Patents

Literature

75results about How to "Thoroughly modified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

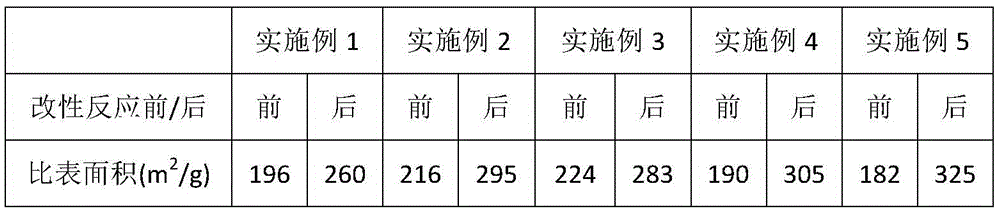

Modification method of attapulgite

The invention relates to a modification method of attapulgite, in particular relates to a modification method of the attapulgite by utilizing the steps of purifying the attapulgite, modifying the attapulgite, treating the attapulgite and the like. In the attapulgite purification step, operations such as smashing, soaking, centrifuging and the like are fully combined; and the purity of the purified attapulgite is greatly improved through specific steps and selection of parameters such as smashing degree, soaking time, centrifugation rotation speed and the like, and the times required by the purification and modification of the attapulgite are significantly shortened, so as to provide a good basis for subsequent modification, thus the purification step has a high industrial value. Stirring and heating operations are set along with the proceeding of modification, sodium bicarbonate and sodium hydroxide particles are added while stirring in the stirring process, and the modification vitality of the attapulgite is improved by utilizing a chemical reaction theory so that the attapulgite is thoroughly modified, and the modified attapulgite has a strong adhesion property and is not easy to disintegrate.

Owner:LANZHOU UNIVERSITY

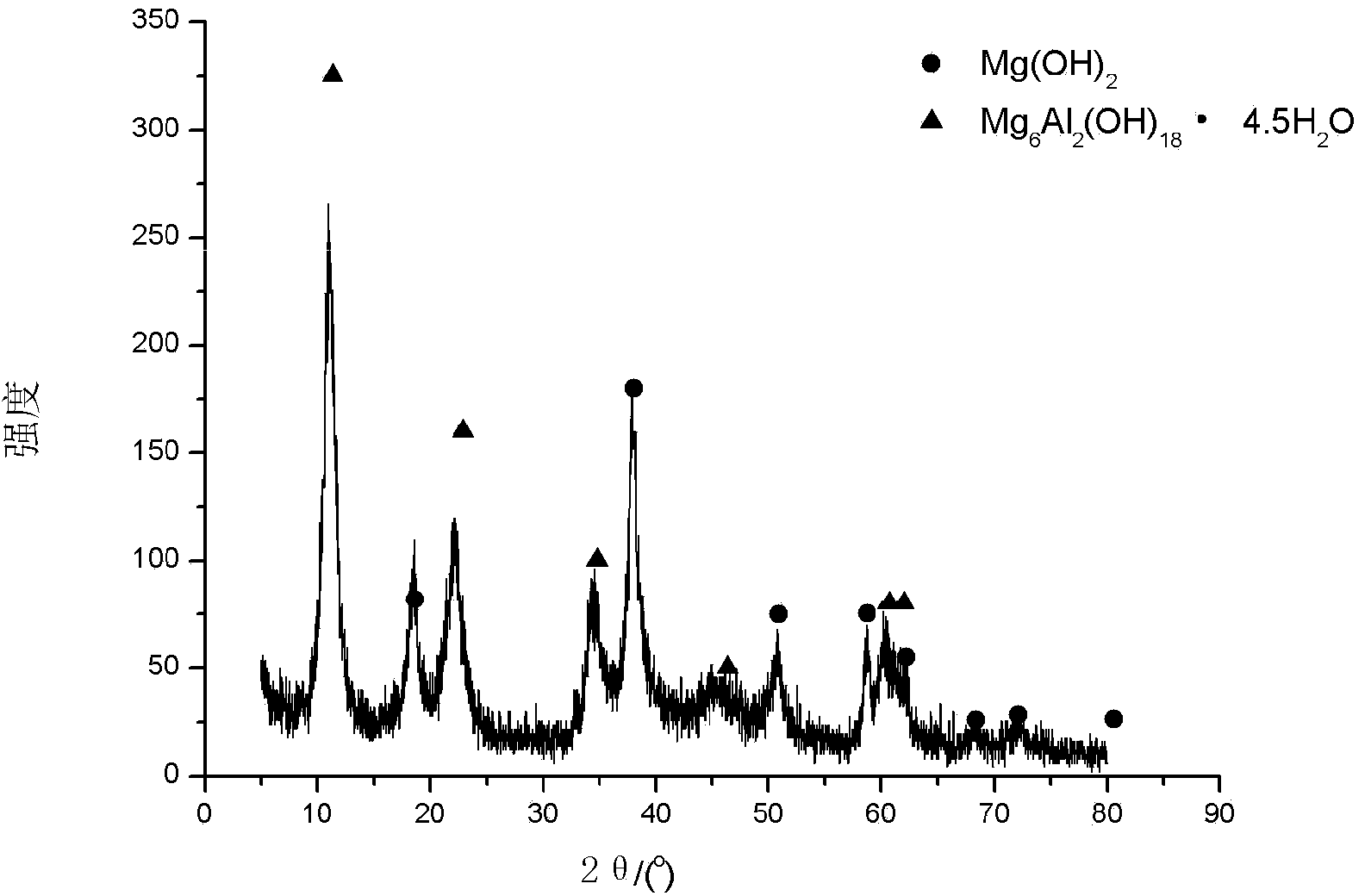

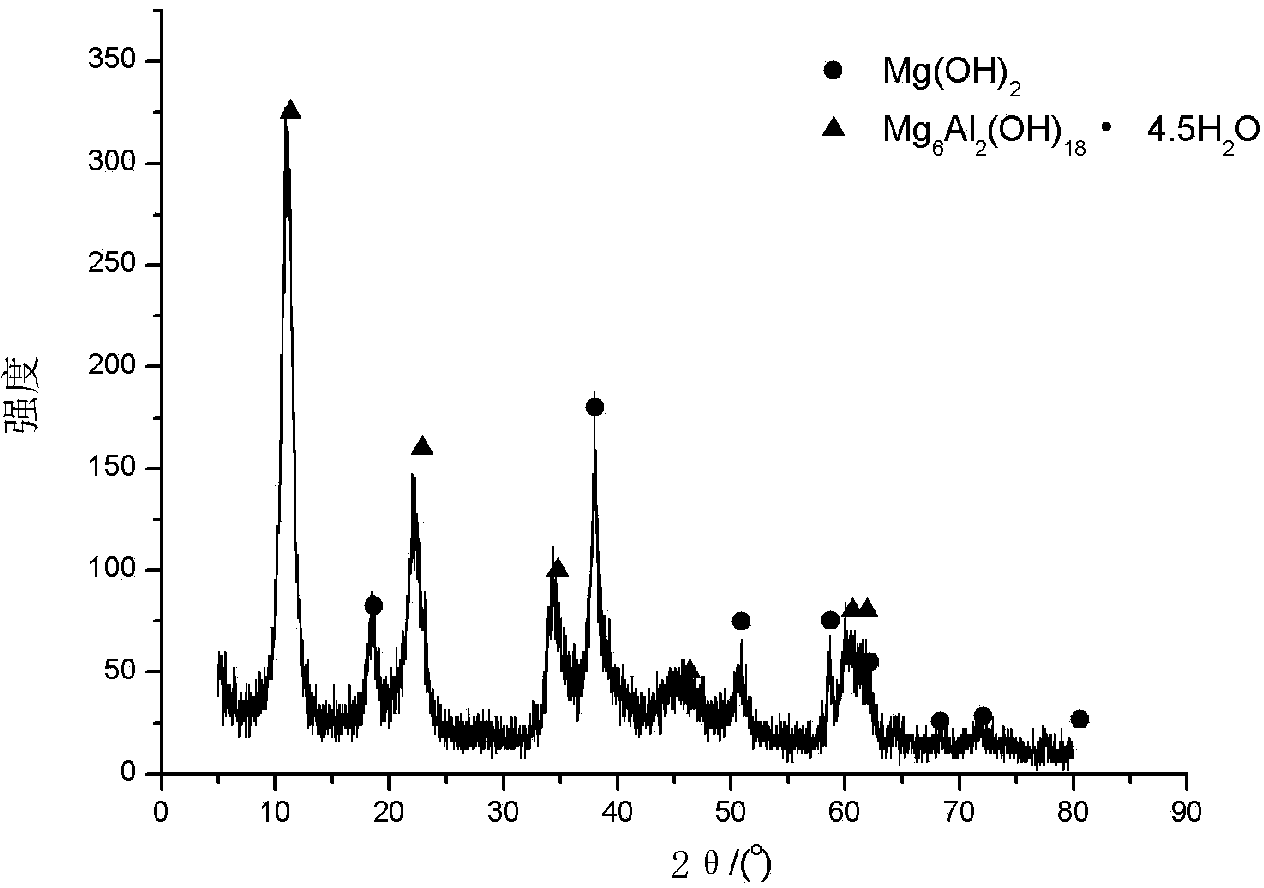

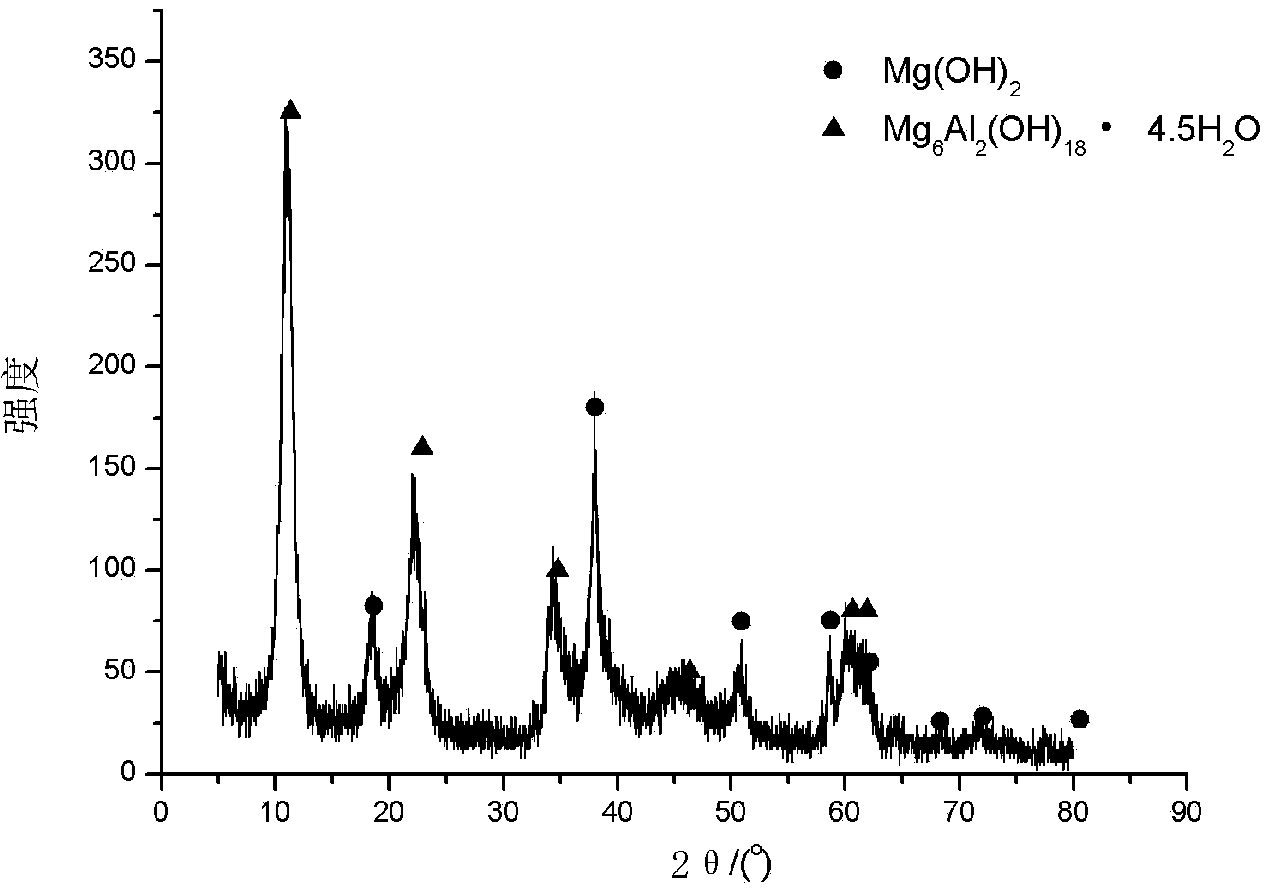

Preparation method of modified nanometer magnesium-aluminum composite fire retardant

A preparation method of a modified nanometer magnesium-aluminum composite fire retardant comprises the following steps: dissolving a soluble aluminum salt and a magnesium salt into a surface modifier solution to obtain a mixed solution, and heating the mixed solution to a reaction temperature of 65-95DEG C; preparing an alkali solution, and heating the alkali solution to a temperature same to the mixed solution, adding the alkali solution to the mixed solution while violent stirring at 65-95DEG C for 0.5-2h, ageing at room temperature for 1.5-3h, pump-filtering, washing with water, washing with alcohol, and drying the obtained filter cake at 90-120DEG C for 1-6h to obtain a target product. The composite fire retardant has the advantages of environmental protection, low cost and high thermal stability.

