Patents

Literature

109results about How to "Absorb noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

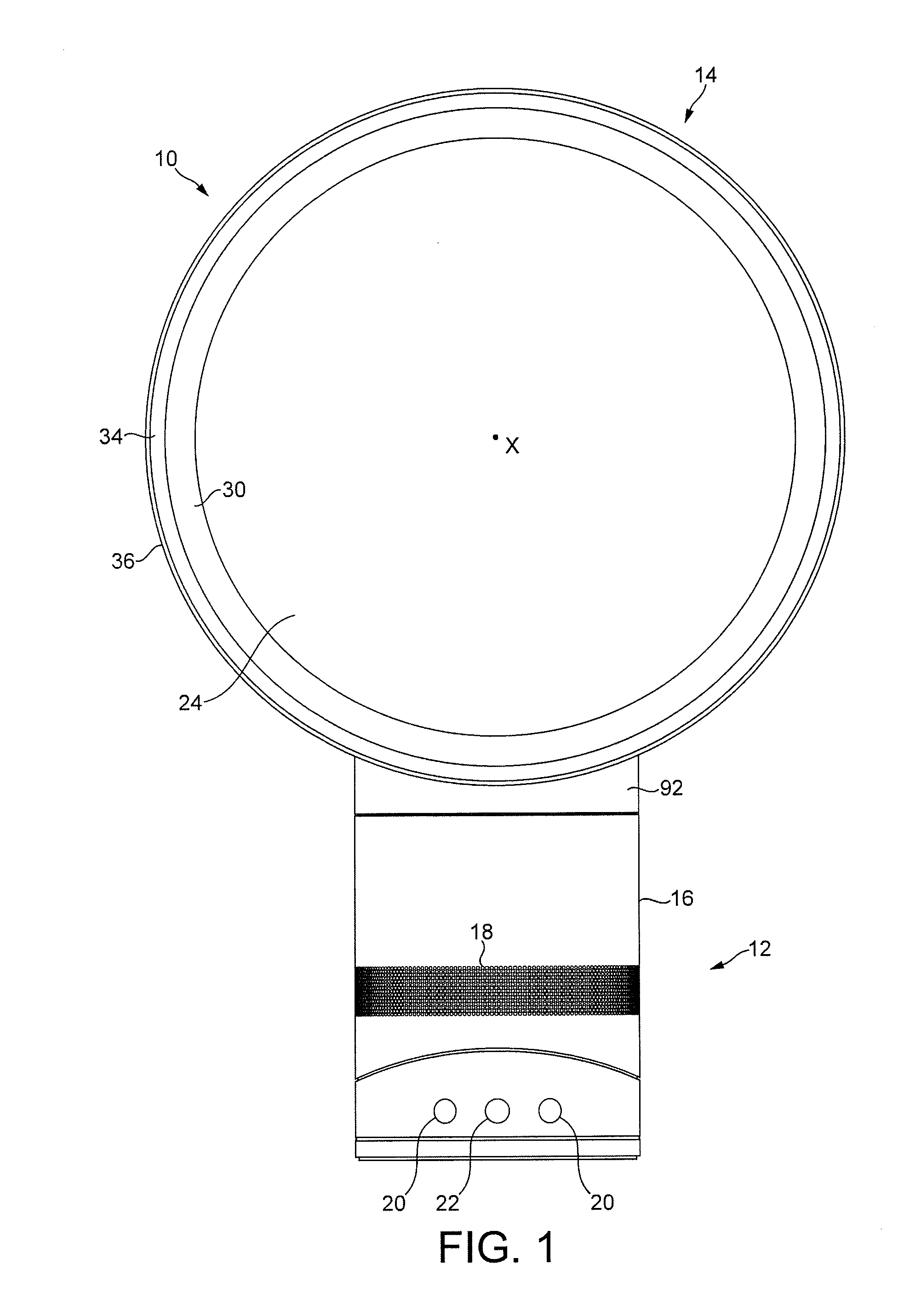

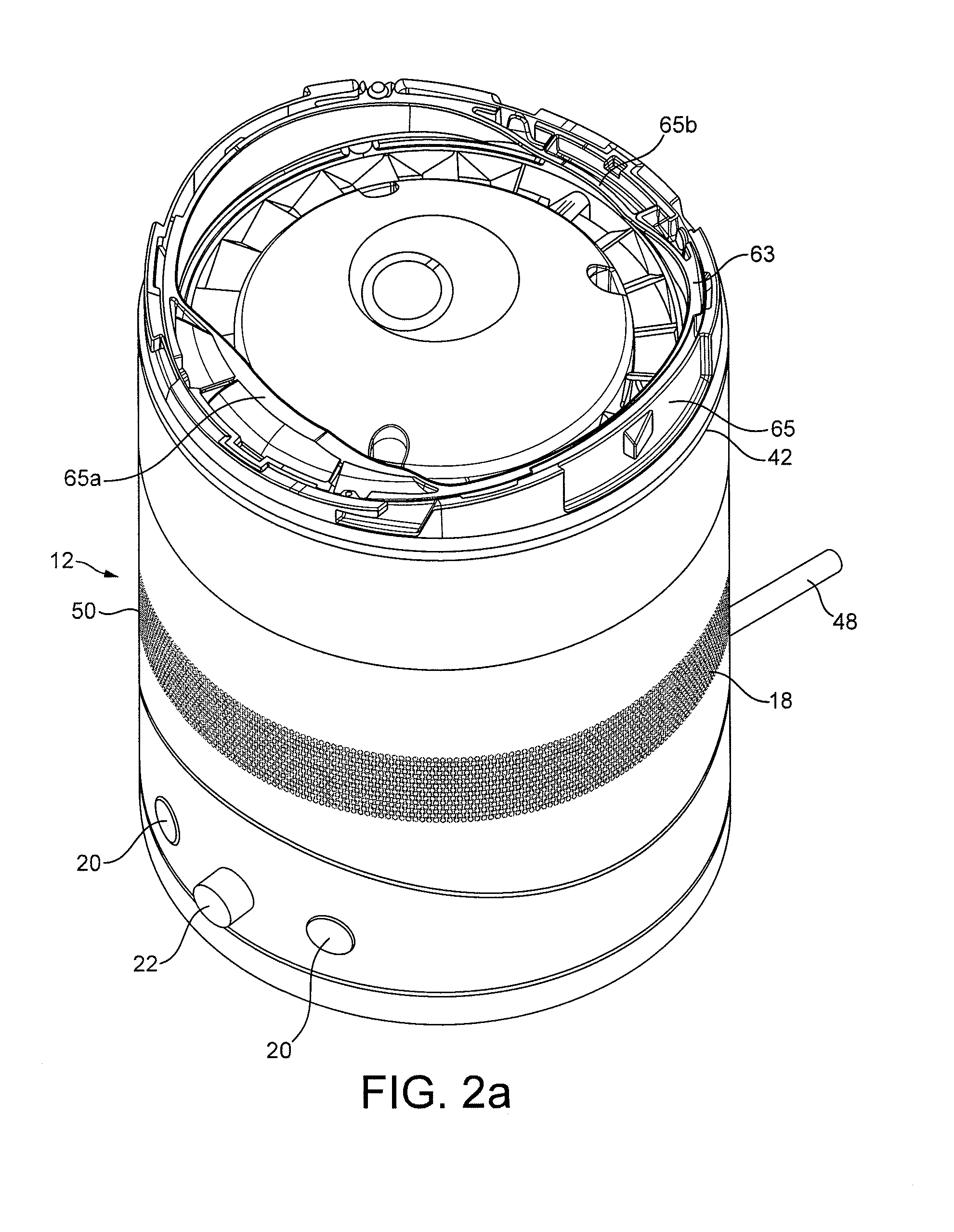

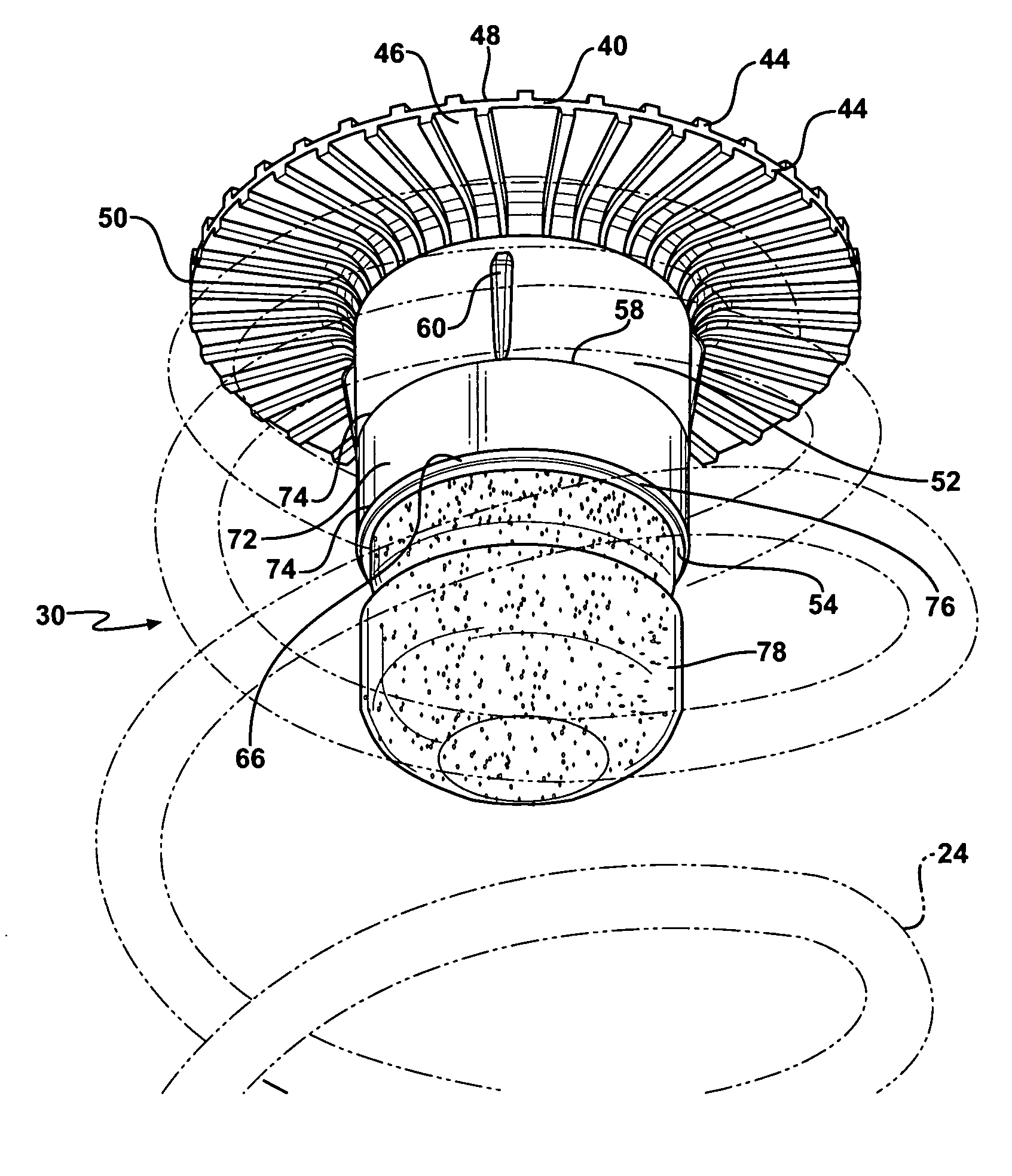

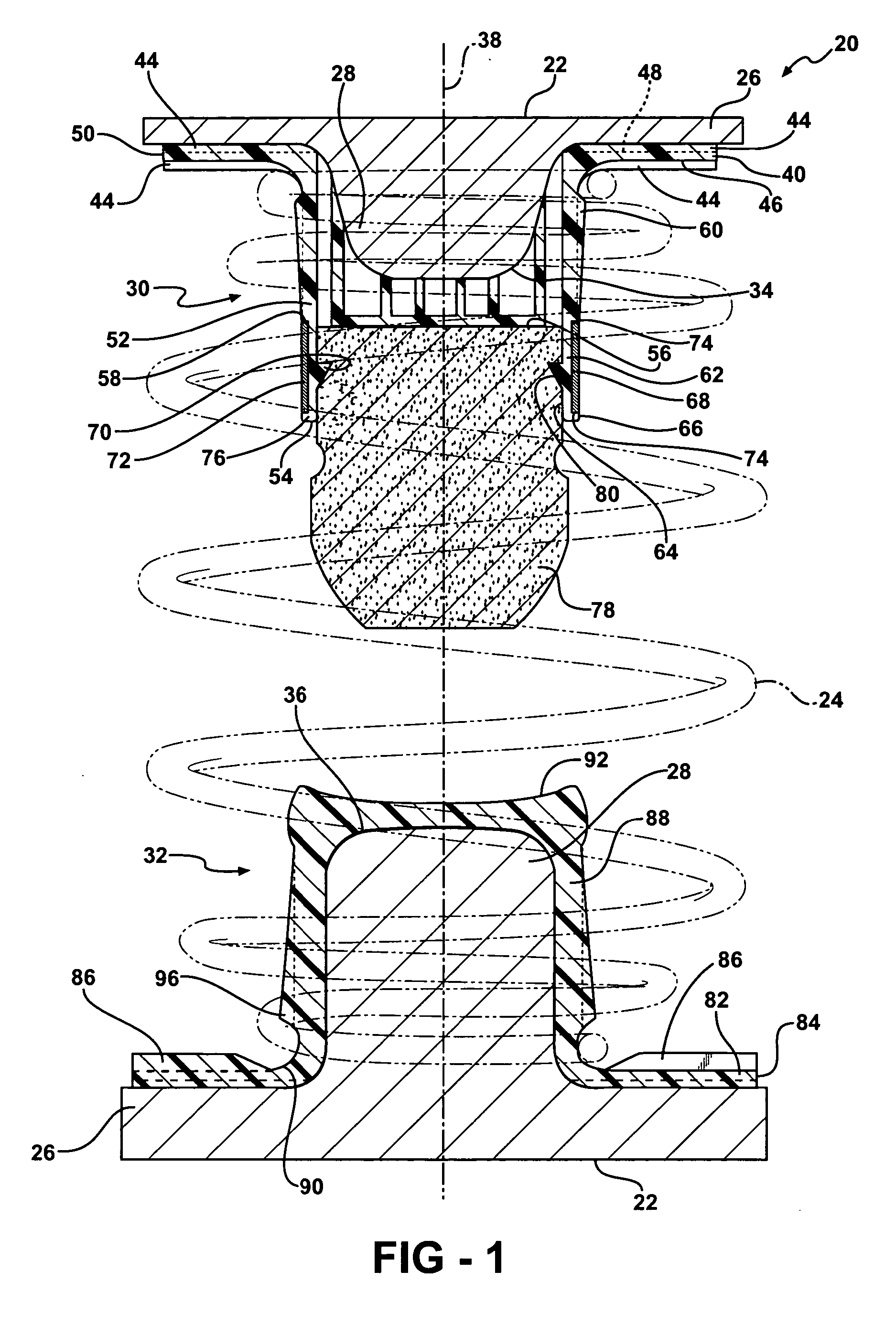

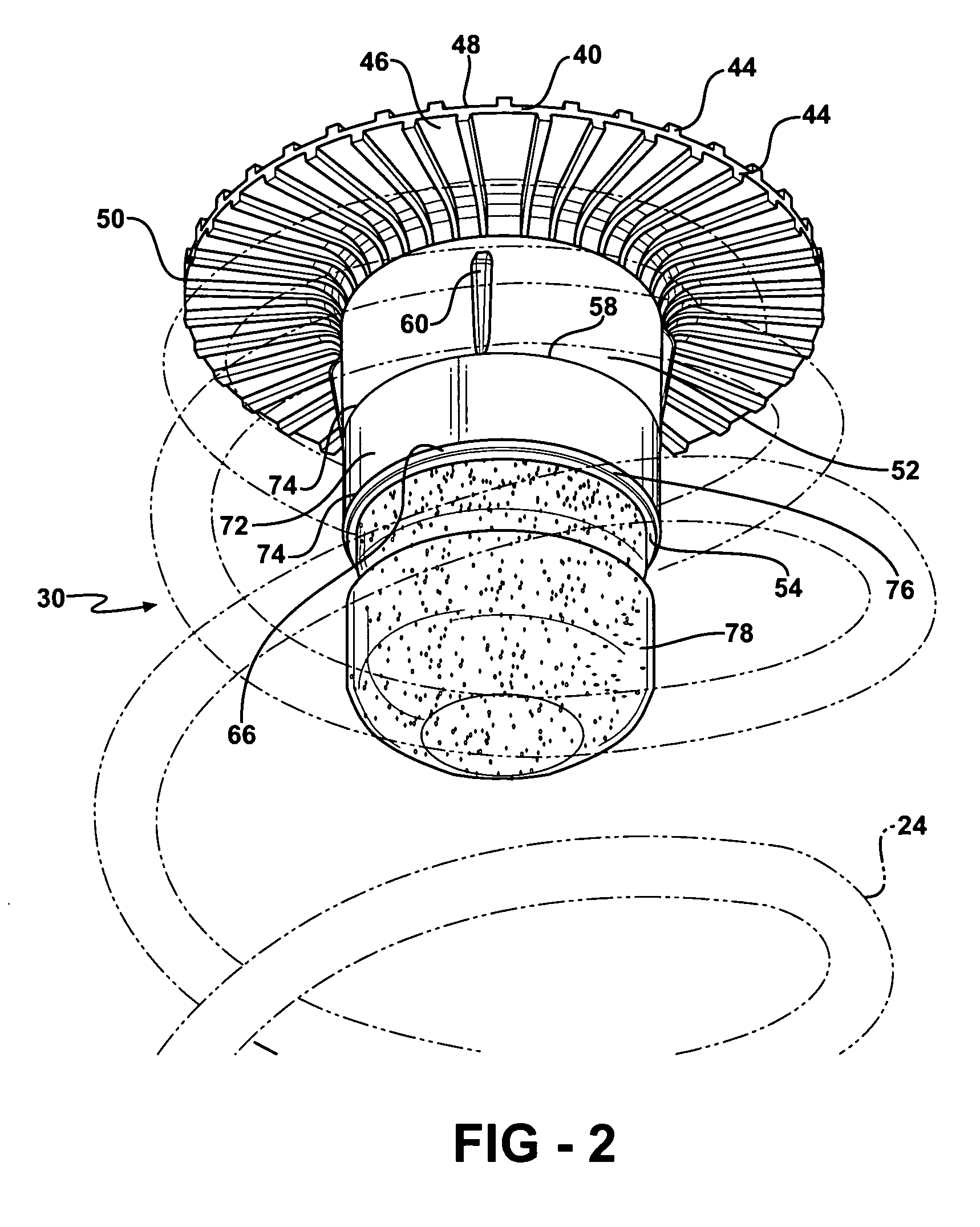

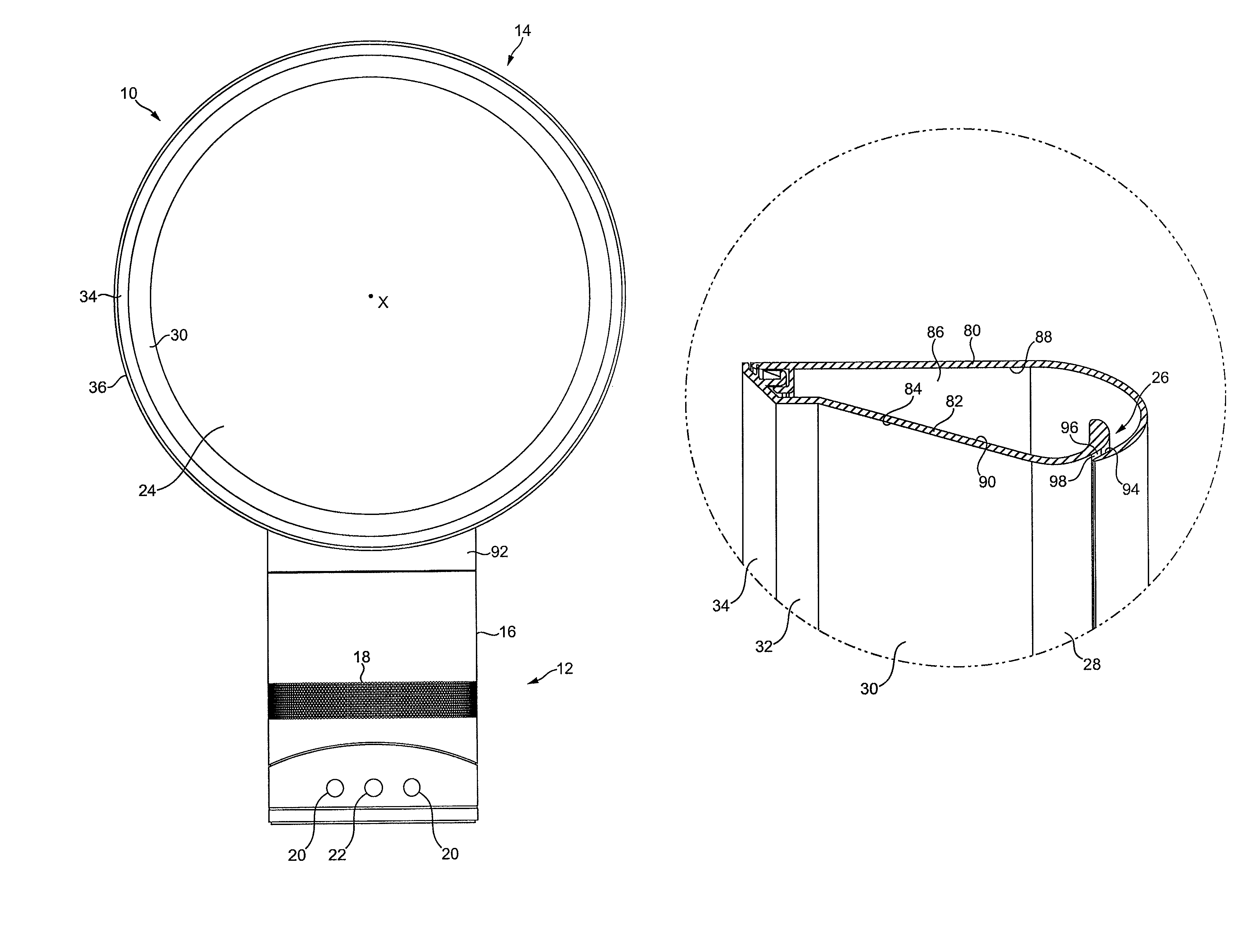

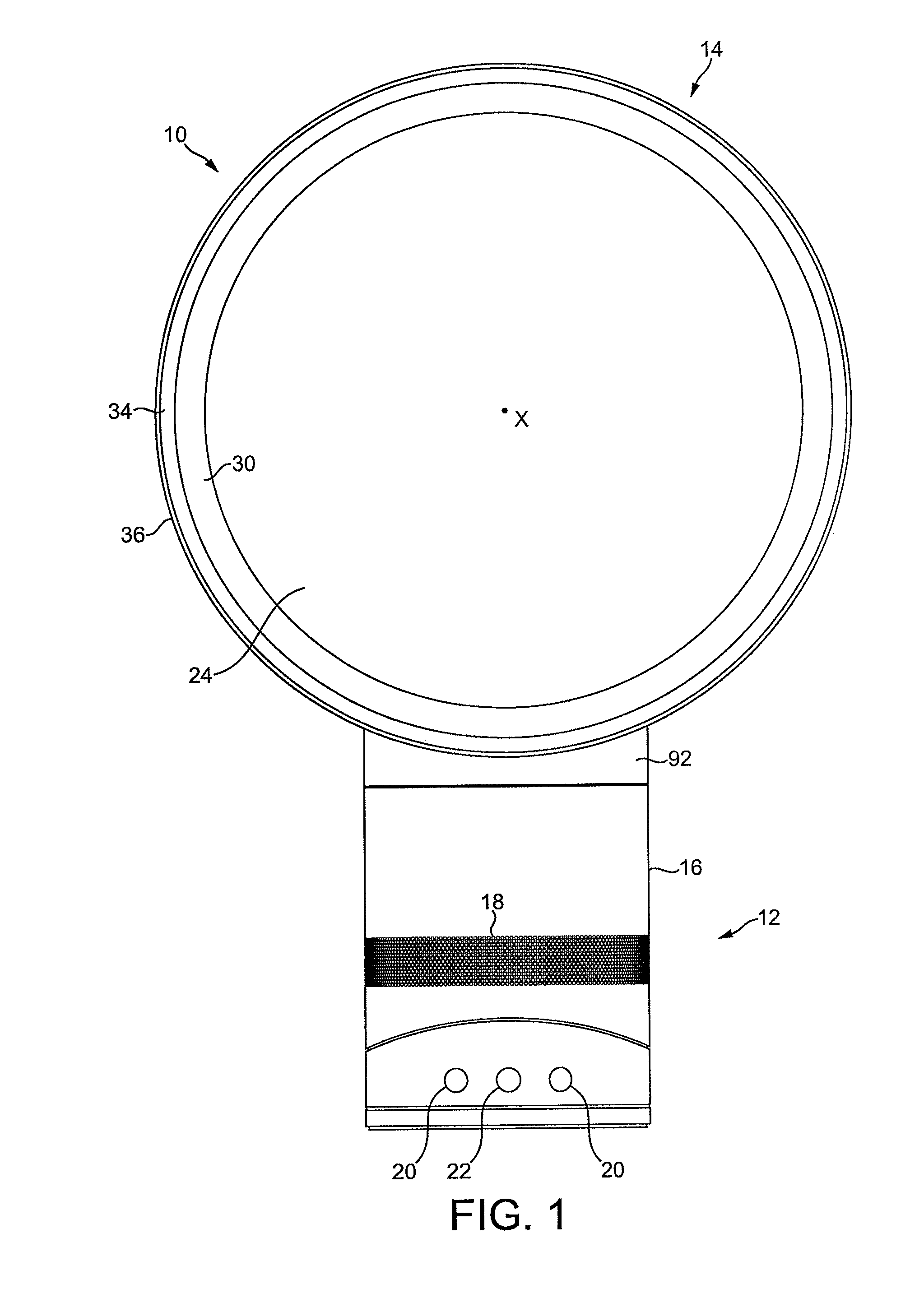

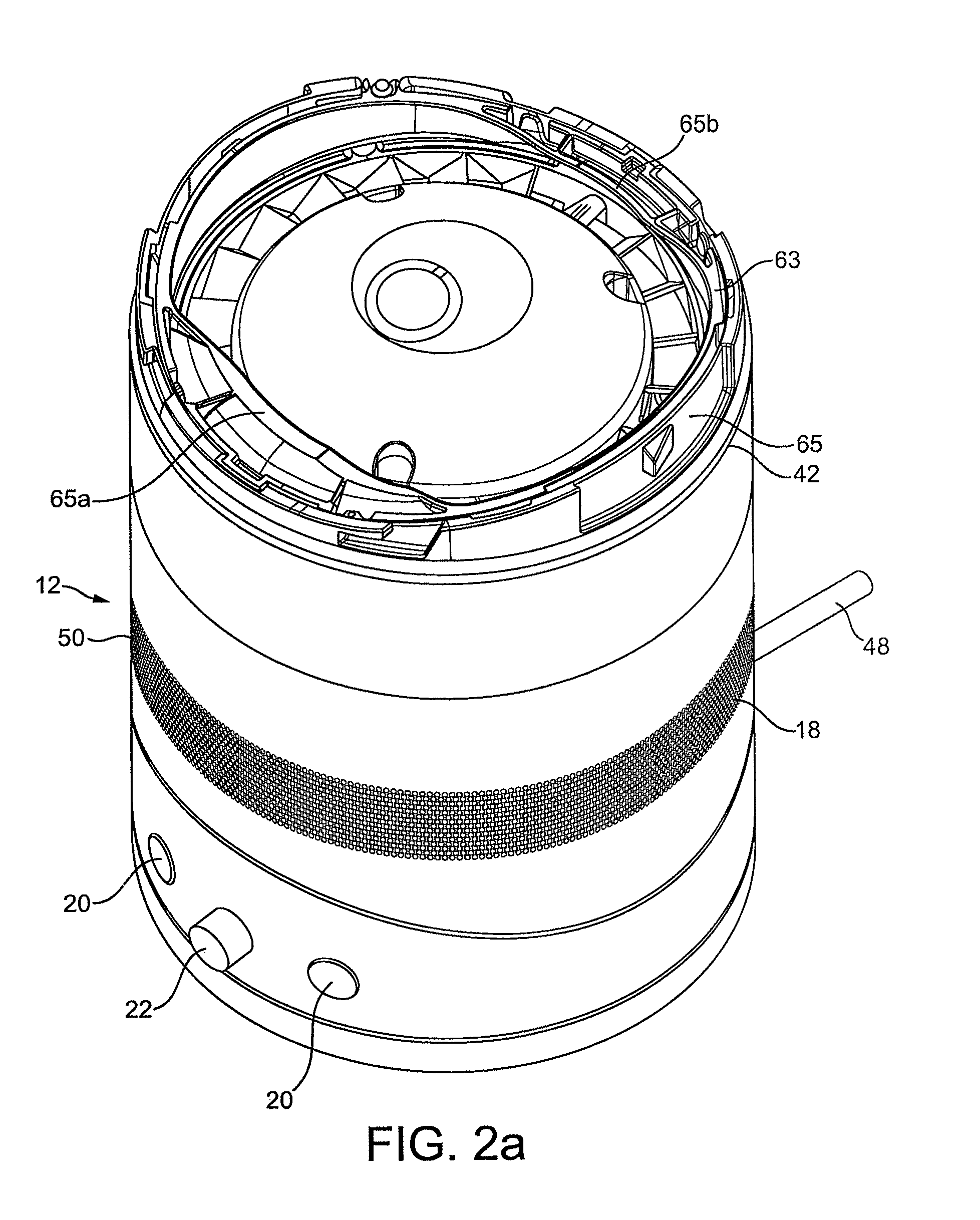

Fan assembly

InactiveUS20100226771A1Difference in pressureLow efficiencyPump componentsJet pumpsImpellerEngineering

