Composite modifier and low-strength concrete prepared from same

A compound modifier and concrete technology, which is applied in the field of building materials, can solve problems affecting the service life and driving safety of subgrade engineering structures or foundation treatment engineering, degradation of service performance, microstructure changes, etc., to achieve superior performance and improve performance , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

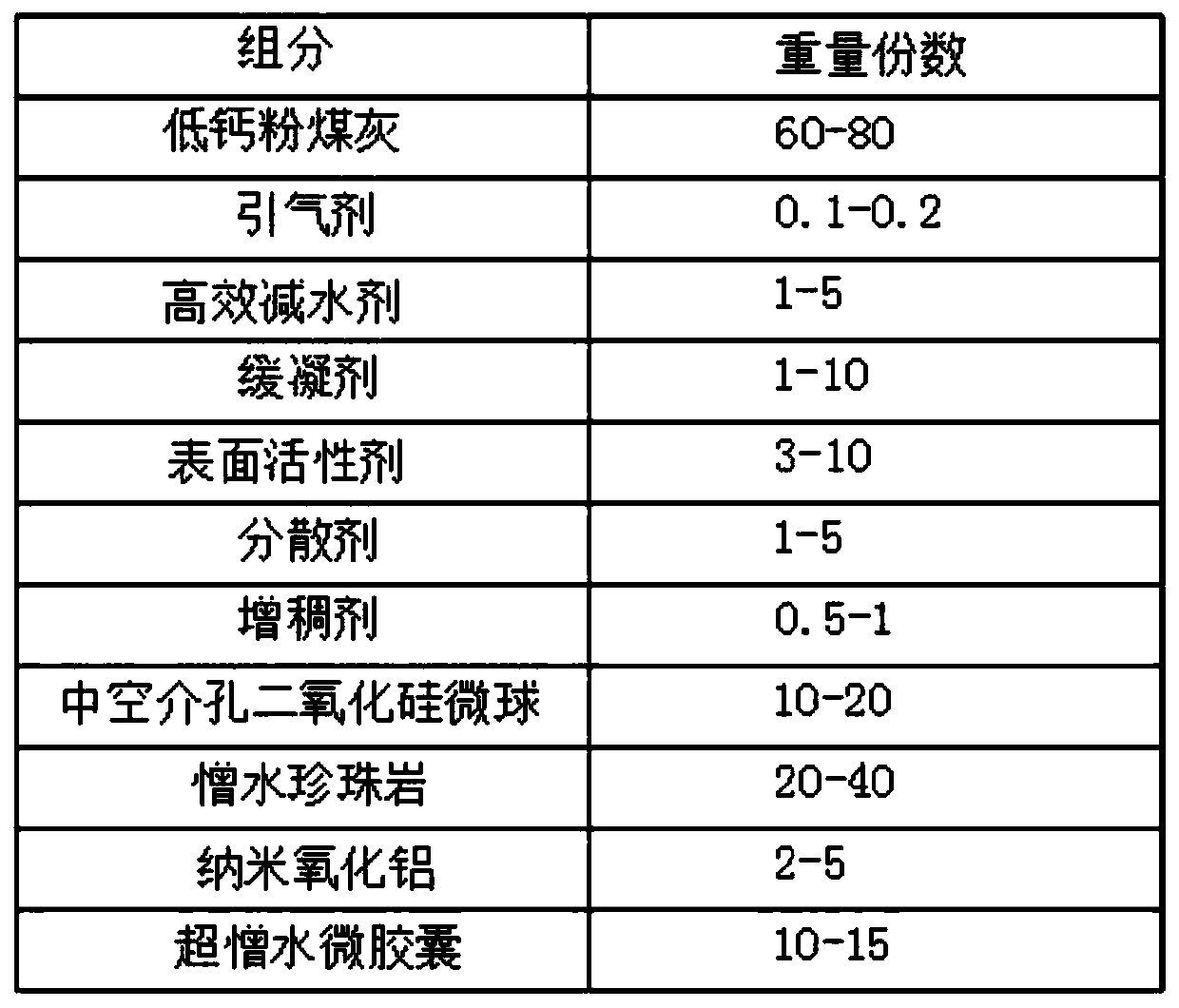

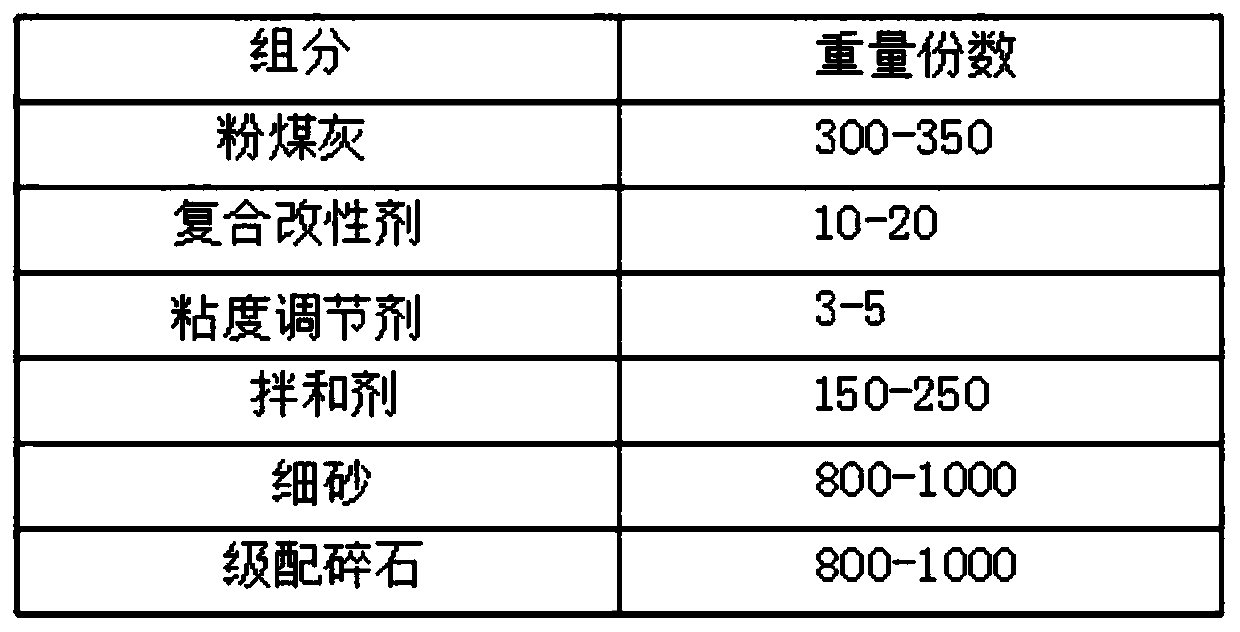

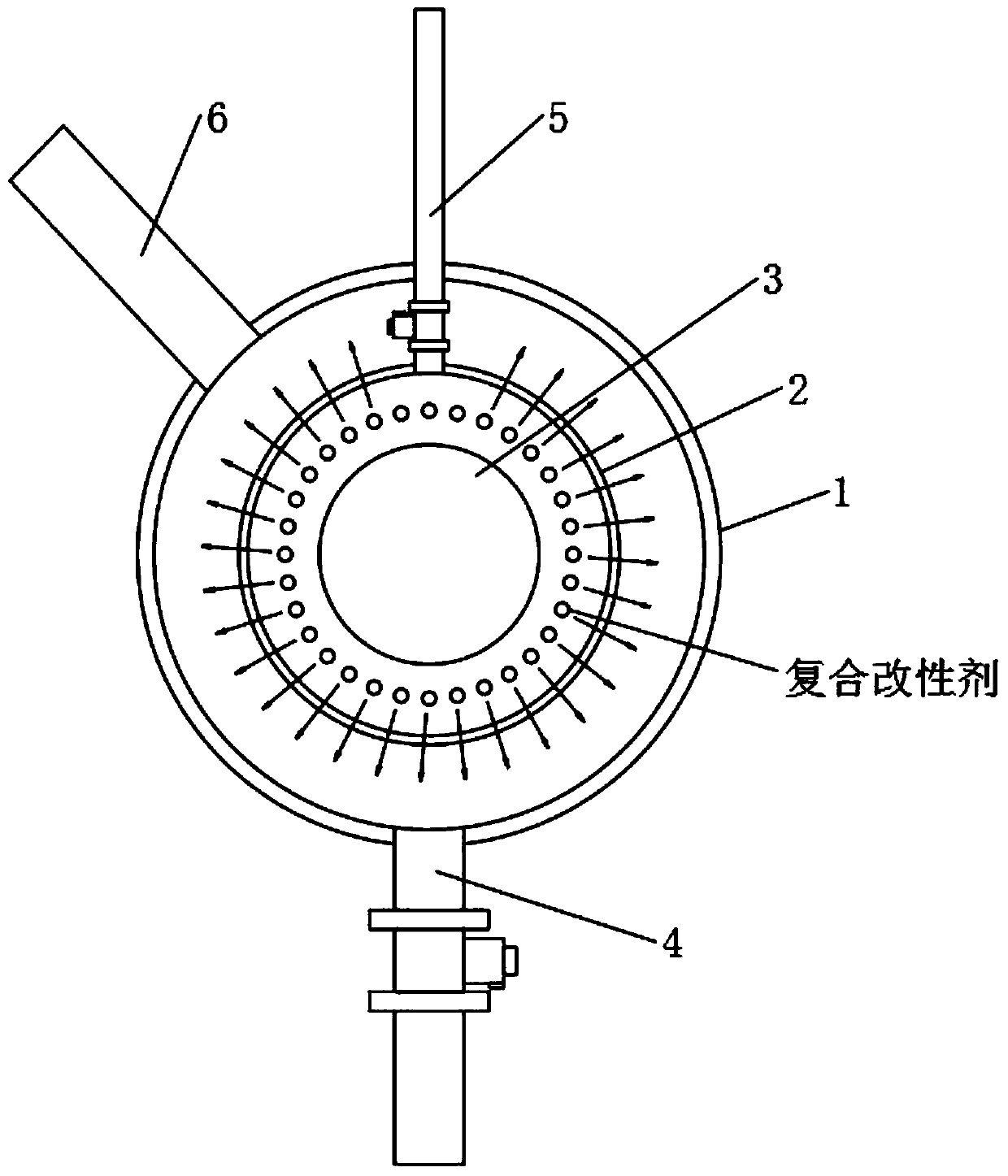

[0041] see figure 1 , a composite modifier, the composite modifier is composed of the following components by weight: 60 parts of low-calcium fly ash, 0.1 part of air-entraining agent, 1 part of high-efficiency water reducer, 1 part of retarder, 3 parts Surfactant, 1 part of