Owner:CHINA RES INST OF DAILY CHEM IND

Vegetable insecticide and preparation method thereof

InactiveCN106900768AThoroughly modifiedHigh activityBiocideAnimal repellantsBacillus thuringiensisBiology

The invention discloses a vegetable insecticide and a preparation method thereof and relates to the technical field of insecticides. The vegetable insecticide is prepared from 80-90 parts of attapulgite, 55-75 parts of sepiolite powder, 55-65 parts of natural plant extracts, 45-50 parts of kieselguhr, 15-30 parts of bacillus thuringiensis, 10-20 parts of veratrine, 10-15 parts of additive and 250-300 parts of water. The vegetable insecticide is good in insecticidal efficacy and long in action time, the raw materials are easy to obtain, and the vegetable insecticide is safe, environmentally friendly and harmless to the human body.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

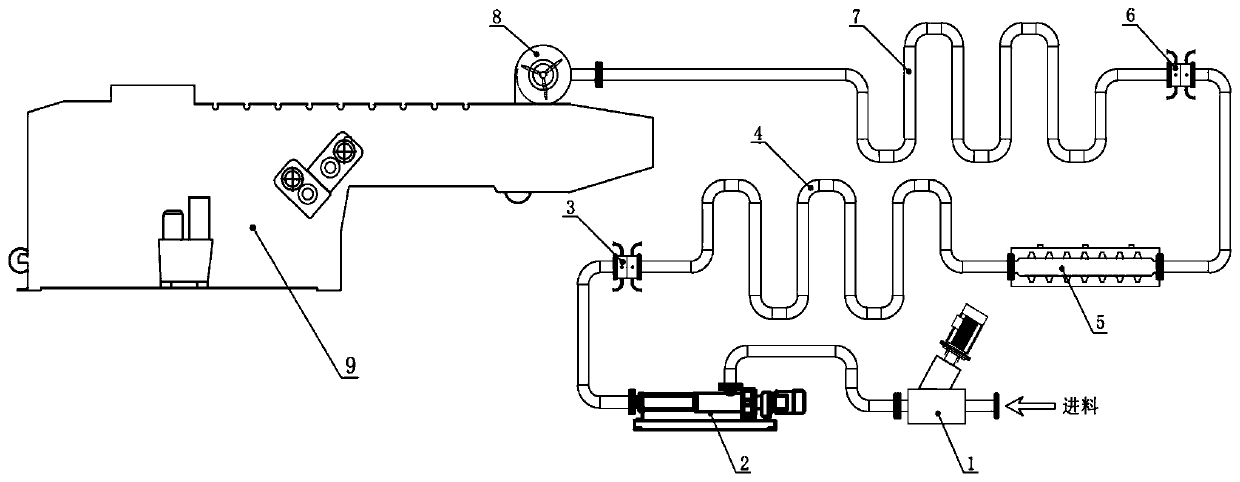

Sludge dewatering pretreatment apparatus and sludge dewatering pretreatment method

PendingCN110228935AThoroughly modifiedShort conditioning timeSludge treatment by de-watering/drying/thickeningMechanical crushingPretreatment method

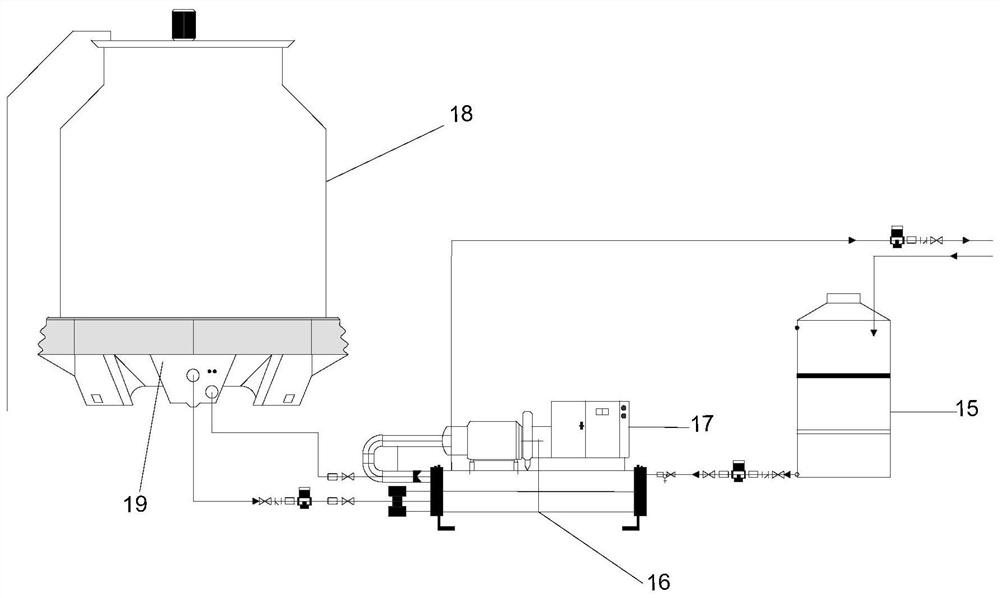

The invention discloses a sludge dewatering pretreatment apparatus and a sludge dewatering pretreatment method. The apparatus comprises a mechanical crushing pretreatment device, a sludge transfer pump, a first sludge and reagent mixer, a first serpentine tube, an ultrasonic reactor, a second sludge and reagent mixer, a second serpentine tube, a stirring device and a concentrating filter press; the mechanical crushing pretreatment device is used for crushing block impurities in the sludge, and the outlet of the mechanical crushing pretreatment device is connected with the sludge transfer pump;the first sludge and reagent mixer is connected with the sludge transfer pump and the first serpentine tube respectively, and is used for mixing a sludge conditioning reagent with the sludge; the ultrasonic reactor is arranged on the outer wall of a pipeline between the first serpentine tube and the second sludge and reagent mixer; the second sludge and reagent mixer is connected with the secondserpentine tube, and is used for mixing a flocculant with the sludge; and the inlet of the stirring device is connected with the second serpentine tube, and the outlet of the stirring device is connected with the concentrating filter press. The method has the advantages of short sludge conditioning time, completeness in sludge modification, and high sludge dewatering efficiency.

Owner:湖南北控威保特环境科技股份有限公司

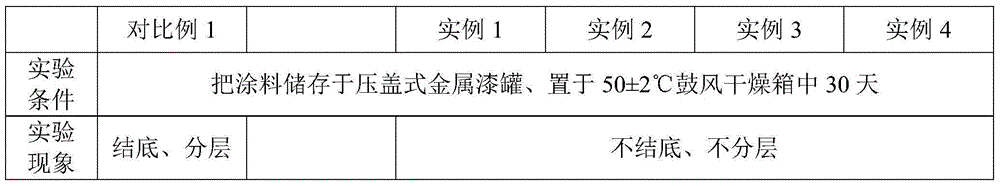

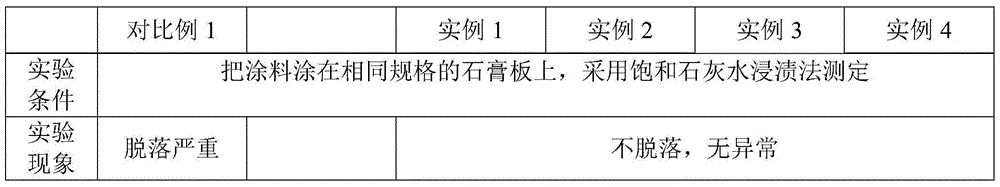

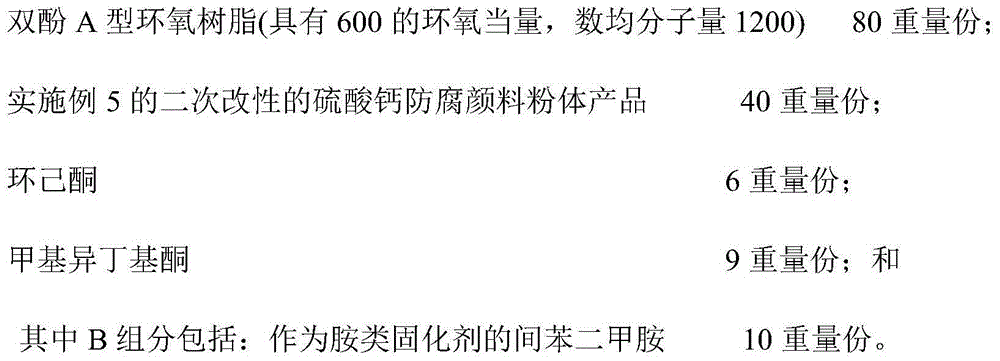

Modified calcium sulphate anticorrosive pigment as well as preparation method and application thereof

ActiveCN104945955AHigh temperature resistantWith acid and alkali corrosion resistanceAnti-corrosive paintsPigment treatment with organosilicon compoundsGas phaseBall mill

The invention discloses a modified calcium sulphate anticorrosive pigment as well as a preparation method and an application thereof. The preparation method comprises the following steps: preparing calcium sulphate extracted from industrial by-product gypsum into a suspension with a certain solid content, adding a modifier according to a certain mass percent, and then placing the modifier in a ball mill and uniformly mixing and grinding; drying the ground mixture for 3-6 hours at 80-150 DEG C, cooling the mixture and then grinding the mixture into a powder and crushing, wherein preferably, aminosilane-modified gas-phase silica is added during the grinding and crushing process. The calcium sulphate anticorrosive pigment disclosed by the invention is capable of effectively solving the pressure brought to an environment by the industrial by-product gypsum, and capable of improving the industrial by-product gypsum, wear resistance and corrosion resistance of a coating film in case of being mixed and used with other anticorrosive pigments; the pigment is good in dispersibility in resin, simple in production process, low in production cost, and capable of bringing good social and economic benefits.

