Macroporous biochar-based hybrid material for ultrafast removing heavy metals in water body as well as preparation method and application of macroporous biochar-based hybrid material

A biochar, heavy metal technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as slow adsorption kinetics, and achieve the effects of increasing adsorption speed, small proportion, and simple modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

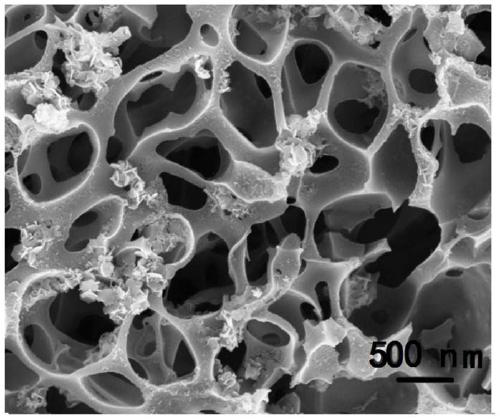

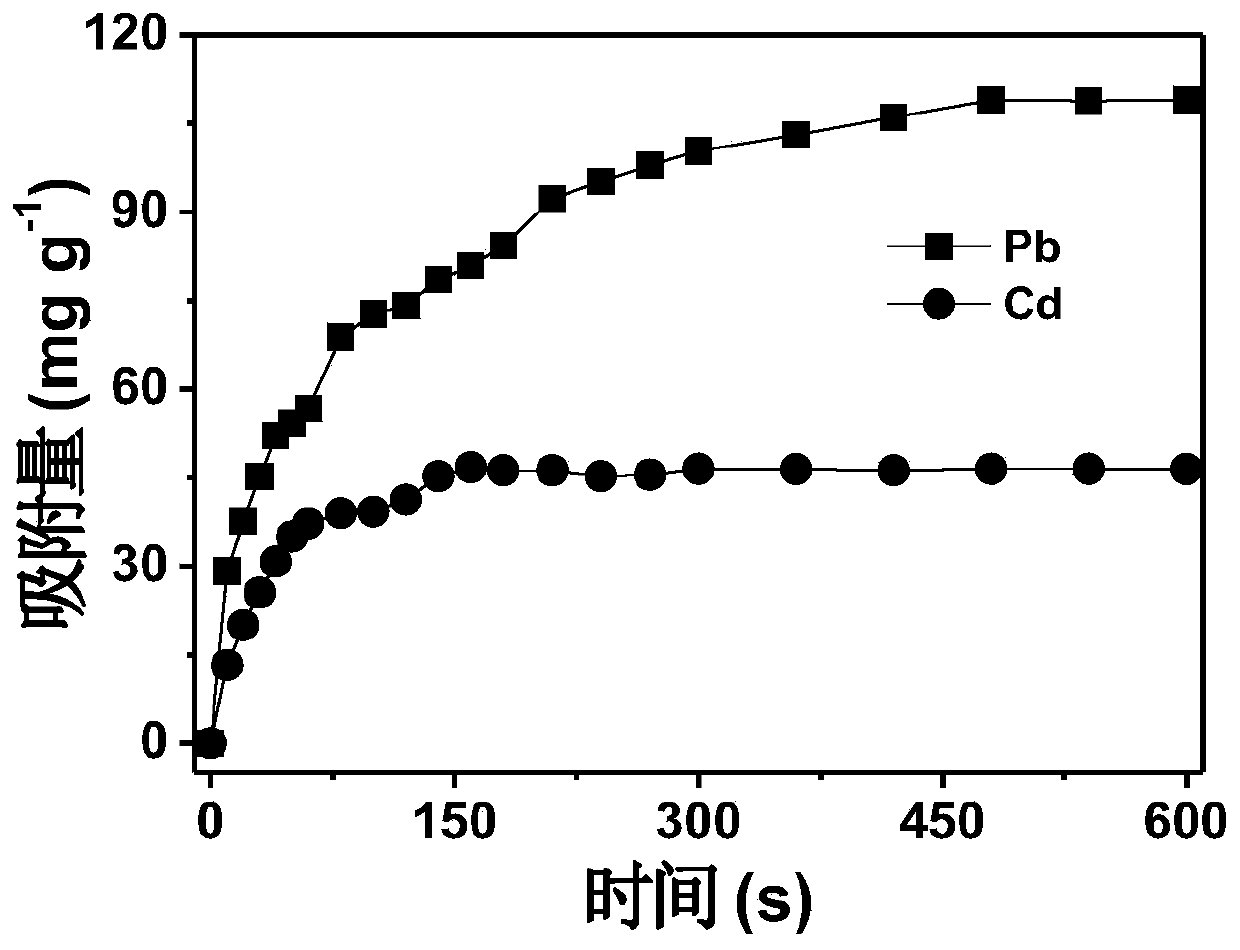

[0034] Combine 2g peanut shells with 10g KHCO 3 Mix evenly, pyrolyze at 600°C for 1 hour under argon atmosphere to prepare macroporous biochar, then wash and dry with dilute hydrochloric acid with a mass fraction of 10%, and then screen out macroporous biochar with a particle size of 0.2-0.3mm Add to 200mL 1mol / L MnCl 2 solution, and then stirred at 60°C water bath temperature for 20h to ensure that Mn 2+ Fully diffuse into the pores of macroporous biochar, and then filter out to obtain solid materials; add the solid materials to 200mL of a mixed solution composed of NaOCl solution and NaOH solution, the active chlorine content in the mixed solution is 5%, and the mass fraction of NaOH is 10%; Stir at 25°C for 24h, then filter out the solid and wash repeatedly until the pH of the eluate is 8.5, dry the solid substance at 50°C to constant weight, and obtain the macroporous biochar-based nano manganese oxide hybrid material.

[0035] The particle size of the hybrid material is...

Embodiment 2

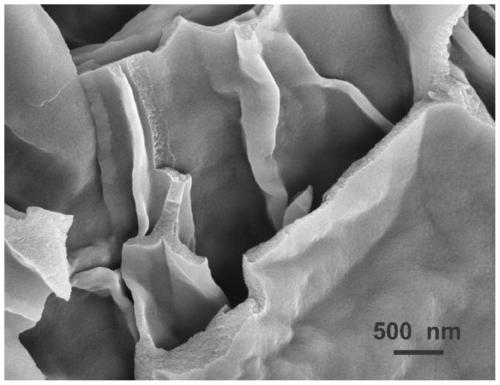

