Integrative three-bent tridimensional cyclic oxidation ditch

A technology of three-dimensional circulation and oxidation ditch, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sewage multi-stage treatment, etc., can solve the problem of increased aeration equipment requirements, inability to achieve dephosphorization, and land occupation Reduction of other problems, to achieve the effect of good water quality, save operation, and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

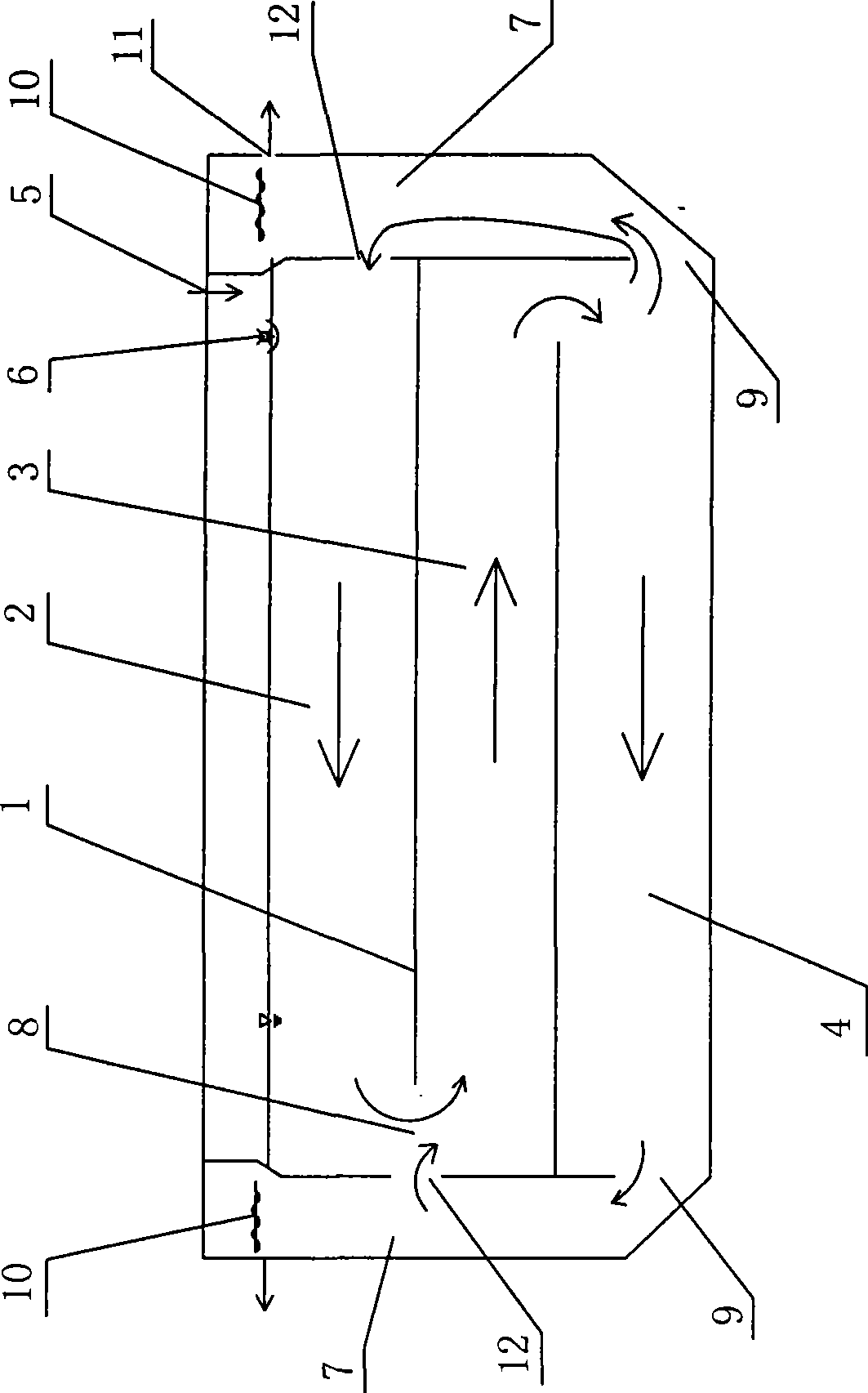

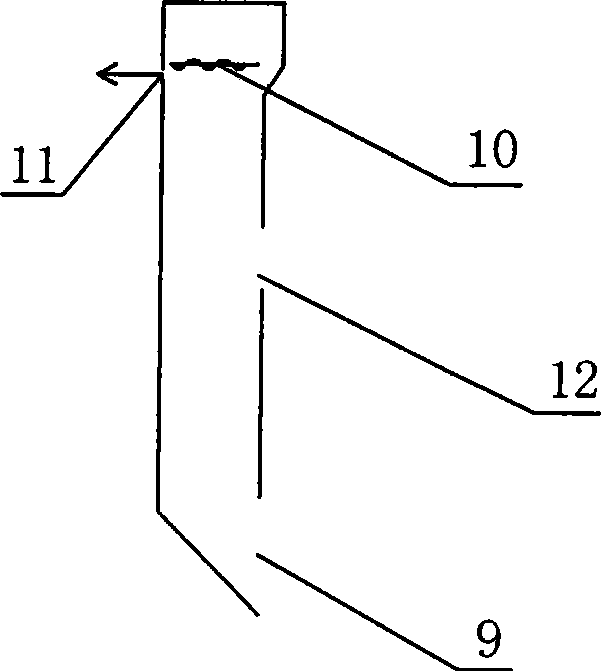

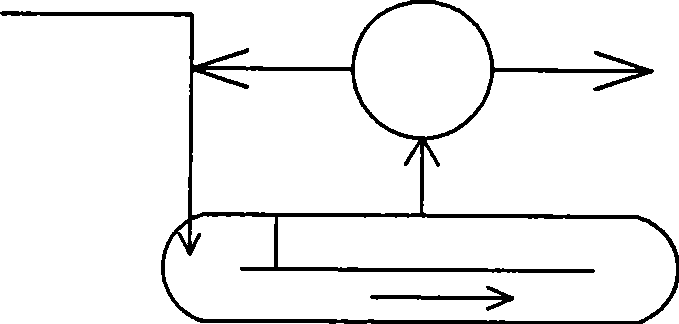

[0024] like figure 1 As shown, two horizontal partitions 1 are arranged in the oxidation ditch of the present invention, and the oxidation ditch is divided into three hollow chambers, the upper layer aerobic zone 2 , the middle layer anoxic zone 3 and the lower layer anaerobic zone 4 . A water inlet 5 is opened on the top of the oxidation ditch, and an aeration rotating brush 6 is installed in front of the water inlet 5 to facilitate the discharge of sewage into the oxidation ditch. Two solid-liquid separators 7 are installed on both sides of the oxidation ditch at the same time. The opposite channels 8 are left between the walls to allow the sewage to circulate smoothly, or the inner walls of the solid-liquid separator 7 on both sides of the oxidation ditch of the partition 1 are airtightly connected, and water supply circulation is provided at both ends of the partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com