Owner:HUNAN RUISHI SCI & TECH DEV

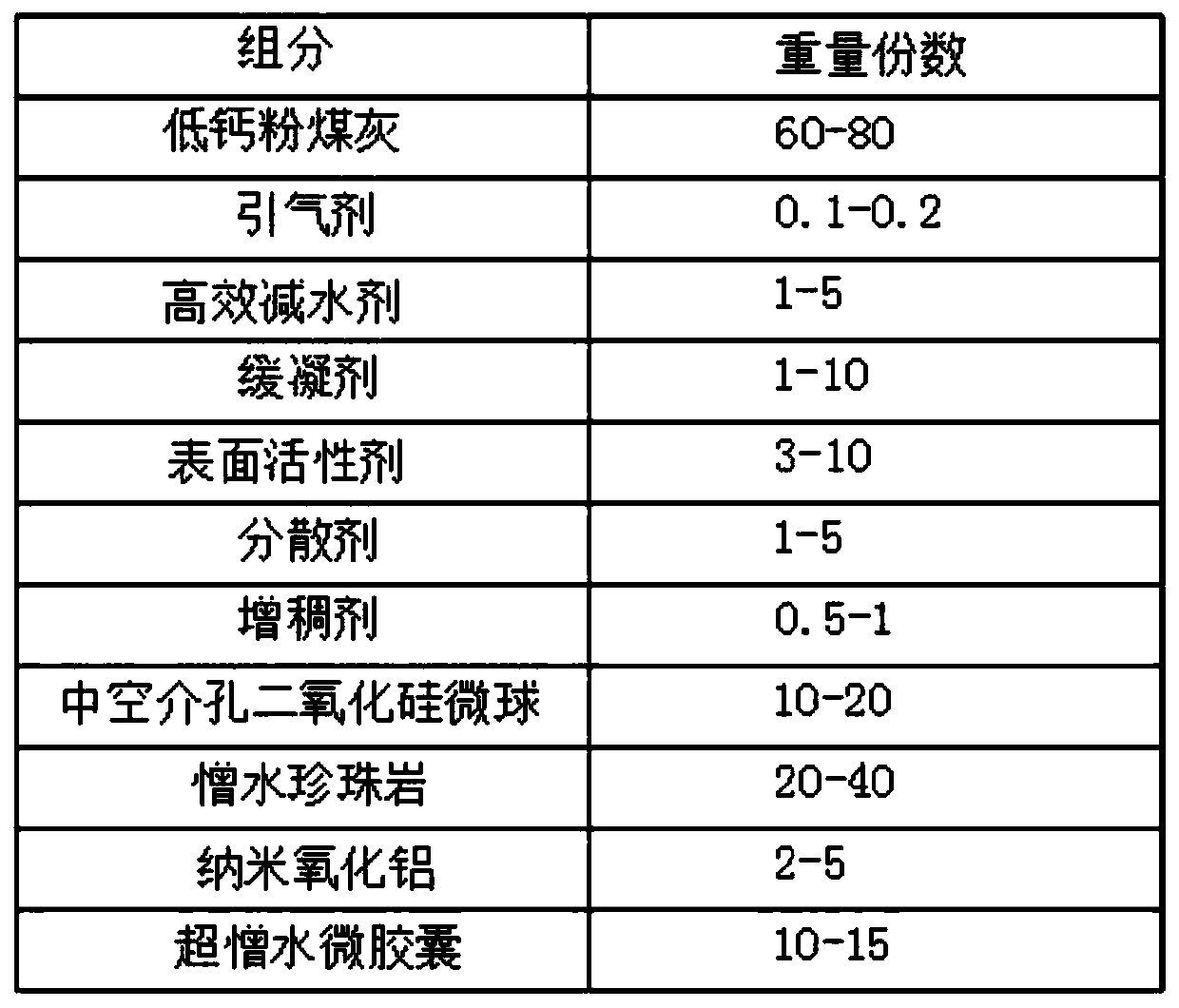

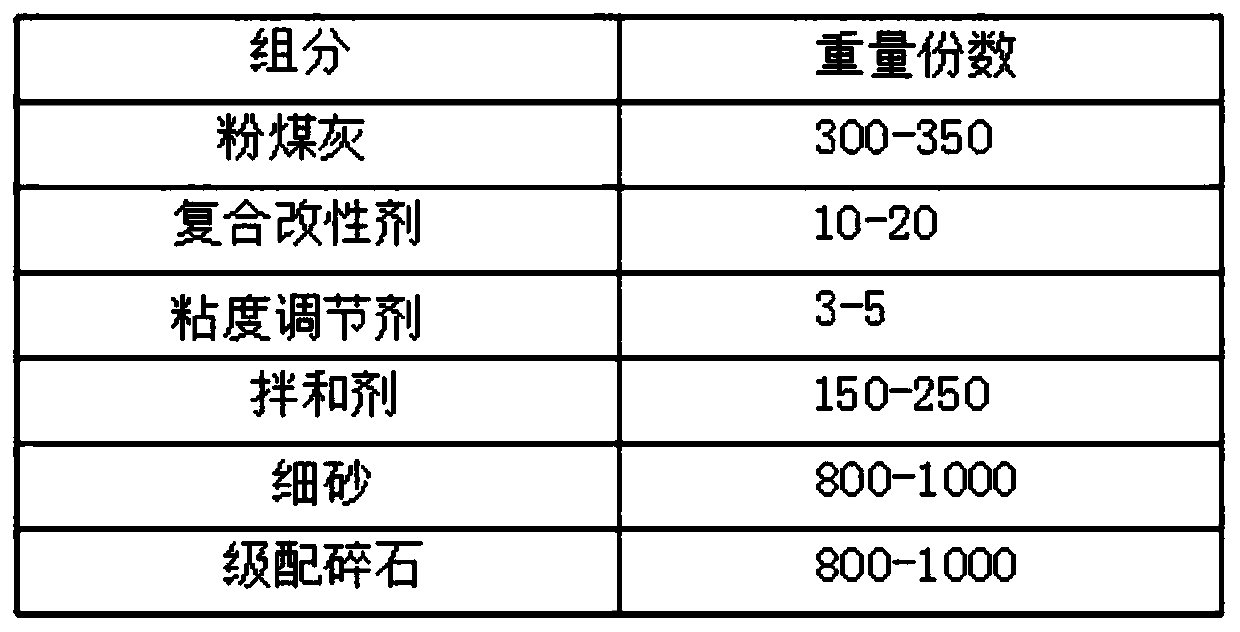

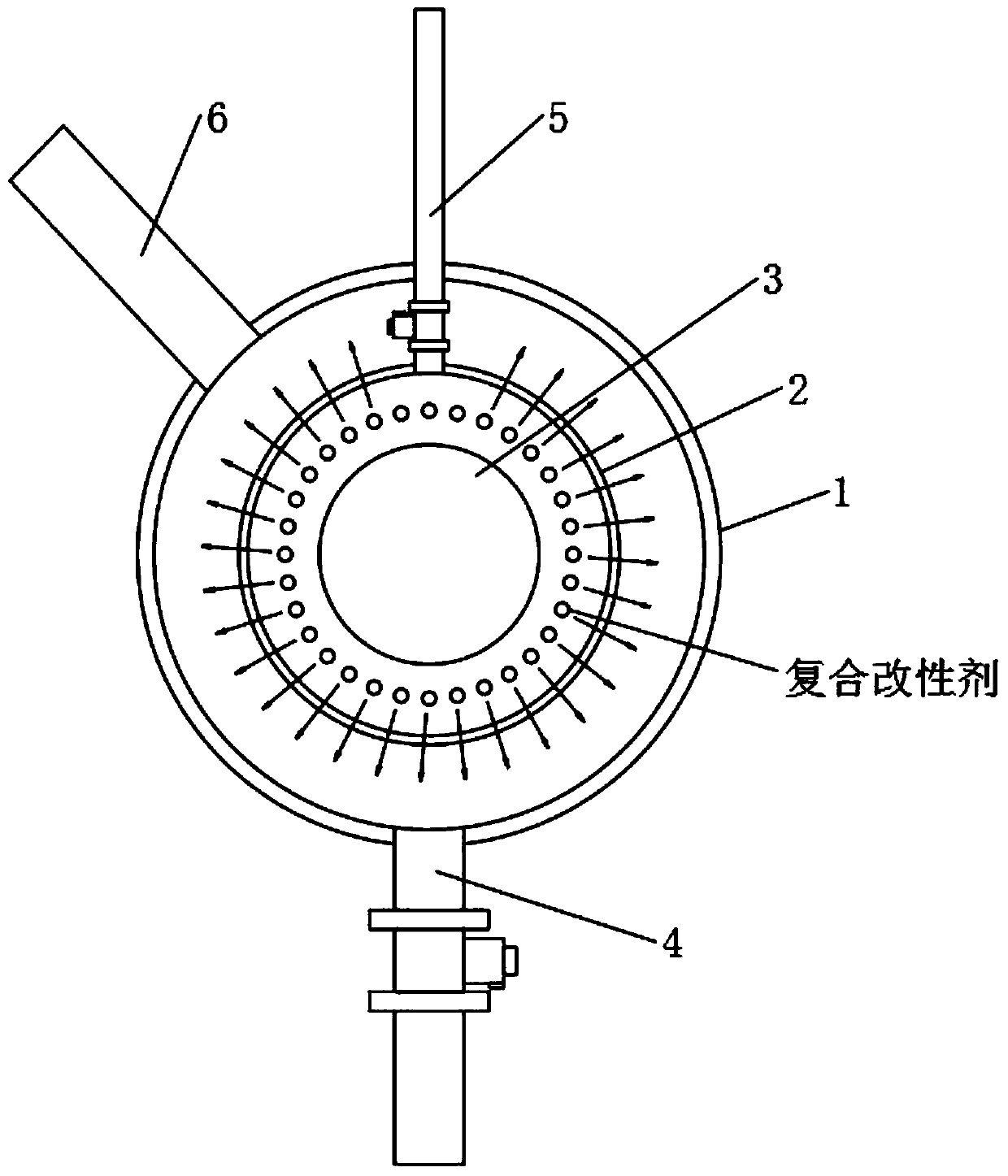

Composite modifier and low-strength concrete prepared from same

The invention discloses a composite modifier and low-strength concrete prepared from same and belongs to the technical field of building materials. The composite modifier consists of the following components: a low-calcium powder coal ash air entraining agent, a superplasticizer, a retarder, a surfactant, a dispersing agent, a thickening agent, hollow mesoporous silica microspheres, hydrophobic perlite, nano aluminum oxide and super-hydrophobic microcapsules. Modification of the low-strength concrete with the composite modifier can be achieved, and due to adoption of dual modes of dense waterresistance and surface hydrophobicity, a remarkable corrosion resistance function can be achieved for environment water, meanwhile, a conventional stirring mode is replaced by using a uniform mixing device, the composite modifier is uniformly filled into concrete, then the concrete can be sufficiently modified, properties of the low-strength concrete can be improved, and according to practical construction requirements of a construction site, an external magnetic field is applied to orient the super-hydrophobic microcapsules, and the super-hydrophobic microcapsules can be distributed on a surface to implement release and water resistance.

Owner:GUANGZHOU JIANSHENG BUILDING MATERIALS CO LTD

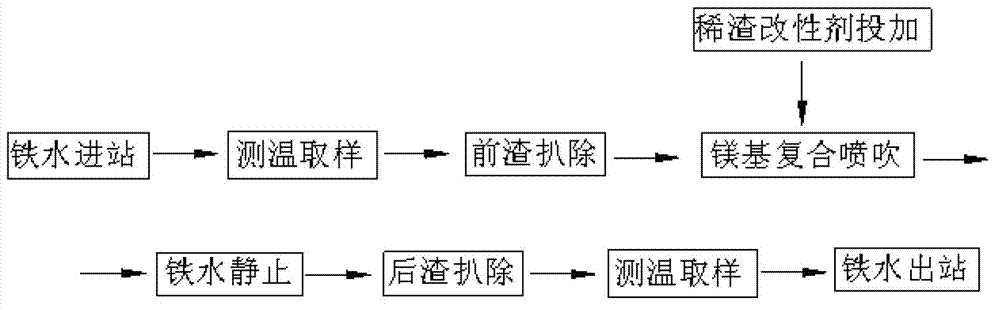

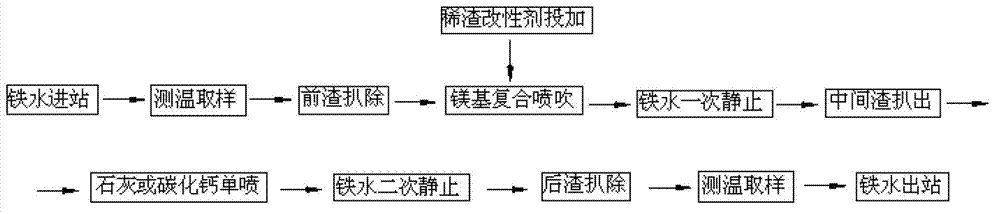

Deep desulfuration method for magnesium-based composite jetted molten iron

The invention discloses a deep desulfuration method for magnesium-based composite jetted molten iron. The deep desulphurization method comprises the following steps of: after the molten iron is fed and subjected to temperature measurement and sampling, scrabbling primary slag before a slag scrabbling station; subsequently desulfurating the molten iron in a magnesium-based composite jetting mode at a jetting and desulfuration station, adding a lean slag modifier in the jetting process and modifying the lean slag of the solid or semi-molten desulfurated slag; subsequently transferring to the slag scrabbling station to carry out primary standing on the molten iron and accomplish middle slag scrabbling; separately jetting lime or calcium carbide at the jetting and desulfuration station so as to carry out deep desulfuration on the molten iron and coagulate and modify residual liquid slag; after the separate jetting, transferring the molten iron tank to the slag scrabbling station to carry out secondary standing on the molten iron and accomplish later slag scrabbling; and after the later slag scrabbling, measuring the temperature, sampling and discharging the molten iron so as to meet the requirements on a molten iron material of a low-sulfur steel. The deep desulfuration method adopts a mode that desulfurated slag of different properties is respectively modified and scrabbled, and has the advantages of simplicity in operation, convenience in application and sufficiency in desulfurated slag modification.

Owner:武汉钢铁有限公司

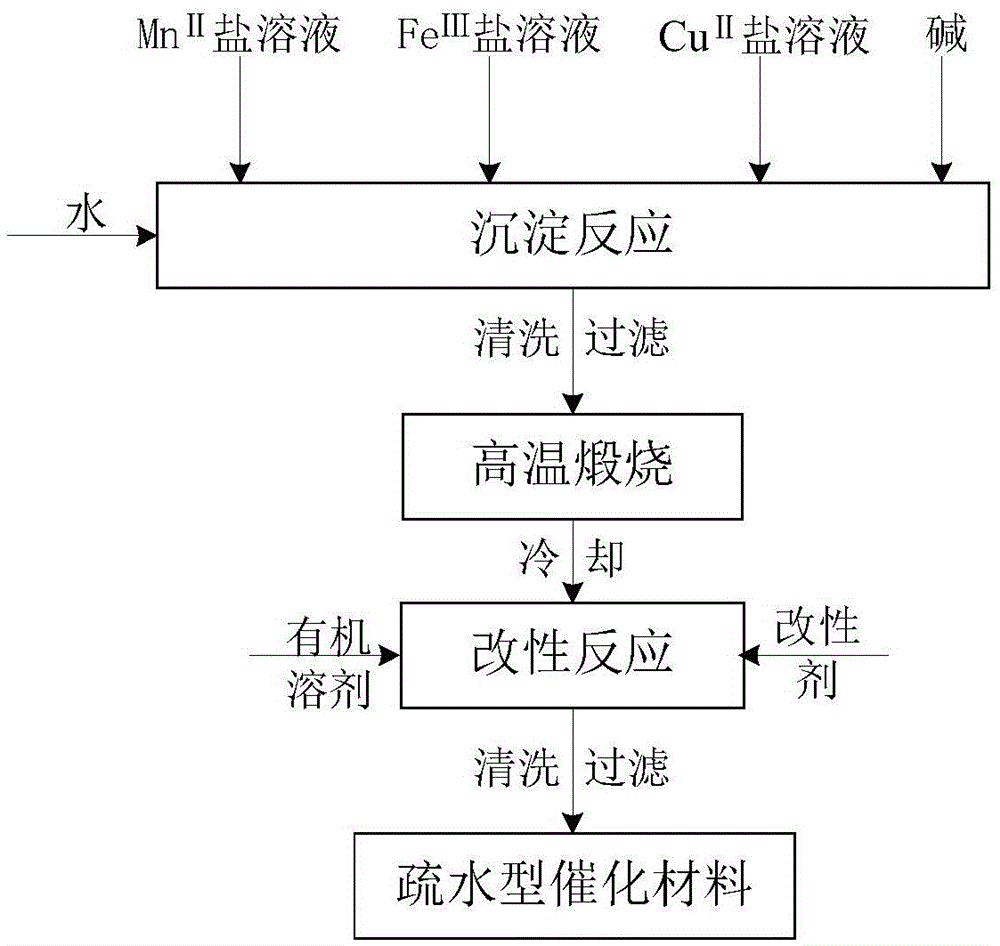

Hydrophobic air purifying composite catalyst and preparing method thereof

ActiveCN105562108AModification process is simpleExtended service lifeOrganic-compounds/hydrides/coordination-complexes catalystsHeterogenous catalyst chemical elementsDispersityAlcohol

The invention provides a hydrophobic air purifying composite catalyst and a preparing method thereof. The preparing method comprises the following steps that MnII salt, FeIII salt and CuII salt are dissolvent into water and stirred to be fully dissolved, alkali is added to adjust a pH value of a mixed reaction solution to be alkaline, the mixture is stirred to be subjected to a precipitation reaction, and after the reaction is completed, washing and filtering are carried out to obtain filter residues; the obtained filter residues are calcined; after the filter residues are calcined and cooled, a sample is placed into absolute ethyl alcohol containing a proper amount of water, meanwhile, a silane coupling agent is added to carry out a modification reaction, after the reaction is finished, washing, filtering and drying are carried out, and finally the hydrophobic air purifying composite catalyst is obtained. The preparation process is simple, a prepared hydrophobic air purifying material has high dispersity and hydrophobic performance, and the situation that due to adsorption of water in air, catalytic degradation performance of the material is reduced can be avoided.

Owner:NINGBO TAIAN NEW MATERIAL TECH CO LTD

Attapulgite particles for purifying air and preparation method thereof

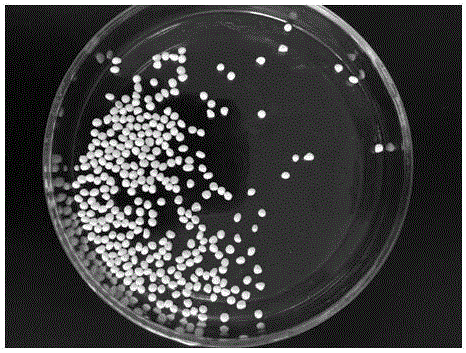

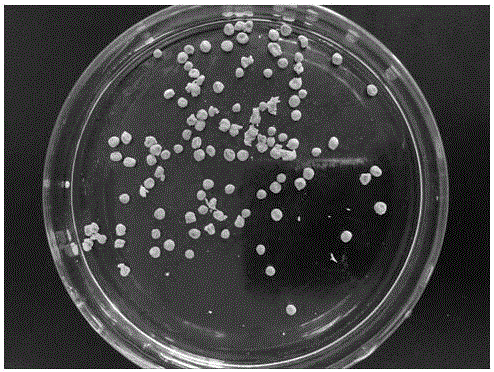

InactiveCN106861611AAvoid secondary pollutionImprove adsorption capacityBiocideGas treatmentPotassium persulfateFiber

The invention discloses attapulgite particles for purifying air and a preparation method thereof and relates to the technical field of processing of attapulgite. The attapulgite particles are prepared from the following raw materials: 130 to 150 parts of attapulgite, 60 to 70 parts of solid waste fiber pulp, 10 to 13 parts of diatomite, 5 to 10 parts of nano bentonite, 5 to 10 parts of modified sepiolite, 3 to 5 parts of sodium carbonate, 3 to 5 parts of butadiene-styrene emulsion, 3 to 5 parts of camphor tree bark, 3 to 5 parts of ammonium molybdate, 3 to 5 parts of folium artemisiae argyi, 3 to 5 parts of ammonium chloride, 1 to 3 parts of amino resin, 1 to 3 parts of Carbomer, 1 to 3 parts of methyl citrate, 1 to 3 parts of xanthan gum, 1 to 3 parts of acrylic acid, 1 to 3 parts of octyl acrylate, 1 to 3 parts of potassium persulfate, 1 to 3 parts of tourmaline powder, 3 to 5 parts of a pore forming agent, 3 to 5 parts of an auxiliary agent and 180 to 200 parts of water. The attapulgite particles disclosed by the invention are used as an ammonia-removing adsorption material for purifying air and have a good adsorption effect.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