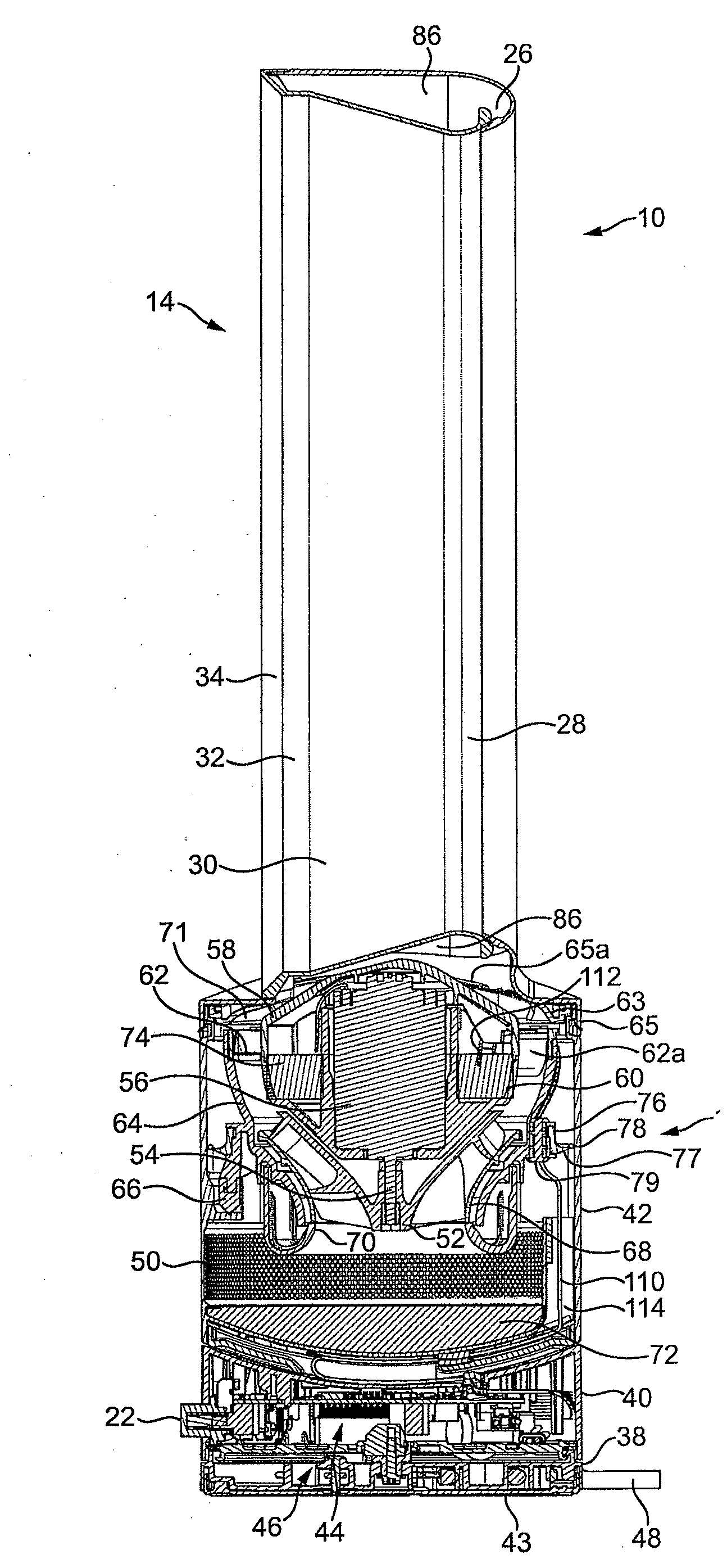

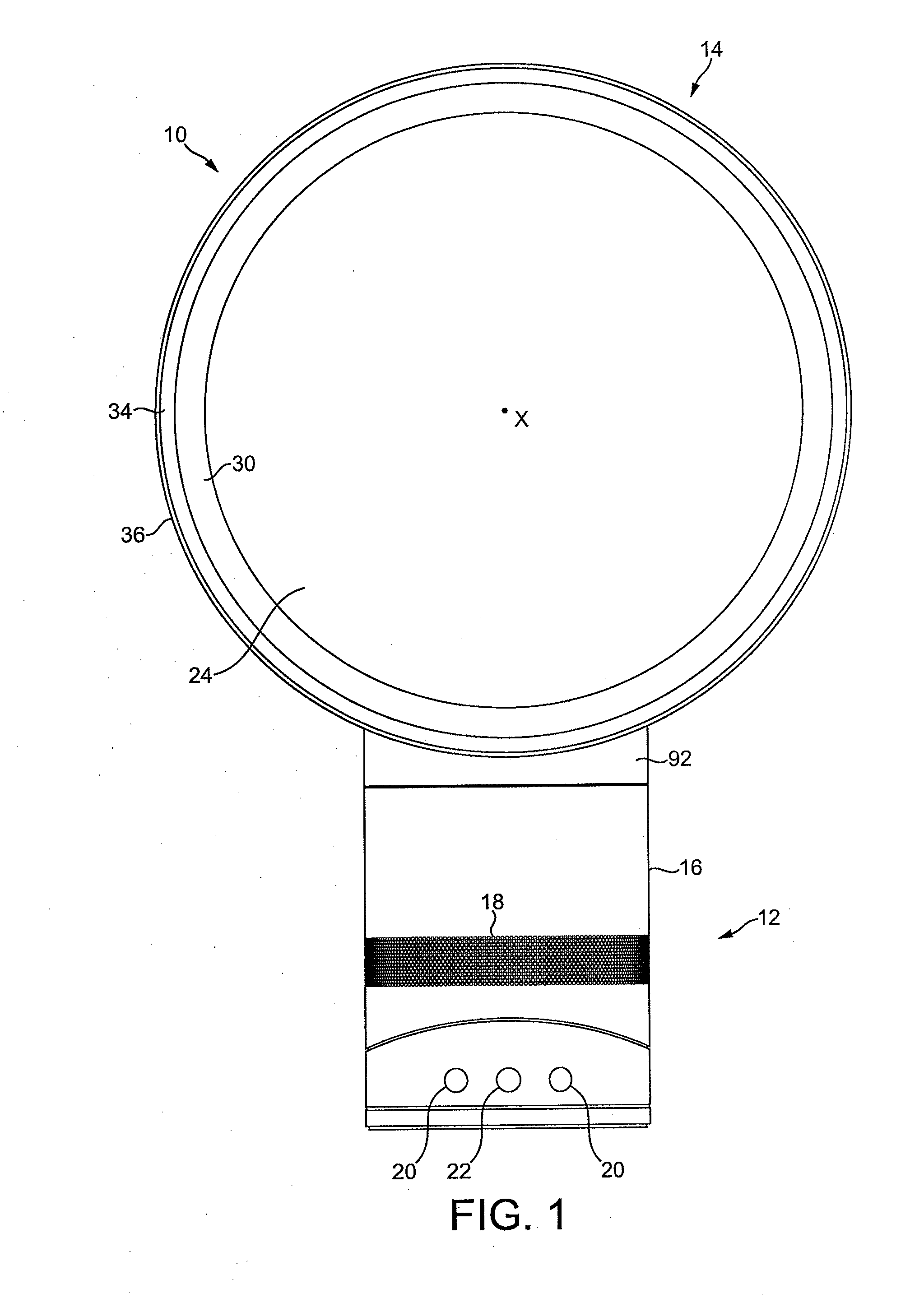

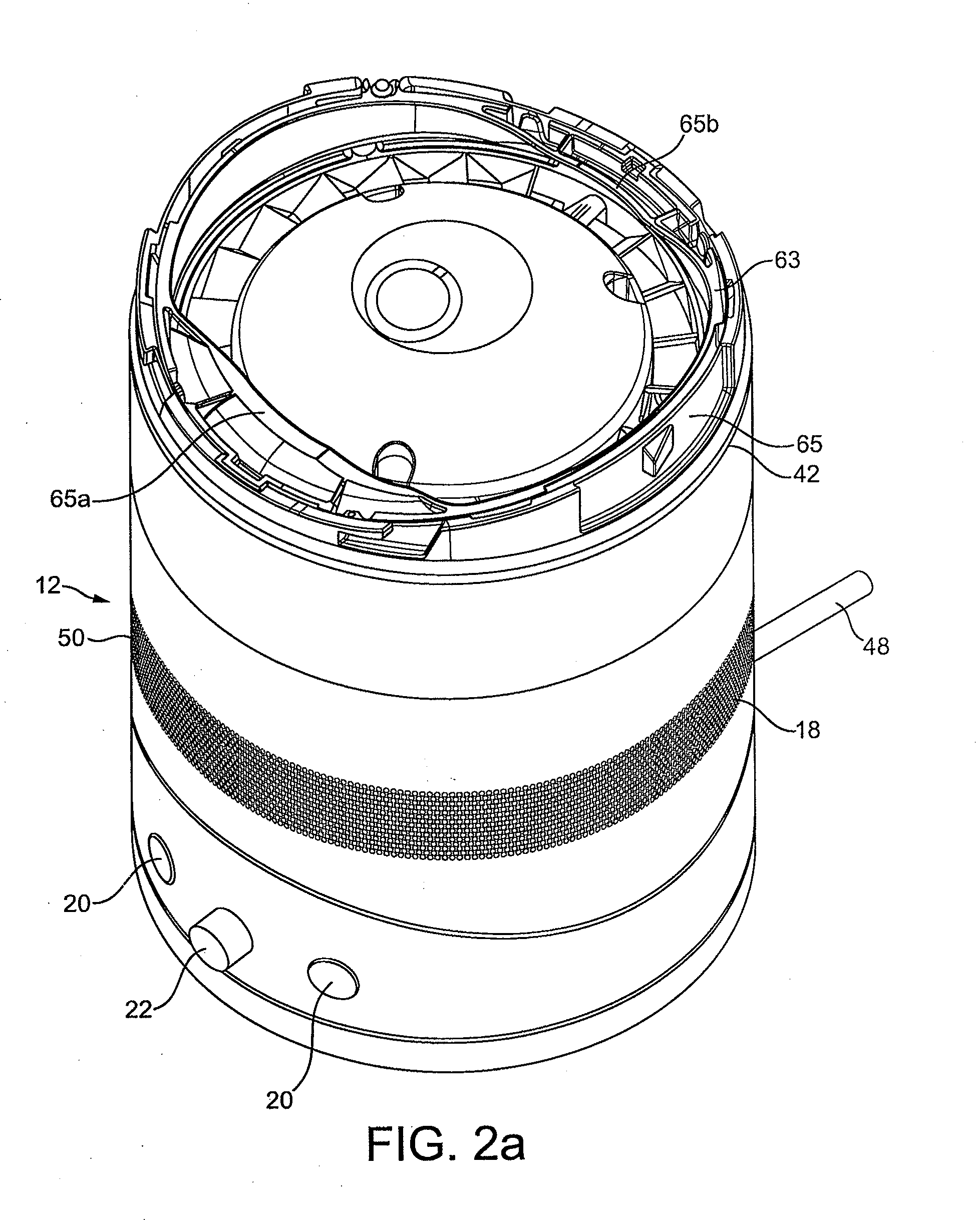

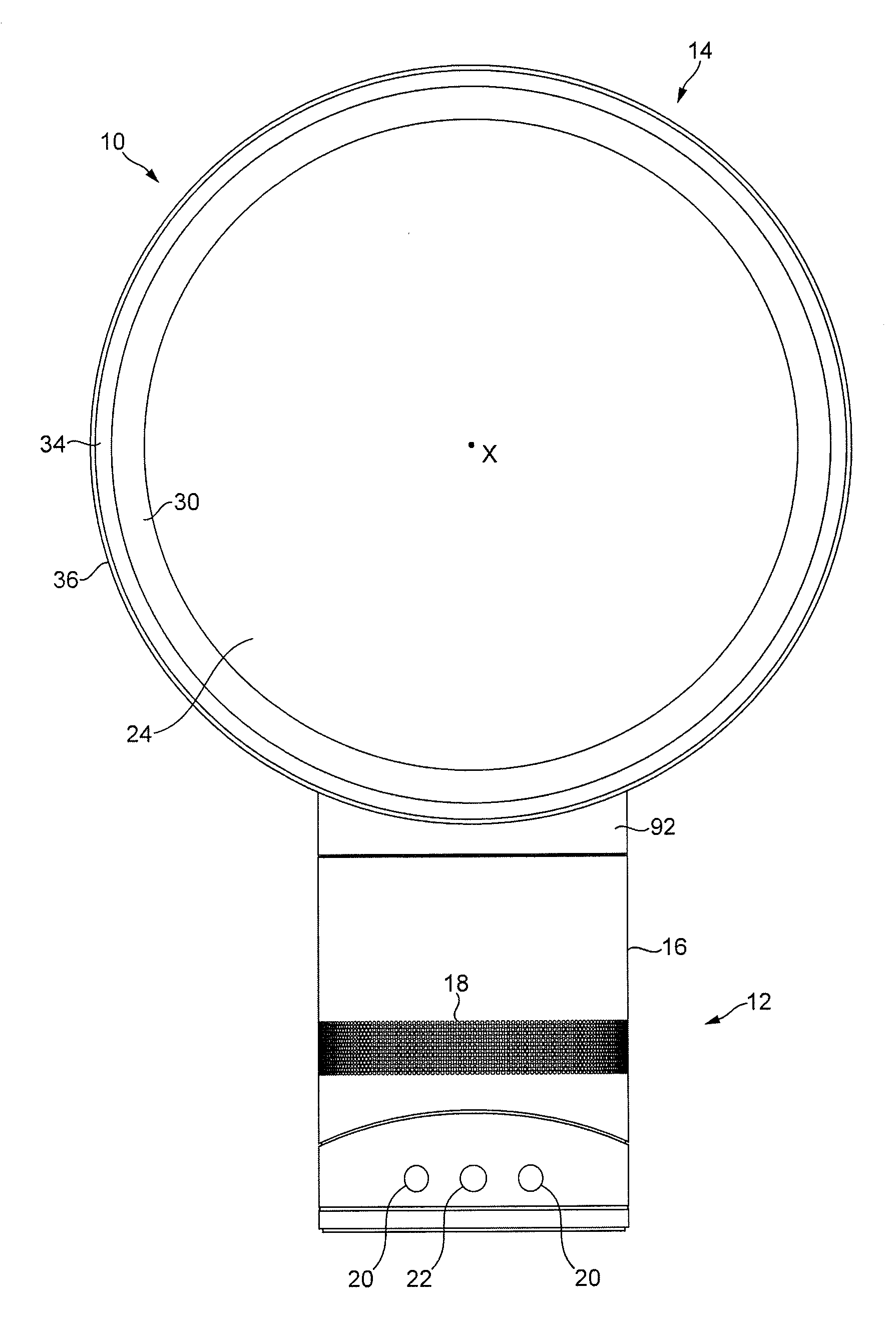

A fan assembly for creating an air current includes a nozzle mounted on a base. The base comprises an outer casing, an impeller housing located within the outer casing, the impeller housing having an air inlet and an air outlet, an impeller located within the impeller housing and a motor for driving the impeller to create an air flow through the impeller housing. The nozzle includes an interior passage for receiving the air flow from the air outlet of the impeller housing and a mouth through which the air flow is emitted from the fan assembly. A flexible sealing member is located between the outer casing and the impeller housing.

Owner:DYSON TECH LTD

Fan assembly

A fan assembly for creating an air current includes a nozzle mounted on a base. The base comprises an outer casing, an impeller housing located within the outer casing, the impeller housing having an air inlet and an air outlet, an impeller located within the impeller housing and a motor for driving the impeller to create an air flow through the impeller housing. The nozzle includes an interior passage for receiving the air flow from the air outlet of the impeller housing and a mouth through which the air flow is emitted from the fan assembly.

