A kind of modification method that iron ions promote the rapid formation of γ-feooh layer on the surface of iron filings

A technology of iron ions and iron filings, applied in the modification field of rapidly forming γ-FeOOH on the surface of iron filings, can solve the problems of difficult control of modification conditions, catalyst agglomeration, complicated preparation process, etc. Excellent performance and good engineering applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

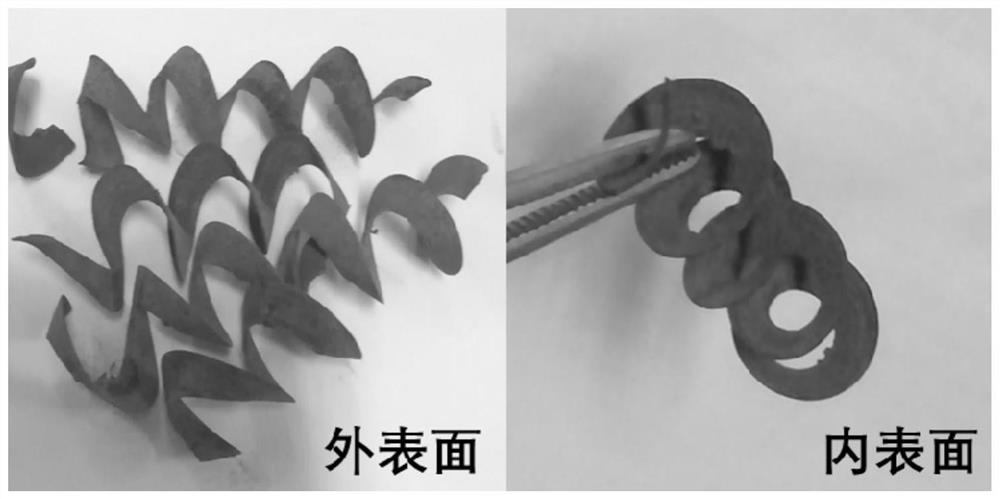

[0042] The modification method of rapidly forming γ-FeOOH on the surface of iron filings proposed by the present invention, the specific steps are as follows:

[0043] (1) Select low carbon steel, medium carbon steel and low alloy structural steel used in the metal processing industry, and pretreat the scrap iron filings produced by drilling, planing, milling and other processes;

[0044] The pretreatment: first, the industrial iron filings are washed several times with detergent to remove the outer oil stains; then soaked in 1mol / L sodium hydroxide solution for 2 hours to remove the oil stains tightly adsorbed on the surface, and repeatedly washed with tap water The iron filings are neutral to the cleaning water; before oxidation modification, soak in 1% hydrochloric acid for 1 hour, and then repeatedly wash the iron filings with tap water until the cleaning water is neutral.

[0045] (2) place the iron filings that step (1) obtains in the mixed modification liquid containing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com