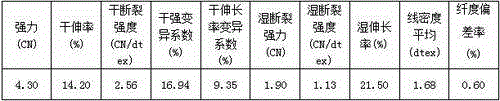

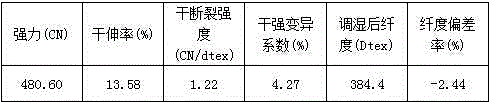

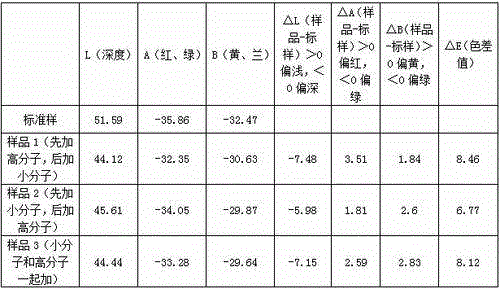

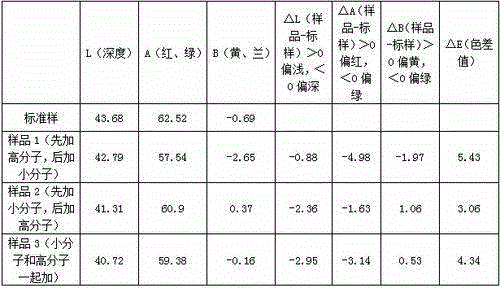

Salt-free low-alkaline modifying dyeing method of cellulose fiber

PendingCN104404793AIncrease reaction rateHigh reactivityDyeing processProcess engineeringCellulose fiber

The invention relates to a salt-free low-alkaline modifying dyeing method of a cellulose fiber, and belongs to the technical field of dope dyeing. The method disclosed by the invention comprises the following steps of modified treatment, water processing, dyeing and aftertreatment for the cellulose fiber, wherein the modified treatment for the cellulose fiber adopts an epoxy quaternary ammonium salt compound and a cationic polyacrylamide compound to perform the modified treatment on the cellulose fiber. The method disclosed by the invention adopts two kinds of specific modifying agents, has the function of the synergistic effect of the two agents, and matches with specific dyeing steps, so that the salt-free low-alkaline dyeing for the cellulose fiber is realized in dyeing, pollution is reduced, the cost is saved, the technology is simplified, the difficulty is reduced, and the modifying effect and the dyeing effect are good, so that the method is suitable for the industrial mass production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

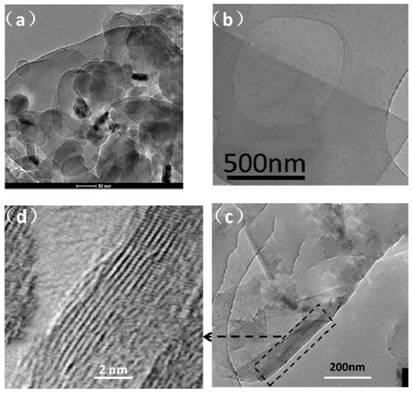

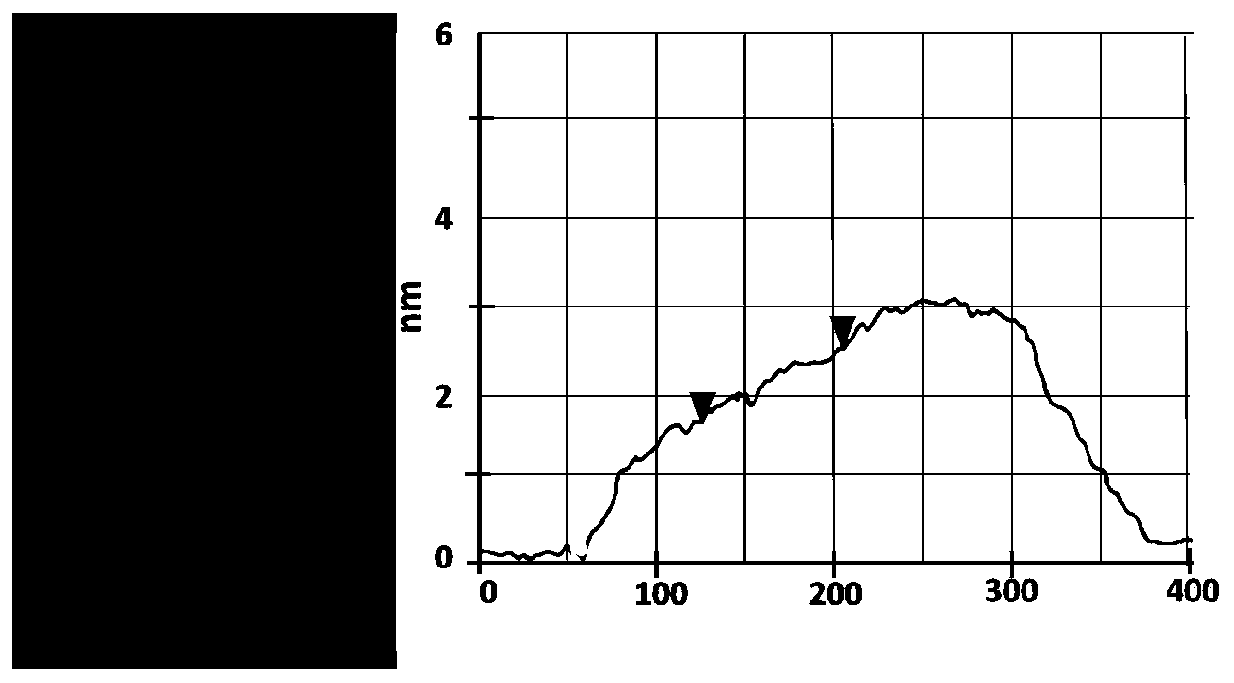

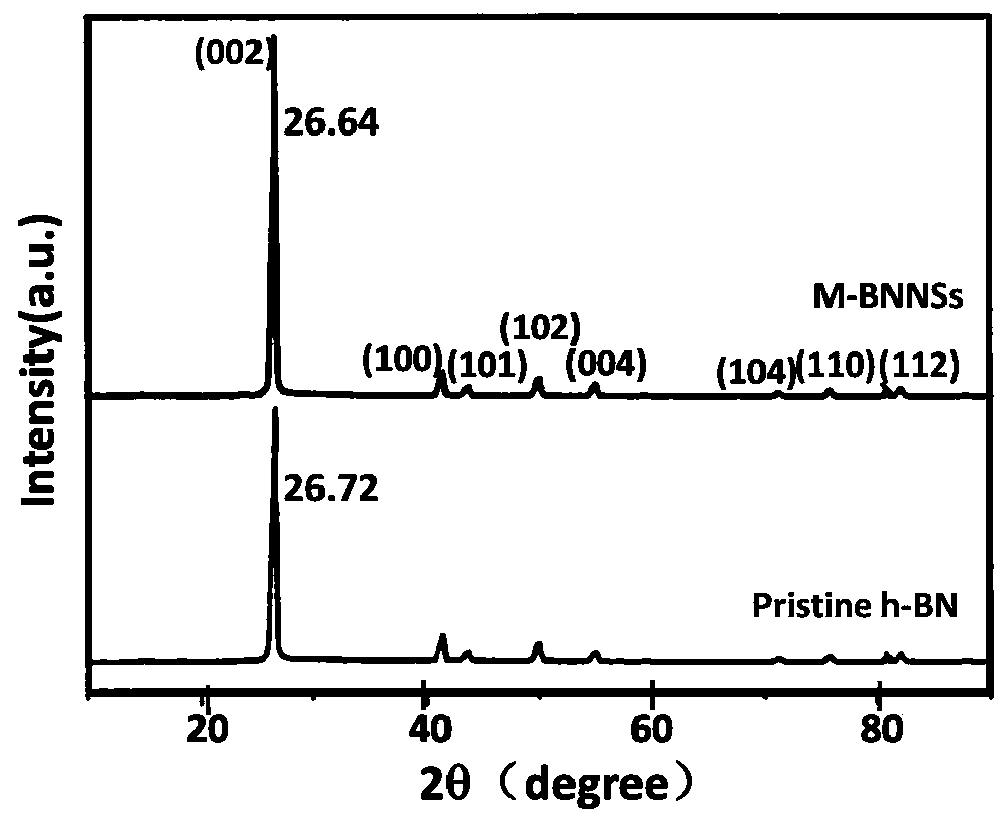

Modified epoxy organosilicon high-thermal-conduction insulating impregnating paint and preparation method thereof

The invention discloses an insulating impregnating paint and a preparation method thereof. The insulating impregnating paint comprises a matrix resin, a diluent and a curing agent, wherein the matrixresin is prepared by carrying out a condensation reaction on a modified epoxy resin and organic silanol having silanol, the raw materials of the modified epoxy resin comprise an epoxy resin, a vinyl monomer containing an ester group and a hydrophobic hexagonal boron nitride nano-sheet containing vinyl, the modified epoxy resin is produced by polymerizing the epoxy resin and the remaining raw materials, and the boron nitride nano-sheet is prepared by using the following specific method: carrying out surface hydroxyl modification, carrying out freeze-thaw expansion treatment, and catalyzing boron nitride stripping and esterification modification by combining with a specific compound one-pot method. The preparation method of the insulating impregnating paint comprises: mixing and stirring thematrix resin, the diluent and the curing agent to obtain the product. According to the present invention, the insulating impregnating paint has advantages of stable inter-batch product quality and the like on the basis of high thermal conductivity coefficient, low dielectric loss, high-low temperature impact resistance, good bonding strength, good permeability, high electric field strength and high mechanical strength.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD +1