dispersant, 0.5 part of thickener, 10 parts of hollow mesoporous silica microspheres, 20 parts of hydrophobic perlite, 2 parts of nano-alumina, 10 parts of superhydrophobic microcapsules.

[0042] Nano-alumina has a small particle size and a large specific surface area, while hollow mesoporous silica microspheres have a high specific surface area and good dispersion. Its unique hollow cavity and mesoporous shell characteristics can be well Adsorption aids, while enhancing the interfacial adhesion between the composite modifier and concrete, which is conducive to stress transfer and improves the strength and stability of concrete.

[0043] Low-calcium fly ash is Class I or Class II low-calcium fly ash, or ...

Embodiment 2

[0051] see figure 1 , a composite modifier, the composite modifier is composed of the following components by weight: 80 parts of low-calcium fly ash, 0.2 parts of air-entraining agent, 5 parts of high-efficiency water reducer, 10 parts of retarder, 10 parts Surfactant, 5 parts of dispersant, 1 part of thickener, 20 parts of hollow mesoporous silica microspheres, 40 parts of hydrophobic perlite, 5 parts of nano-alumina, and 15 parts of superhydrophobic microcapsules.

[0052] Low-calcium fly ash is Class I or Class II low-calcium fly ash, or a mixture of Class I and Class II low-calcium fly ash, and the mixing ratio is 1:1.5. Low-calcium fly ash can dilute silicate The content of C3A minerals in cement that is sensitive to environmental water erosion can also react with Ca(OH)2 formed by cement hydration to produce pozzolanic reactions, increasing the relatively stable and low calcium-silicon hydrated silicon hydrate under environmental water erosion Calcium acid C-S-H conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com