[0039] Mix 3g coconut shell with 12g NaHCO 3 Mix evenly, and pyrolyze at 500°C for 1 hour under an argon atmosphere to prepare macroporous biochar, then wash and dry with 15% dilute hydrochloric acid, and then filter out macroporous biochar with a particle size of 0.4-0.5mm and add it to 500mL. .5mol / L of MnSO 4 solution, and then stirred at 30°C water bath temperature for 15h to ensure that Mn 2+ Fully diffuse into the pores of macroporous biochar, and then filter out to obtain solid materials; add the solid materials to 400mL of a mixed solution composed of NaOCl solution and NaOH solution, the active chlorine content in the mixed solution is 6%, and the mass fraction of NaOH is 8%; Stir at 25°C for 18h, then filter out the solid and wash repeatedly until the pH of the eluate is 7, and dry the solid at 50°C to constant weight to obtain a macroporous biochar-based nano manganese oxide hybrid material.

[0040] The particle size of the hybrid material is 0.4-0.5mm and the su...

Embodiment 3

[0042] Mix 1g of peanut shells with 4g of KHCO 3 Mix evenly, and pyrolyze at 600°C for 1 hour under an argon atmosphere to prepare macroporous biochar, then wash and dry with 20% dilute hydrochloric acid, and then filter out macroporous biochar with a particle size of 0.1-0.2mm and add to 200mL1mol / L MnCl 2 solution, and then stirred at 60°C water bath temperature for 20h to ensure that Mn 2+ Fully diffuse into the pores of macroporous biochar, and then filter out to obtain solid materials; add the solid materials to 200mL of a mixed solution composed of NaOCl solution and NaOH solution, the active chlorine content in the mixed solution is 3%, and the mass fraction of NaOH is 5%; Stir at 25°C for 24h, then filter out the solid and wash repeatedly until the pH of the eluate is 8.5, and dry the solid at 50°C to constant weight to obtain a macroporous biochar-based nano manganese oxide hybrid material. The particle size of the hybrid material is 0.1-0.2mm, and the surface area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com