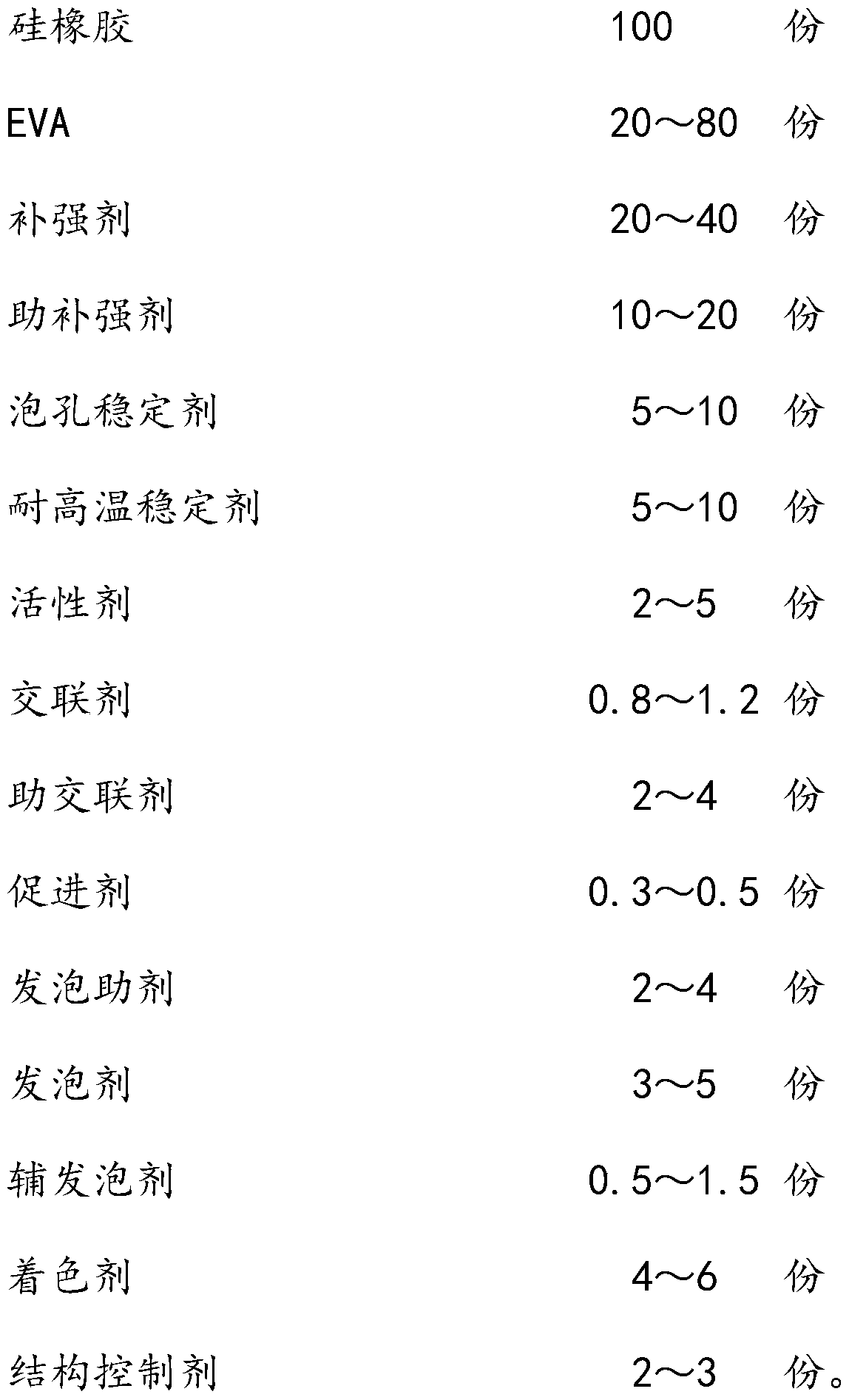

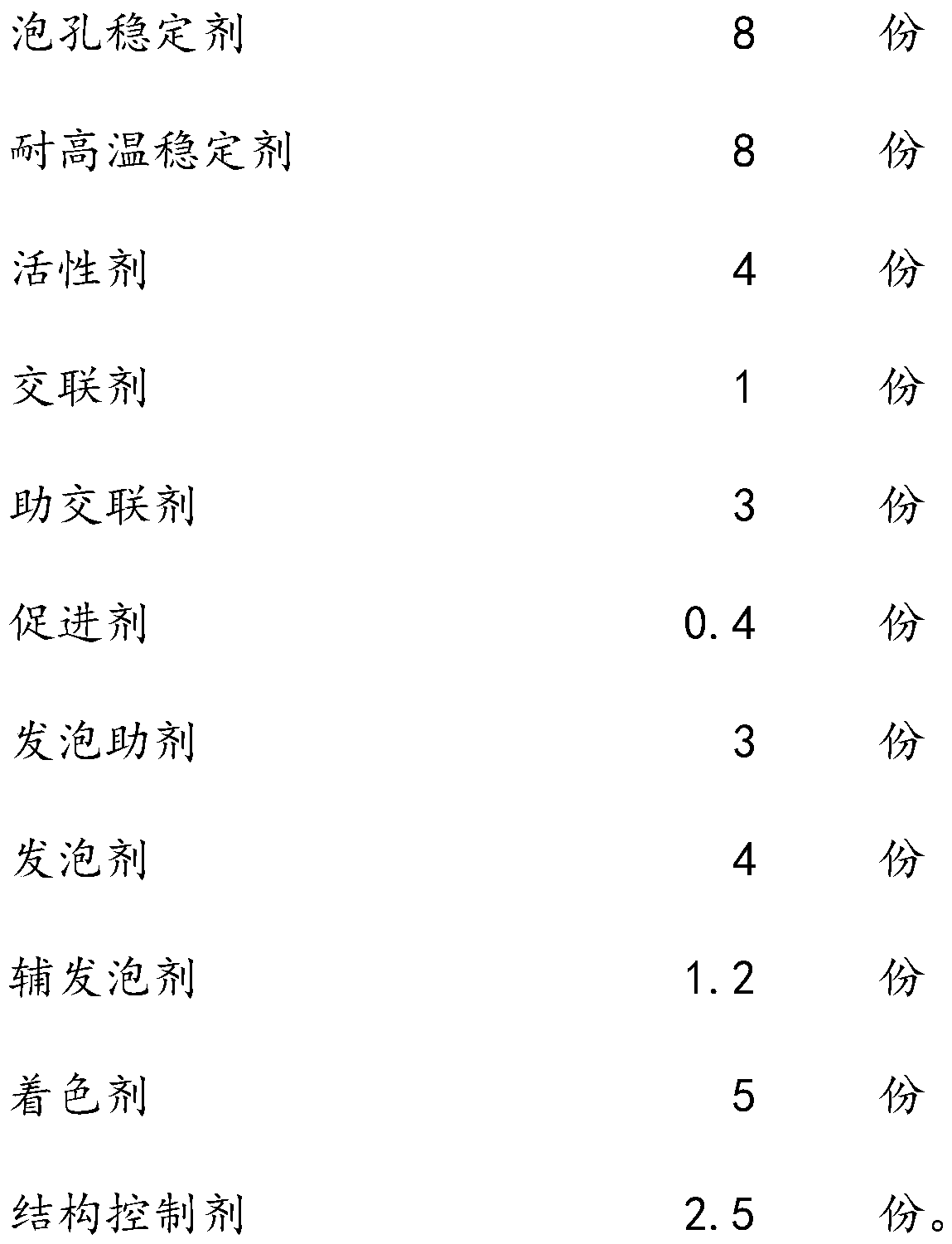

High-temperature-resistant heat shrinkage silicon rubber and EVA rubber plastic blending closed hole molding pressing high-temperature secondary foaming material and preparation method thereof

PendingCN109810509AEvenly blendedBlended closed-cell molding high temperature secondary foaming uniformPolymer scienceShrinkage rate

The invention relates to a foaming material, and provides a high-temperatureresistant heat shrinkage silicon rubber and EVA rubber plastic blending closed hole molding pressing high-temperature secondary foaming material and a preparation method thereof. Through blending, a proper recipe and process are matched; crosslinking foaming is performed to obtain a secondary foaming material with smallerdensity, lighter weight, higher softness and small heat shrinkage rate during high-temperature resistance. The problems of easy foaming and great high-temperature-resistant heat shrinkage rate duringthe existing silicon rubber and EVA rubber plastic blending high-temperature molding pressing closed hole foaming are solved.

Owner:YIBAO FUJIAN POLYMER MATERIALS

Cellulose fiber modification method

The invention relates to a cellulose fiber modification method, belonging to the technical field of textile dyeing. The cellulose fiber modification process comprises the following steps: putting cellulose fibers in a container, then adding water to the container, and then carrying out modification treatment on the cellulose fibers with two kinds of cationic modifiers, namely a low molecular quaternary ammonium salt cationic modifier and a high molecular quaternary ammonium salt cationic modifier, thereby obtaining modified cellulose fibers after modification treatment is completed, wherein the low molecular quaternary ammonium salt cationic modifier is 3-acrylamide-2-hydroxypropyl trimethylammonium chloride; the high molecular quaternary ammonium salt cationic modifier is polyamide polyamine epichlorohydrin. The cellulose fiber modification method has the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Sepiolite-supported nanoscale zero-valent iron material and preparation process and application thereof

InactiveCN108187609ASuit one's needsAdjustable water pH environmentOther chemical processesWater contaminantsWater qualityNitrogen gas

The invention discloses a preparation process and application of a sepiolite-supported nanoscale zero-valent iron material. Sepiolite powder is subjected to microwave heating reaction in hydrochloricacid solution, and is then washed, dried, roasted and ground, so that modified sepiolite is obtained, ferrous sulfate solid is then added to undergo impregnation and oscillation, and under the conditions of ultrasonic agitation and constant nitrogen injection, mixture sufficiently reacts with weakly alkaline NaBH4 solution, so that the sepiolite-supported nanoscale zero-valent iron material is obtained. The sepiolite-supported nanoscale zero-valent iron material not only can rapidly adsorb and remove heavy metals of Cu, Pb, Zn, Cr and As in aquaculture water, but also regulate the pH environment of water quality and meet the requirement of aquaculture water; moreover, reaction conditions are easy to meet, the raw materials are cheap and easy to obtain, consumed time is shorter and reactionis mild, and operation is convenient.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

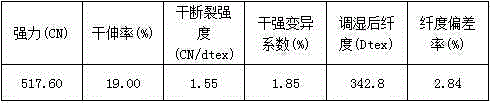

Polyester tempering palm fiber adhesion activating agent and treatment process of polyester tempering palm fiber

The invention belongs to the technical field of manufacturing of polyester tempering palm fiber in a driving belt, and in particular discloses a polyester tempering palm fiber adhesion activating agent and a treatment process of the polyester tempering palm fiber. The process comprises the steps of feeding propanetriol-diglycidyl-ether type epoxy resin, enclosed isocyanate and an epoxy resin dispersing agent into a reaction kettle, and stirring to form the polyester tempering palm fiber adhesion activating agent; inserting the polyester tempering palm fiber into the adhesion activating agent and soaking to form an epoxy resin surface layer on the surface. The treated polyester tempering palm fiber is subjected to two-bath immersion by using an RFL (condensation compound of resorcinol, formaldehyde and latex) adhering agent used in a two-bath gum dipping system and using the conventional RFL again, thereby greatly improving the numerical value of the adhesive force. The problem of poor adhesion strength of the polyester tempering palm fiber and rubber is solved, so that the polyester tempering palm fiber becomes the ideal tensile body of the rubber product.

Owner:HEBEI HUANYU RUBBER TECH

Wood-plastic material prepared from papermaking waste and preparation method thereof

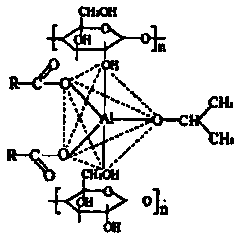

The invention discloses a wood-plastic material prepared from papermaking waste. The wood-plastic material comprises the following components in percentages by mass: 30% to 35% of papermaking waste, 30% to 40% of wood flour, 15% to 20% of ceramic powder, 1% to 5% of sorbitol, 1% to 3% of a silane coupling agent, 3% to 6% of maleic anhydride grafted polyethylene, 1% to 2% of aluminum chloride, 3% to 5% of poly ethylene glycol monomethyl ether and 1% to 2% of blocking isocyanate. Firstly, the silane coupling agent, maleic anhydride grafted polyethylene and aluminum chloride are added and mixed,the aluminum chloride is beneficial for uniform mixing of the raw materials, and in combination with the adding sequence of the raw materials, the modification effect of each accessory ingredient on plastic, wood flour and ceramic powder can be strengthened; the sorbitol is further added as an activation modifier, and is matched with the blocking isocyanate and poly ethylene glycol monomethyl ether, so that modification on the wood four and ceramic powder can be realized sufficiently, the interfacial compatibility among the wood flour, ceramic powder and plastic is improved, and the performance of the wood-plastic material is strengthened.