Owner:DYSON TECH LTD

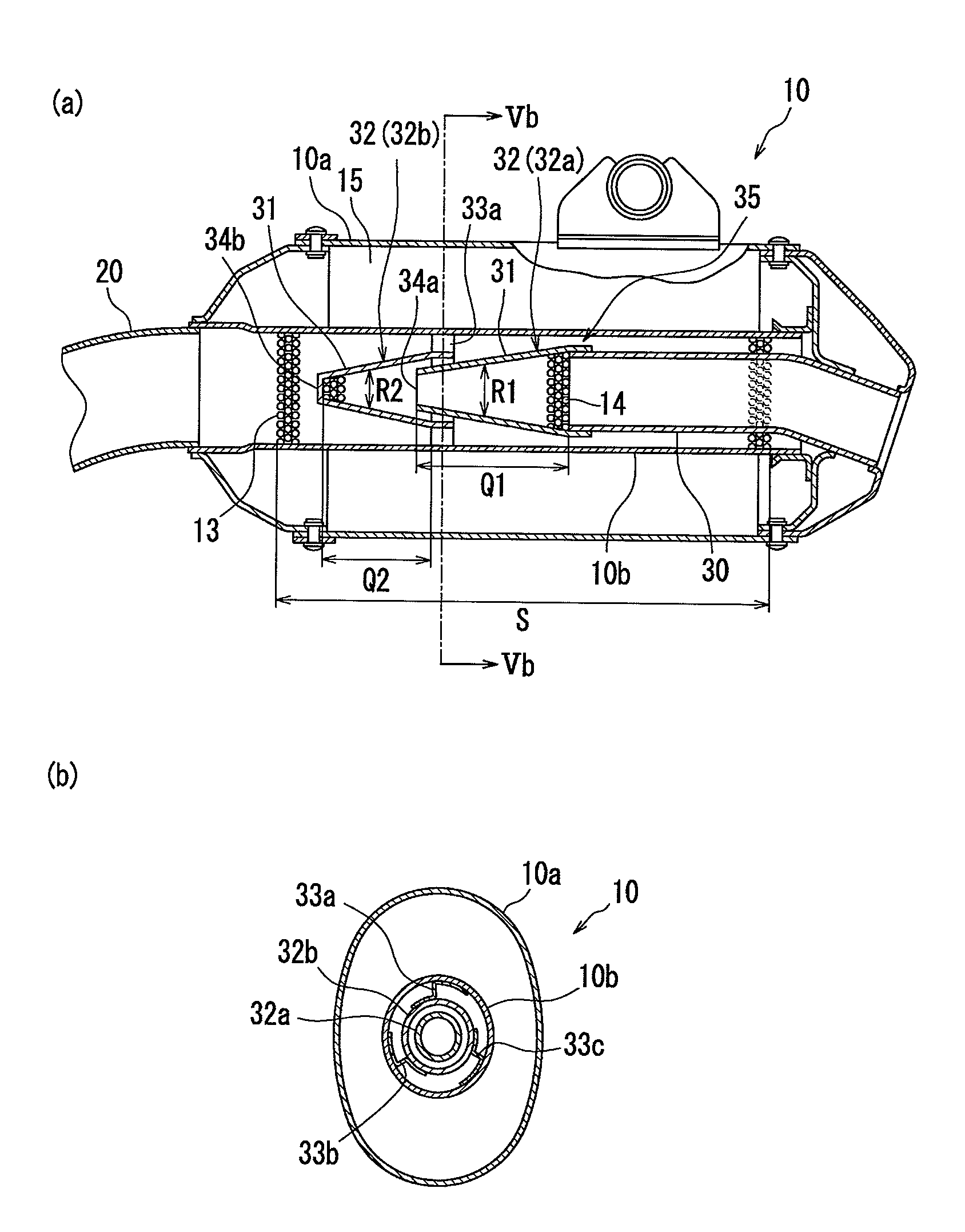

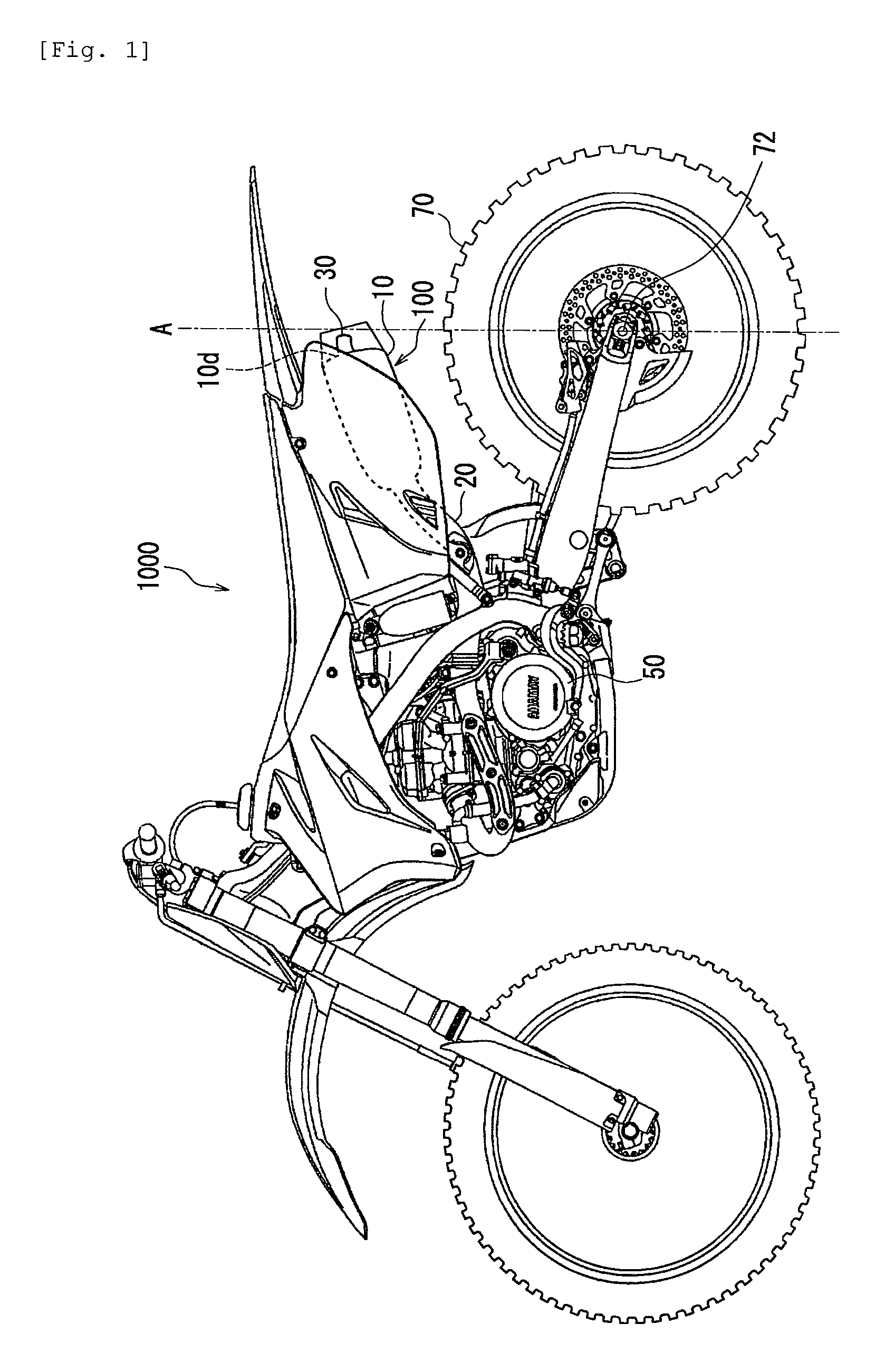

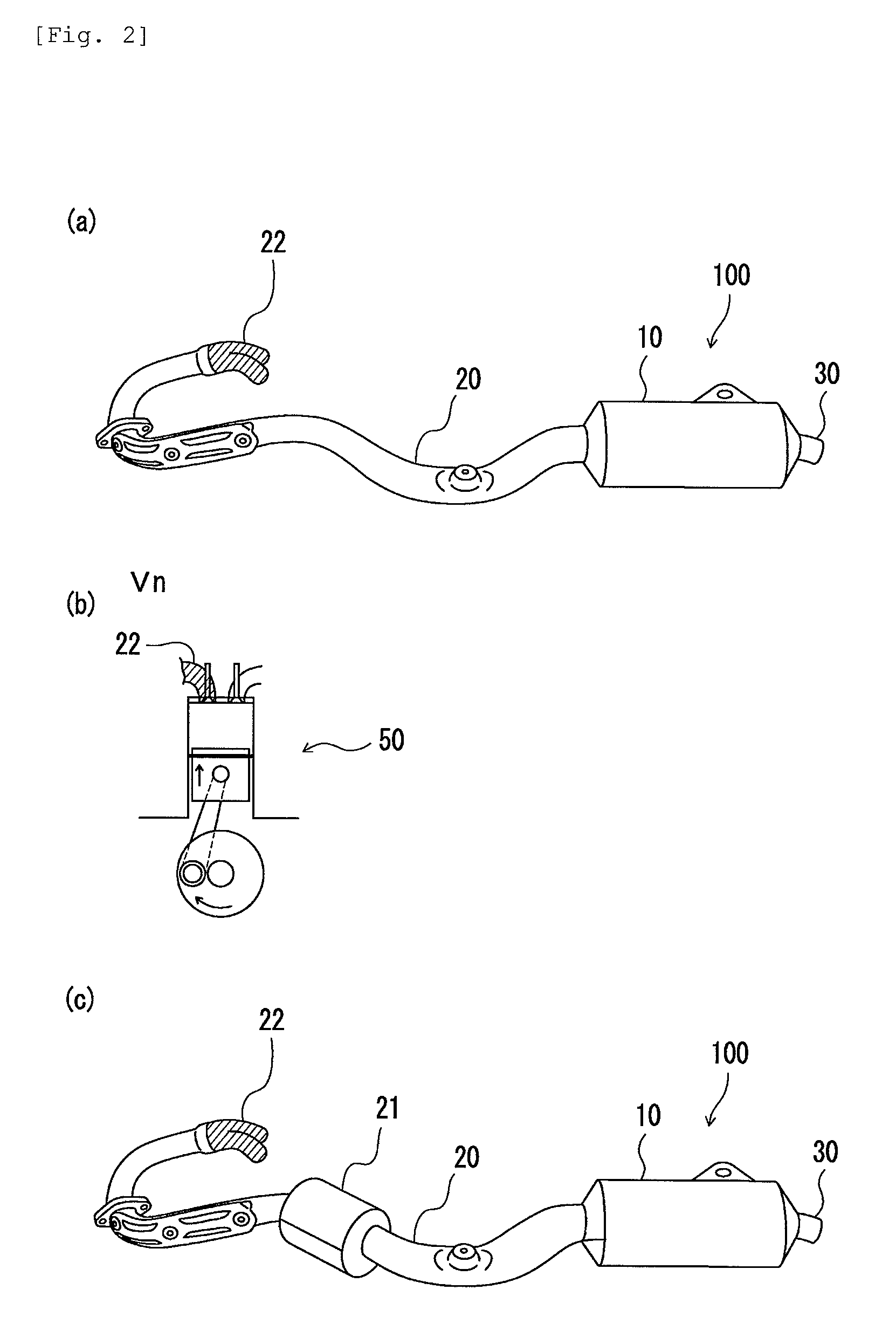

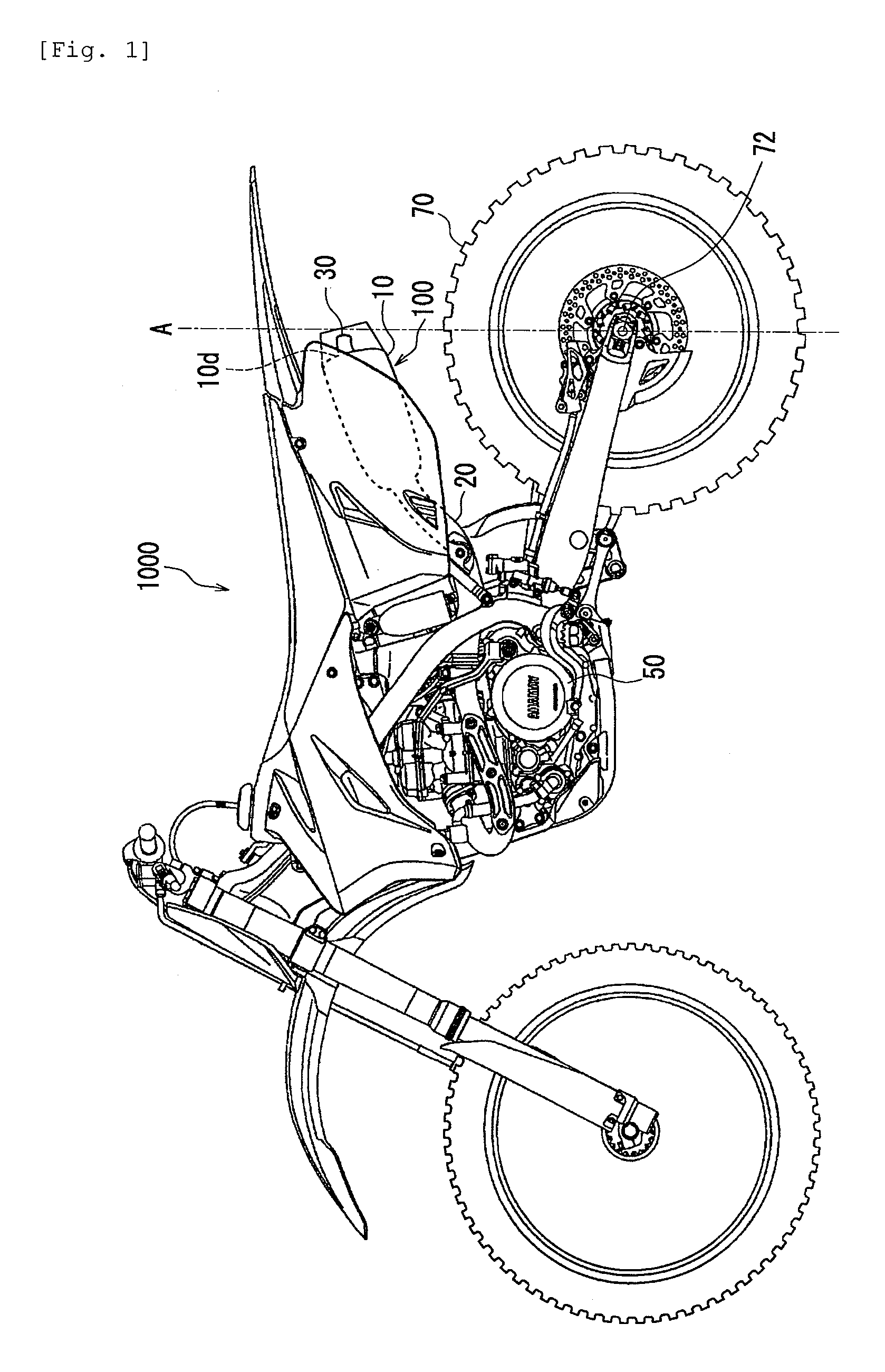

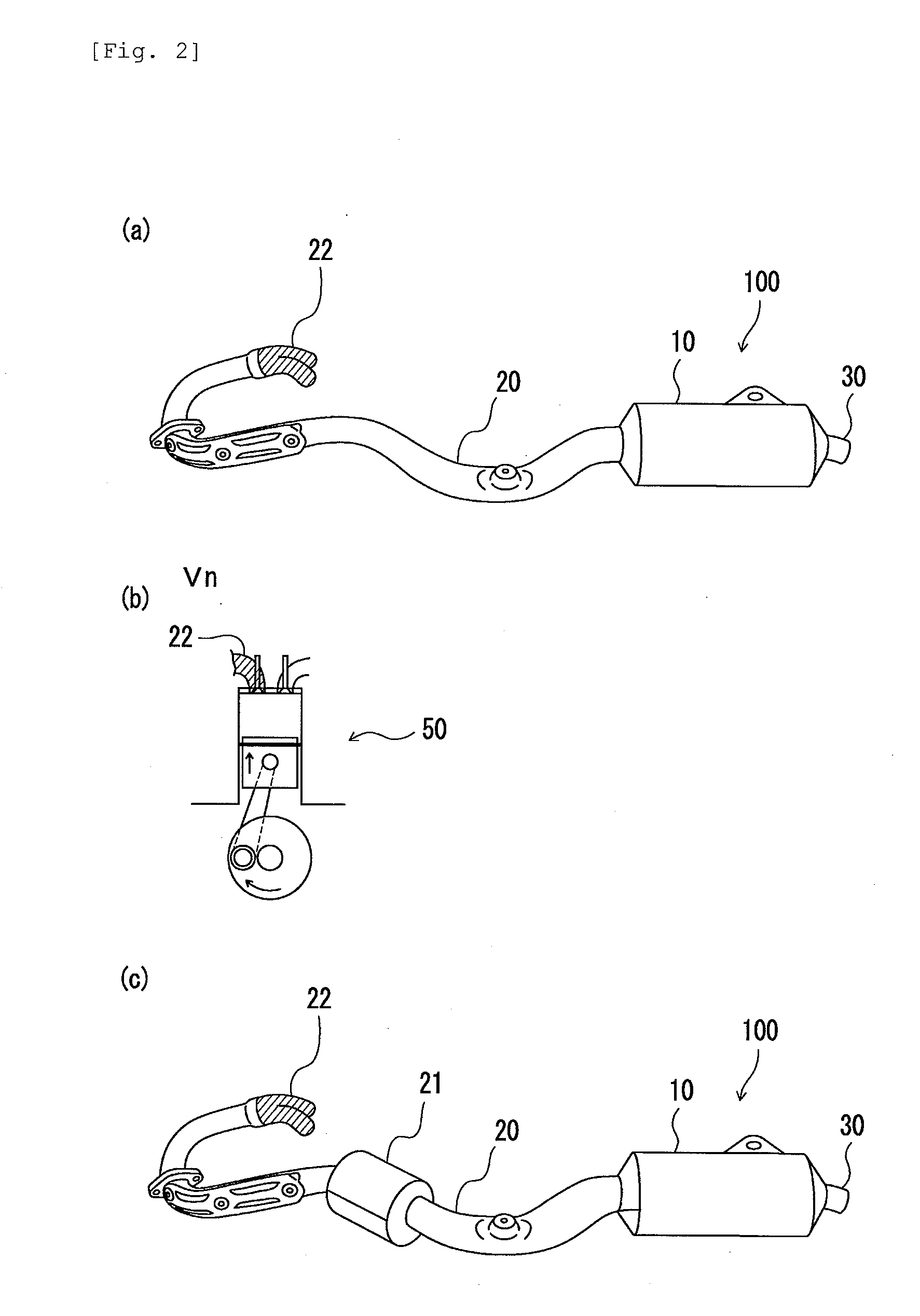

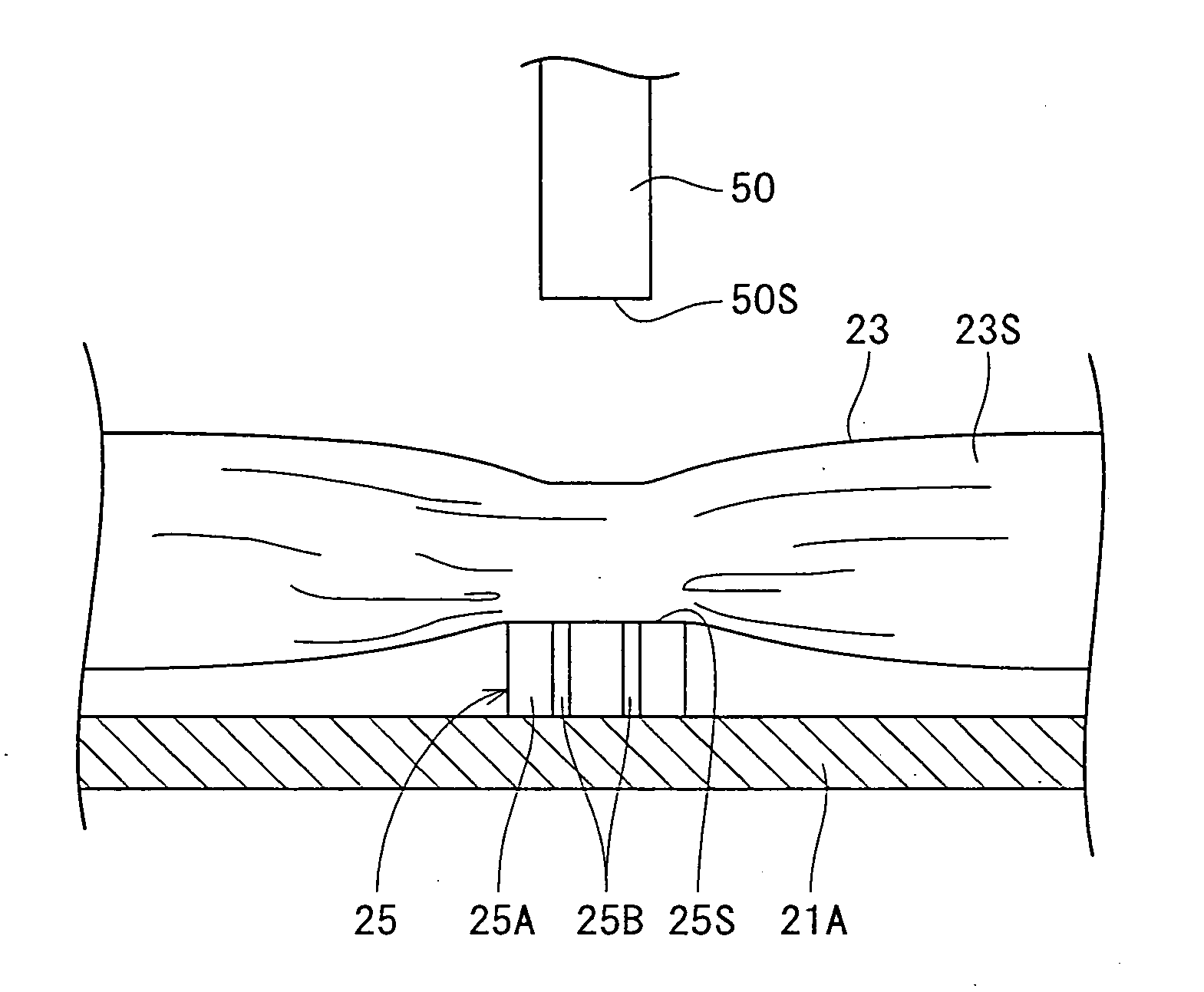

Vehicle exhaust system

InactiveUS7766123B2Improve featuresAbsorb noiseSilencing apparatusMachines/enginesMiniaturizationEngineering

An exhaust system for a vehicle, such as a motorcycle or other straddle-type vehicle, that achieves miniaturization while providing advantageous noise reduction characteristics. The exhaust system is associated with an engine of a vehicle and includes an exhaust pipe connected to the engine and a silencer. A conical member is positioned within the silencer and includes an upstream end and a downstream end. At least a portion of a side wall of the conical member includes a plurality of through-holes. The conical member is oriented such that a radial dimension of the conical member increases in a direction from the upstream end to the downstream end.

