Improved plastic and preparation method thereof

A technology for plastics and modification, applied in the field of modified plastics and their preparation, can solve the problems such as the inability to improve the wettability of plastics and fibers, the poor performance of modified plastics, and the weak interfacial adhesion, and achieve a sufficient phase. Capacitance, strong interfacial adhesion and strong interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

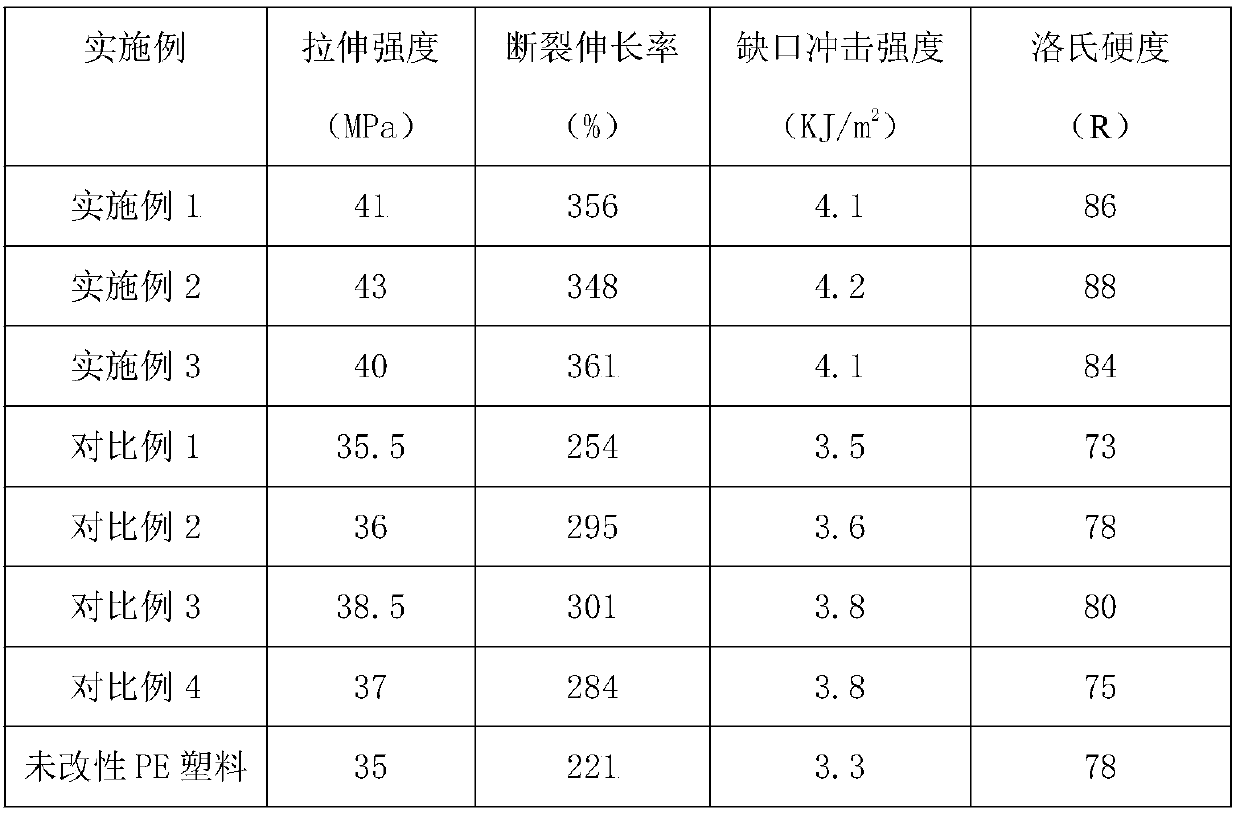

Examples

Embodiment 1

[0033] A modified plastic, including the following components in mass percentage: waste plastic 75%, glass fiber 10%, waste ceramic powder 5%, silane coupling agent KH5501%, compatibilizer maleic anhydride 1%, SBS 3%, Dimethyldiazophenoxysilane 1%, Methyl Methacrylate 4%.

[0034] Preparation method: 1) Add waste ceramic powder, glass fiber, and dimethyl diazophenoxysilane into a mixer and mix at a mixing temperature of 100°C for 30 minutes, then cool down to 60°C and add methyl Methyl acrylate, fully mixed for 1 hour to obtain a mixture;

[0035] 2) Add the dried waste plastics and SBS into the mixer according to the stated ratio and mix them. The mixing temperature is 120°C. After fully mixing, the temperature is raised to 140°C. Add the mixture obtained in step 1), silane coupling agent KH550 and The compatibilizer maleic anhydride is fully mixed to obtain a mixture;

[0036] 3) Place the mixture obtained in step 2) in a twin-screw extruder for extrusion and granulation t...

Embodiment 2

[0038]A modified plastic, including the following components in mass percentage: waste plastic 66%, glass fiber 12%, waste ceramic powder 10%, silane coupling agent KH5500.5%, compatibilizer maleic anhydride 2% , SBS 2%, Dimethylbisazophenoxysilane 1.5%, Methyl Methacrylate 6%.

[0039] Preparation method: 1) Add waste ceramic powder, glass fiber, and dimethyl diazophenoxysilane into a mixer and mix at a mixing temperature of 120°C for 20 minutes, then cool down to 80°C and add methyl Methyl acrylate, fully mixed for 1.2h to obtain the mixture;

[0040] 2) Add the dried waste plastics and SBS into the mixer according to the stated ratio and mix them. The mixing temperature is 110°C. After fully mixing, the temperature is raised to 140°C. Add the mixture obtained in step 1), silane coupling agent KH550 and The compatibilizer maleic anhydride is fully mixed to obtain a mixture;

[0041] 3) Place the mixture obtained in step 2) in a twin-screw extruder for extrusion and granula...

Embodiment 3

[0043] A modified plastic, including the following components in mass percentage: waste plastic 60%, glass fiber 15%, waste ceramic powder 6%, silane coupling agent KH5501%, compatibilizer maleic anhydride 3%, SBS 5%, Dimethyldiazophenoxysilane 2%, Methyl Methacrylate 8%.

[0044] Preparation method: 1) Add waste ceramic powder, glass fiber, and dimethyl diazophenoxysilane into a mixer and mix at a mixing temperature of 110°C for 25 minutes, then cool down to 70°C and add methyl Methyl acrylate, fully mixed for 1.5h to obtain the mixture;

[0045] 2) Add the dried waste plastics and SBS into the mixer according to the stated ratio and mix them. The mixing temperature is 115°C. After fully mixing, the temperature is raised to 130°C. Add the mixture obtained in step 1), silane coupling agent KH550 and The compatibilizer maleic anhydride is fully mixed to obtain a mixture;

[0046] 3) Place the mixture obtained in step 2) in a twin-screw extruder for extrusion and granulation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com