Owner:HUNAN YINGHONG SCI & TECH

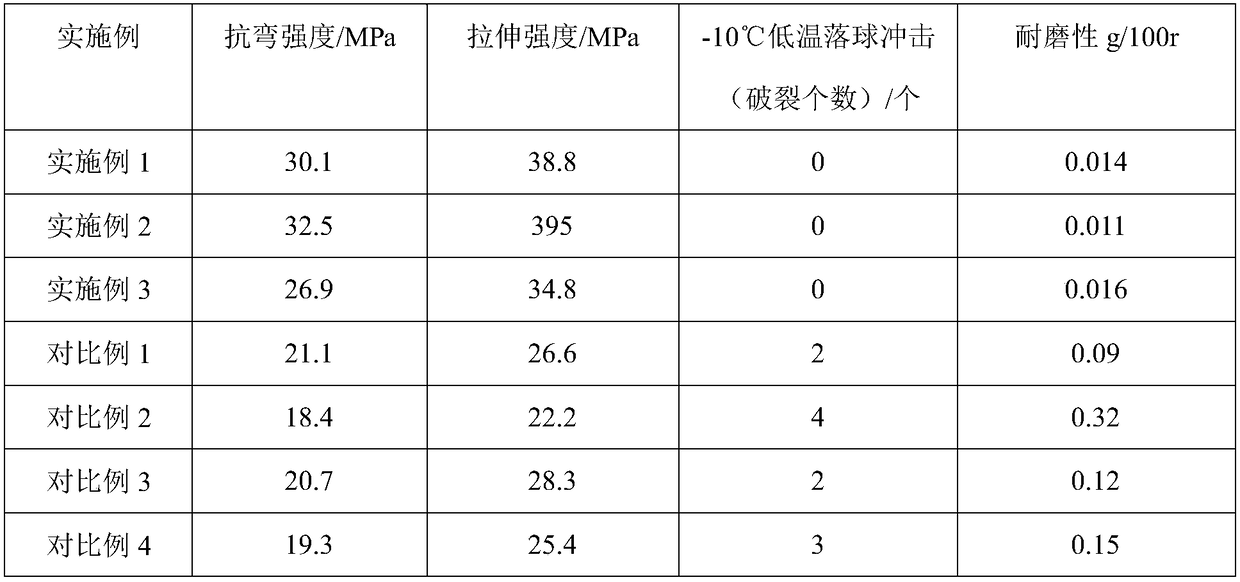

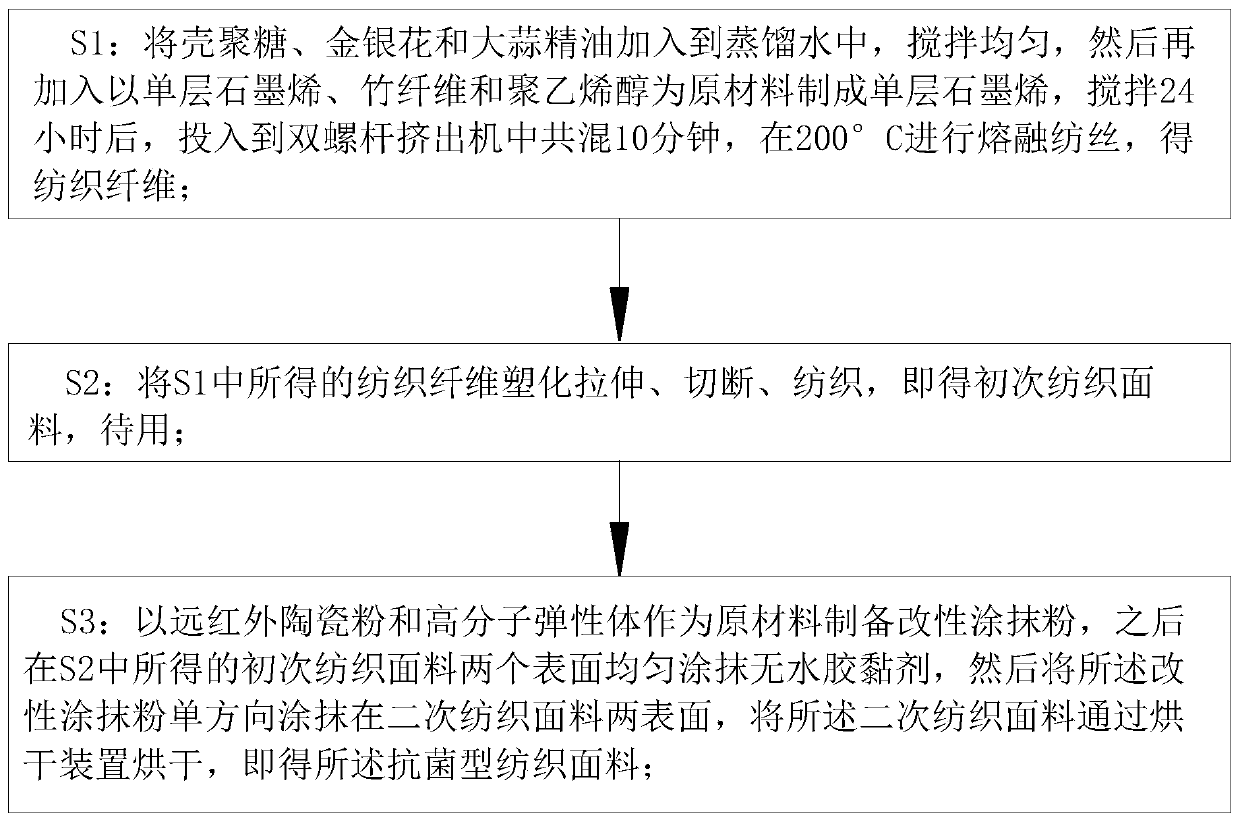

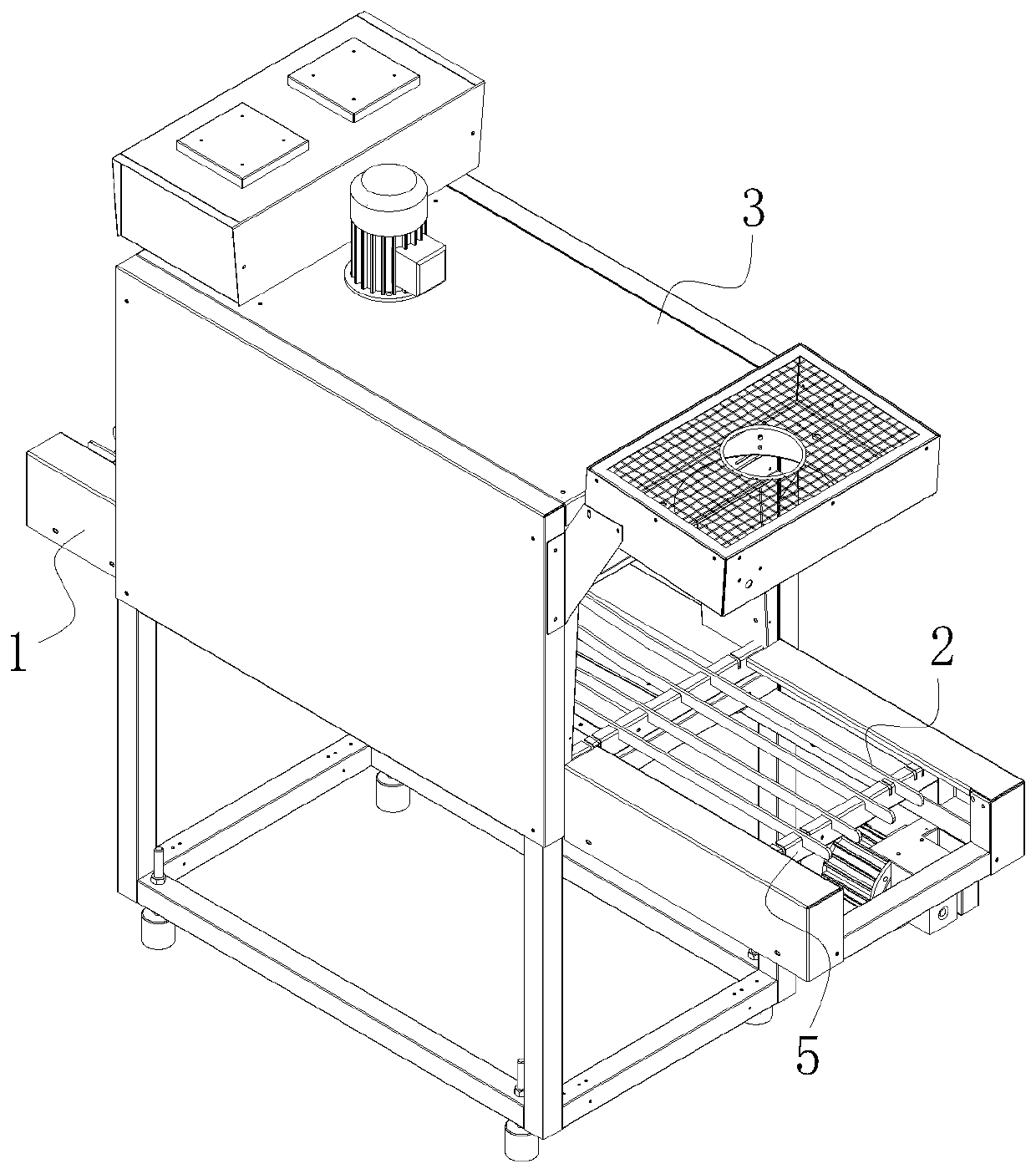

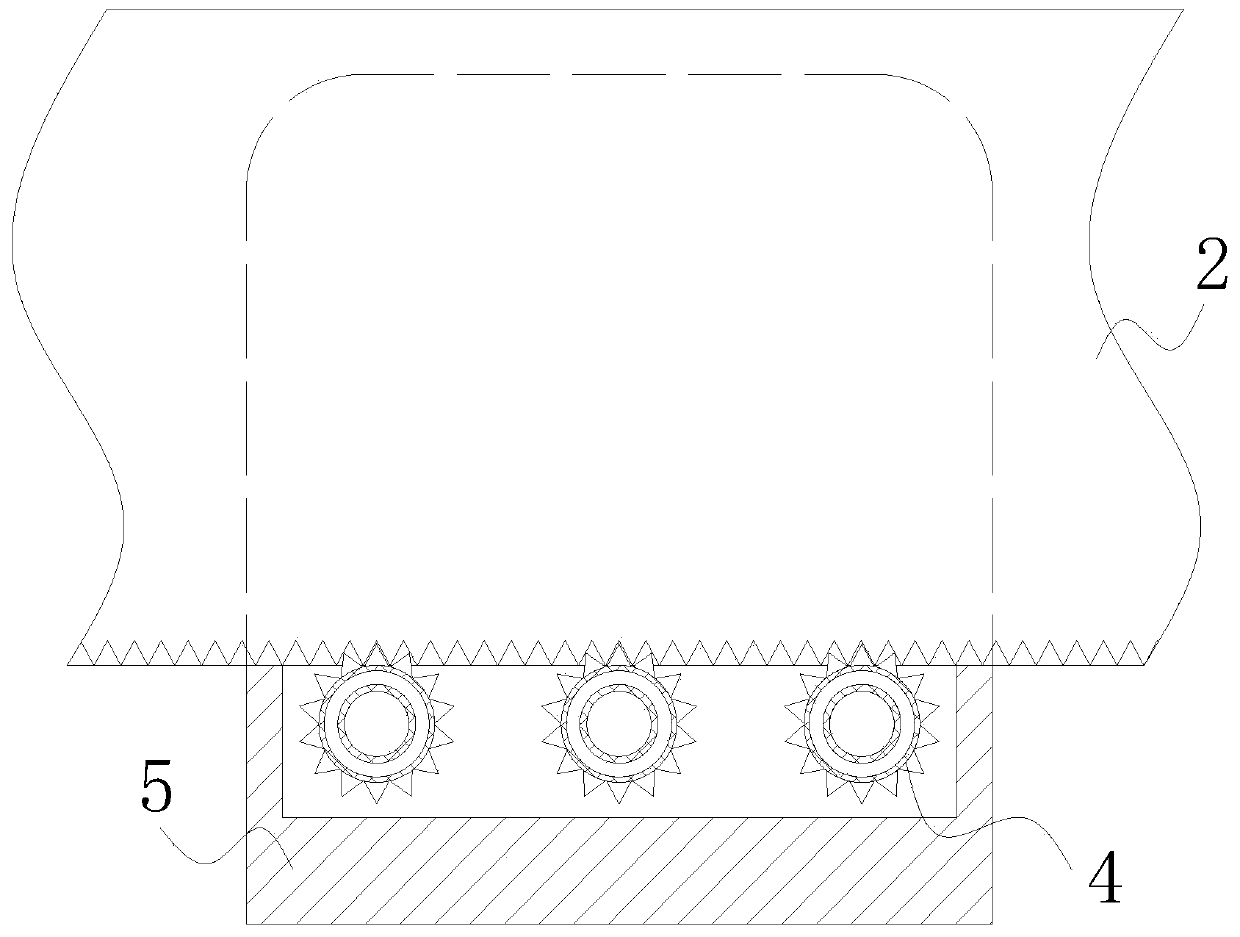

Preparation method for antibacterial type textile fabric

InactiveCN111379171AEfficient removalImprove ventilationMonocomponent synthetic polymer artificial filamentArtifical filament manufactureElastomerFiber

The invention belongs to the technical field of textile materials, and particularly relates to a preparation method for antibacterial type textile fabric which comprises the following components in parts by weight: 35 parts of polyvinyl alcohol, 21 parts of chitosan, 30 parts of distilled water, 17 parts of bamboo fibers, 8 parts of far-infrared ceramic powder, 7 parts of lonicera japonica, 3 parts of garlic essential oil, 10 parts of deionized water, 5 parts of single-layer graphene and 6 parts of high-molecular elastomer. The preparation method is mainly used for providing the antibacterialtype textile fabric; under irradiation of sunlight (especially ultraviolet rays), far-infrared ceramic paint is generated into OH<->, so that sulfides, ammonia and odor substances can be effectively removed, and a sterilization function is achieved; meanwhile, far-infrared ceramic powder is mixed with the high-molecular elastomer, so that air permeability of the textile fabric can be improved while the textile fabric is in a drying state; and meanwhile, while encountering water drops or water steam, the high-molecular elastomer can be expanded for generating sealing effect on gas holes of thetextile fabric, so that warming and heating effect of the textile fabric can be improved.

Owner:吴嘉惠

Preparation method of silicon-based hybrid aerogel balls for removing copper ions in water

InactiveCN106215875AImprove adsorption capacityReduce recycling costsWaste water treatment from quariesOther chemical processesWastewaterPhysical chemistry

The invention discloses a preparation method of silicon-based hybrid aerogel balls for removing copper ions in water, and belongs to the technical field of novel materials. According to the invention, sodium alginate and water glass are used as raw materials for preparing the silicon-based hybrid aerogel balls, the silicon-based hybrid aerogel balls are modified by a silane coupling agent, and the balls are applied to treatment of copper ion wastewater to have a very good adsorption effect. Furthermore, the silicon-based hybrid aerogel balls can be reused to lower the recovery cost.

Owner:YANGZHOU TIANCHEN FINE CHEM +2

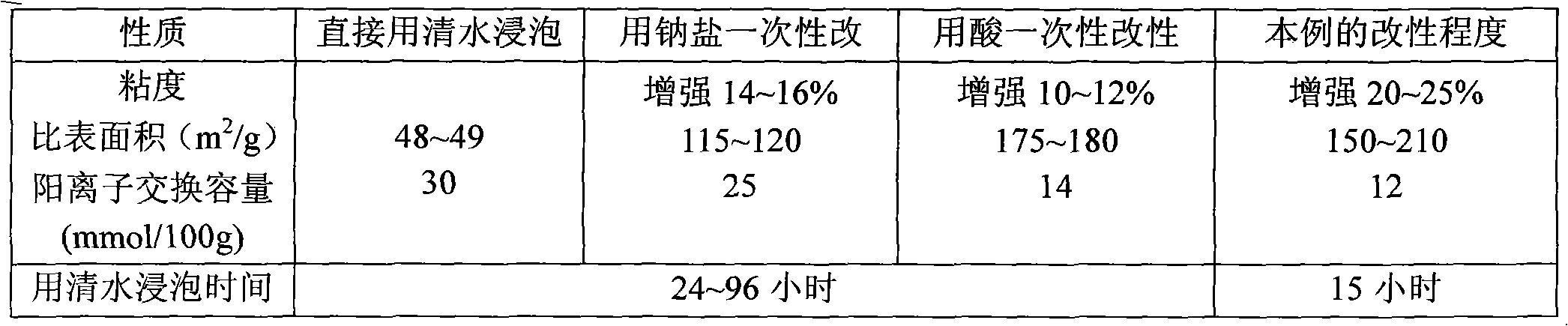

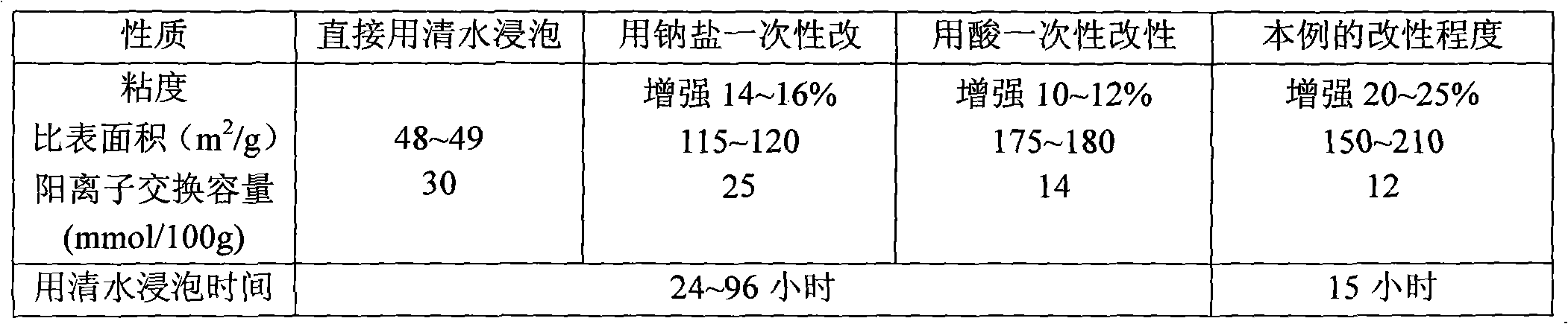

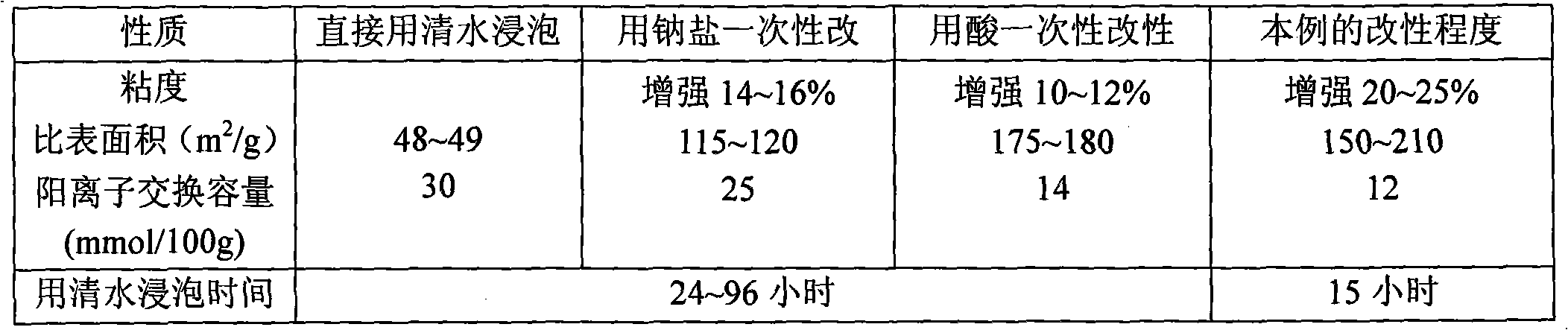

Attapulgite clay treatment process

InactiveCN106904620AExtension of timeHigh industrial valueSilicon compoundsPorositySodium bicarbonate

The invention belongs to the technical field of sewage treatment, and provides an attapulgite clay treatment process which comprises the following steps: (1) purifying attapulgite, to be more specific, crushing and sieving the attapulgite, adding the sieved attapulgite into clean water, evenly stirring, soaking, centrifuging, after the centrifugation, filtering and drying to obtain an attapulgite semi-finished product; (2) modifying the attapulgite, to be more specific, putting the attapulgite semi-finished product into a sodium bicarbonate solution, stirring and heating; and in the stirring process, adding sodium bicarbonate and sodium hydroxide particles while stirring; and (3) processing the attapulgite, to be more specific, filtering , drying and crushing the attapulgite obtained by the step (2) to obtain the modified attapulgite. The attapulgite clay treatment process can improve the adsorption performance, the decoloration rate, the catalytic effect, the specific surface area, the porosity and the viscosity of the attapulgite clay.