Owner:YAMAHA MOTOR CO LTD

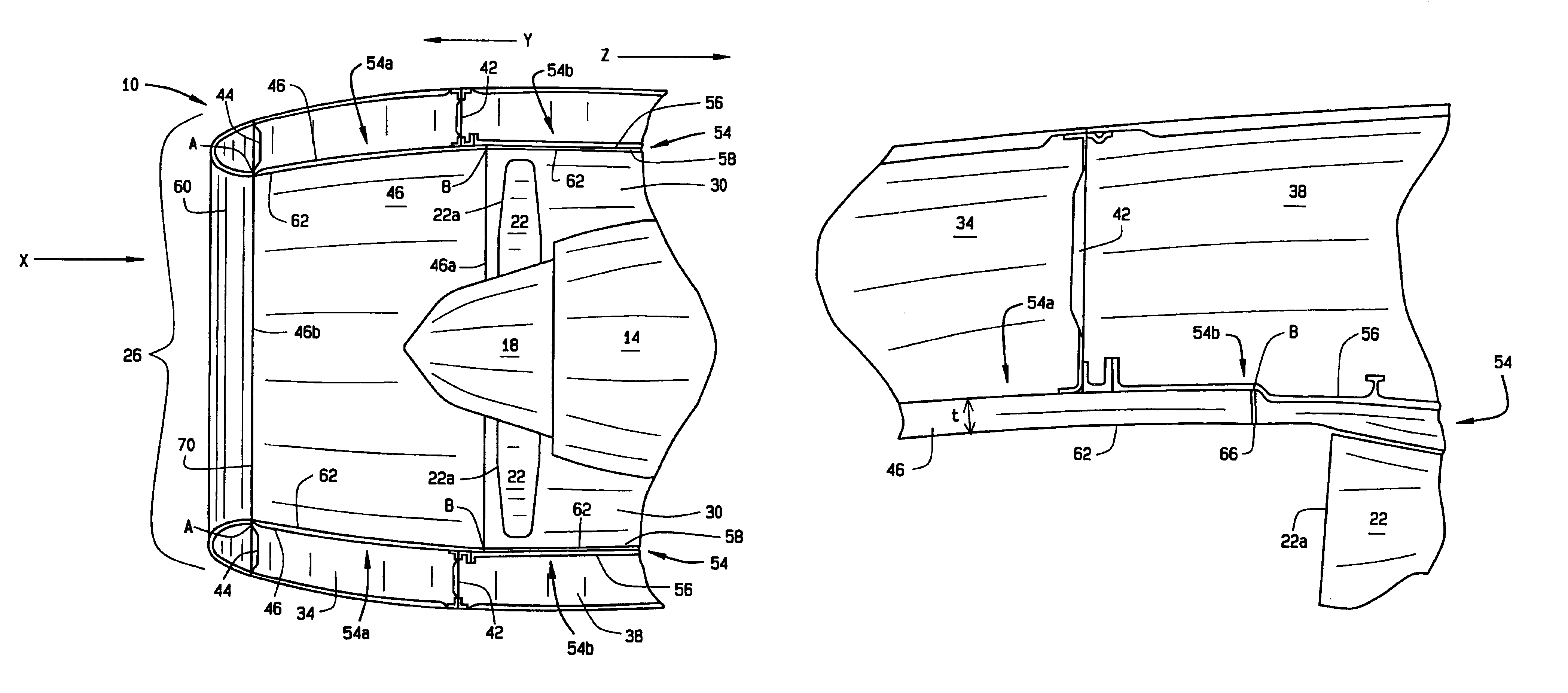

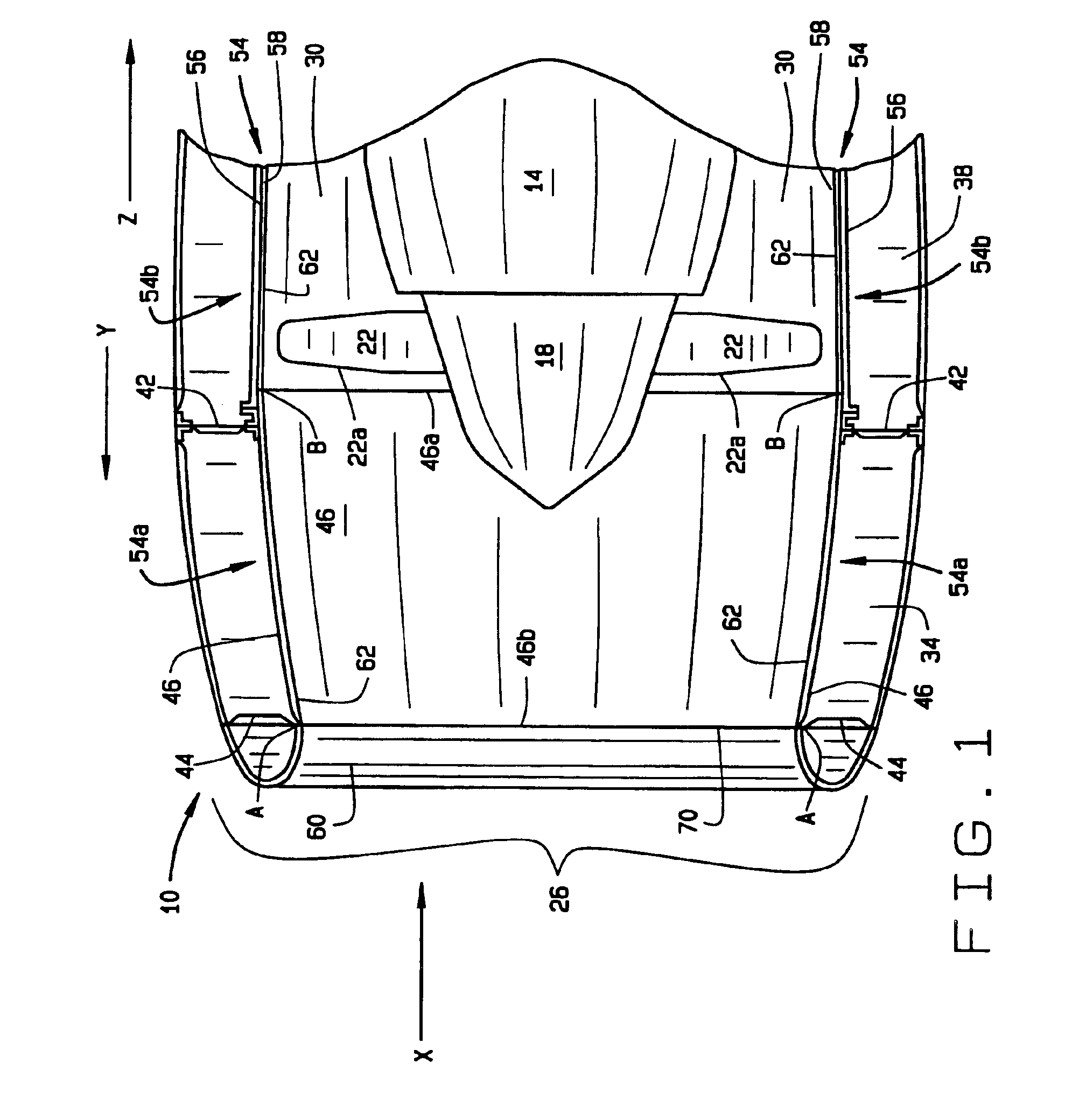

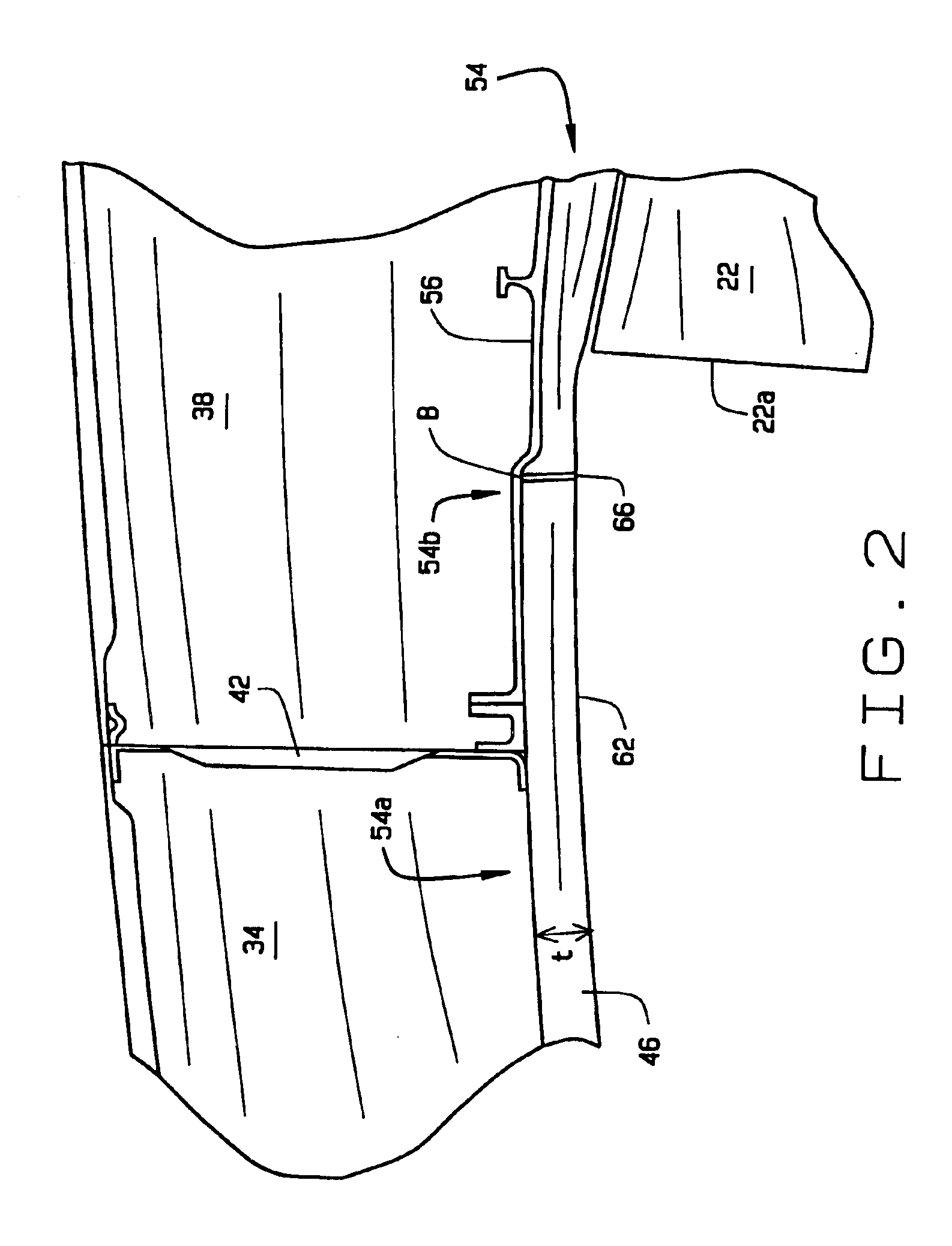

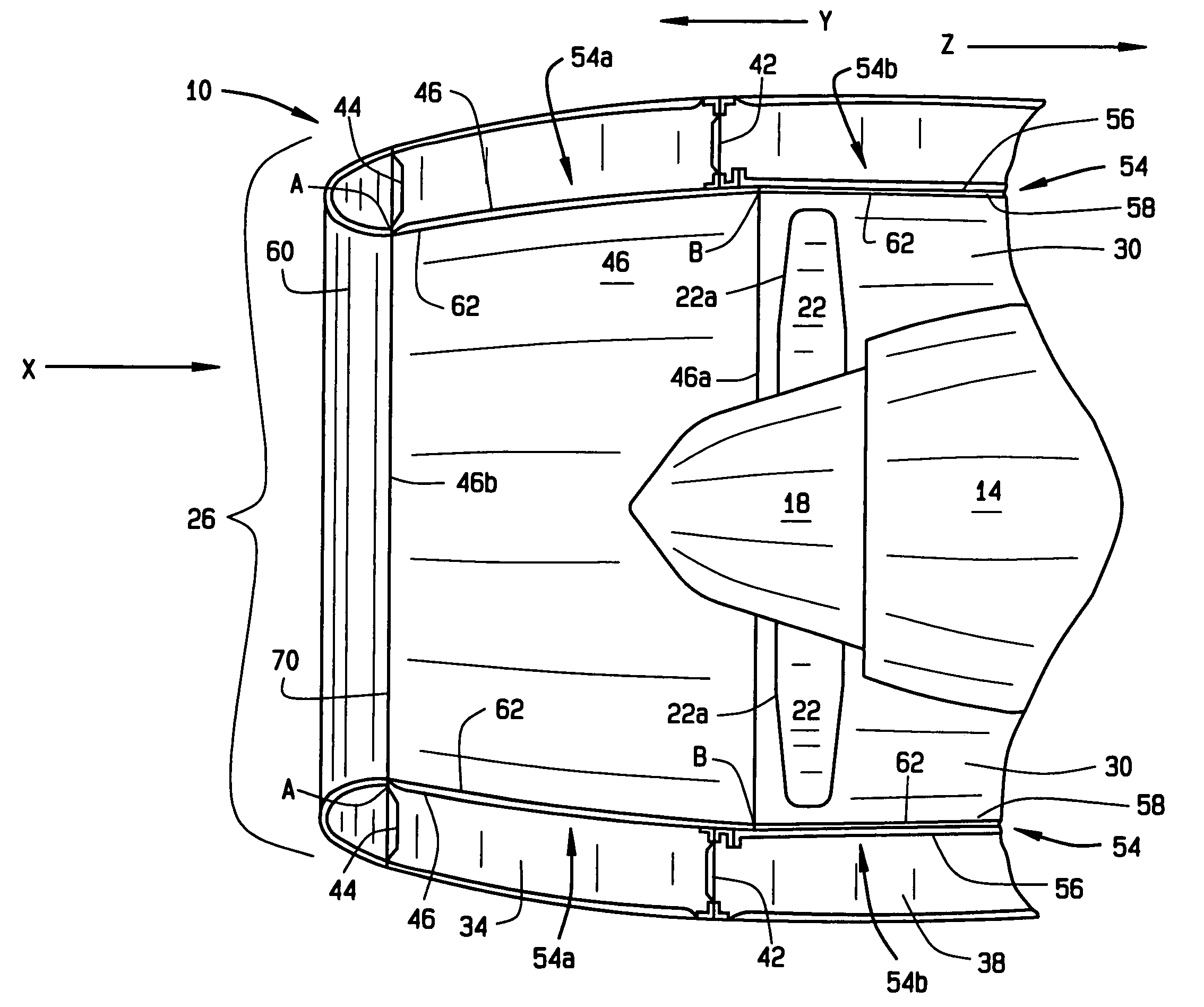

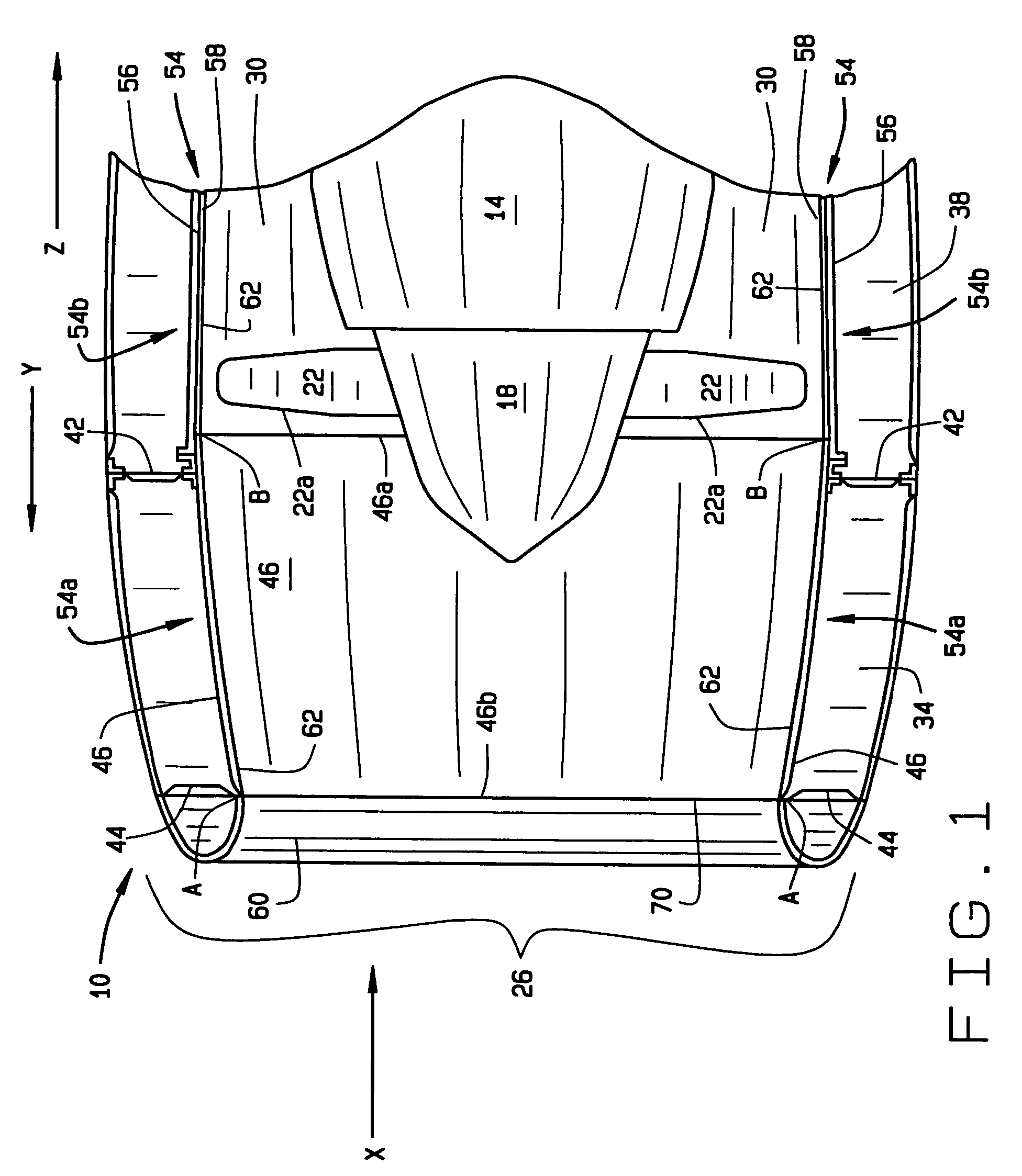

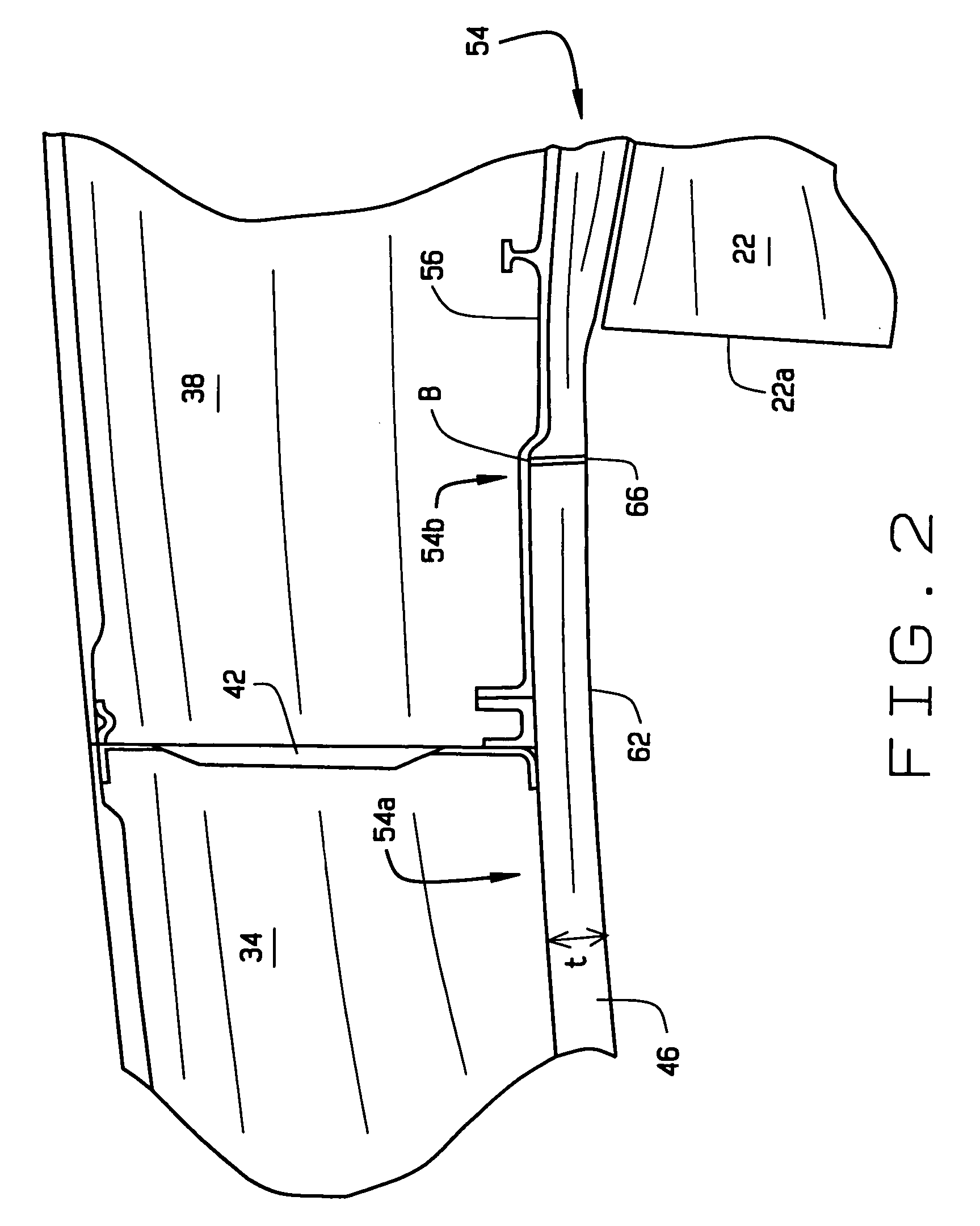

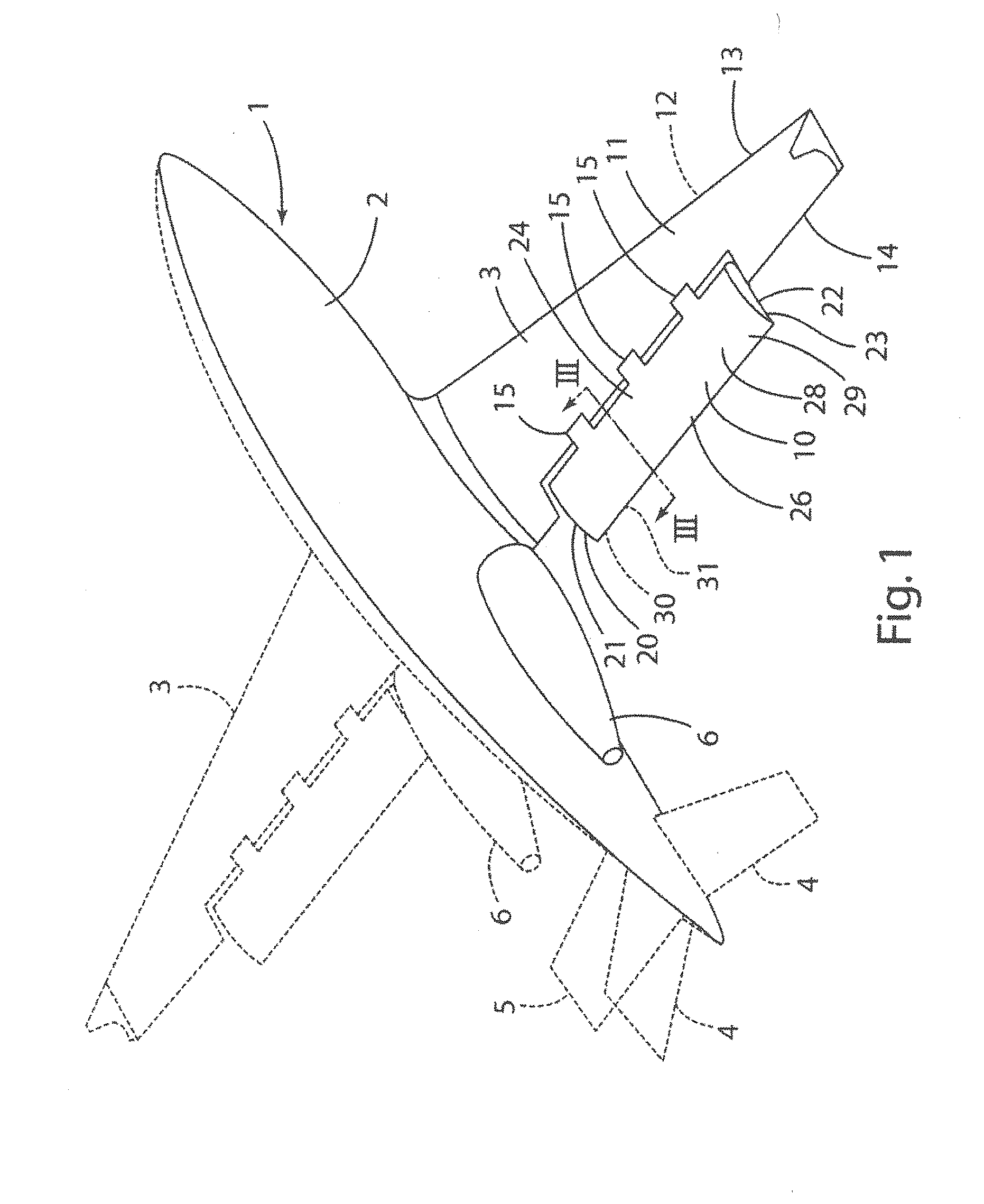

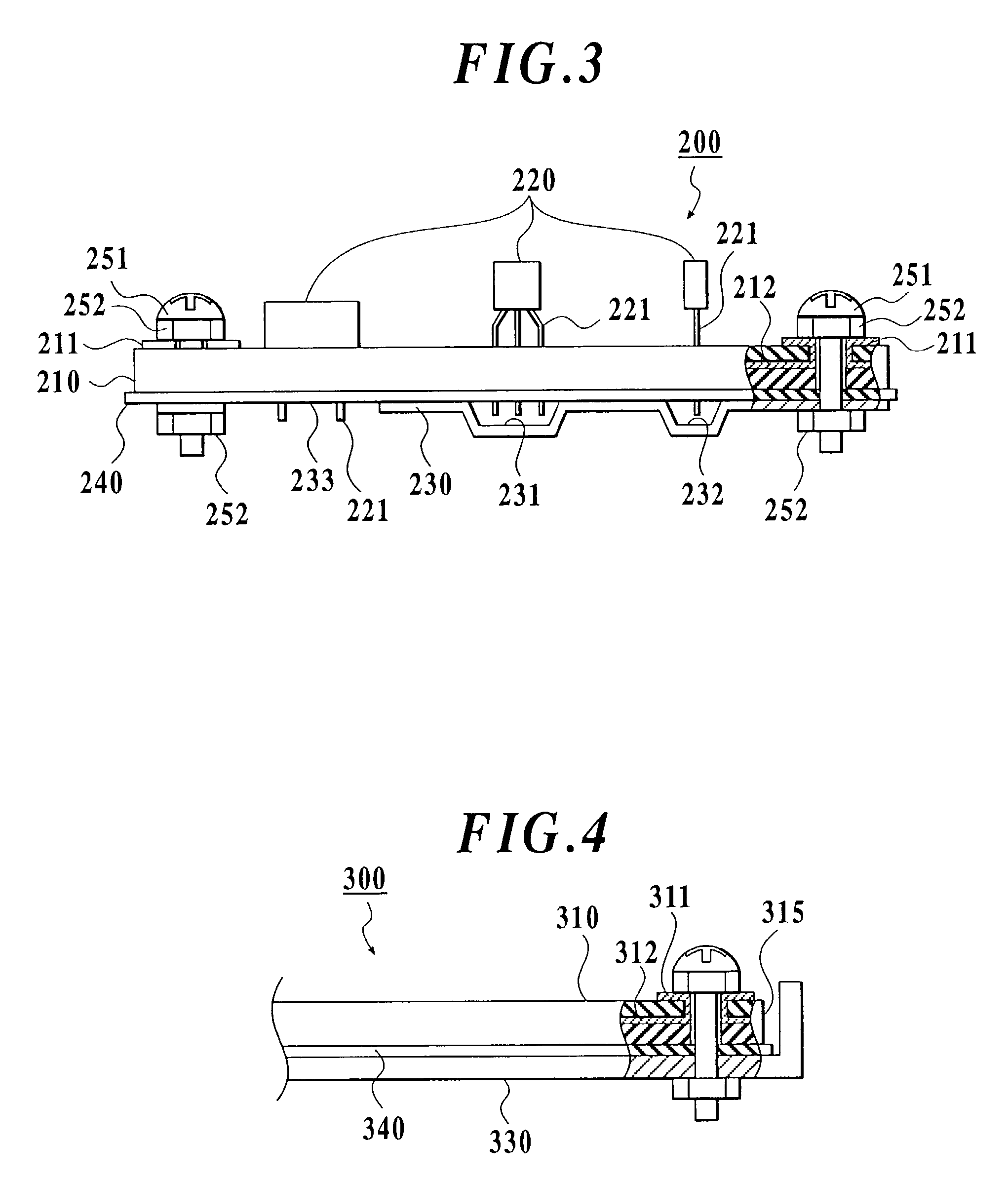

Annular acoustic panel

InactiveUS6920958B2Reduce noiseIncreasing noise absorption qualityNoise reduction installationsEngine fuctionsNacelleEngineering

An aircraft engine assembly is provided that is adapted to reduce noise produced by an engine included in the engine assembly. The engine assembly includes a nacelle having an inlet section and a main section that is houses the engine and fan assembly associated with the engine. The inlet section is coupled to the main section at a main bulkhead junction between the inlet section and the main section. A one piece annular acoustic panel is located within a recess in an internal wall of the nacelle. The annular acoustic panel extends from a forward portion of the inlet section to a forward portion of the main section such that the bulkhead is covered by the annular acoustic panel.

Owner:THE BOEING CO

Spring seat assembly

InactiveUS20060082037A1Reduce vibrationAbsorb noisePortable framesStands/trestlesCoil springEngineering

A spring seat assembly for a suspension system of a vehicle utilizing a coil spring. The spring seat assembly includes a first spring seat retainer having a central axis. The first spring seat retainer includes a flange and a pocket portion extending from the flange toward a distal end. The flange includes a first side and a second side extending radially from the central axis in a spaced and parallel relationship. The flange includes a plurality of ribs that extend radially relative to the central axis. The ribs project axially from the first side and the second side of the flange and are spaced angularly from one another. The ribs on the first side are angularly offset from the ribs on the second side for dampening vibration and absorbing noise upon a compression of the coil spring.

Owner:BASF CORP

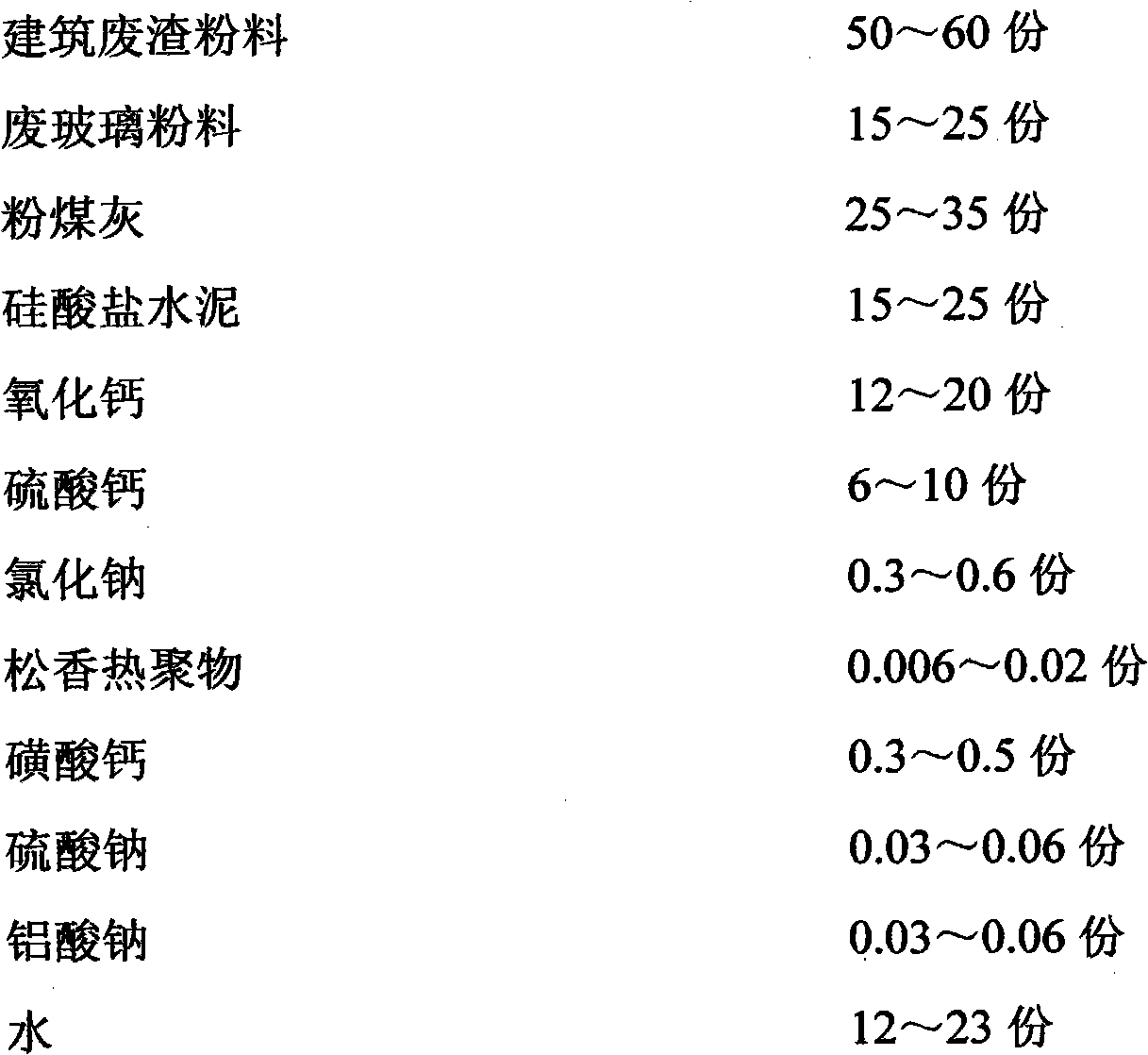

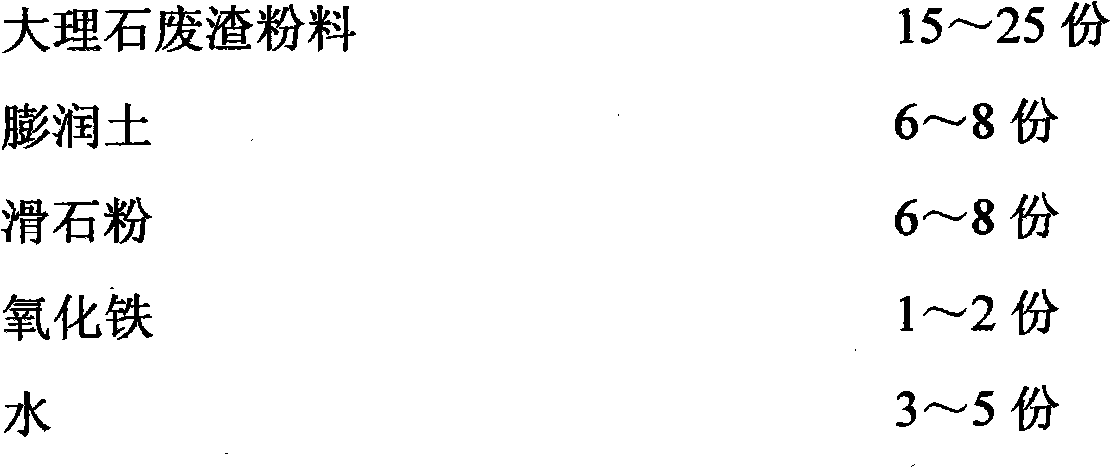

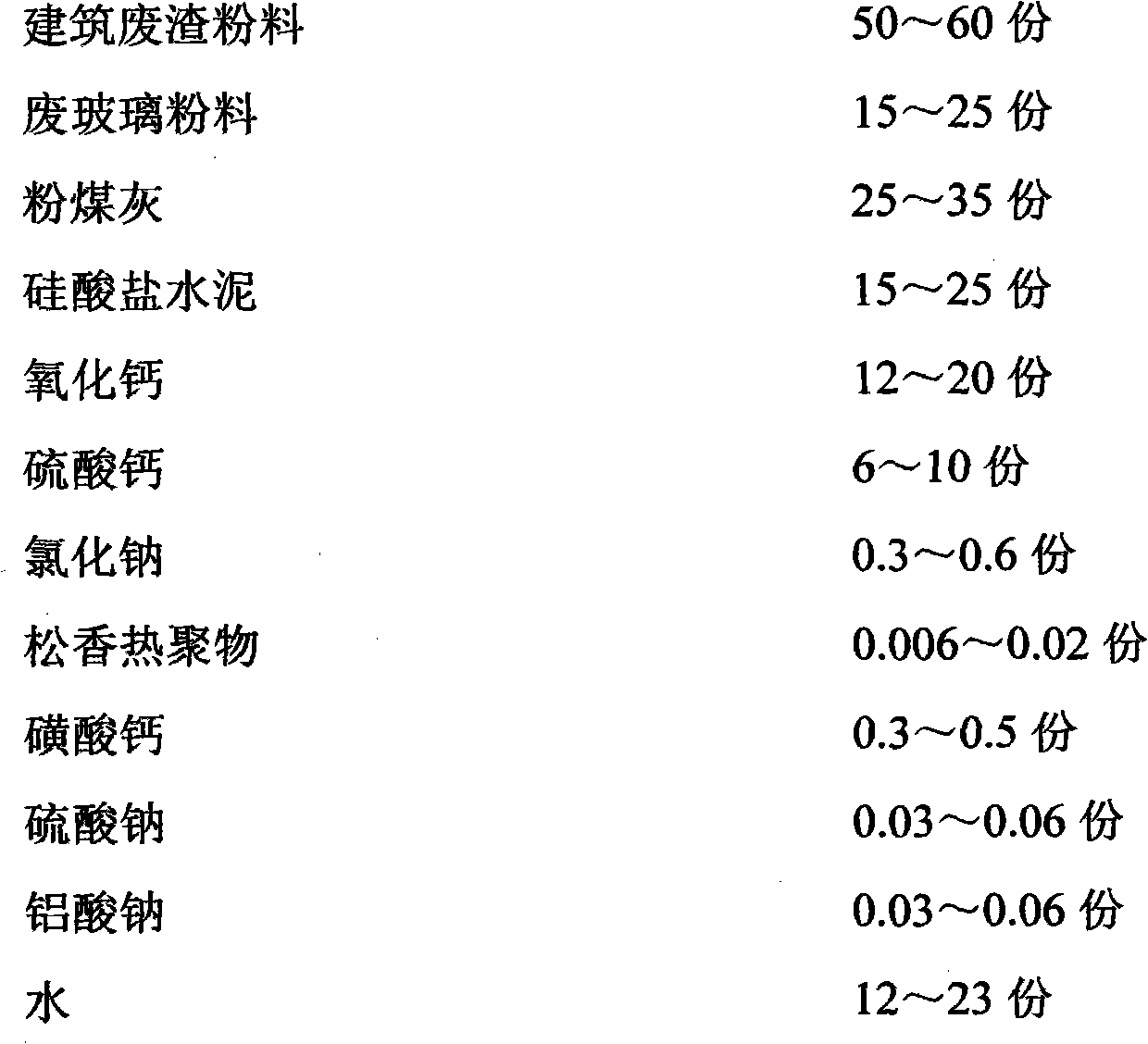

Water permeable bricks produced by using building waste residue and manufacturing method thereof

InactiveCN102418308APrevent subsidenceEasy constructionSolid waste managementSingle unit pavingsSodium BentoniteBrick

The invention relates to water permeable bricks produced by using building waste residue and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps: mechanically stirring a lower-layer brick material, which is formed by uniformly mixing building waste residue powder, waste glass powder, fly ash, portland cement, calcium oxide, calcium sulfate, sodium chloride, rosin pyrolytic polymer, calcium sulfonate, sodium sulfate, sodium aluminate and water, to be in a moist state, then performing mechanical vibration extrusion to form lower-layer bricks, further uniformly distributing an upper-layer brick material, which is formed by uniformly mixing marble waste residue powder, bentonite, talcum powder, iron oxide and water, on the upper parts of the lower-layer bricks through a secondary material distributing machine for forming a layer of surface material, then preparing water permeable adobe under the pressure of 25-30MPa, further performing steam curing, heating, keeping temperature constant and naturally cooling down to prepare water permeable brick products by using the building waste residue. The products have multiple functions of having water permeability, gas permeability and water retention property, reducing the temperature, reducing the noise, regulating the climate, eliminating the heat island effect of an urban, improving the air quality, keeping the circulation of surface water and the like, and have the advantages and effects of no pollution, low cost and good benefits.

Owner:河源市固体废物集中处置中心有限公司

Annular acoustic panel

ActiveUS20050082112A1Reduce noiseIncreasing noise absorption qualityNoise reduction installationsEngine fuctionsNacelleEngineering

An aircraft engine assembly is provided that is adapted to reduce noise produced by an engine included in the engine assembly. The engine assembly includes a nacelle having an inlet section and a main section that is houses the engine and fan assembly associated with the engine. The inlet section is coupled to the main section at a main bulkhead junction between the inlet section and the main section. A one piece annular acoustic panel is located within a recess in an internal wall of the nacelle. The annular acoustic panel extends from a forward portion of the inlet section to a forward portion of the main section such that the bulkhead is covered by the annular acoustic panel.

Owner:THE BOEING CO

Vehicle exhaust system

InactiveUS20070227810A1Absorb exhaust noiseReduce exhaust noiseSilencing apparatusMachines/enginesMiniaturizationEngineering

An exhaust system for a vehicle, such as a motorcycle or other straddle-type vehicle, that achieves miniaturization while providing advantageous noise reduction characteristics. The exhaust system is associated with an engine of a vehicle and includes an exhaust pipe connected to the engine and a silencer. A conical member is positioned within the silencer and includes an upstream end and a downstream end. At least a portion of a side wall of the conical member includes a plurality of through-holes. The conical member is oriented such that a radial dimension of the conical member increases in a direction from the upstream end to the downstream end.

