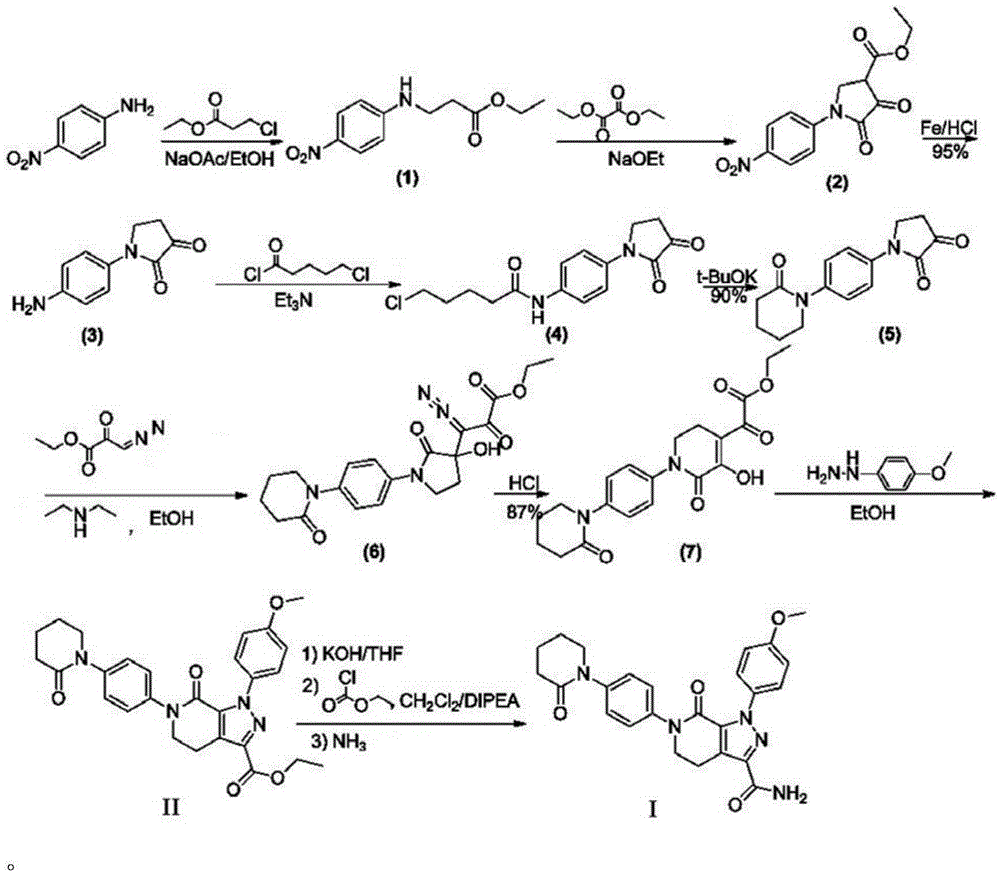

Examples

Embodiment 1

[0045] Compound 1: Synthesis

[0046] Add 138g (1mol) of p-nitroaniline, 700ml of ethanol, 163g (1.2mol) of ethyl 3-chloropropionate to the reaction bottle, add 82g (1mol) of sodium acetate in small amounts at 40°C, and keep the temperature for reaction For 3 to 5 hours, LCMS followed the reaction until the reaction of p-nitroaniline was complete. The reaction liquid was cooled to 0-5oC in an ice-water bath, and 2L of water was added to stir and crystallize, filtered with suction, and vacuum-dried at 40°C for 4 hours to obtain 214g of compound 1, mol Yield: 90%.

[0047] Compound 2: Synthesis

[0048] Add 119g (0.5mol) of compound 1, 600ml of ethanol, 80.3g (0.55mol) of diethyl oxalate to the reaction flask, add 6.8g (0.1mol) of sodium ethoxide in small amounts at 52°C, and keep the temperature for reaction 2 -3 hours, LCMS followed the reaction until the reaction of compound 1 was complete, the reaction solution was cooled to 0-5°C in an ice-water bath, neutralized with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com