Owner:明光市外泰高分子材料有限公司

Method for manufacturing toplift

A formulation of the invention comprises 40 to 70 percent of artificial rubber, 5 to 15 percent of polyvinyl chloride, 0.4 to 2.5 percent of sulfur, and 0 to 50 percent of white carbon black. In a finished product manufactured by the formulation, the total weight percentage of the components is 100 percent. The toplift manufactured by the method not only has the abrasion-resistance property of the prior toplift, but also has ultra good elasticity, is comfortable to be worn, and can preferably protect the cervical vertebra and vertebral column of a wearer. The toplift has directer and more remarkable effect that the toplift can reduce the intensity sound made by knocking the ground by shoe heels by more than 50 percent, and has ineffable good effects for users and environment.

Owner:于圣洁

Recycled plastic and preparation method thereof

The invention discloses a recycled plastic. The recycled plastic comprises the following components in percentages by mass: 60-75% of waste plastics, 10-15% of waste ceramic powder, 0.5-2% of a coupling agent, 0.1-0.5% of monostearin, 5-10% of floating beads, 2-4% of SBS, 3-5% of a maleic anhydride grafted ethylene-propylene copolymer, 1-2% of 4-methylcatechol, 2-3% of ammonium ferric sulfate, and1-3% of phthalate. According to the recycled plastic disclosed by the invention, the 4-methylcatechol, the ammonium ferric sulfate, the floating beads are added and mixed with other raw materials, sothat full modification can be performed on the surface of the ceramic powder, and the difference between the polyolefin plastics and the ceramic powder can be reduced; and the ceramic powder and theplastics have good compatibility and strong interfacial adhesion, and the obtained recycled plastic has improved rigidity and toughness compared with a pure plastic substrate, and significantly-improved wear resistance, durability, corrosion resistance and heat resistance.

Owner:HUNAN YINGHONG SCI & TECH

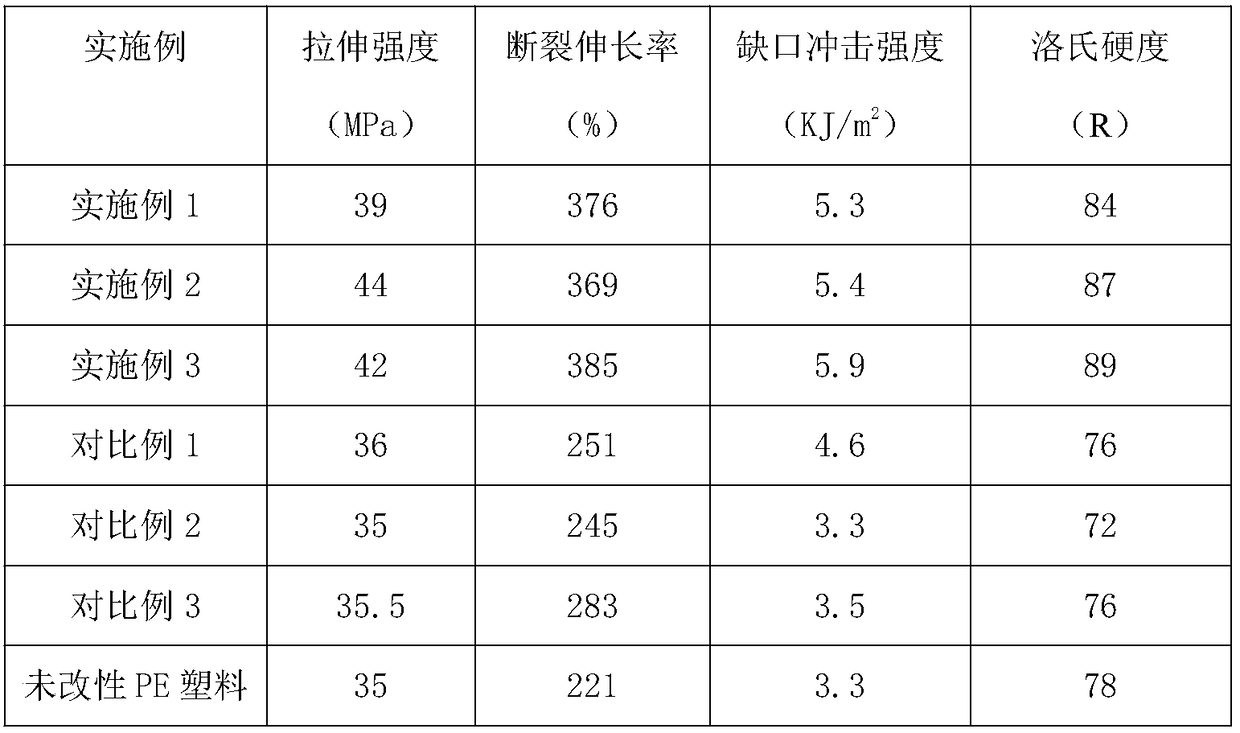

Modified asphalt and preparation method thereof

InactiveCN107216665AImprove impact resistanceThoroughly modifiedBuilding insulationsHigh intensityPolypropylene

The invention discloses modified asphalt, which is mainly prepared from 75 to 90 parts of petroleum asphalt, 1 to 3 parts of modifier A, 5 to 20 parts of modifier B, 2 to 5 parts of sulphur, and 0.5 to 3 parts of toughening agent, wherein the modifier A is PE (Poly Ethylene) gelatin powder; the modifier B is mainly prepared from PP (Polypropylene) recycling material particles, PE recycling material particles, and PP / PE pre-blending material particles. The PP / PE pre-blending material particles are selected to be together with the PP recycling material particles, the PE recycling material particles and the PE gelatin powder to jointly modify asphalt, so that when modifying is carried out, the high-strength PP / PE pre-blending material is introduced at the same time, meanwhile, when modifying is carried out, the PP recycling material particles, the PE recycling material particles and the PE gelatin powder are further crosslink blended, the stability of the system is improved, various performances of the modified asphalt cannot be affected, and meanwhile, waste recovery is realized. The invention also discloses a preparation method of the modified asphalt.

Owner:广东诚泰投资集团有限公司

Degradable vegetable fiber environmental-protection composite material capable of being subjected to extrusion or plastic suction thermal molding

InactiveCN110194863AImprove mechanical propertiesImprove degradation efficiencyVegetable fibersLubricant

The invention provides a degradable vegetable fiber environmental-protection composite material capable of being subjected to extrusion or plastic suction thermal molding, wherein the material comprises, by mass, 5-85 parts of modified plant fiber powder, 5-85 parts of a thermoplastic resin, 0.1-1 part of a lubricant, 0.1-4 parts of a pigment, and 0.2-1 part of other auxiliary agents. According tothe present invention, the environmental-protection composite material is easy to degrade, and is formed by compounding plant fibers and a thermoplastic resin, such that the materials are convenientto take.

Owner:东莞市腾卓美环保新材料科技有限公司

Method for synthesizing iron-modified bentonite

ActiveCN102861550AMove quicklyFully modifiedOther chemical processesWater/sewage treatment by sorptionSodium BentonitePrecipitation

The invention discloses a method for synthesizing iron-modified bentonite, which comprises the steps of: taking an iron sheet electrode as a positive electrode of an electrolytic cell and a graphite electrode as a negative electrode of the electrolytic cell, and isolating the negative electrode and the positive electrode by a microporous membrane; adding de-ionized water into the electrolytic cell, and adding dried bentonite into the positive electrode zone; stirring in the positive electrode zone at a stirring rate of 50-150r / min; conducting current of 5-40mA to the electrolytic cell; precipitating and separating for 4-5h; and drying the bentonite which is obtained by precipitation at 105-110 DEG C, to obtain the iron-modified bentonite. In the electrolysis process, the iron electrode is gradually oxidized into iron ions which enter into a solution, and iron ions are moved towards the negative electrode under function of an electric field and are adsorbed among layers of the bentonite during moving. Since the existence of the electric field in the exchange process, the ions are rapidly moved under the function of the electric field, so that the modification is complete and absolute. The iron-modified bentonite obtained from the modification is better in uniformity and quality.

Owner:江阴智产汇知识产权运营有限公司

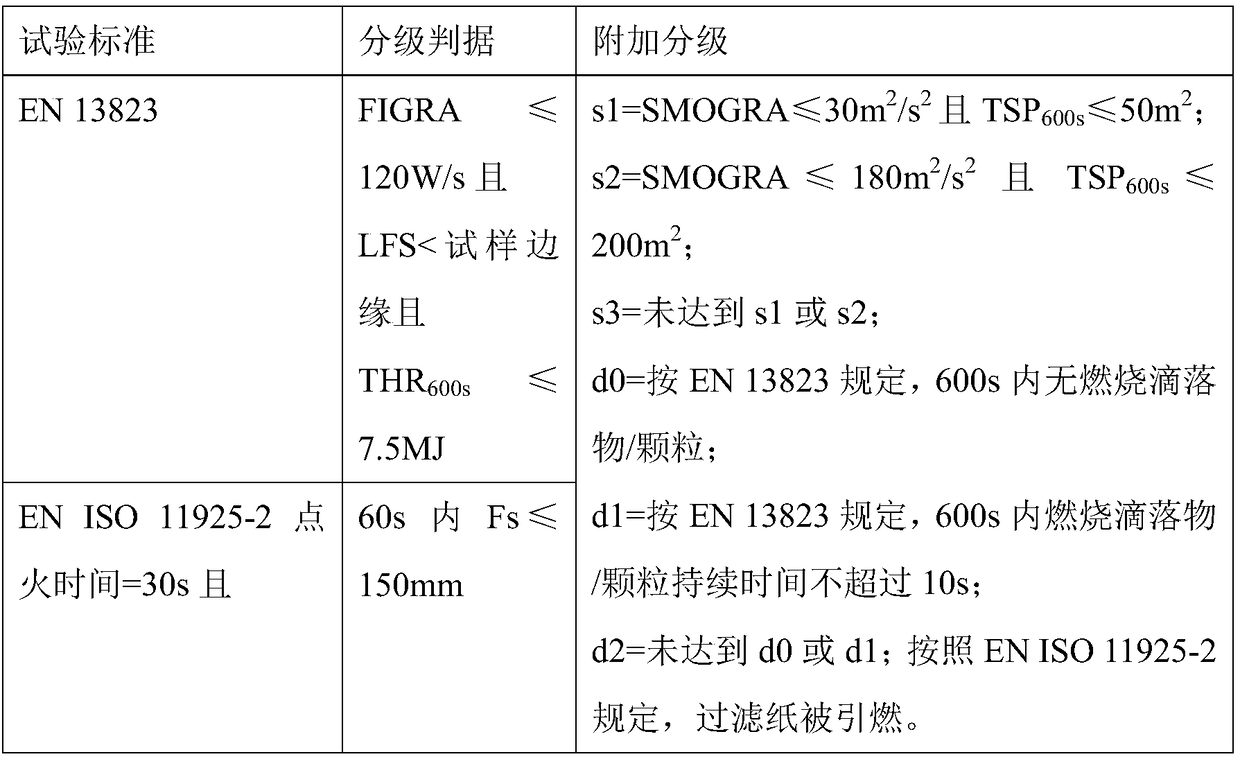

Preparation method of plastic and wood section with high flame-retardant property

ActiveCN108102196AImprove flame retardant performanceLarge particle sizeState of artMechanical property

The invention discloses a preparation method of a plastic and wood section with high flame-retardant property, and belongs to the technical field of composite materials. The preparation method comprises the following steps of modifying a flame-retardant system, treating and modifying wood powder, mixing and granulating, treating granulated material, post-treating the surface and the like, so as toobtain the plastic and wood section with high flame-retardant property. The preparation method has the advantages that the defects in the prior art are overcome; the plastic and wood section with high flame-retardant property is prepared, the appearance is good, the mechanical property is good, the fireproof class reaches Class B, the safety and fireproof property are improved, and the application range is widened.

Owner:南京聚锋新材料有限公司 +1

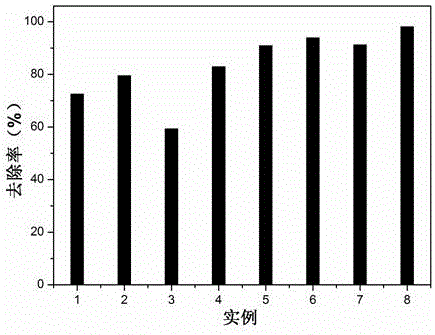

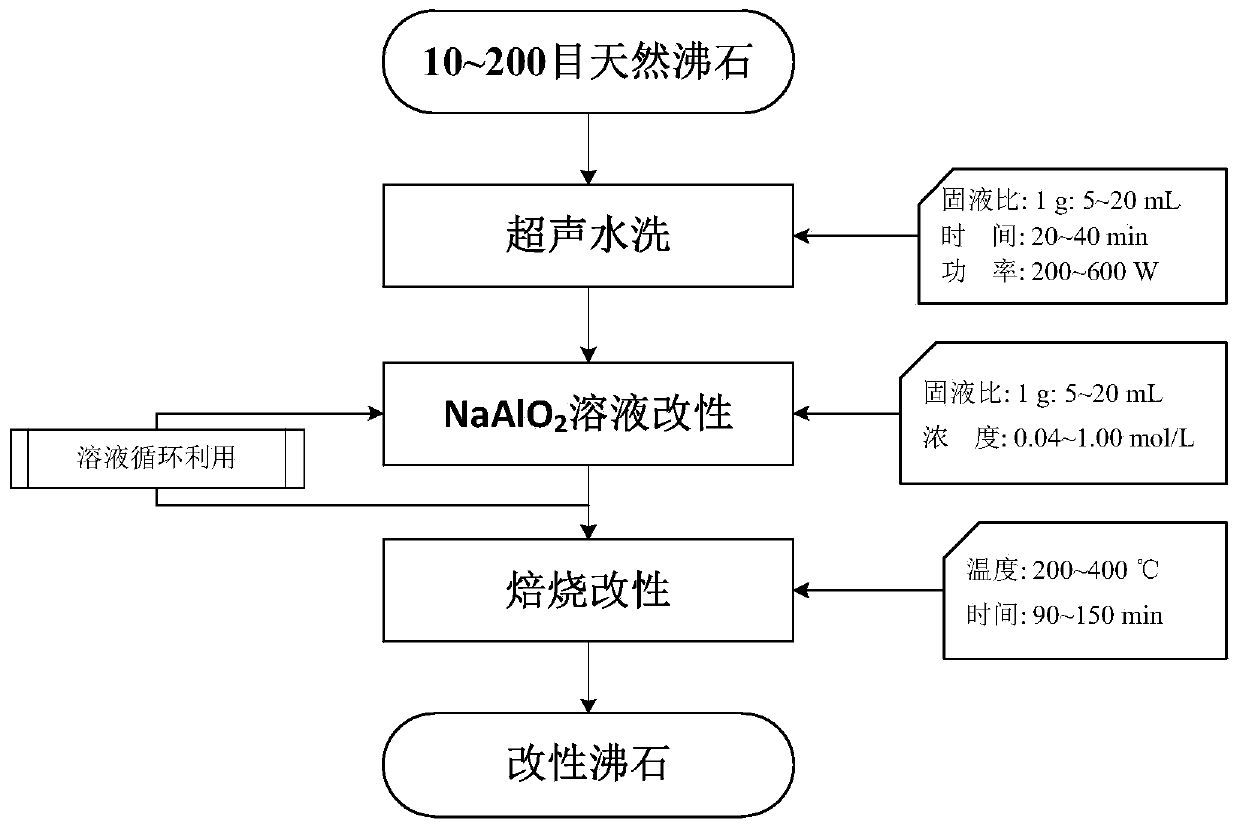

Natural zeolite multifunctional modification method for improving ammonia nitrogen removal rate of water body

PendingCN111054303AEfficient removalEasy accessOther chemical processesAluminium silicatesAmmoniacal nitrogenSodium aluminate

The invention discloses a natural zeolite multifunctional modification method for improving the ammonia nitrogen removal rate of a water body. The method comprises the following steps: (1) crushing and screening natural zeolite, and carrying out ultrasonic cleaning pretreatment; (2) immersing the pretreated zeolite into a sodium metaaluminate solution, carrying out solid-liquid separation a certain time later, and drying the zeolite for later use; and (3) calcining the zeolite impregnated with the sodium metaaluminate solution to obtain the multifunctional modified zeolite. Sodium ions are used for increasing the ion exchange capacity, part of silicon element of zeolite is removed by utilizing solution alkalinity, the aluminum element is increased, and the silicon-aluminum ratio is reduced; and the exogenous aluminum element is embedded into a zeolite framework through calcination, meanwhile, and pore channels are dredged, so the mesoporous proportion is increased, the pore structure is improved, multifunctional modification of the natural zeolite is achieved, secondary pollution caused by the washing link after solution impregnation is avoided, and the removal rate of the modifiednatural zeolite on ammonia nitrogen in water body is remarkably increased.

