Gear shaving machining tooth form modification method

A technology of shaving cutter and concave tooth profile, which is applied in the field of involute gear tooth root modification, can solve the problems of poor gear meshing stability, affecting the performance of gears, affecting the performance of the whole machine, etc., so as to reduce gear meshing. Noise, good economic efficiency, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

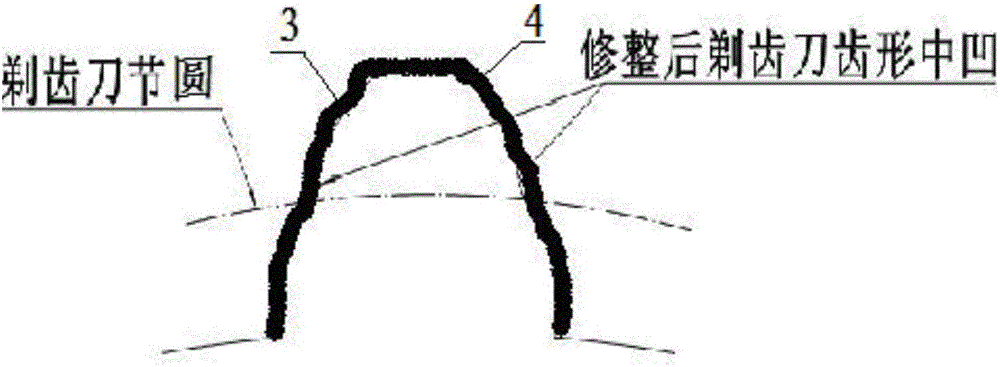

[0014] The present invention is a kind of involute gear dedendum modification method of trimming shaving cutter, according to the concave defect of the tooth shape produced by the gear part, it is characterized in that using the gear type diamond trimming wheel pair to carry out the concave repair around the pitch circle of the cutter tooth, See figure 1 , 3 , using a shaving cutter with a concave pitch circle to reprocess the workpiece gear to eliminate the problem of "shaving concave", the implementation steps are as follows:

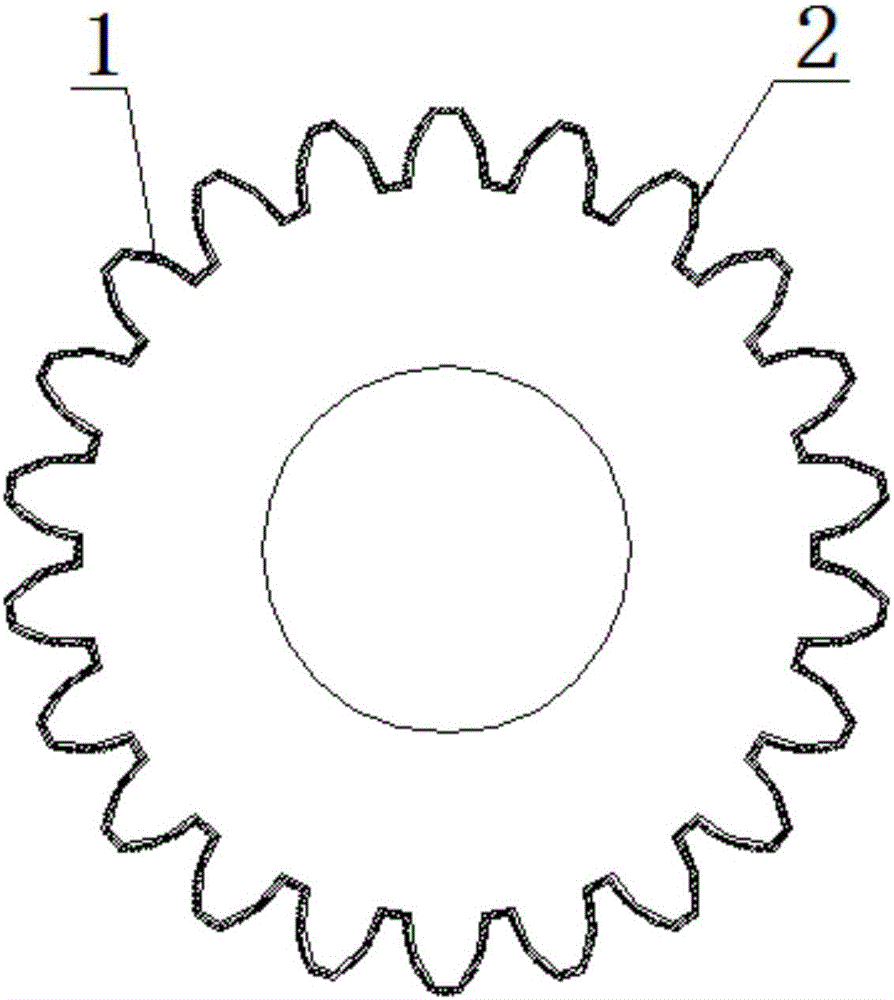

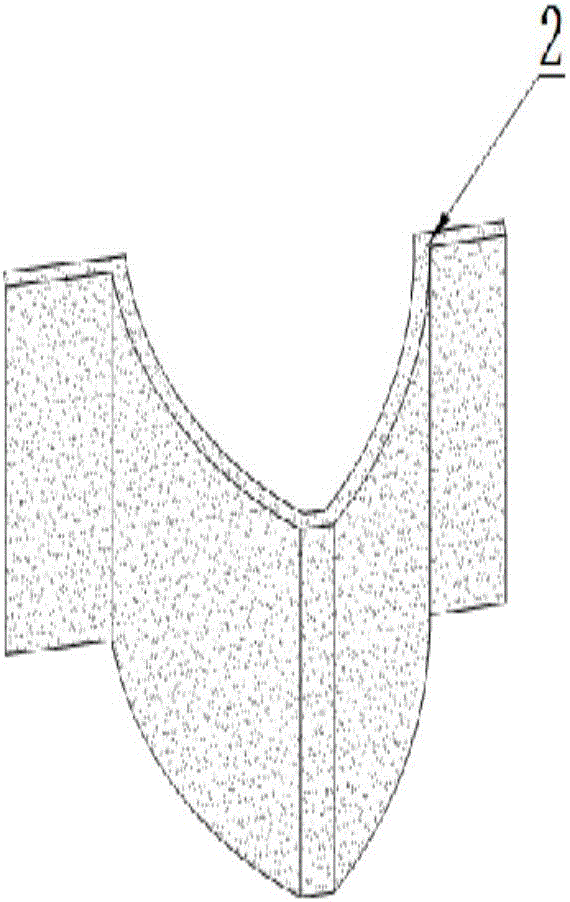

[0015] Step 1: Design the dressing wheel 1 of the gear type diamond, the dressing wheel is a standard gear shape, and the surface of the gear teeth is coated with a solid diamond particle layer 2, see figure 2 , the gear-type diamond dressing wheel needs to be customized by a professional manufacturer. The number of teeth of the dressing wheel 1 is selected according to the specific modulus and number of teeth of the gear product produced. Generall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com