Modified ceramsite capable of efficiently removing phosphorus and preparation method of modified ceramsite

A ceramsite, efficient technology, used in ceramic products, chemical instruments and methods, clay products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the modified ceramsite of above-mentioned efficient dephosphorization comprises the following steps:

[0028] (1) With papermaking lime mud and fly ash as the main raw materials, after mixing according to the ratio, the green balls are made into green balls through a centrifugal ball forming machine, and the particle size of the green balls is controllable within the range of 2-20mm;

[0029] (2) After natural curing of the green balls prepared in step (1) for 20h-24h, drying at 105°C, and finally calcining to obtain ceramsite;

[0030] (3) Put the ceramsite in step (2) into KH with a total phosphorus concentration of 15-20mg / L 2 PO 4 In the solution, take it out after static adsorption to saturation;

[0031] (4) Dry the saturated ceramsite at 105°C for 1-2 hours, and then calcinate in a sintering furnace to obtain modified ceramsite with high efficiency for phosphorus removal.

Embodiment 1

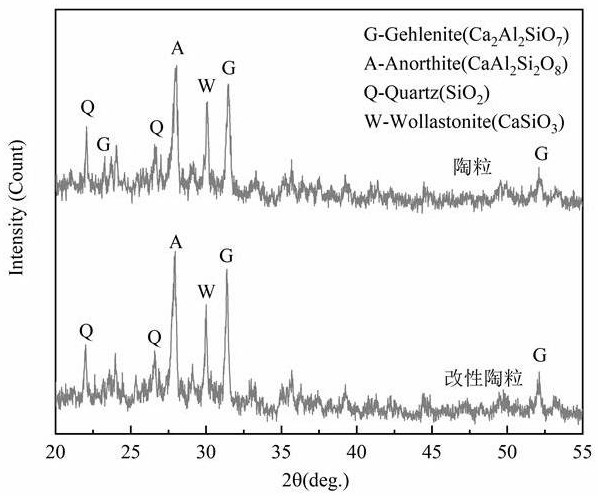

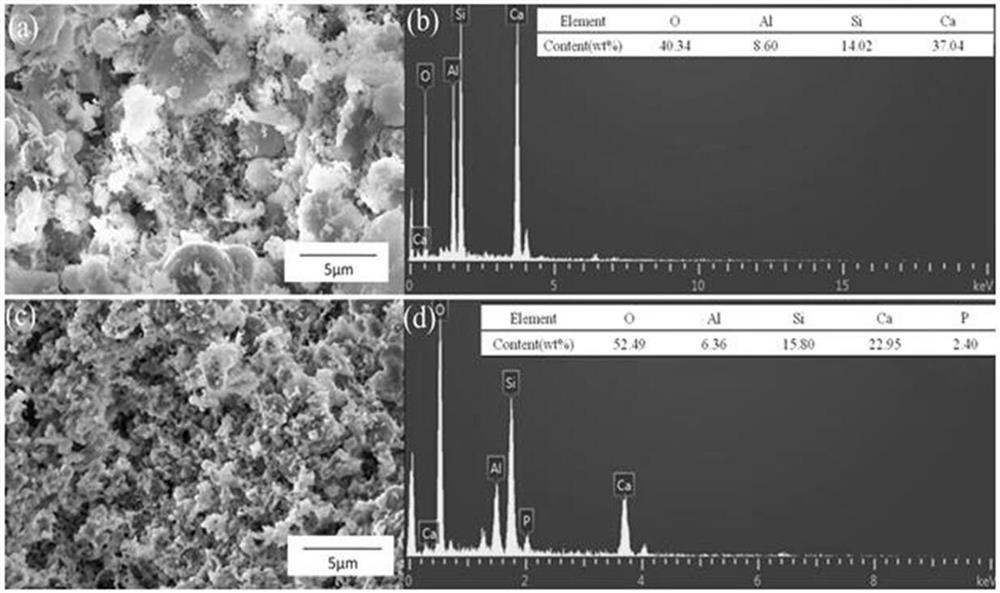

[0034] Select the ratio of raw materials as 50wt% papermaking white mud and 50wt% fly ash, mix them with a cement mortar mixer, control the water-solid ratio to 0.05, and put the mixture into a centrifugal ball forming machine to form green balls. After natural curing for 24 hours, put the raw balls into a drying oven and dry at 105°C for 12 hours, and finally move them into a high-temperature calciner for calcination. ℃ and heat preservation for 2 h, and finally cooled with the furnace, the ceramsite with anorthite and anorthite as the main mineral phases, which has the characteristics of releasing calcium for alkali, and its XRD pattern is as follows figure 1 shown.

Embodiment 2

[0035] Example 2 Phosphorus removal and modification of ceramsite by static adsorption method

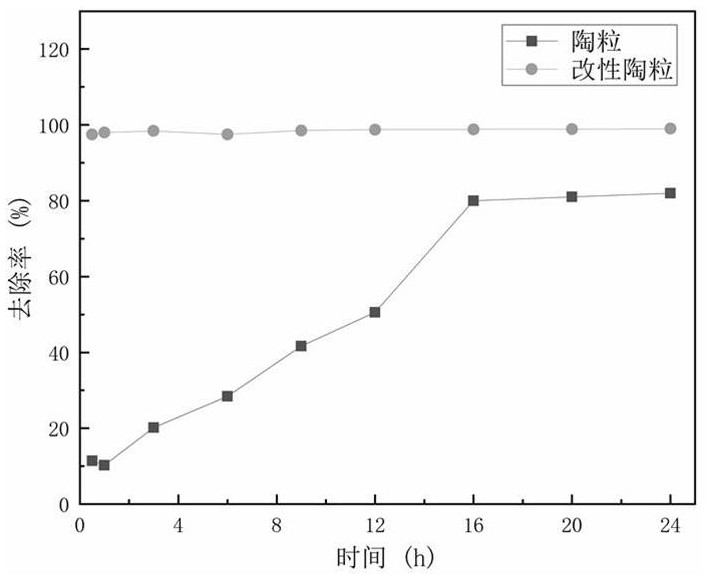

[0036] Analytical grade reagent KH 2 PO 4 Configure the simulated phosphorus-containing sewage with a total phosphorus concentration of 20mg / L. Put the ceramsite prepared in Example 1 into the simulated phosphorus-containing sewage with the dosage of 20g / L, put it into the water bath constant temperature oscillation box, and vibrate horizontally under the conditions of 25°C and 120r / min, at different time intervals (0.5 , 1, 3, 6, 9, 12, 16, 20, 24h) to take samples, filter and extract water samples through a 0.45μm filter membrane, measure the remaining phosphorus concentration, and calculate the phosphorus removal rate. The results are as follows figure 2 shown. It can be seen that the ceramsite reached the adsorption equilibrium in about 16 hours, the removal rate was 82%, and the adsorption capacity was 0.82 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com