Owner:YAMAHA MOTOR CO LTD

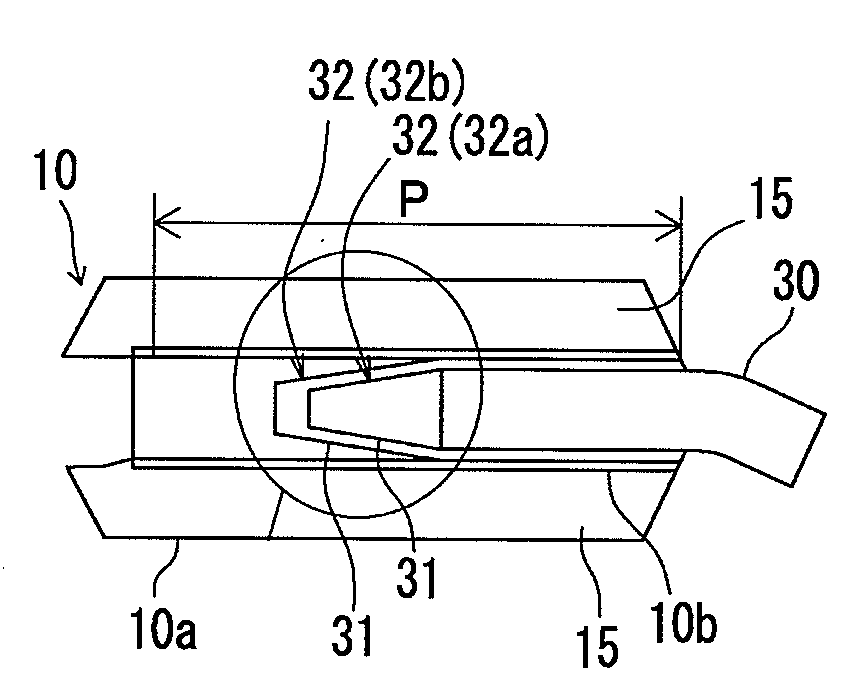

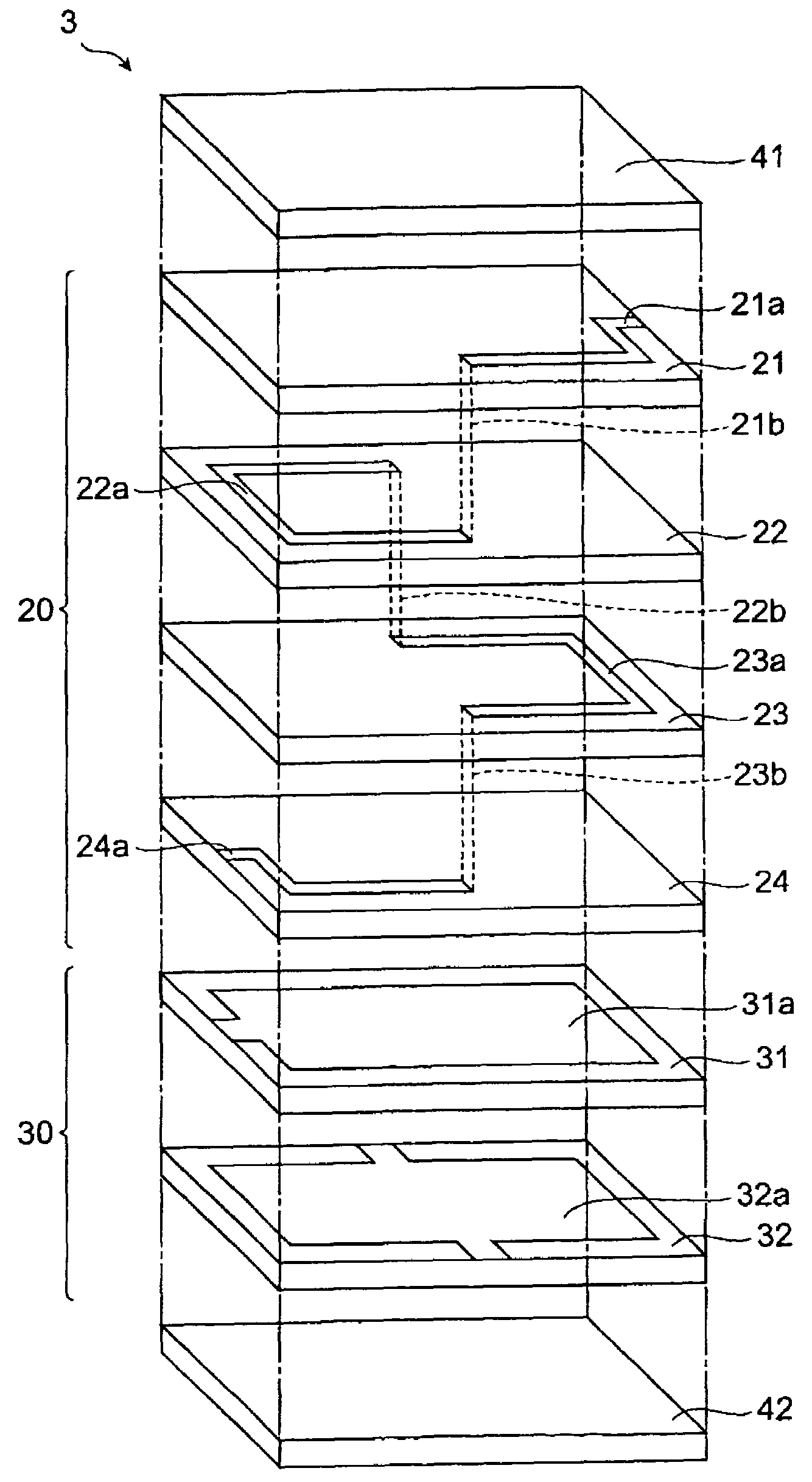

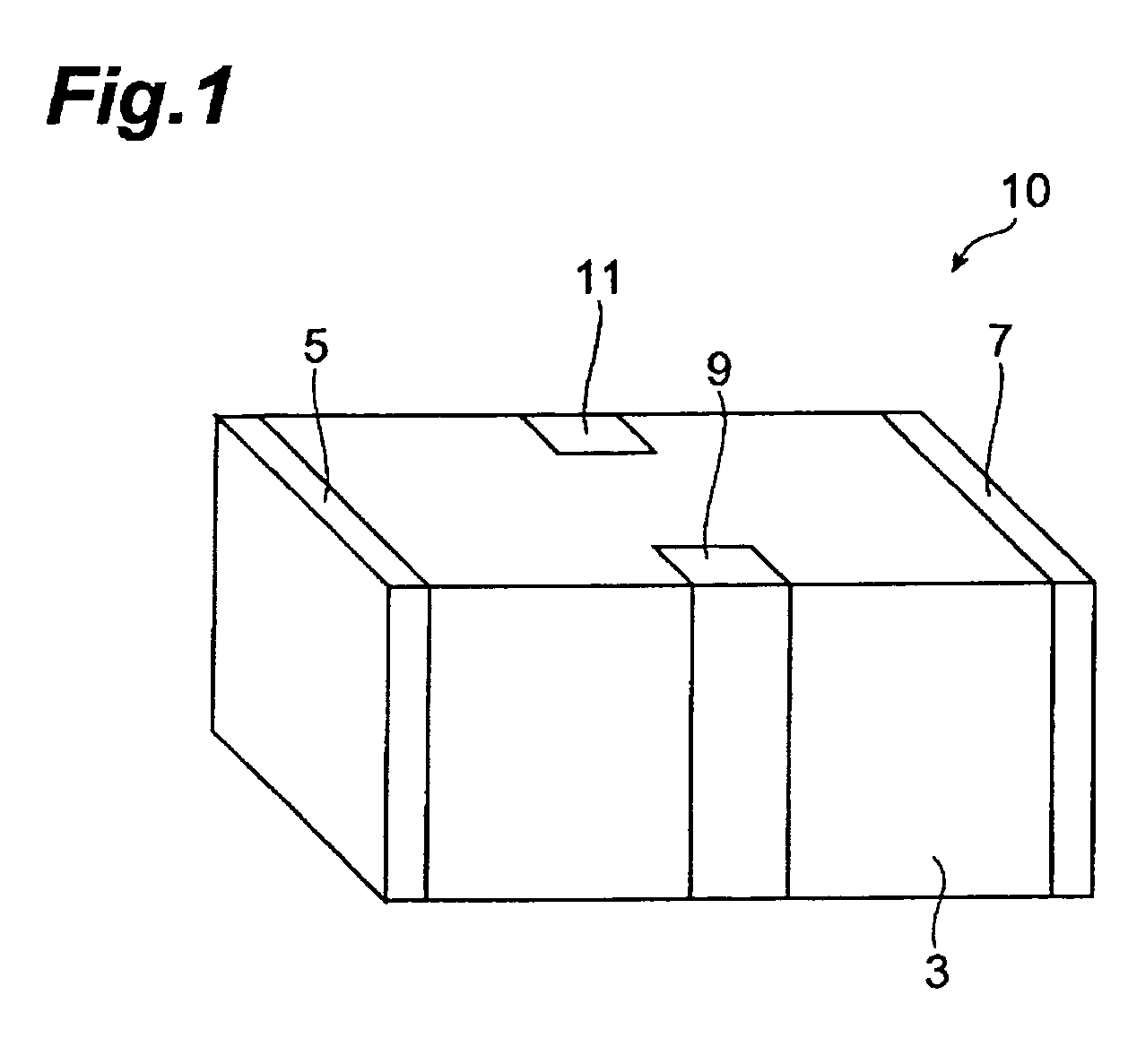

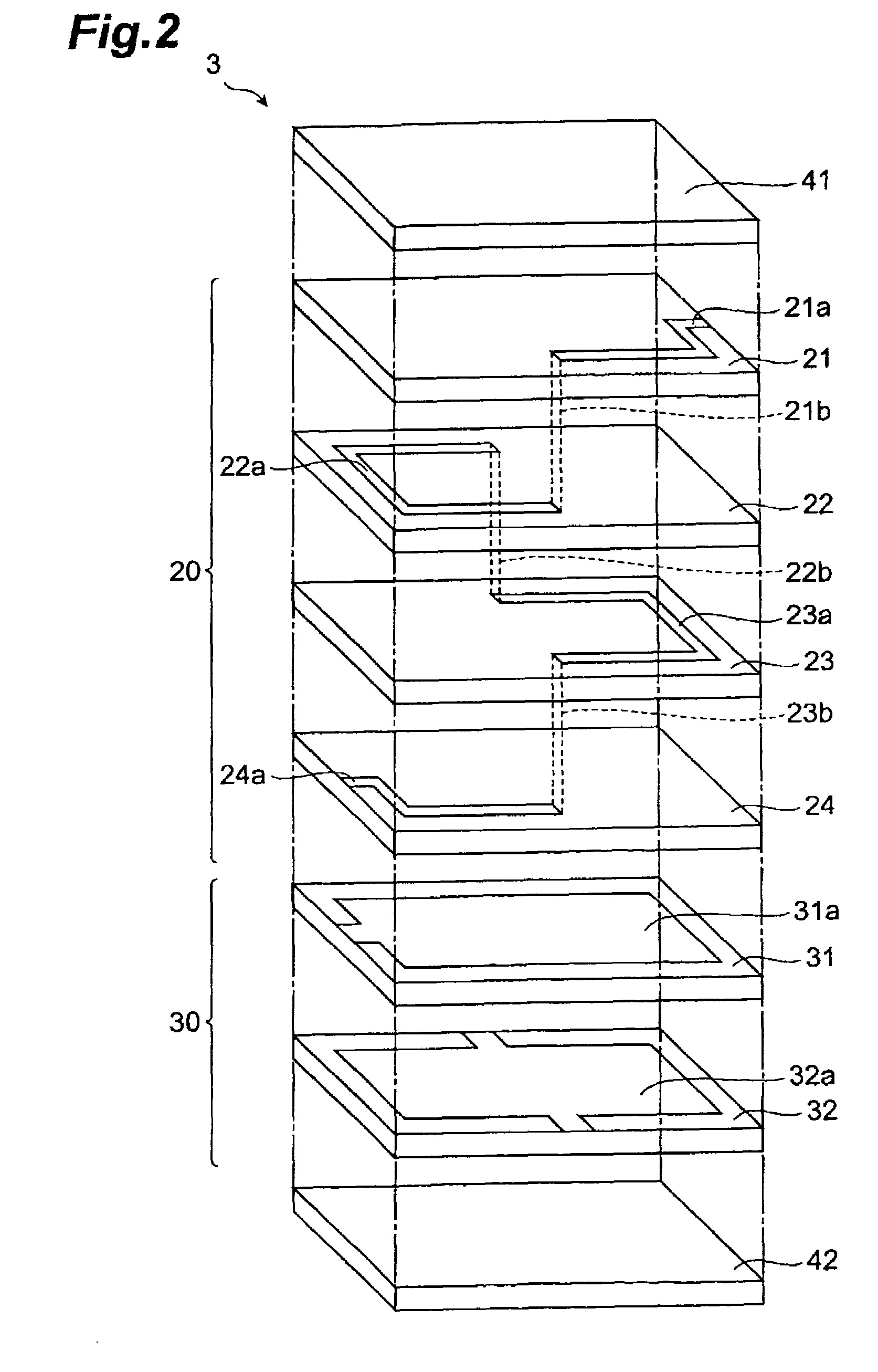

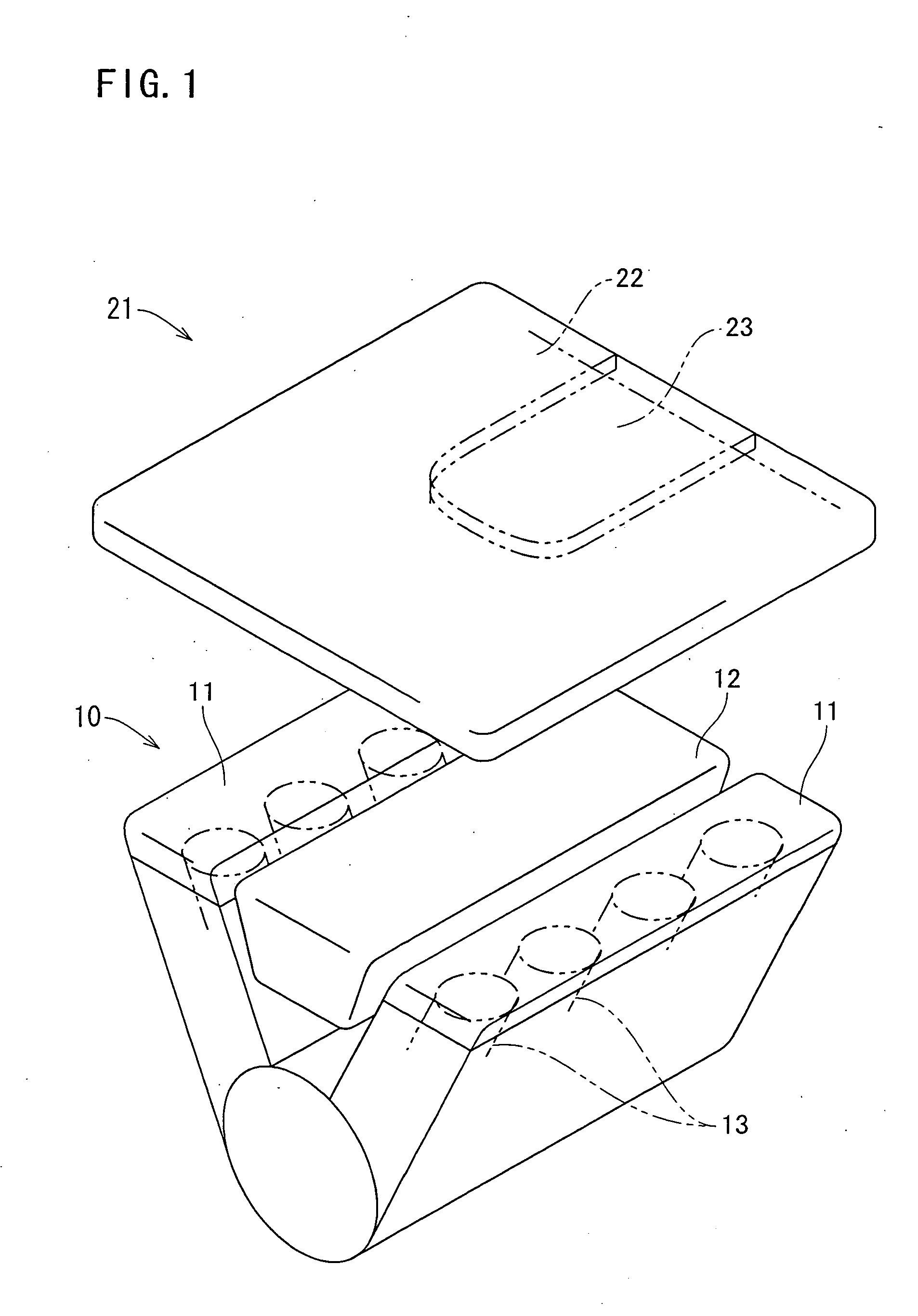

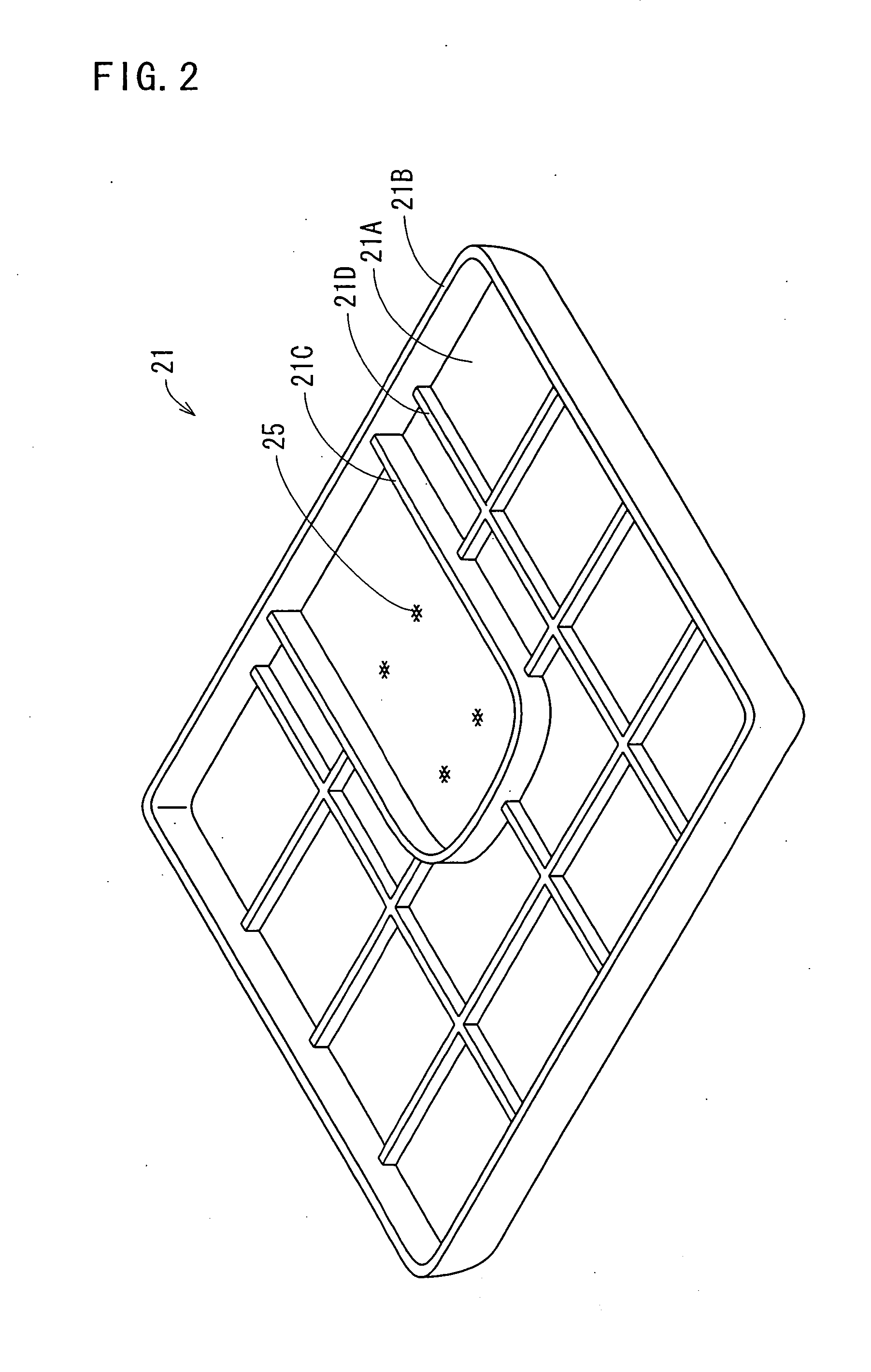

Multilayer filter

ActiveUS7652554B2Reduce flakingExcellent inductor characteristicMultiple-port networksSolid-state devicesElectrical conductorInductor

An object of the present invention is to provide a multilayer filter constructed so as to be less likely to suffer peeling between a varistor part and an inductor part. A multilayer filter 10 as a preferred embodiment has a structure in which a varistor part 20 and an inductor part are stacked. The varistor part 30 consists of a stack of varistor layers 31, 32 with internal electrodes 31a, 32a, and the varistor layers contain ZnO as a principal component, and contain at least one element selected from the group consisting of Pr and Bi, Co, and Al as additives. The inductor part 20 consists of a stack of inductor layers 21-24 with conductor patterns 21a-24a, and the inductor layers contain ZnO as a principal component and substantially contain neither Co nor Al.

