Explosion container for creating low-temperature negative-pressure environment

An explosion container, low temperature negative pressure technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of low atmospheric pressure environment temperature, less explosion experimental research, etc., to reduce experimental errors, low thermal expansion coefficient, good resistance explosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

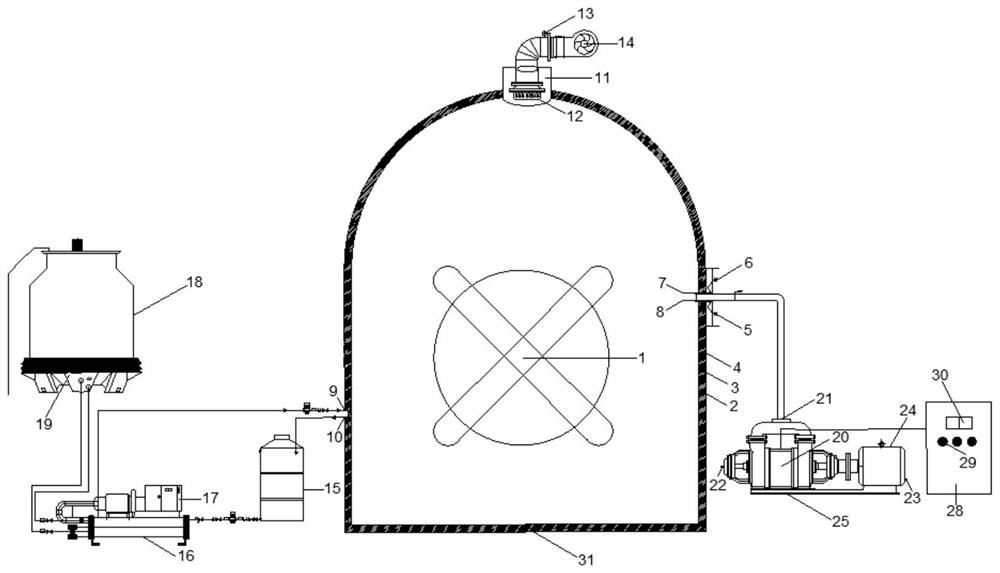

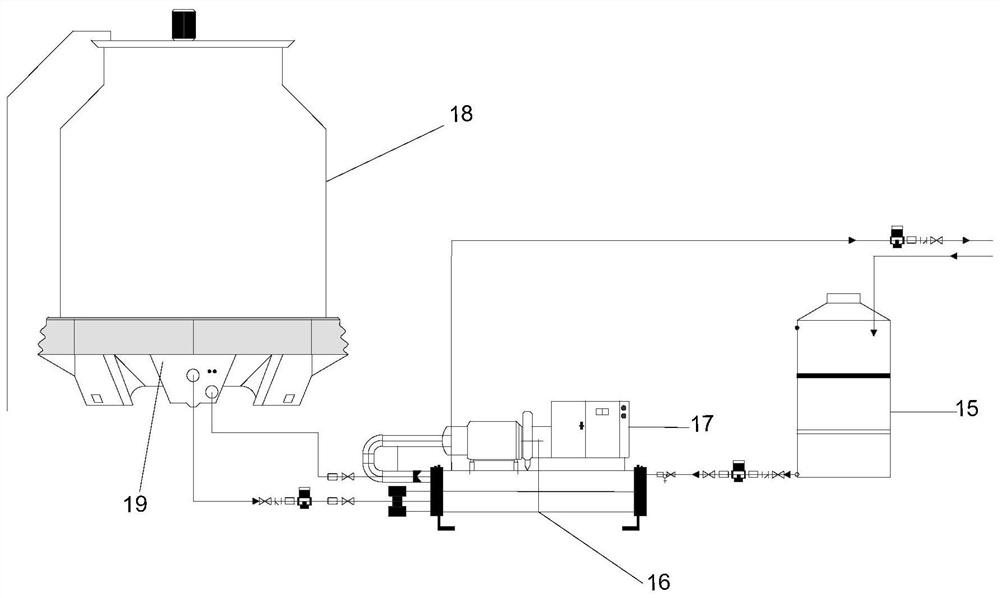

[0044] An explosion container for creating a low-temperature negative pressure environment, comprising the following steps:

