Microsphere-type high-hydrophoby starch, as well as preparation method and application thereof

A high-hydrophobic, microsphere-type technology, which is applied in the field of natural polymer material modification, can solve the problems of affecting the compatibility of synthetic resins, difficulty in significantly improving hydrophobicity, and poor hydrophobicity of modified starch, achieving low cost and hydrophobicity. Good effect and short modification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Prepare dry starch: dry corn starch at 150°C for 1.5h;

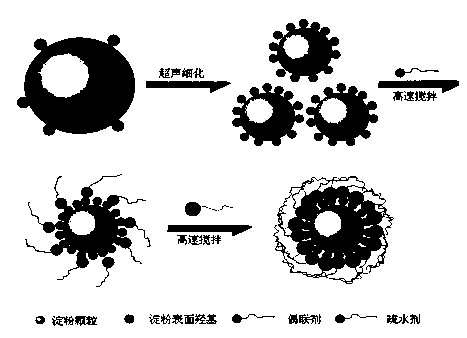

[0027] The second step: preparation of micronized starch: take 100 mass points of dried corn starch in an ultrasonic oscillator, frequency 60KHz, room temperature, ultrasonic oscillation for 2h;

[0028] The third step: preparation of highly hydrophobic starch: transfer 100 mass points of the above-mentioned micronized starch into a high-speed mixer: stir at 3000 rpm, add 0.5 mass fraction of peanut acidified oil, and stir at 80°C for 0.5 h. 3000 rpm, add 1 mass fraction of swill waste oil, and stir at 80°C for 0.5 h. 150 ℃, drying for 2 hours to obtain microspherical high hydrophobic starch.

[0029]Unrefined corn starch granules are irregularly arranged and agglomerated into lumps (see figure 2 ), while the agglomeration phenomenon of microspherical highly hydrophobic corn starch obviously disappeared, the particles became smaller and evenly arranged, and the surface showed a bright hydrophobic layer ...

Embodiment 2

[0031] Step 1: Prepare dry starch: dry wheat starch at 120°C for 3 hours;

[0032] The second step: preparing micronized starch: take 100 parts by mass of dried wheat starch in an ultrasonic oscillator, 80KHz, room temperature, ultrasonic oscillation for 1h;

[0033] The third step: preparing starch with a surface hydrophobic layer: transfer the above-mentioned 100 parts by mass of micronized starch to a high-speed mixer. Under stirring at 2500 rpm, at 60°C, add 1 mass part of soy acidified oil, and stir for 1 hour. Under stirring at 2500 rpm, add 0.5 mass fraction of lard waste oil, and stir at 60° C. for 1 hour. Dry at 120°C for 3 hours to obtain microspherical highly hydrophobic starch.

[0034] The particle size of unmodified wheat starch is mostly distributed in 5-12 microns, and the contact angle is about 20°. The particle size of modified wheat starch is mostly distributed in 0.1-3 microns, and the contact angle is 154°.

Embodiment 3

[0036] The first step: preparing dry starch: drying potato starch at 100°C for 4 hours;

[0037] The second step: preparing micronized starch: take 100 parts by mass of dried potato starch in an ultrasonic oscillator, 100KHz, room temperature, ultrasonic oscillation for 1h;

[0038] Step 3: Preparation of starch with a surface hydrophobic layer: transfer the above 100 mass fractions of micronized potato starch to a high-speed mixer, stir at 2000 rpm, and add 0.8 mass fractions of rapeseed acidified oil / sunflower acidified oil at 40°C (1 / 1 mass ratio), stirring for 2h. Under stirring at 2000 rpm, at 40°C, add 0.7 parts by mass of vegetable oil waste oil, and stir for 2 hours. Dry at 110°C for 4 hours to obtain microspherical highly hydrophobic potato starch.

[0039] The particle size of unmodified potato starch is mostly distributed in 25-39 microns, and the contact angle is about 5°. The particle size of modified potato starch is mostly distributed in 5-8 microns, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com