Owner:TDK CORPARATION

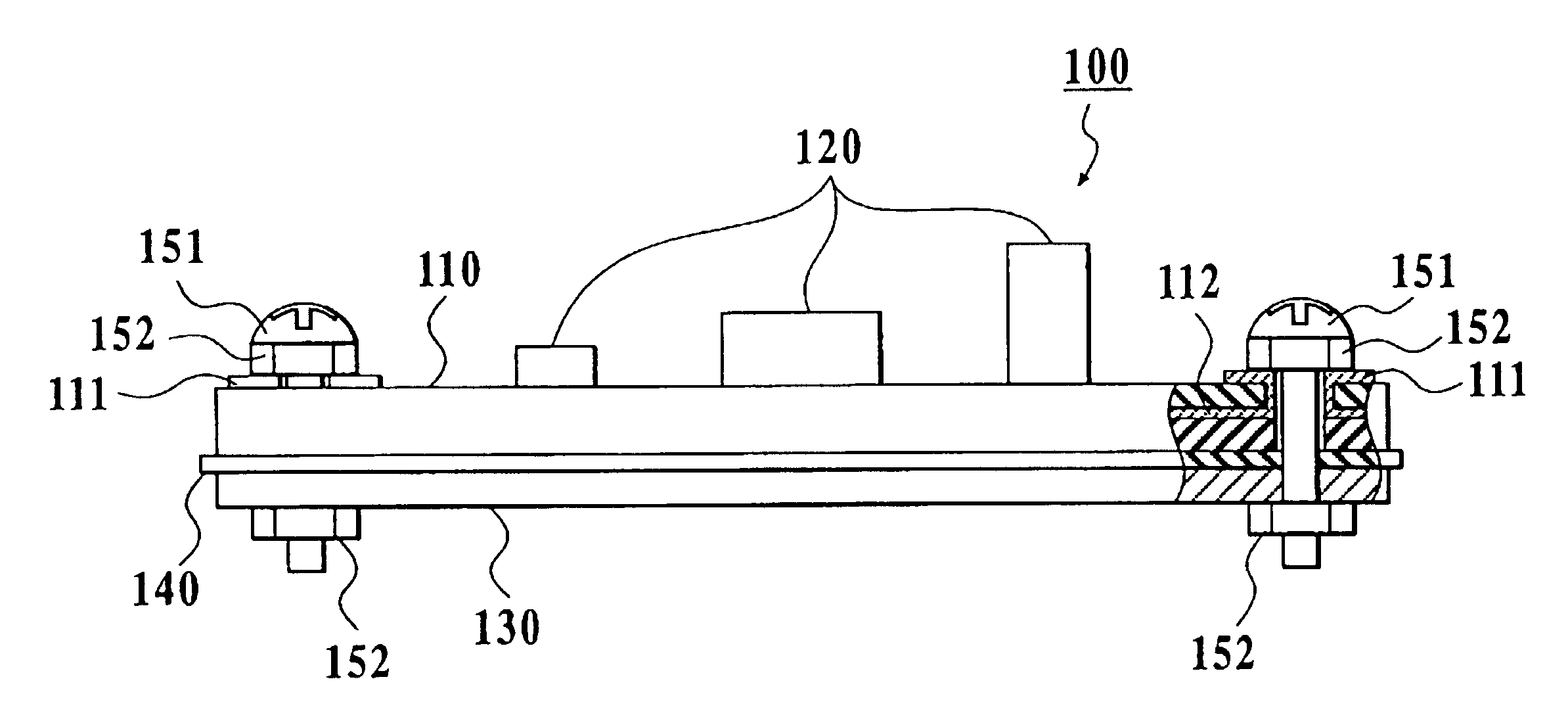

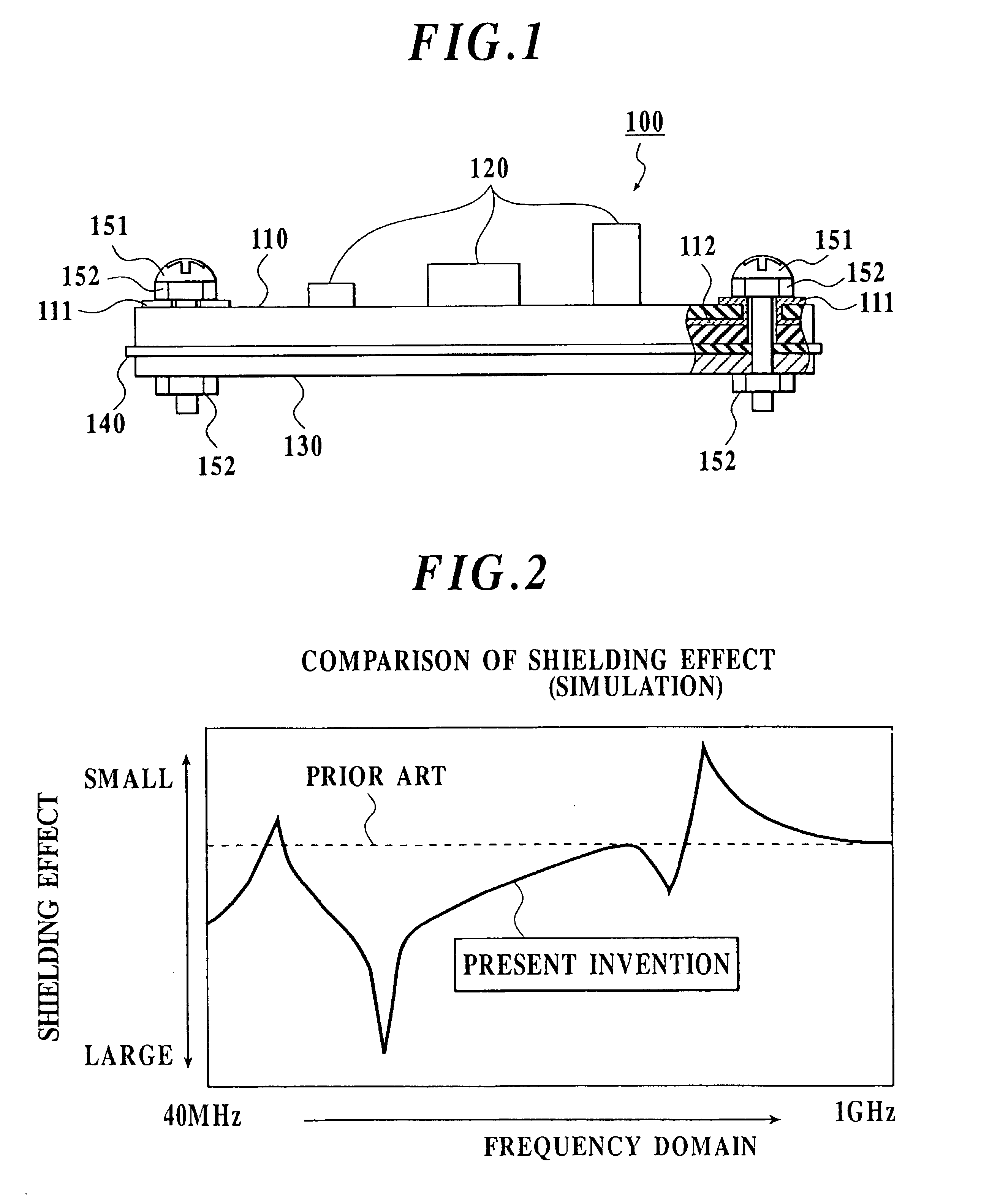

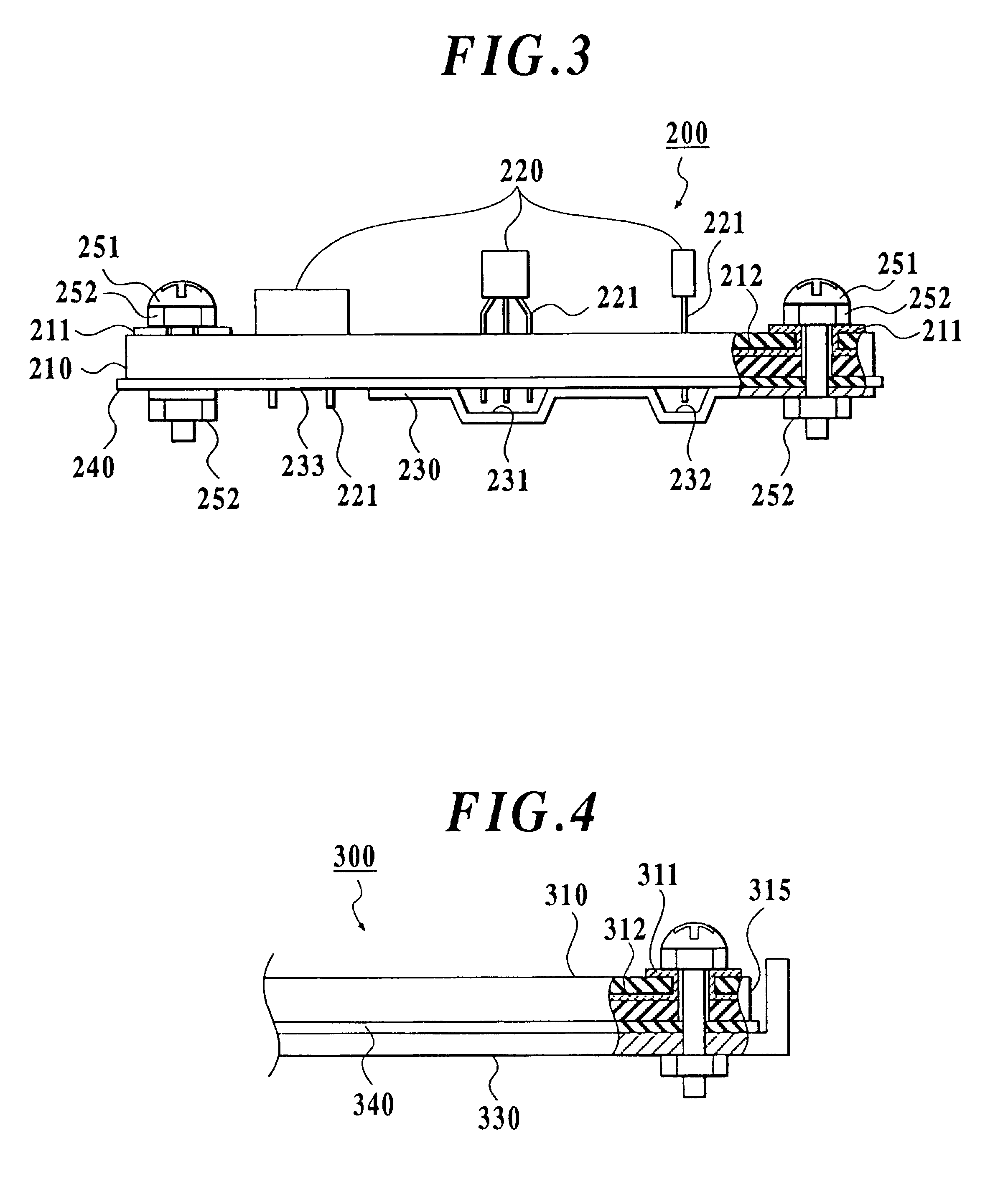

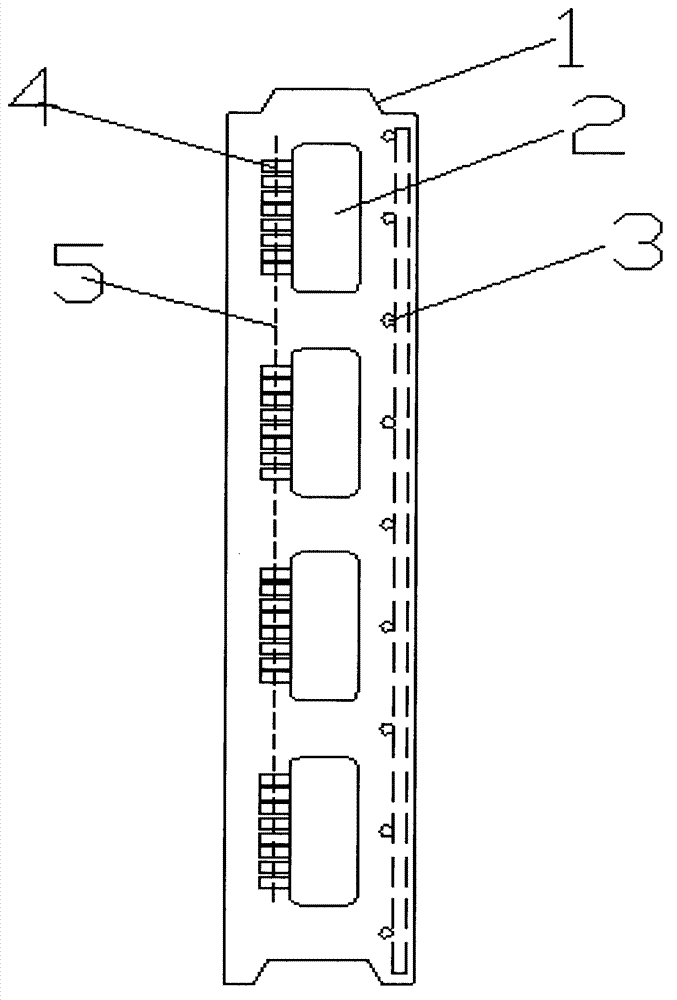

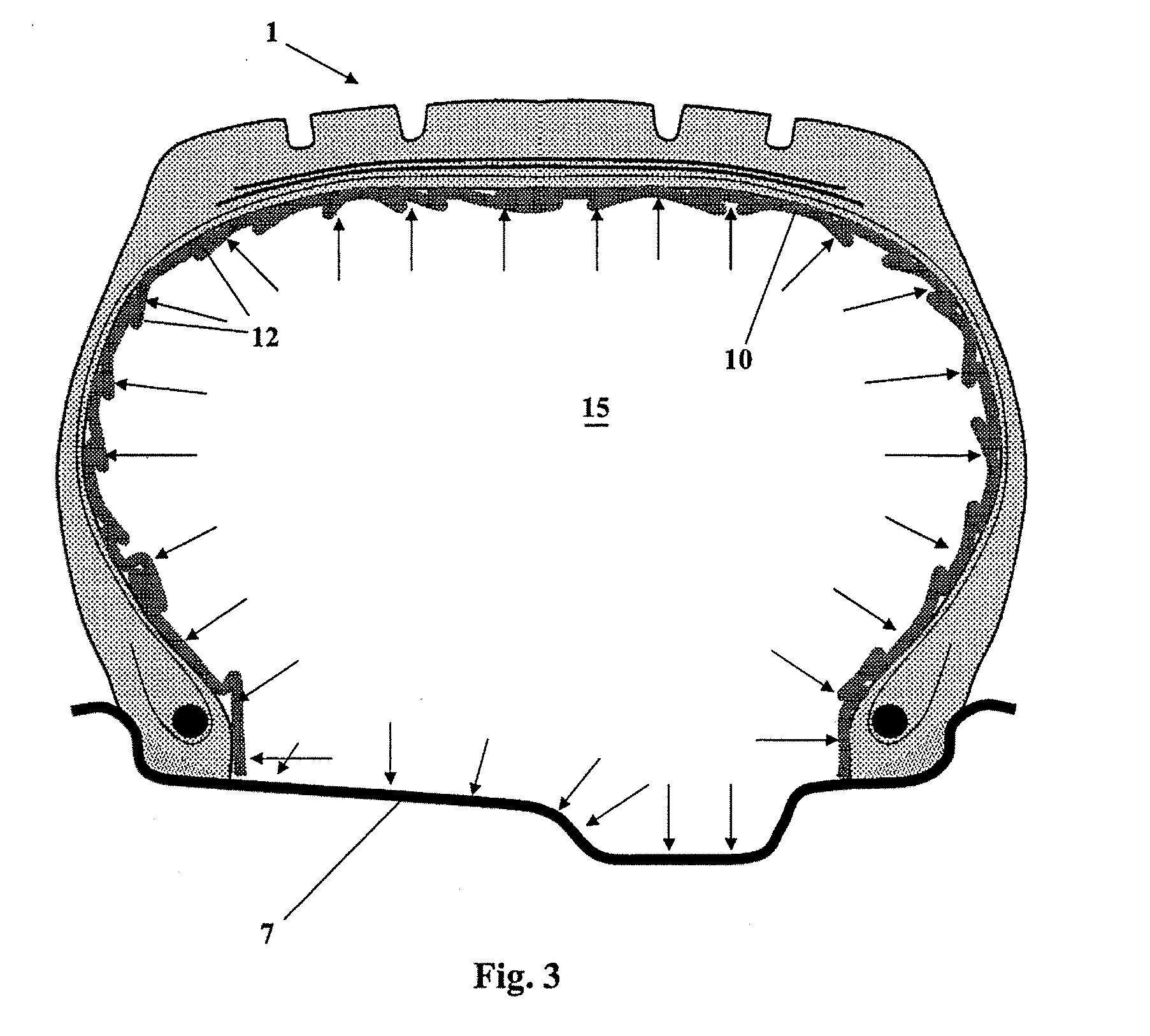

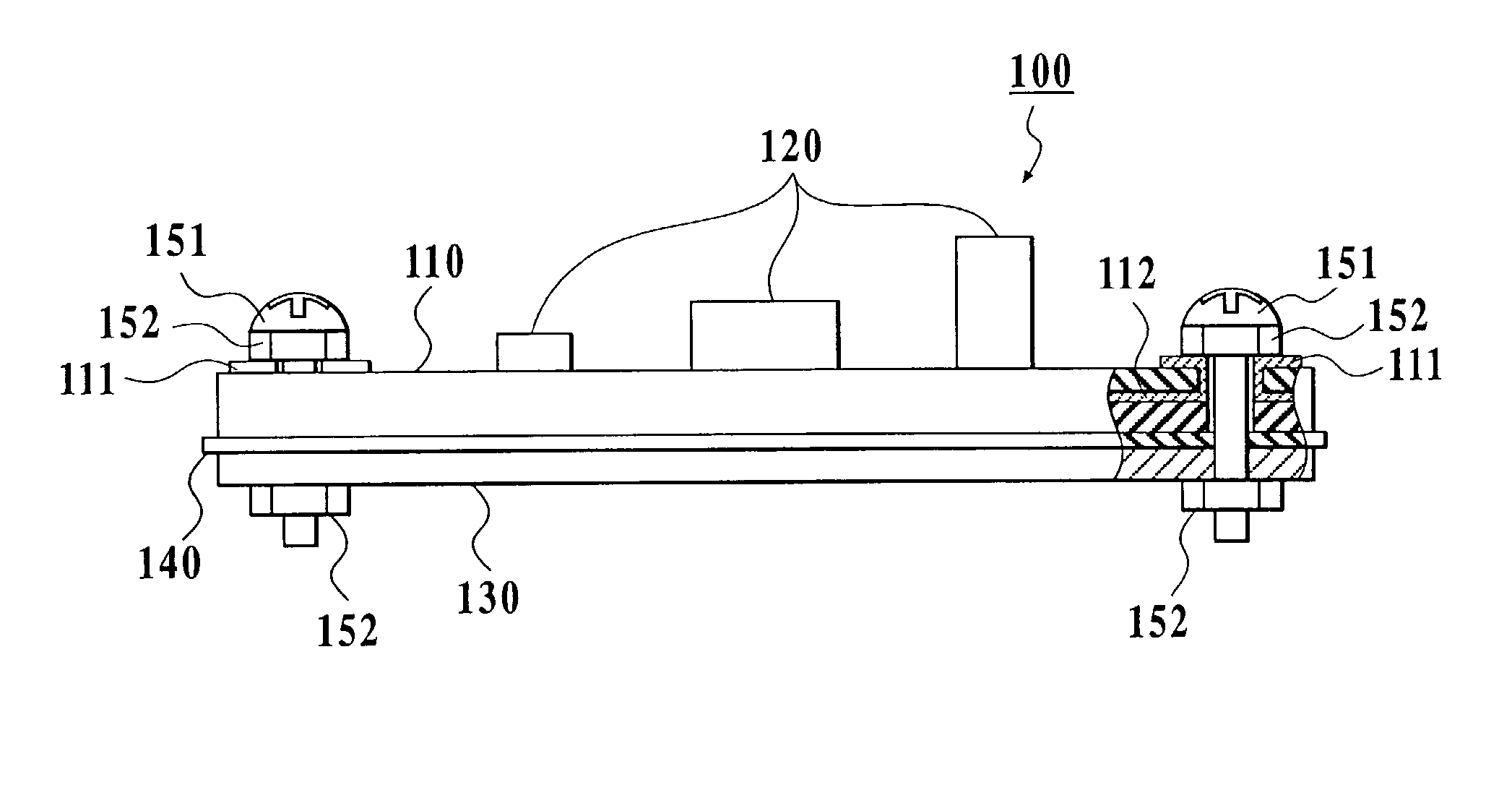

Electronic device and method for manufacturing the same, and method for shielding printed circuit board

InactiveUS6706964B2Reduce noiseGround can be reinforcedCross-talk/noise/interference reductionRack/frame constructionElectromagnetic shieldingPrinted circuit board

Owner:KONICA CORP

Sound insulation board

InactiveCN102926476AImprove sound insulationAvoid "fitting"Noise reduction constructionSound proofingAcoustic waveRebar

The invention discloses a sound insulation board. According to the sound insulation board, one side of the sound insulation board is provided with a perlite surface of which the surface is in a fluffy shape; a cavity is formed in the plate body at intervals; micropores are formed between the cavity and a bottom layer of the perlite layer; the other side of the sound insulation board is provided with a ceramsite cement solid surface; a reinforced steel bar mesh is arranged on the bottom layer of the plate body, and a steel wire mesh is arranged on an upper layer of the plate body; and a composite board is a one-step molding body. The sound insulation board has the advantages that the plate surface is in the fluffy shape, and sound waves can be absorbed and weakened; the composite board has an integral structure, and the plate body is solid, is wholly conveniently mounted and used and is difficult to damage; sound absorption or sound insulation materials can be filled in the cavity, and a noise reduction effect is improved; and moreover, the sound insulation board can be made of cement, perlite, ceramsite and other light-weight materials and is wide in material source and low in construction cost, and the materials and cost are saved.

Owner:王荷琴

Steamed ecological water permeable environmentally friendly brick produced by waste ceramic residues and manufacturing method thereof

ActiveCN101994283AMitigate the heat island effectGuaranteed water circulationSolid waste managementSingle unit pavingsBrickSodium Bentonite

The invention relates to a steamed ecological water permeable environmentally friendly brick produced by waste ceramic residues and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: adding a lower brick material obtained by uniformly mixing waste ceramic residue powder, waste glass powder, garbage clinker powder, portland cement, calcium oxide, calcium sulfate, sodium chloride, a rosin hot polymer, calcium sulfonate, sodium aluminate and water to a double-axis mixing stirrer to stir into a wet state, and then vibrating, extruding and molding into a lower brick of the ecological water permeable environmentally friendly brick; uniformly coating a layer of fine material of an upper brick material obtained by uniformly mixing waste ceramic fragment powder, bentonite, talcum powder and water on the upper part of the lower brick by using a secondary spreader to manufacture a water permeable environmentally friendly brick blank under the pressure of 25-30Mpa; maintaining with steam; heating at constant temperature; and naturally cooling to manufacture the steamed ecological water permeable environmentally friendly brick product of the waste ceramic residues. The raw materials of the invention also can be manufactured into vegetation bricks of different specifications. The product has certain water permeability, air permeability and water retentivity, also has various functions of cooling, reducing noise, regulating the climate, eliminating the heat island effect of a city, improving the air quality, maintaining the surface water circulation, and the like and the advantages of high product strength, no pollution, low cost and good benefit and conforms to the requirements on saving energy, reducing emission, protecting environment and developing low-carbon economy.