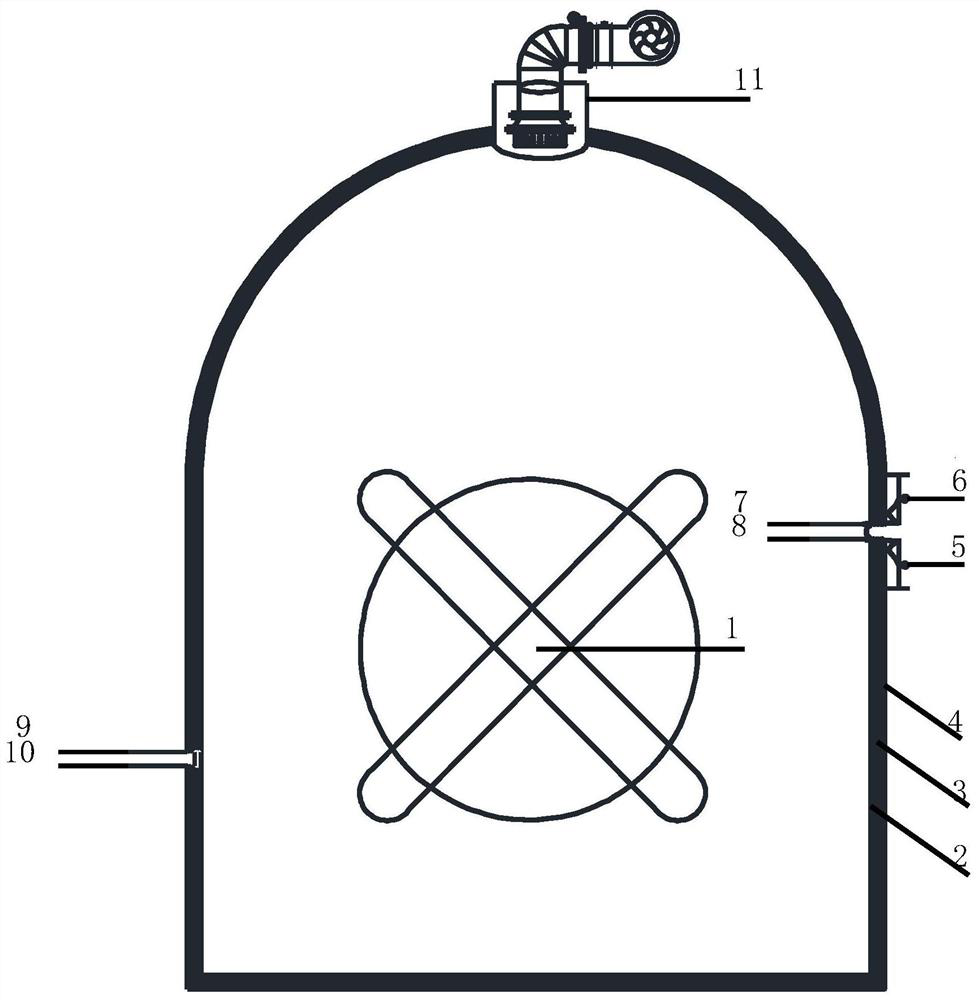

[0045] Step 1: Open the entrance 1 of the explosion container, turn on the smoke exhaust fan 11 above the tank, fully circulate the internal air and the outside world, and then turn off the smoke exhaust fan;

[0046] Step 2: The operator enters the interior of the explosion container, places the explosives, the detonator and other devices, and connects the detonator to the internal detonating wire B8 and the internal detonating wire A7 after short-circuiting the external wires;

[0047] Step 3: Connect the line of the detonation velocity meter to the interface of the equipment and the thermometer. After testing the normal operation of the detonation velocity instrument, tighten the knob and seal the interface with vacuum mud;

[0048] Step 4: After confirming that it is correct, the operator leaves the explosion vessel and closes the entrance to ensure...

Embodiment 2

[0056] The operation steps of an explosion container for creating a low-temperature negative-pressure environment are roughly the same as those in Example 1, except that in Example 2, the detonation wave curve of the explosive is tested in a low-temperature negative-pressure environment, and the connected instruments are replaced with sensors and oscilloscopes.

[0057] Step 1: Open the entrance of the explosion container, turn on the smoke exhaust fan 11 above the tank, fully circulate the internal air and the outside world, and then close the smoke exhaust fan.

[0058] Step 2: The operator enters the inside of the explosion container, places the explosives, the detonator and other devices, and connects the detonator to the internal detonating wire B8 and the internal detonating wire A7 after short-circuiting the external wires.

[0059] Step 3: Connect the sensor to the interface of the equipment line and the thermometer, and connect the sensor to the oscilloscope to test wh...

Embodiment 3

[0068] The operation steps of an explosion container for creating a low-temperature negative-pressure environment are roughly the same as those in Example 1, except that Example 3 tests the explosiveness of explosives in a low-temperature negative-pressure environment without connecting an instrument.

[0069] Step 1: Open the entrance of the explosion container, turn on the smoke exhaust fan 11 above the tank, fully circulate the internal air and the outside world, and then turn off the smoke exhaust fan;

[0070] Step 2: The operator enters the interior of the explosion container, and places the explosives, detonator, test lead post and other devices in place, and connects the detonator with the internal detonating wire B8 and the internal detonating wire A7 after short-circuiting the external wires;

[0071] Step 3: After confirming that it is correct, the operator leaves the explosion vessel and closes the entrance to ensure that the airtightness of the explosion vessel mee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com