Sodium alginate-embedded iron carbon-medicine stone high-efficiency phosphorus removal particles and preparation method thereof

A technology of sodium alginate and medical stone, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of slow iron-carbon micro-electrolysis and low phosphorus removal effect and other problems, to achieve the effect of economical speed, low cost and strong ability to adsorb phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this example, the specific steps for preparing the novel iron-carbon-medicine stone high-efficiency phosphorus removal particles embedded in sodium alginate are as follows:

[0029] (1) Grinding and sieving woody activated carbon to make the particle size less than or equal to 150 μm;

[0030] (2) Prepare 200mL of 10wt% calcium chloride solution;

[0031] (3) Prepare 100mL of 2wt% sodium alginate solution: add sodium alginate to water, stir well, put it in a 65°C oven and heat for 60min, and stir continuously until it is completely dissolved;

[0032] (4) Add 8g of uniformly mixed elemental iron, activated carbon, and medical stone to the 2wt% sodium alginate solution in step (3), and mix evenly to form a mixed solution; the mass of the above-mentioned elemental iron, activated carbon, and medical stone The ratio is 2:1:1.

[0033] (5) Use a syringe to drop the mixed solution in step (4) into the calcium chloride solution in step (2) to obtain gel beads, which are ...

Embodiment 2

[0036] The specific steps for preparing gel beads containing only sodium alginate in this embodiment are:

[0037] (1) Prepare 200mL of 10wt% calcium chloride solution;

[0038] (2) Prepare 100mL of 2wt% sodium alginate solution: add sodium alginate to water, stir well, put it in a 65°C oven and heat for 60min, and stir continuously until it is completely dissolved;

[0039] (3) Use a syringe to drop the sodium alginate solution in step (2) into the calcium chloride solution in step (1) drop by drop to obtain gel beads, which are left to solidify at 25°C for 24 hours;

[0040] (4) Filter out the solidified gel beads to obtain gel beads.

Embodiment 3

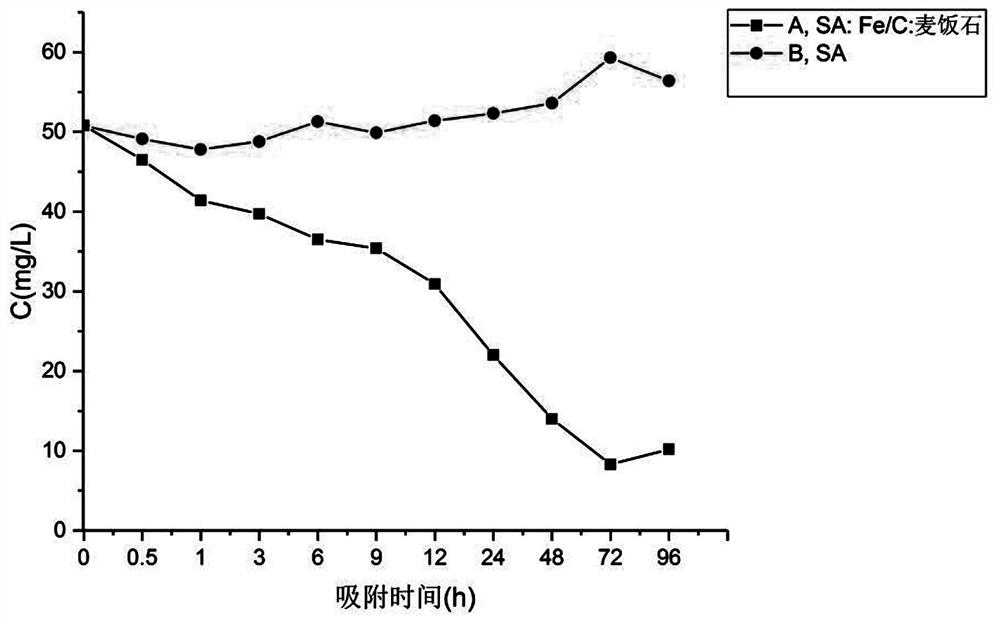

[0042] Evaluation of the dephosphorization performance of the gel beads prepared in above-mentioned embodiment 1 and embodiment 2

[0043] Prepare KH with an initial concentration of 50mg / L 2 PO 4 The solution simulates phosphorus-containing wastewater, and the gel beads prepared in Examples 1 and 2 are respectively added, and shaken at a speed of 150 rpm for 96 hours under the condition that the solid-to-liquid ratio is 1:50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com