Owner:清远绿由环保科技有限公司

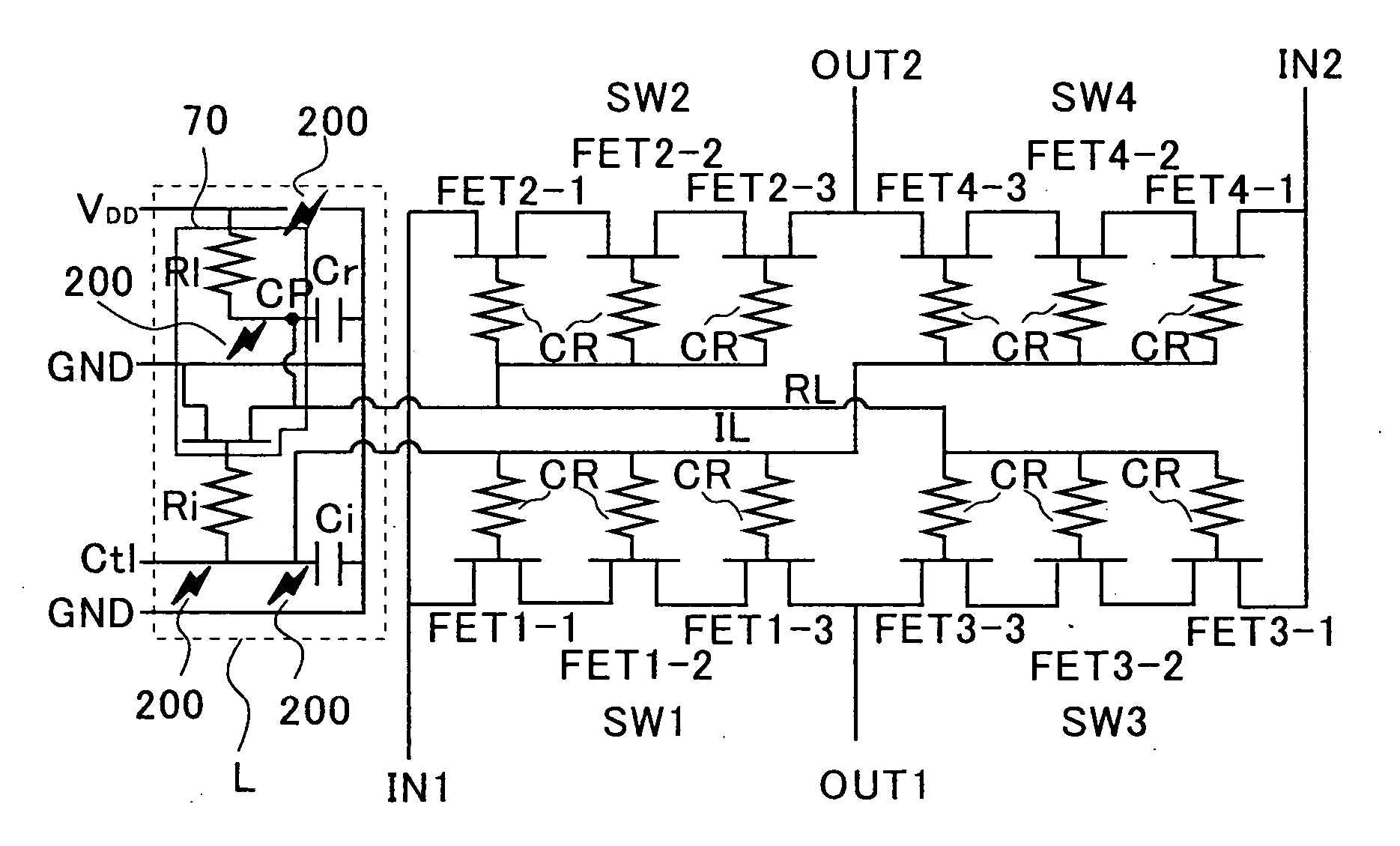

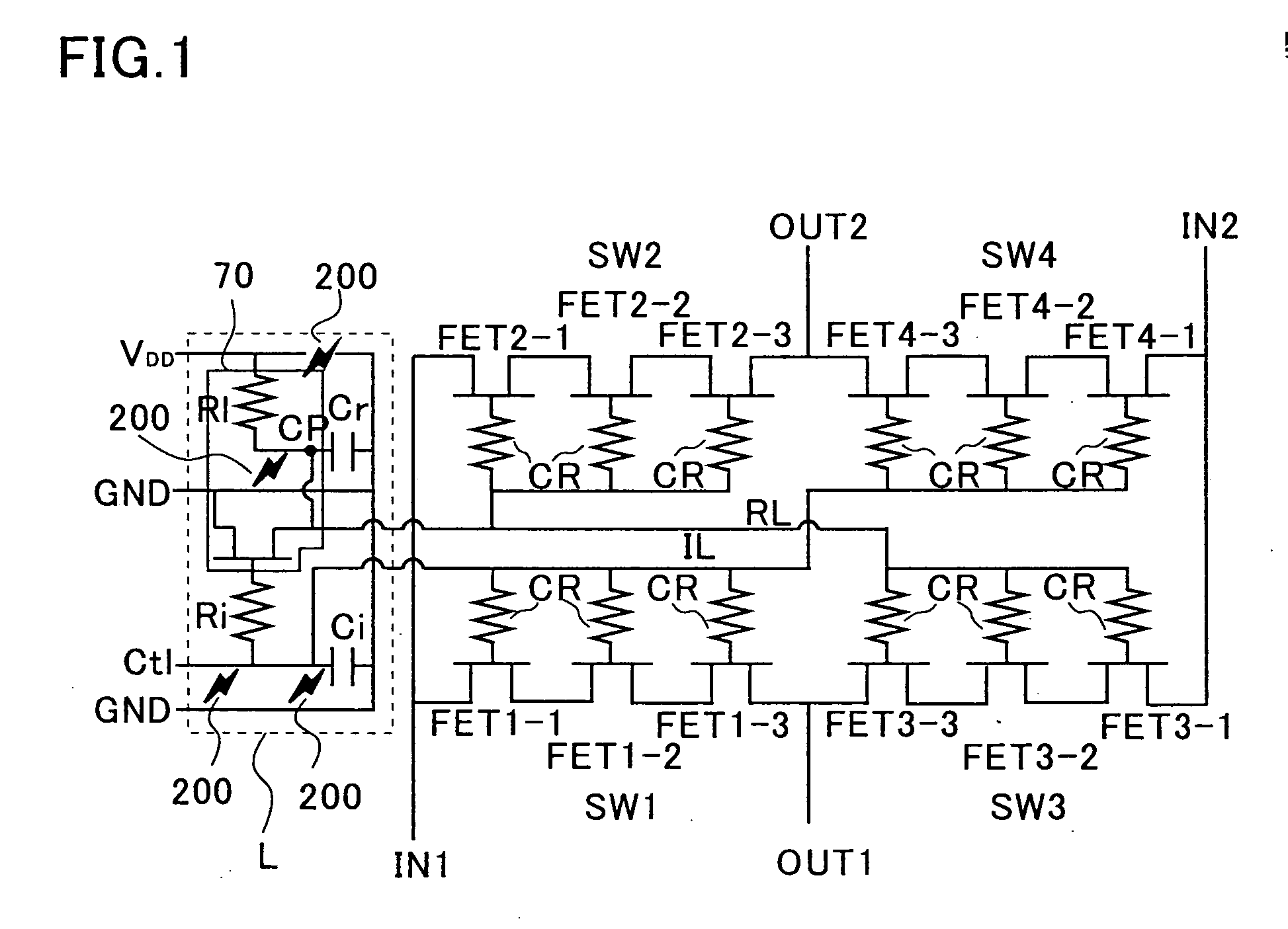

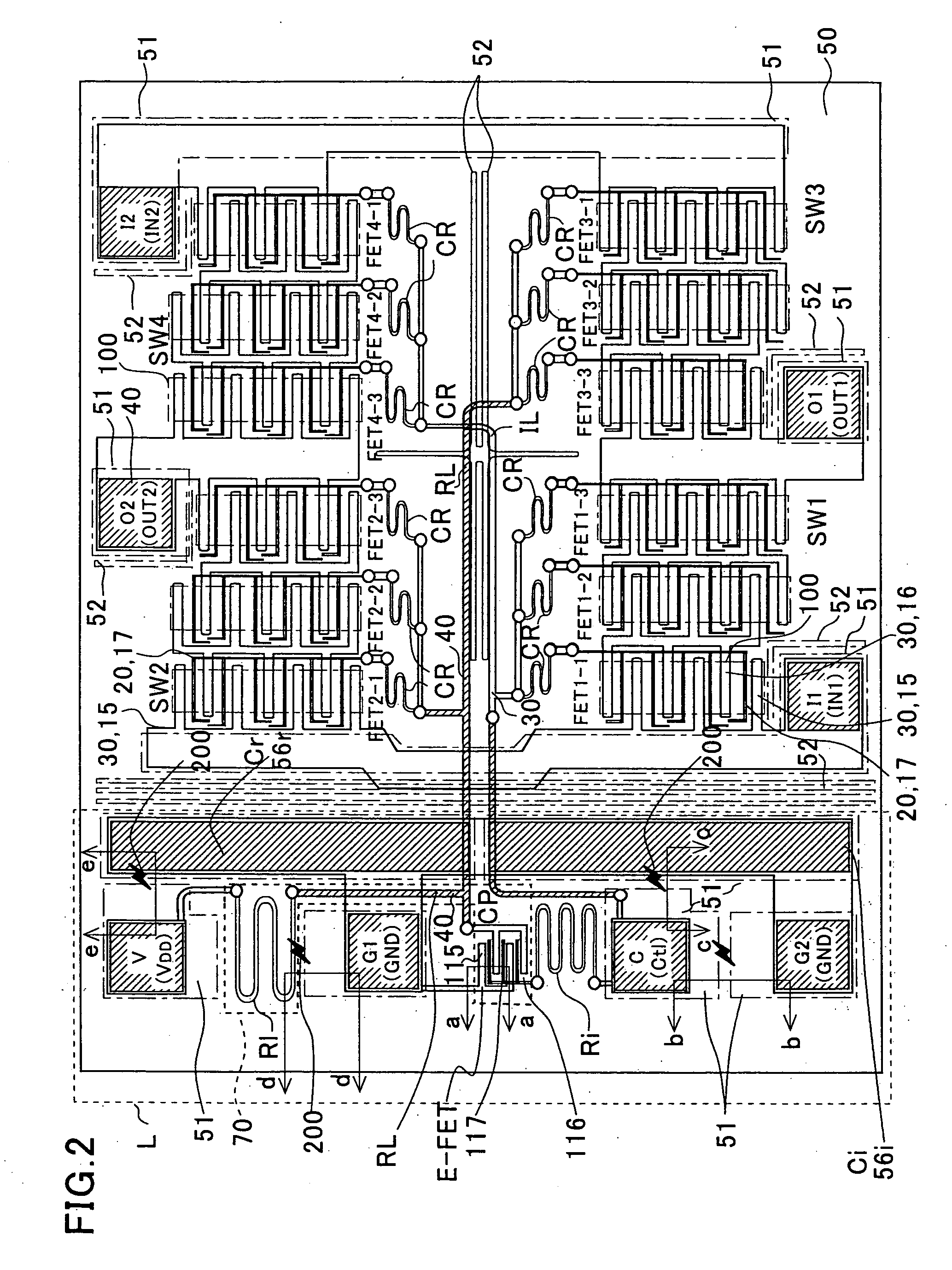

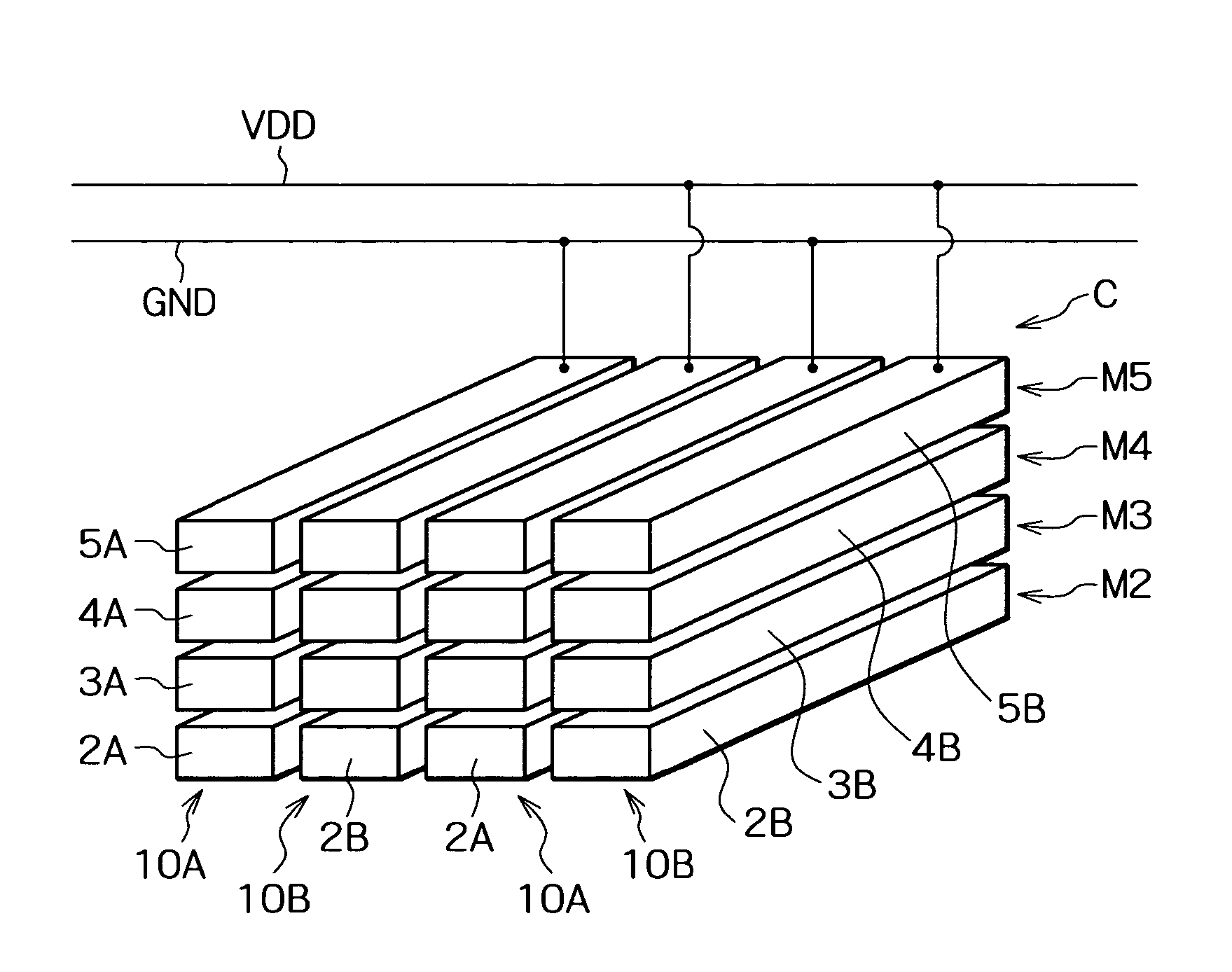

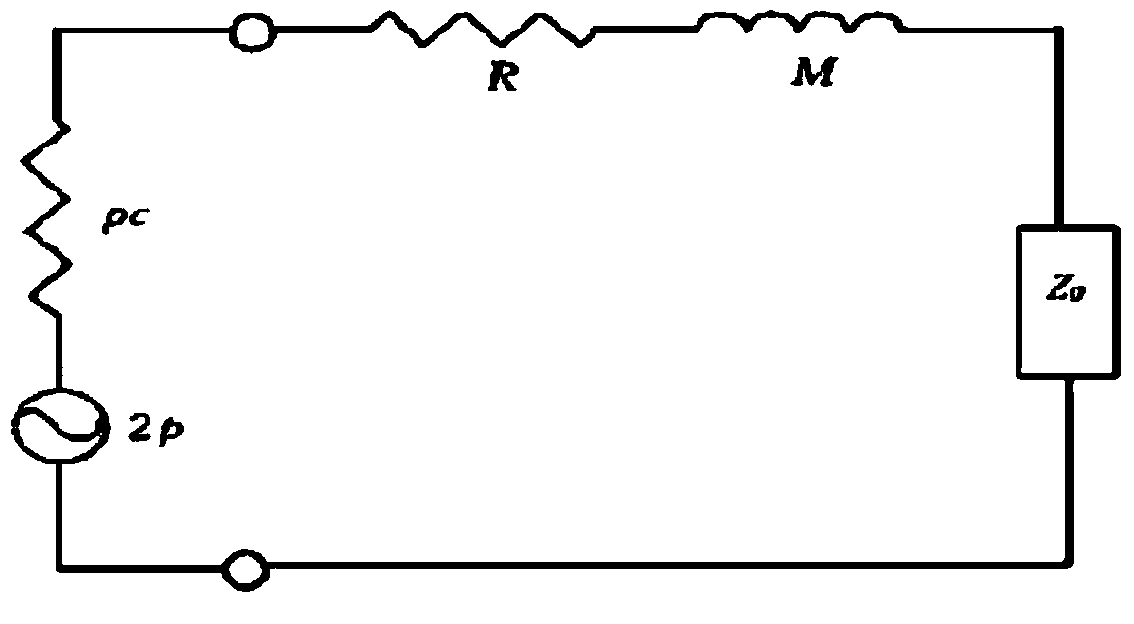

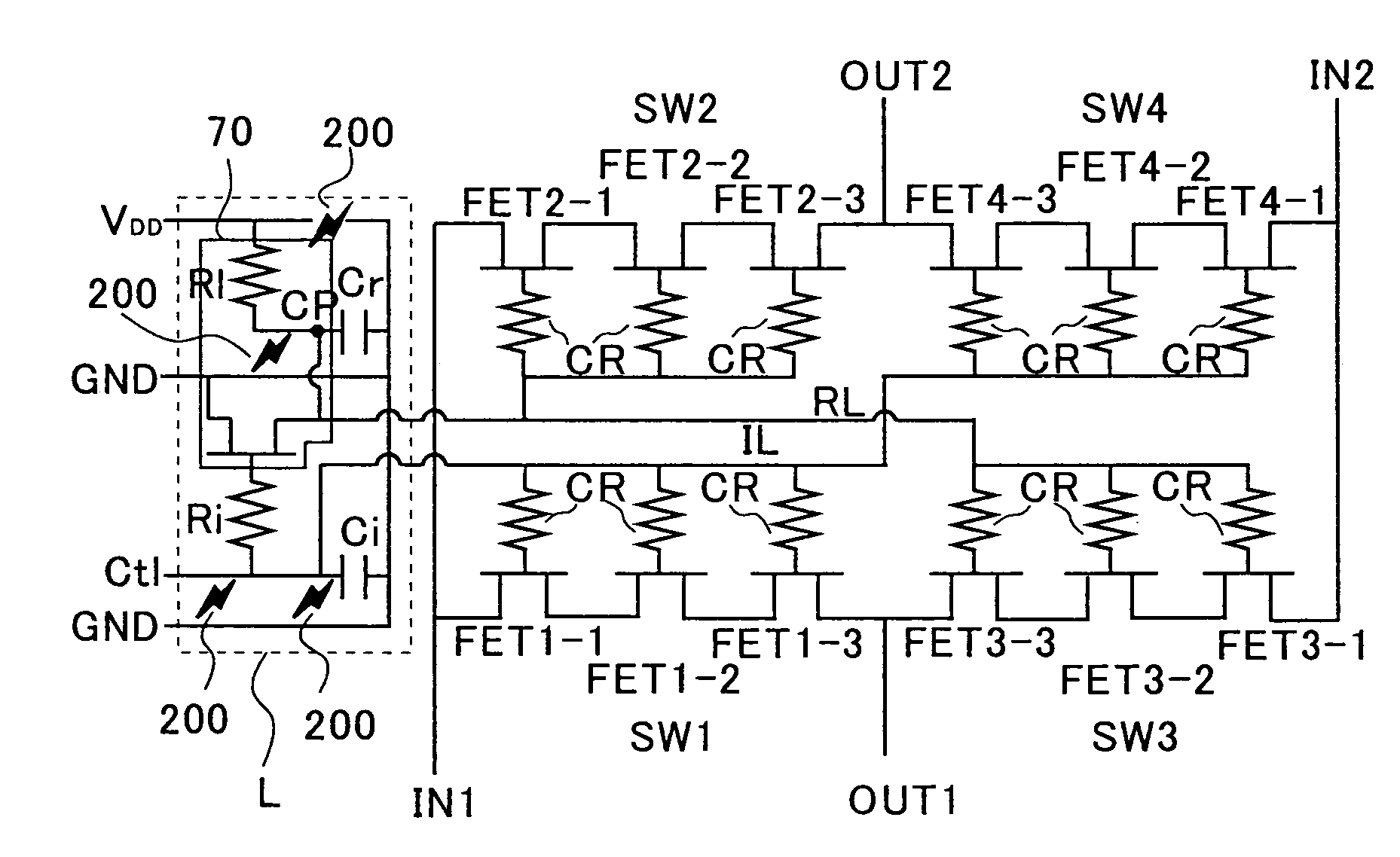

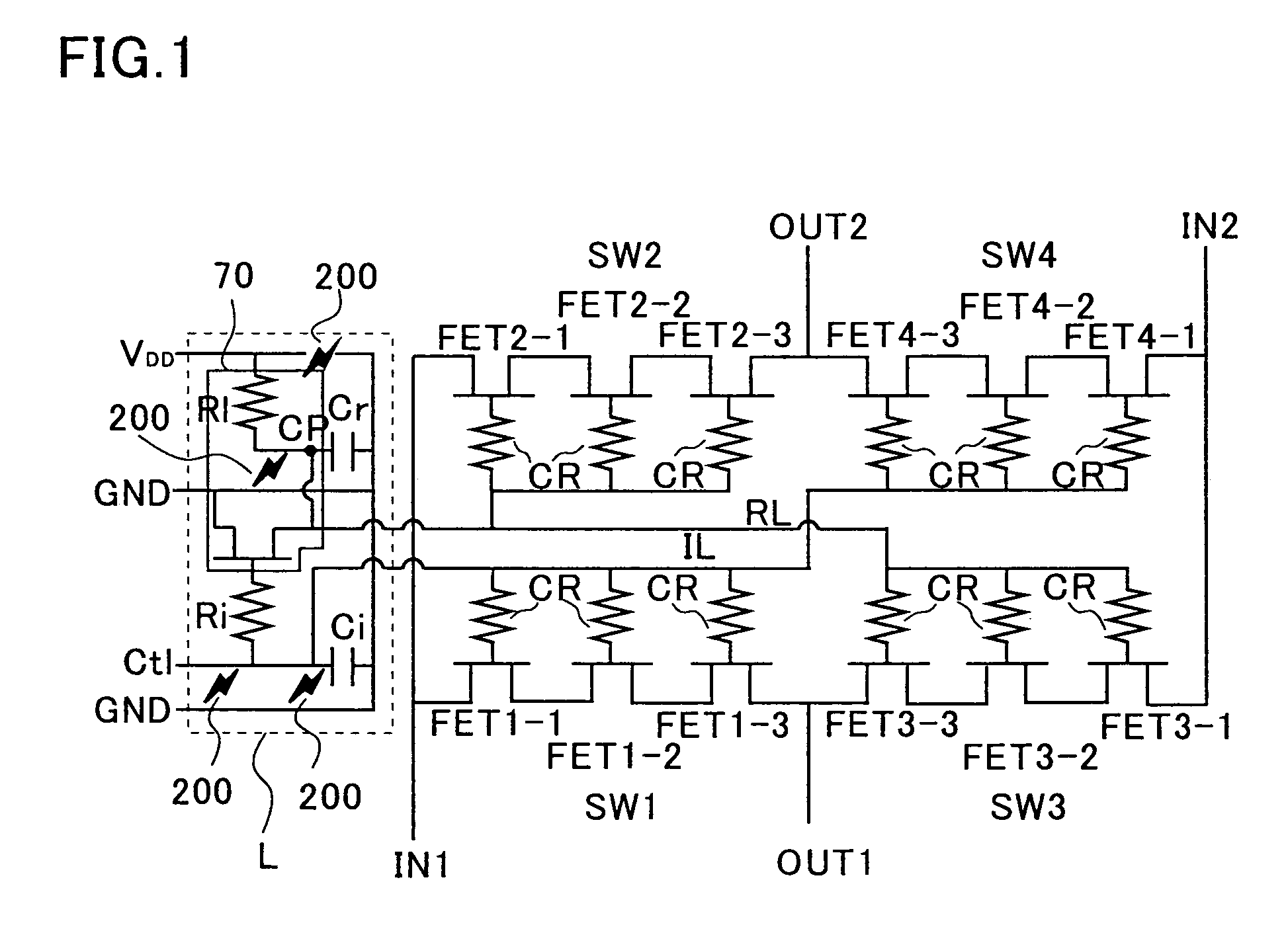

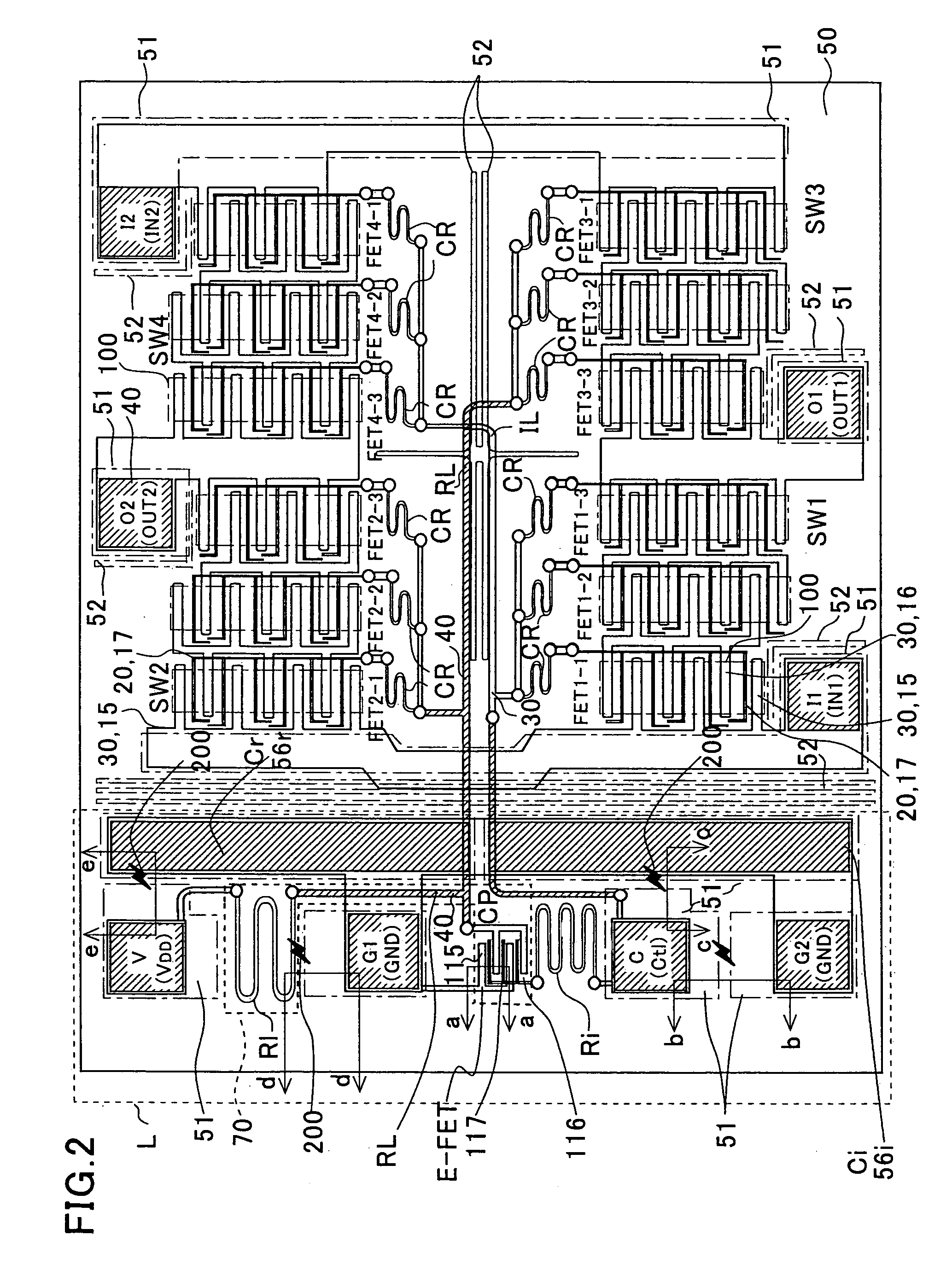

Compound semiconductor switching circuit device

InactiveUS20060252651A1Absorb noiseAvoid oscillationTransistorSuperconductors/hyperconductorsCompound (substance)Capacitor

Protecting elements are respectively connected between a control terminal Ctl and a ground terminal GND of a logic circuit L, between a point Cp and a ground terminal GND, and between a power supply terminal VDD and a ground terminal GND thereof. With this, an E-FET, constituting an inverter 70, and capacitors Ci and Cr can be protected from electrostatic breakdown due to external static electricity. Since the protecting element can be constituted by requisite components for the logic circuit, an additional step or structure is not especially required to provide the protecting element.

Owner:SEMICON COMPONENTS IND LLC

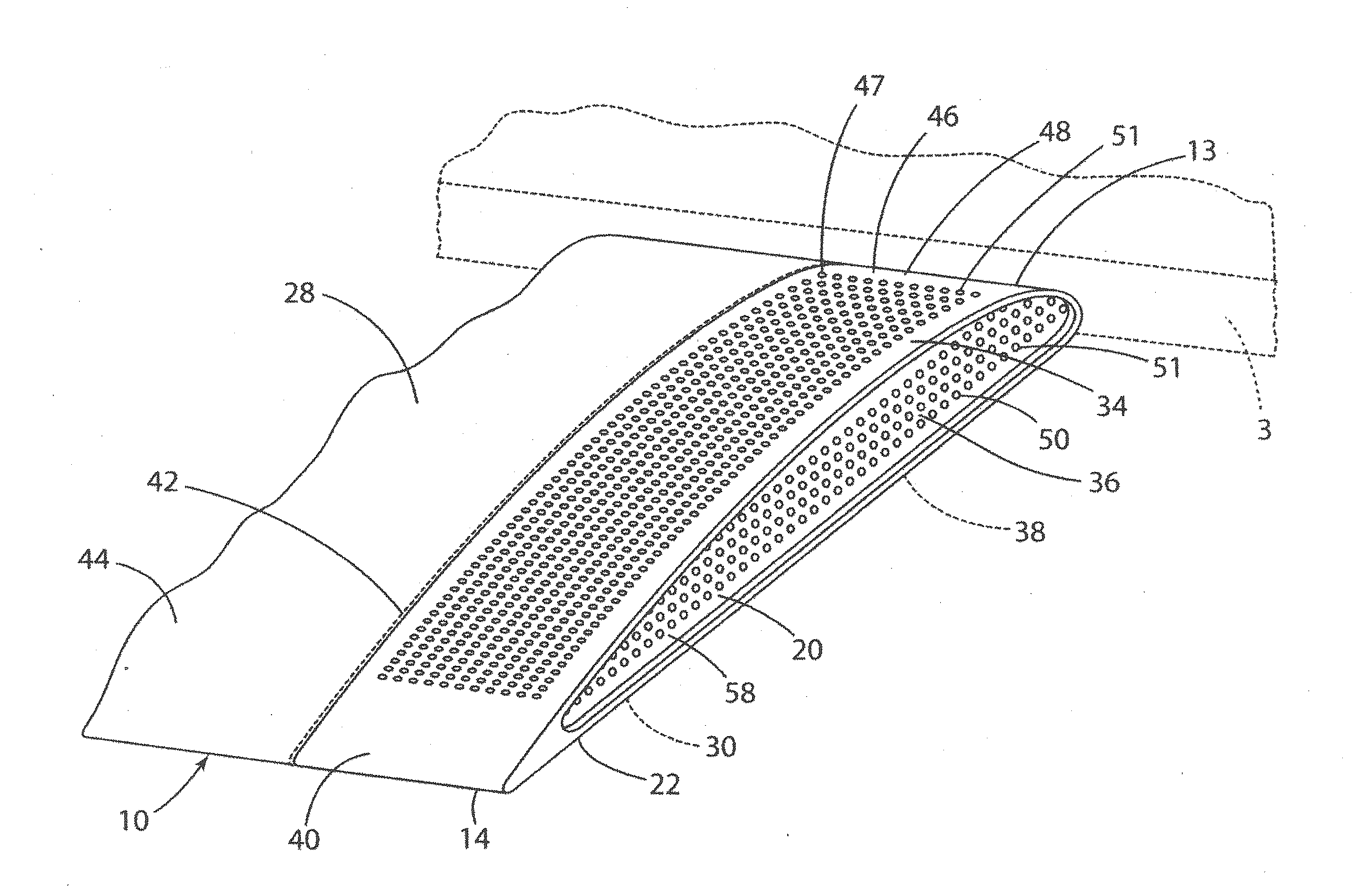

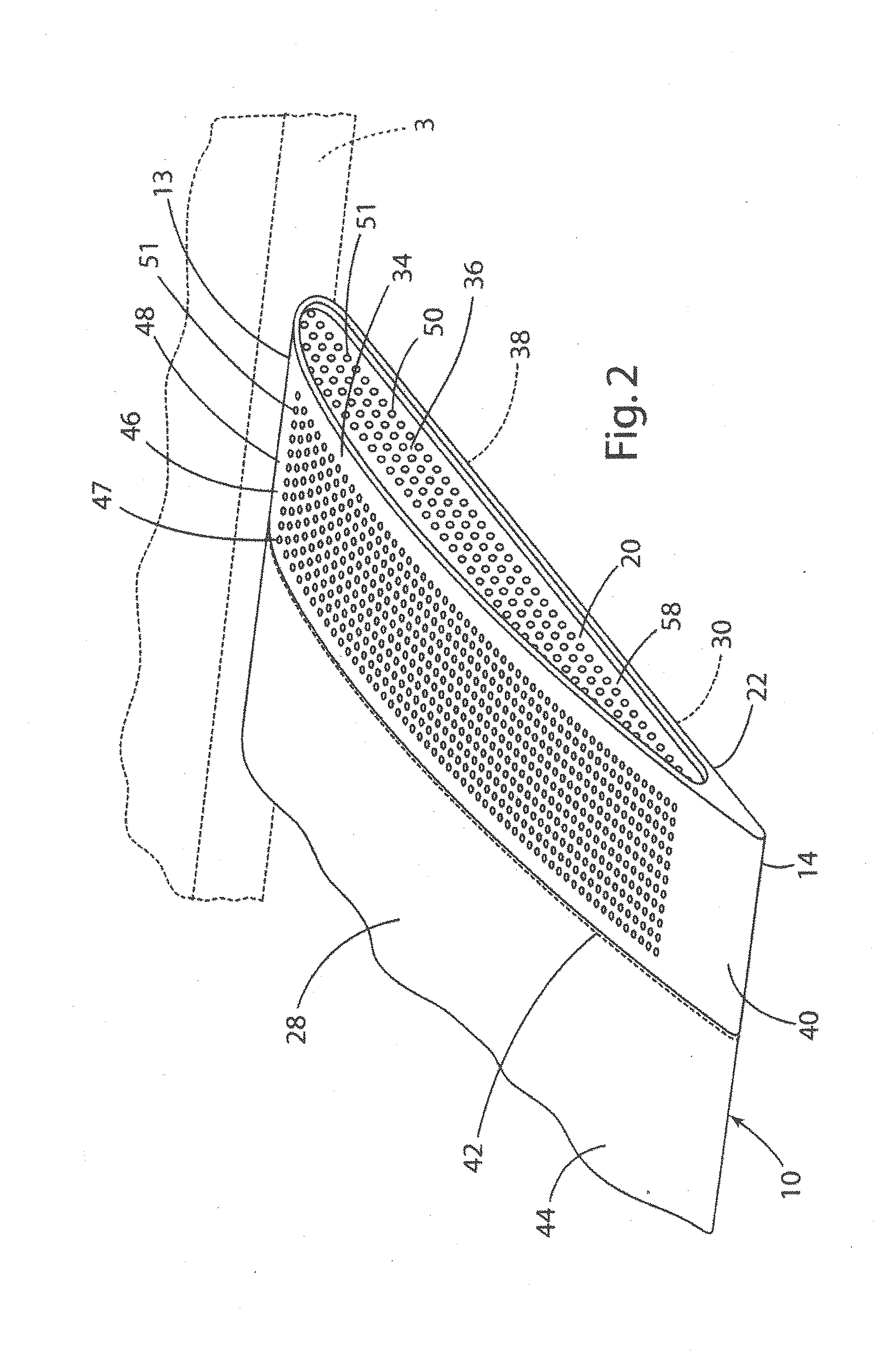

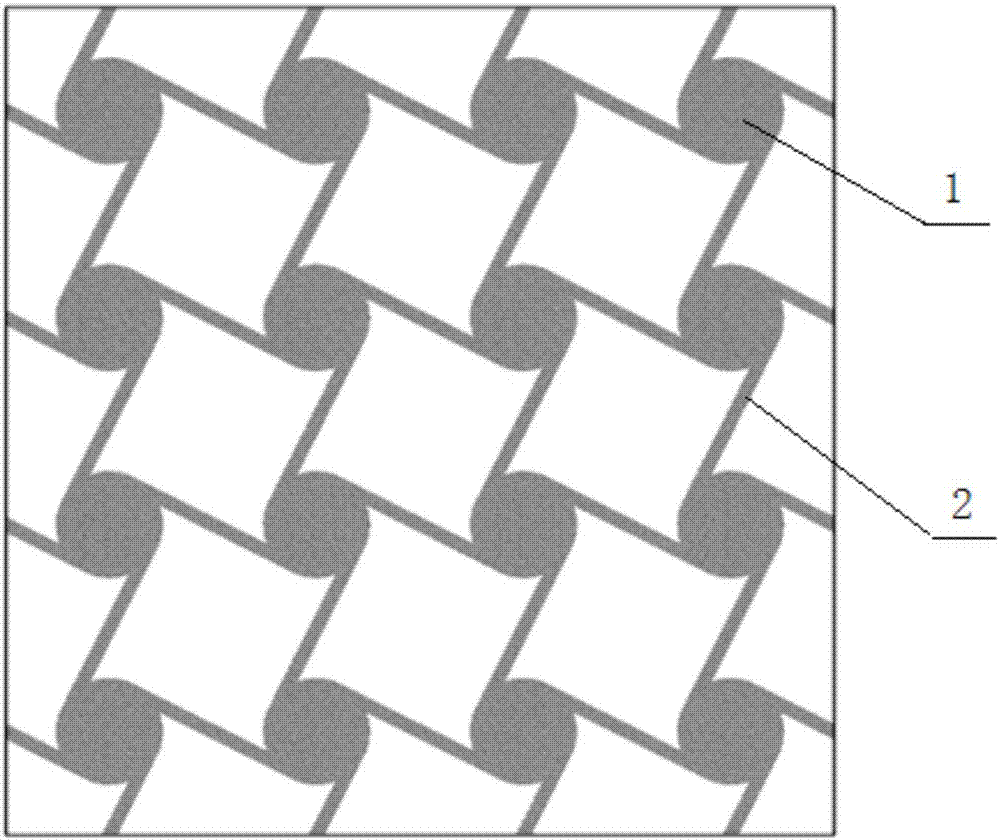

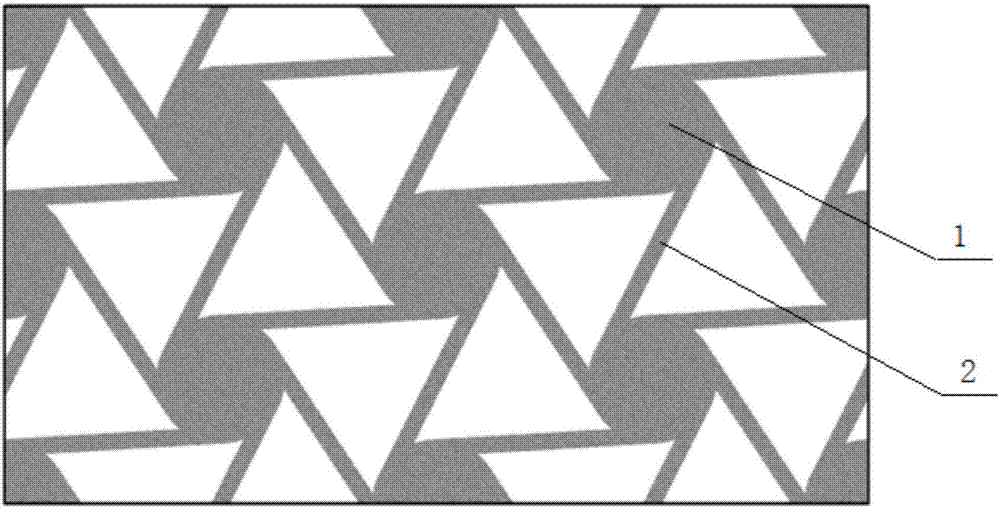

Reactive Orthotropic Lattice Diffuser for Noise Reduction

ActiveUS20150259060A1Reduce amountAbsorb noiseBoundary layer controlsWing lift eficiencyFluid fieldEngineering

An orthotropic lattice structure interconnects porous surfaces of the flap with internal lattice structured perforations to equalize the steady pressure field on the flap surfaces adjacent to the end and to reduce the amplitude of the fluctuations in the flow field near the flap end. The global communication that exists within all of the perforations provides the mechanism to lessen the pressure gradients experienced by the end portion of the flap. In addition to having diffusive effects (diffusing the incoming flow), the three-dimensional orthogonal lattice structure is also reactive (acoustic wave phase distortion) due to the interconnection of the perforations.

Owner:NASA

Curb produced by using waste ceramic slag and waste road concrete and manufacturing method

InactiveCN103058613AImprove performanceEnhance and improve performanceSolid waste managementBrickCalcium formate

The invention relates to a curb produced by using waste ceramic slag and waste road concrete and a manufacturing method. The curb is characterized in that the waste ceramic slag, the waste road concrete, waste incineration residue, waste granite slag, silicate cement, calcium oxide powder, calcium sulfate powder, polycarboxylate efficient water reducing agent, calcium formate, sodium sulfate and water are used as raw materials; and the raw materials are stirred to be moist through a stirrer, extruded by using a hydraulic machine and manufactured into the waste ceramic slag and waste road concrete curb under the pressure of 25 to 30MPa, and the curb is naturally dried and cured for 28 days at normal temperature by using a water spraying method. The raw materials can be manufactured into top wall bricks, plaza bricks and sidewalk bricks with different sizes; and the curb has the advantages of light weight, high strength, pollution prevention, low cost and high benefits. The invention meets the requirements for national energy conservation and emission reduction development and low-carbon economy.

Owner:清远绿由环保科技有限公司 +1

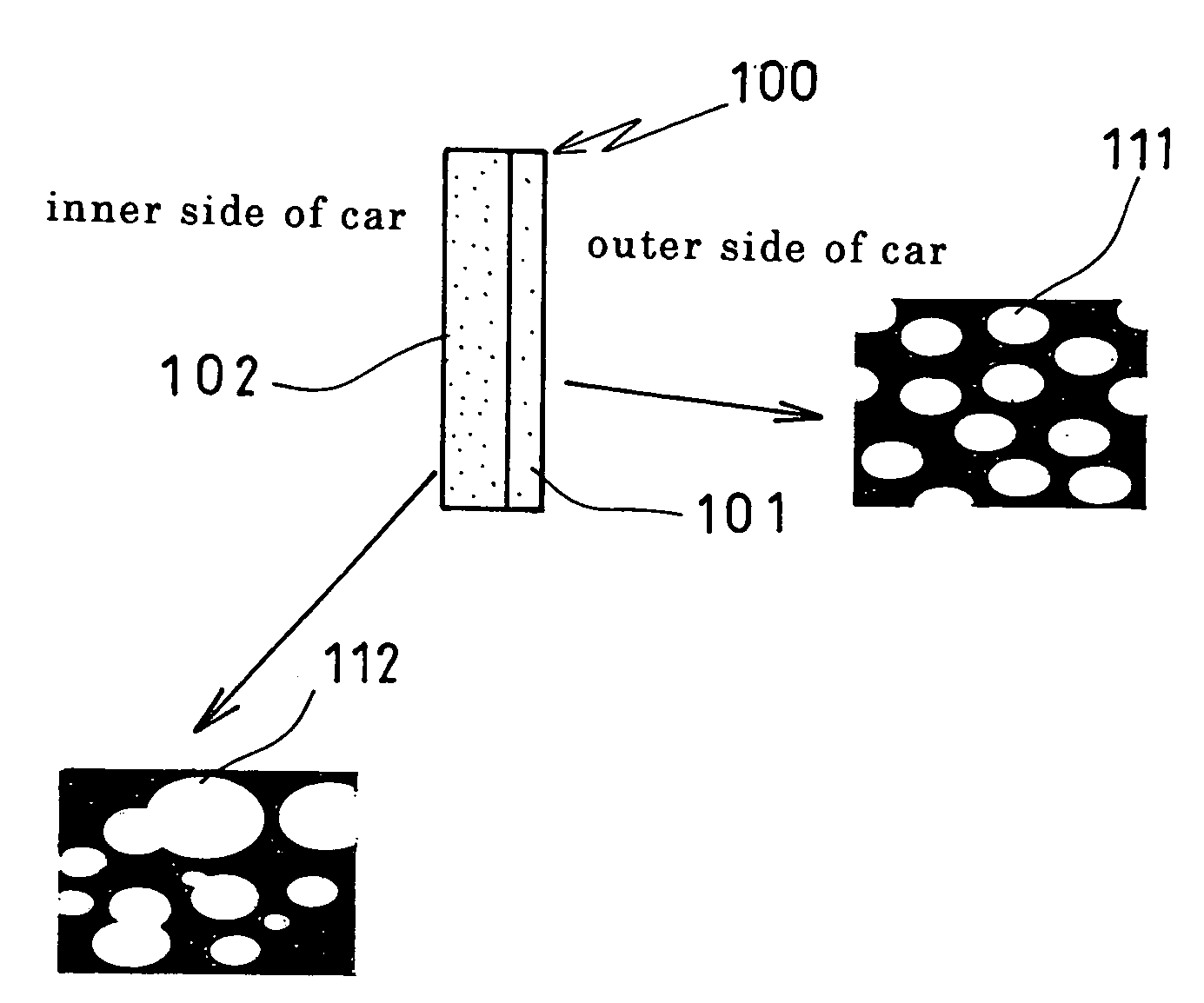

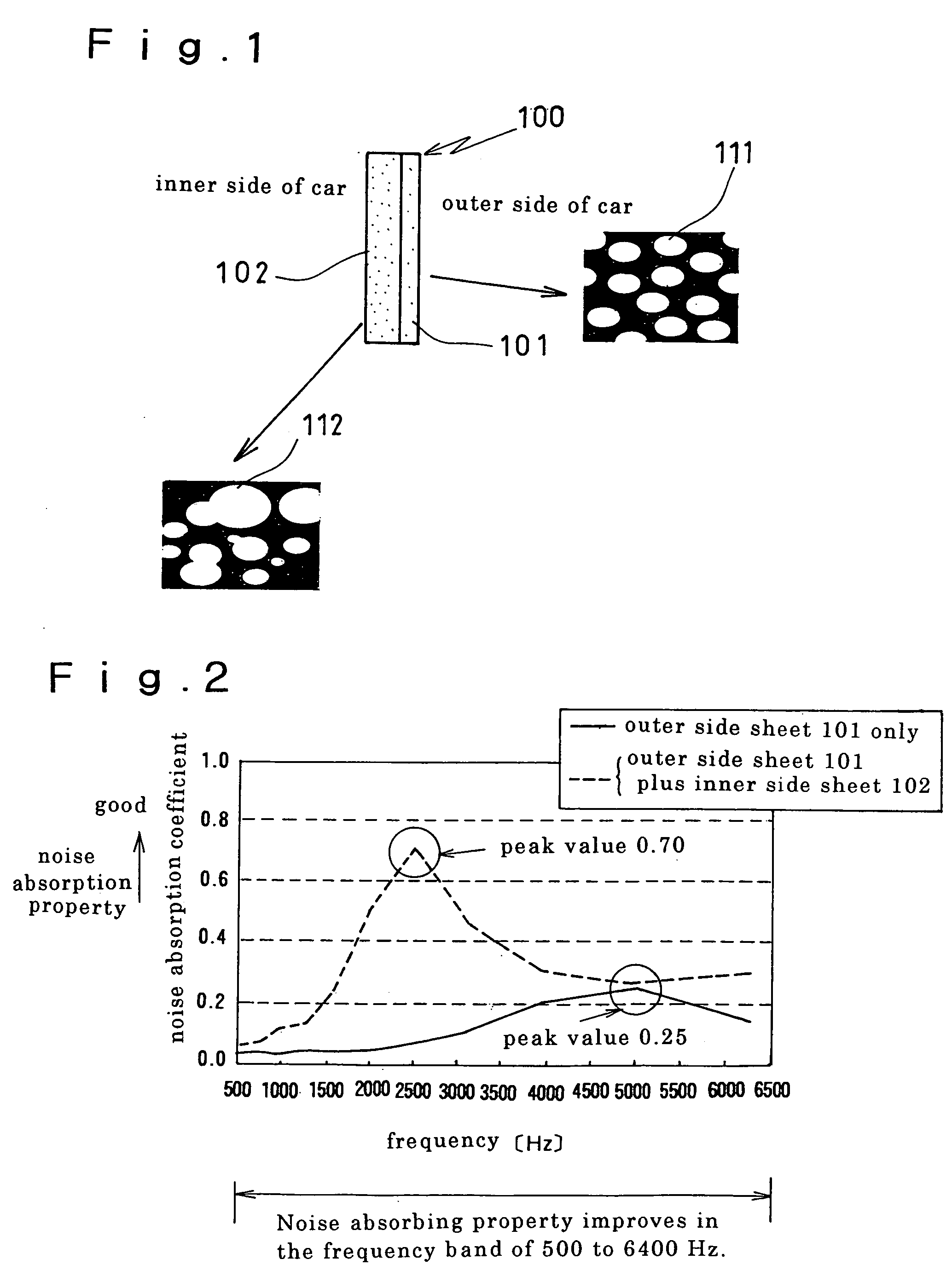

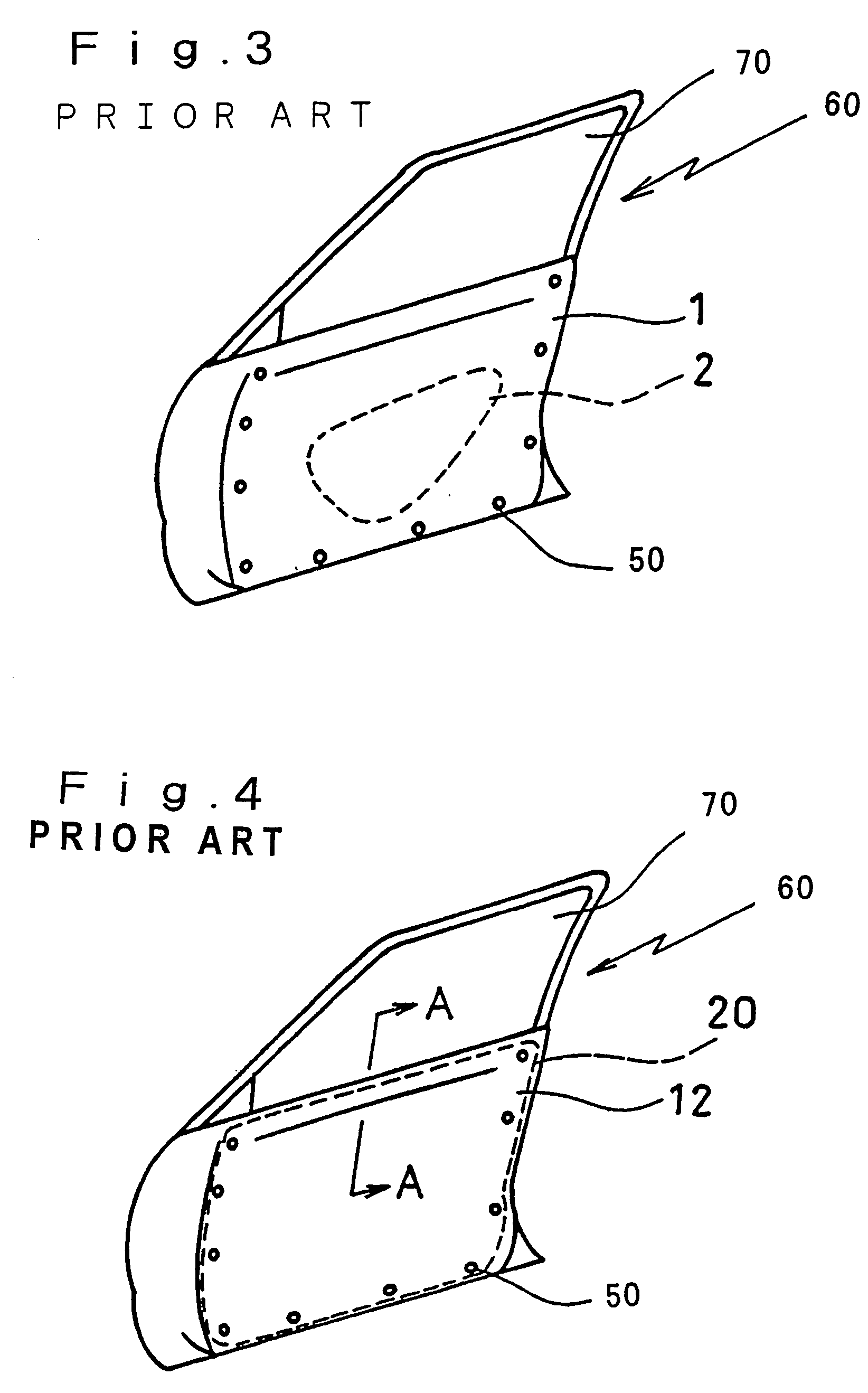

Noise isolation sheet

ActiveUS20060049662A1Improve propertiesAbsorb noiseLayered productsSound producing devicesTrim tabEngineering

Owner:NISHIKAWA RUBBER

Metal glass metamaterial with chiral microstructure

ActiveCN107012409AIncrease elasticityHigh strengthMaterial nanotechnologyEnergy absorptionMechanical property

The invention provides a metal glass metamaterial with a chiral microstructure. Traditional chiral structural design is applied to a metal glass material. The metal glass metamaterial comprises a cylinder made from the metal glass material and ligaments connected with the cylinder in a tangent mode. The overall mechanical property of the structure can be regulated and controlled by changing the number, the thickness, the length and the arranging mode of the ligaments and the radius of the cylinder. According to the metal glass metamaterial with the chiral microstructure, through perfect combination of the advantages of the chiral structure and the metal glass material, the mechanical properties of a traditional multi-hole material, chiral material and metal glass are greatly improved, the light effect and the negative Poisson ratio can be achieved, the metal glass metamaterial is high in elasticity and strength and large in plasticity, a large-scale metal glass metamaterial is expected to be prepared, and the metal glass metamaterial can be applied to the specific fields such as weight reduction and sound and energy absorption.