Owner:CHINA JILIANG UNIV

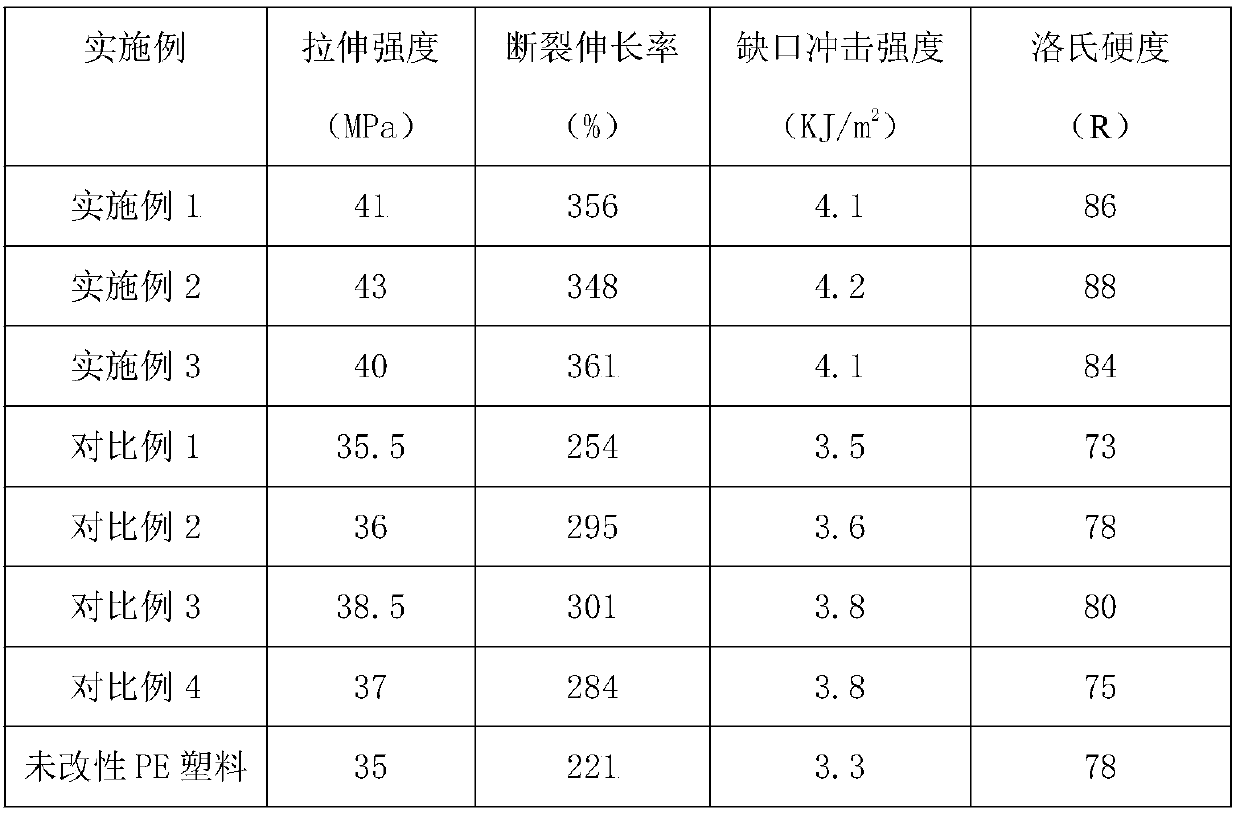

Improved plastic and preparation method thereof

The invention discloses improved plastic, which is prepared from the following ingredients in percentage by mass: 60 to 75 percent of waste and old plastics, 10 to 15 percent of glass fiber, 5 to 10 percent of waste and old ceramic powder, 0.5 to 1 percent of silane coupling agents, 1 to 3 percent of compatilizers, 2 to 5 percent of SBS, 1 to 2 percent of dimethyldiazo phenol oxysilane and 4 to 8percent of methyl methacrylate. The dimethyldiazo phenol oxysilane, the methyl methacrylate and other raw materials are added to be mixed; the glass fiber and ceramic powder surface can be fully modified; the condition that when the coupling agent is used for treating the glass fiber surface, the expected effect cannot be achieved is avoided; greater affinity is realized between the modified glassfiber and a plastic substrate; the glass fiber, the ceramic powder and the plastic have full compatibility; the interface bonding force is strong; the mechanical property of the finally obtained modified plastic is greatly improved.

Owner:湖南省塑坤新材料有限公司

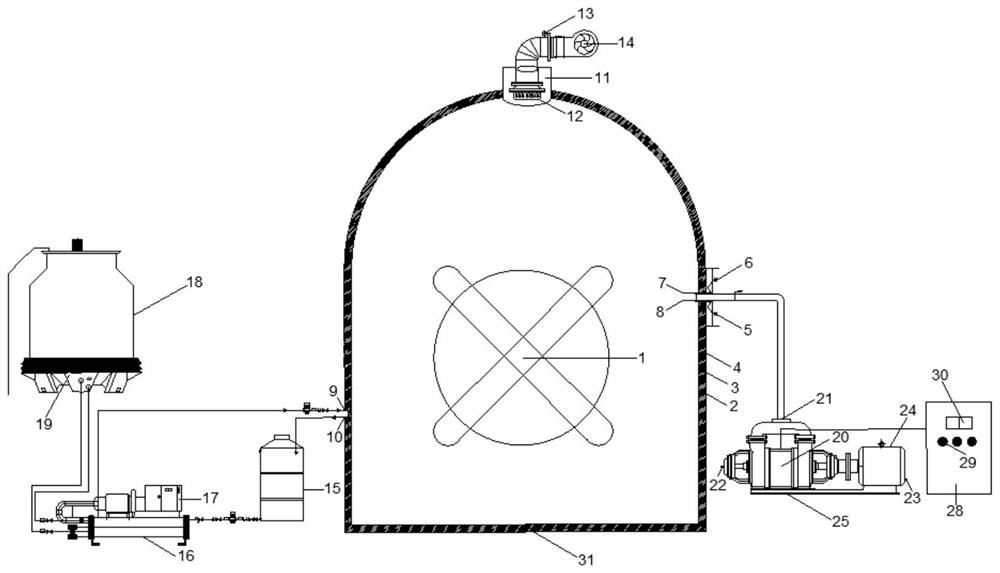

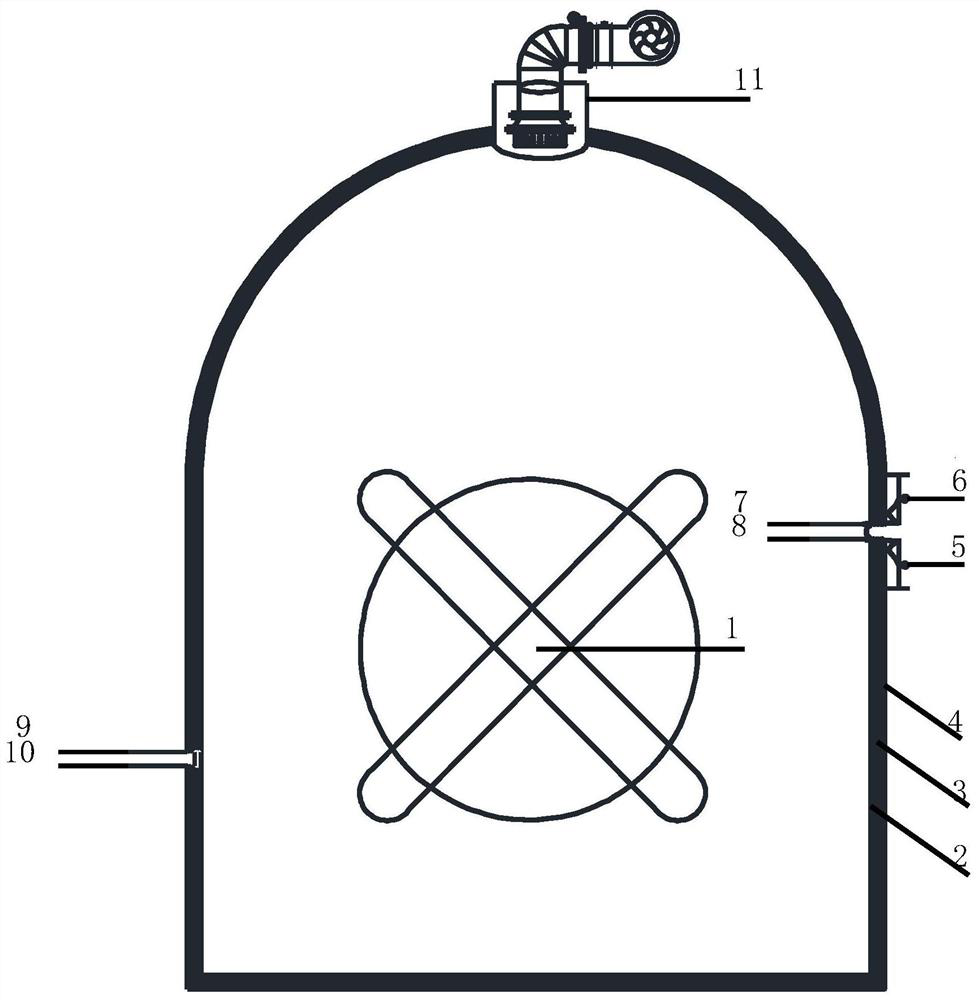

Explosion container for creating low-temperature negative-pressure environment

PendingCN113655196AKeep the temperature constantReduce experimental errorFuel testingEngineeringAir exchange

The invention discloses an explosion container for creating a low-temperature negative-pressure environment, and belongs to the technical field of explosion containers. The explosion container comprises a tank body, a water-cooled vacuum pump mounted on one side of the tank body, a liquid cooling machine mounted on the other side of the tank body and a smoke exhaust fan mounted on the top of the tank body, wherein a cooling water tower is mounted on the other side of the liquid cooling machine, a vacuum pump operation box is arranged on one side of the water-cooled vacuum pump, the tank wall of the tank body is sequentially provided with a tank body inner wall, a tank body middle layer and a tank body outer wall from inside to outside, and an anti-explosion vacuum door is arranged on the tank body. According to the invention, a heat conduction mode is adopted for cooling, air exchange with the interior is not needed, and the cooling process and the vacuumizing process can be carried out at the same time, so that the preparation time needed by an experiment is greatly shortened, and experiment errors caused by multiple times of operation are reduced; and variables can be conveniently changed, explosion parameters under different pressures can be conveniently researched, and due to the constant-temperature design, the next experiment can be quickly carried out only by changing the vacuum degree.

Owner:ANHUI UNIV OF SCI & TECH

Preparation method of plastic wood sectional material based on waste circuit board resin powder

The invention discloses a preparation method of a plastic wood sectional material based on waste circuit board resin powder and belongs to the technical field of composite materials. According to thepreparation method of the plastic wood sectional material based on the waste circuit board resin powder, through preprocessing and modification of the waste circuit board resin powder, pre-mixing, preparation of the sectional material, surface after-processing and other steps, the plastic wood sectional material is prepared. According to the preparation method, the waste circuit board resin powderis adopted for completely replacing wood powder, harmless and resource utilization of the waste circuit board resin powder is achieved, the shortage of wood material resources is relieved, and meanwhile the prepared plastic wood sectional material is environmentally friendly and has excellent waterproofness, mildew resistance and structural toughness.

Owner:苏州市富荣环保科技有限公司 +1

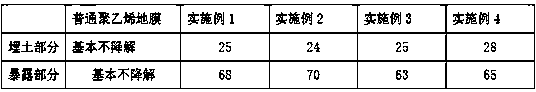

Method for preparing agricultural plastic mulching film special for arachis hypogaea from automotive sound-absorbing cotton leftover waste material

InactiveCN109265937AReduce pollutionPromotes vigorous growth of seedlingsPlant protective coveringsPolyethylene glycolPlastic mulch

The invention discloses a method for preparing agricultural plastic mulching film special for arachis hypogaea from automotive sound-absorbing cotton leftover waste material. Raw materials include theautomotive sound-absorbing cotton leftover waste material, modified starch, arachis hypogaea vine powder, calcium carbonate, polyethylene glycol terephthalate, an ethylene-acrylic copolymer, maleic anhydride, dicumyl peroxide and an auxiliary, wherein the automotive sound-absorbing cotton leftover waste material is used as a main raw material, through starch modification, mixing, compatibility and sound-absorbing material leftover waste material recovery, resource recycling is achieved, energy and material consumption are saved, the problem of three wastes pollution is avoided, the product cost is low, and the agricultural plastic mulching film special for the arachis hypogaea can be degraded in a natural environment, meets a crop growth cycle, is turned into organic waste after being degraded, can be absorbed by soil to improve the plantable property and to promote thriving of an arachis hypogaea seedling stage, and has good economic benefits and social benefits.

Owner:袁志平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com