Owner:XI AN JIAOTONG UNIV

Fan assembly

A fan assembly for creating an air current includes a nozzle mounted on a base. The base comprises an outer casing, an impeller housing located within the outer casing, the impeller housing having an air inlet and an air outlet, an impeller located within the impeller housing and a motor for driving the impeller to create an air flow through the impeller housing. The nozzle includes an interior passage for receiving the air flow from the air outlet of the impeller housing and a mouth through which the air flow is emitted from the fan assembly. A flexible sealing member is located between the outer casing and the impeller housing.

Owner:DYSON TECH LTD

Preparation method of high-strength anti-puncture synthesized leather bass by performing impregnation treatment on UHMWPE fiber three-dimensional compound nonwoven cloth through water-base resin

The invention relates to the field of leather making, and discloses a preparation method of a high-strength anti-puncture synthesized leather bass by performing impregnation treatment on UHMWPE fiber three-dimensional compound nonwoven cloth through water-base resin. The preparation method comprises the following steps: preparation of the UHMWPE fiber three-dimensional compound nonwoven cloth, pre-impregnation, primary microwave drying, ironing, main impregnation, secondary microwave drying, washing, microwave drying for the third time and leather grinding, wherein the UHMWPE fiber three-dimensional compound nonwoven cloth is formed by weaving coarse denier UHMWPE fiber yarns, fine denier UHMWPE short fibers and water-soluble short fibers which serve as raw materials; in the main impregnation process, main impregnation liquid contains graphene-modified aqueous polyurethane resin. The synthesized leather bass disclosed by the invention is higher in strength, modulus, specific strength and specific modulus, high in weather resistance, high temperature resistance, chemical resistance and wear resistance, and extremely high in impact strength, can absorb shock impact and prevent noise, is low in friction coefficient, and is high in moisture permeability and breathability, green, environment-friendly, comfortable and low in cost.

Owner:ZHEJIANG FANSHENG MICROFIBER PROD

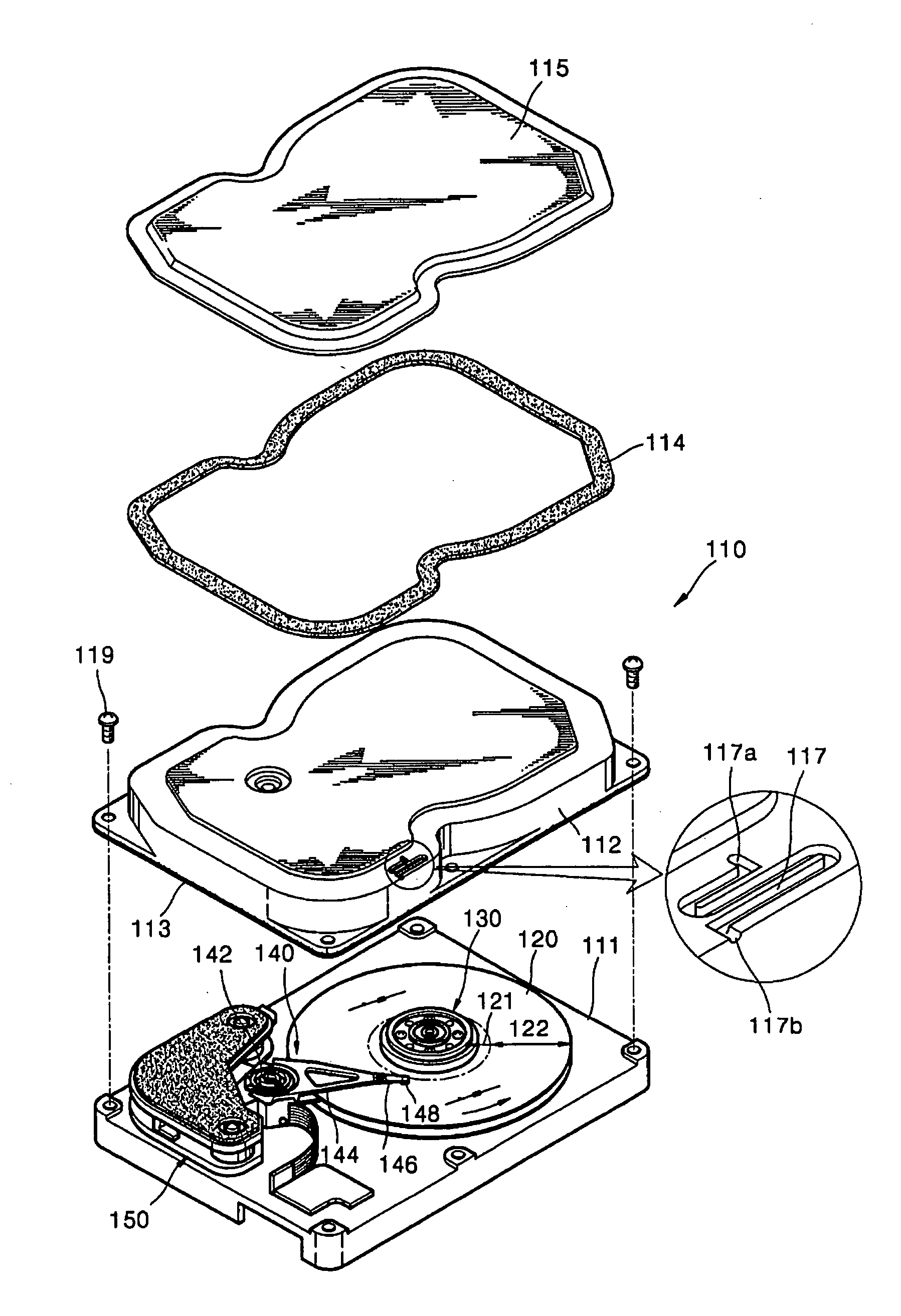

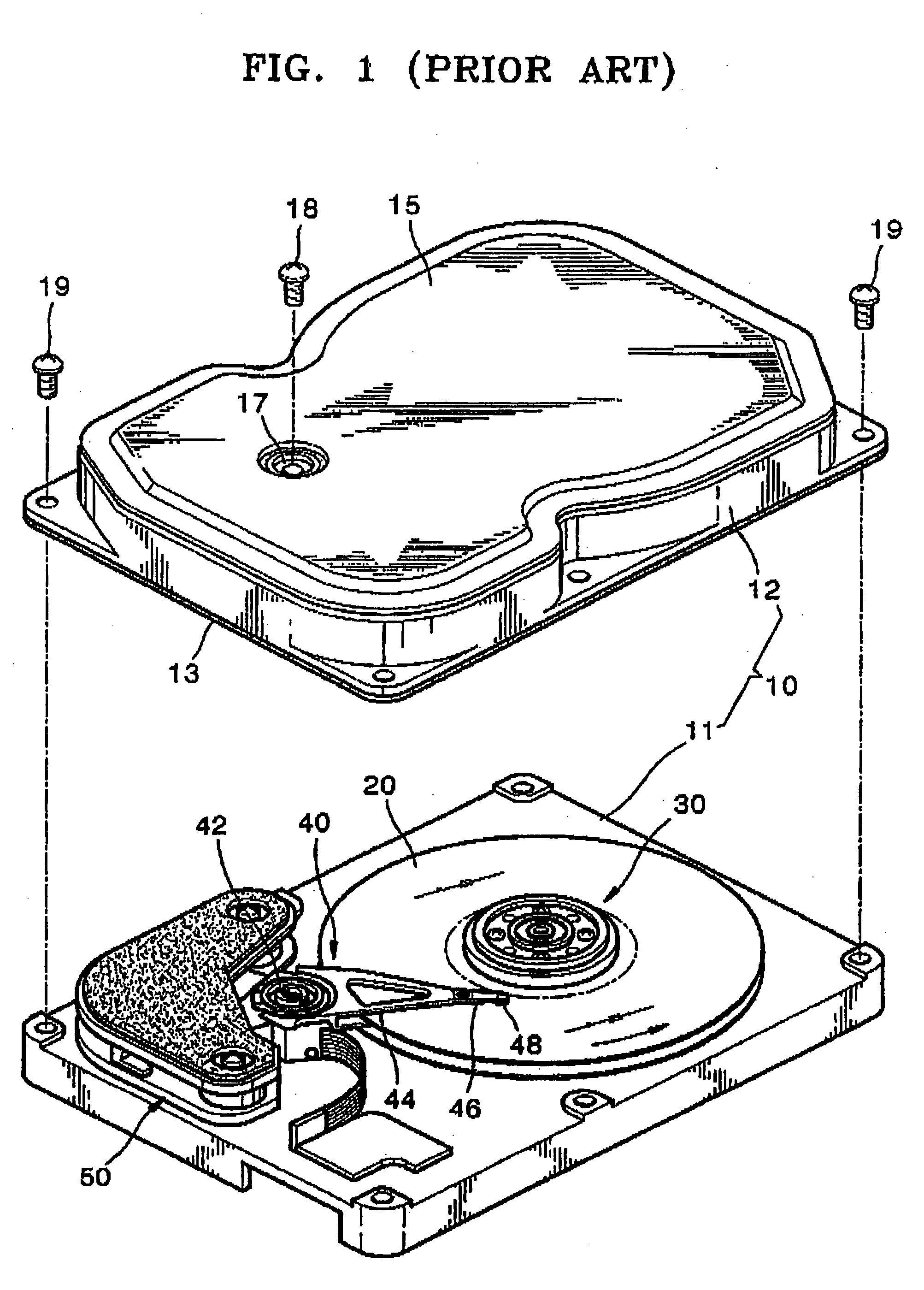

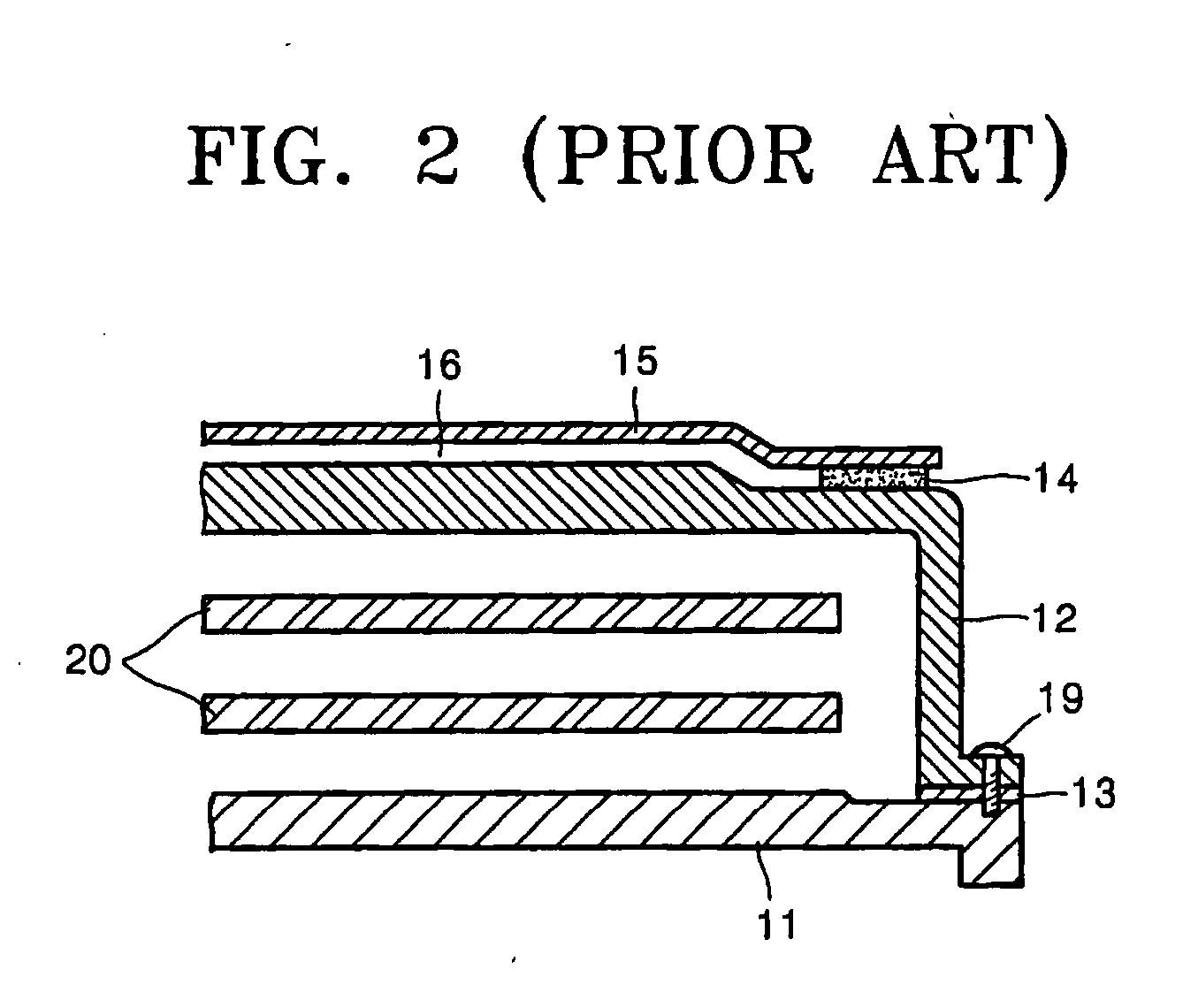

Hard disk drive with damping plate

InactiveUS20050286163A1Maintain performanceAbsorbing external impactApparatus for flat record carriersUndesired vibrations/sounds insulation/absorptionHard disc driveElectric machine

A hard disk drive with a housing including a base member supporting a spindle motor rotating a data storage disk and an actuator having a read / write head, a cover member coupled to the base member to encompass the spindle motor and the actuator, a damping plate spaced a predetermined distance from an upper surface of the cover member to form an air gap between the damping plate and the cover member, a buffer member arranged between an edge portion of the cover member and an edge portion of the damping plate, and an air channel between the cover member and the damping plate to connect the air gap with the outside.

Owner:SAMSUNG ELECTRONICS CO LTD

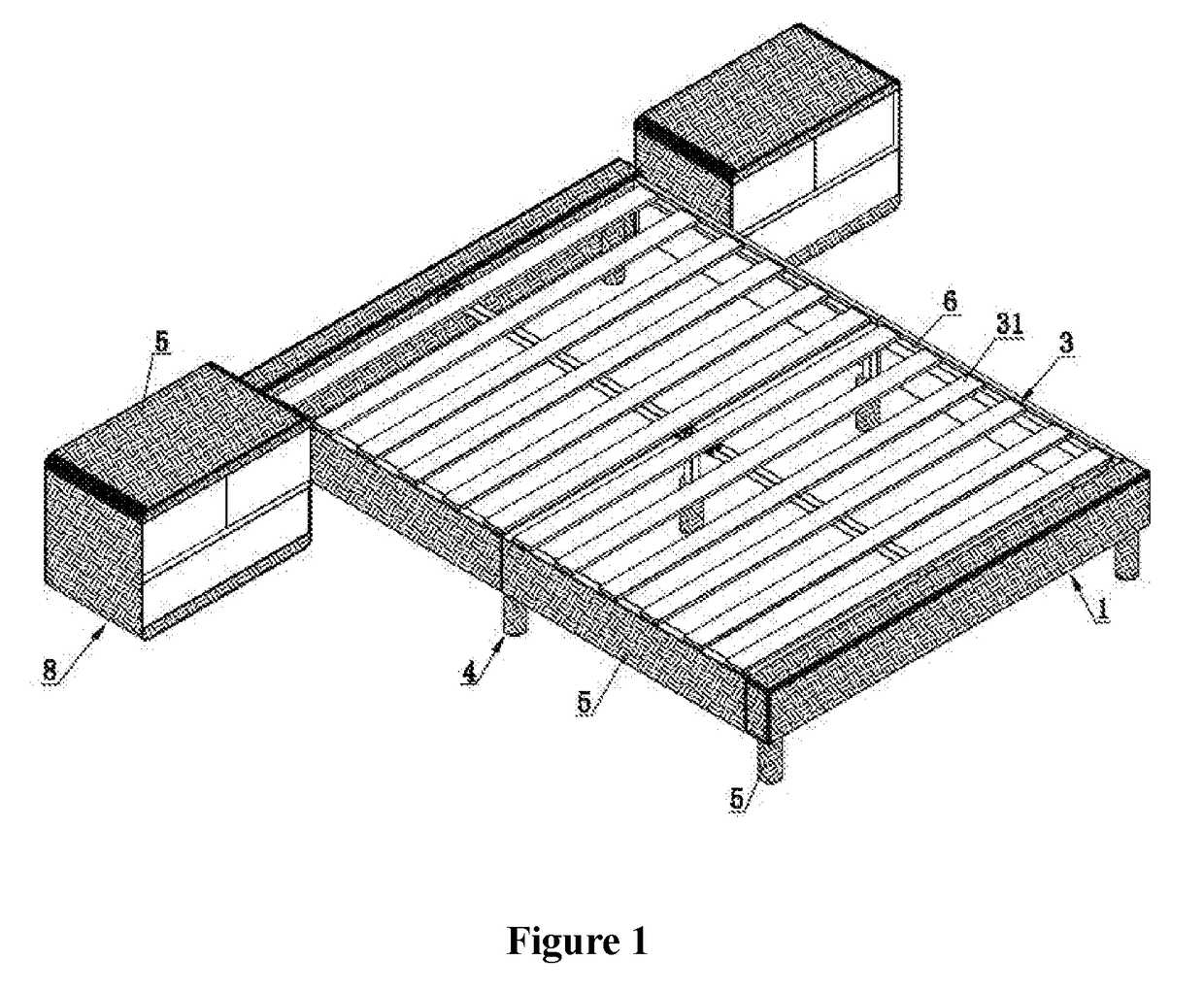

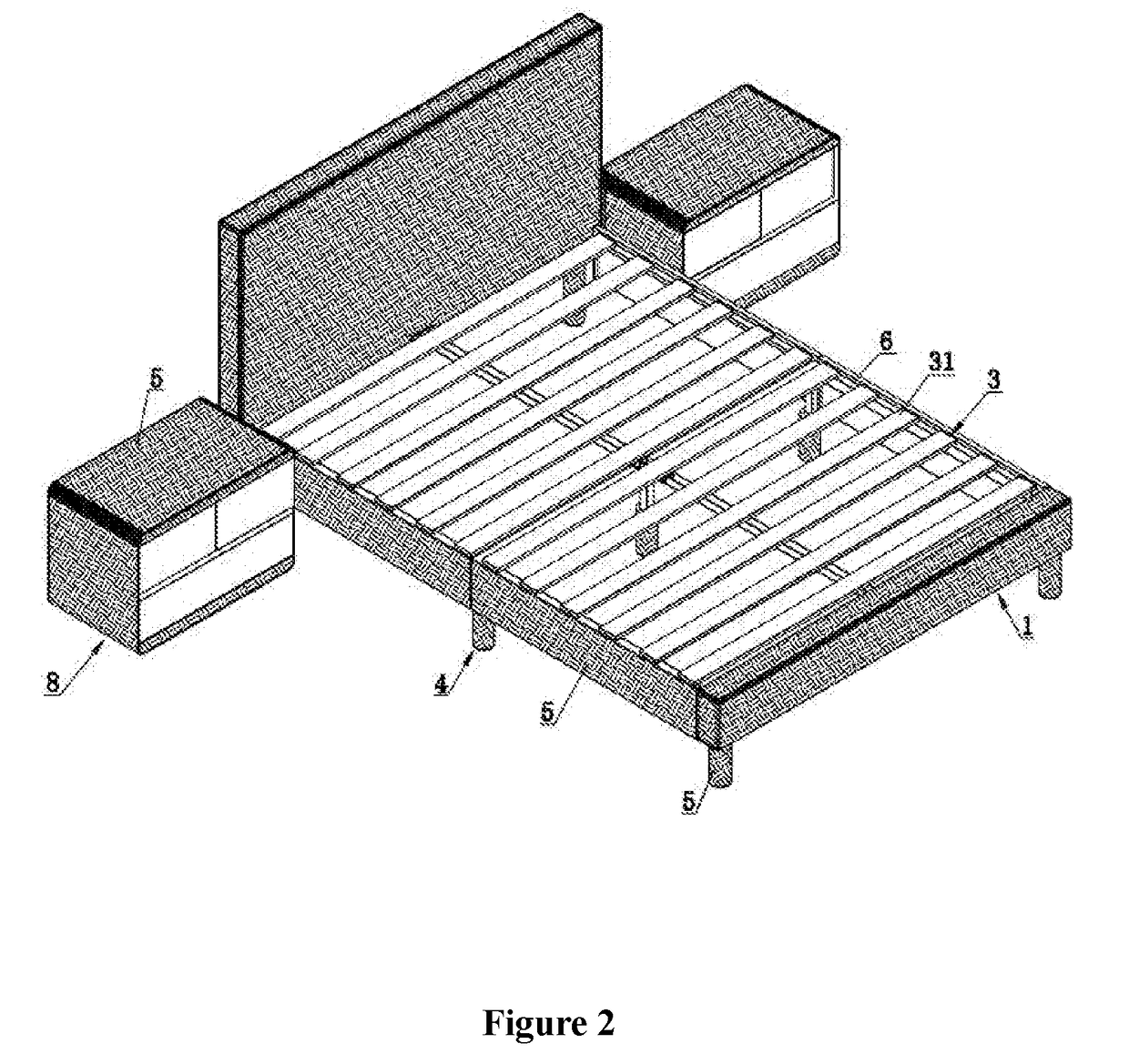

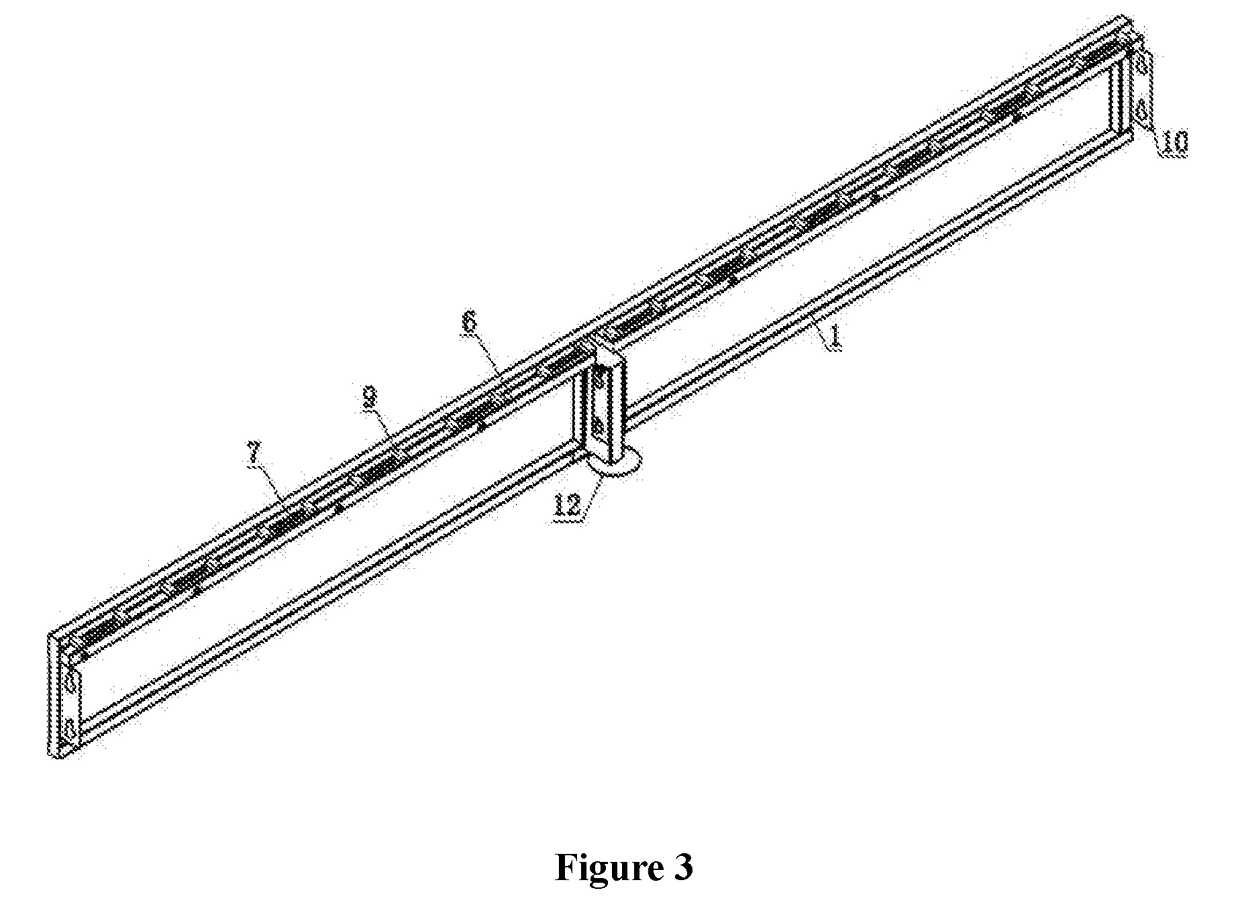

Easy assembling and disassembling type rattan bed

An easy assembling and disassembling type rattan bed is disclosed, comprising six support frame boards, a detachable bedstead, a bed board and a plurality of support legs. The six support frame boards, having rattan panels covered on all outer surfaces thereof, are successively and detachably connected to each other end to end, and the rattan panels are woven by a plurality of vertical rattans and a plurality of horizontal rattans. The six support frame boards are connected to each other end to end to form a bed frame, and the bedstead is arranged inside the bed frame and connected to inner sides of the bed frame. Detachable support bars, top surfaces of which and that of the bedstead both have EVA silencing pads attached thereon, are arranged on all inner sides of the support frame boards on the left and right sides.

Owner:QUANZHOU XIBAO HOME TEXTILES TECH CO LTD

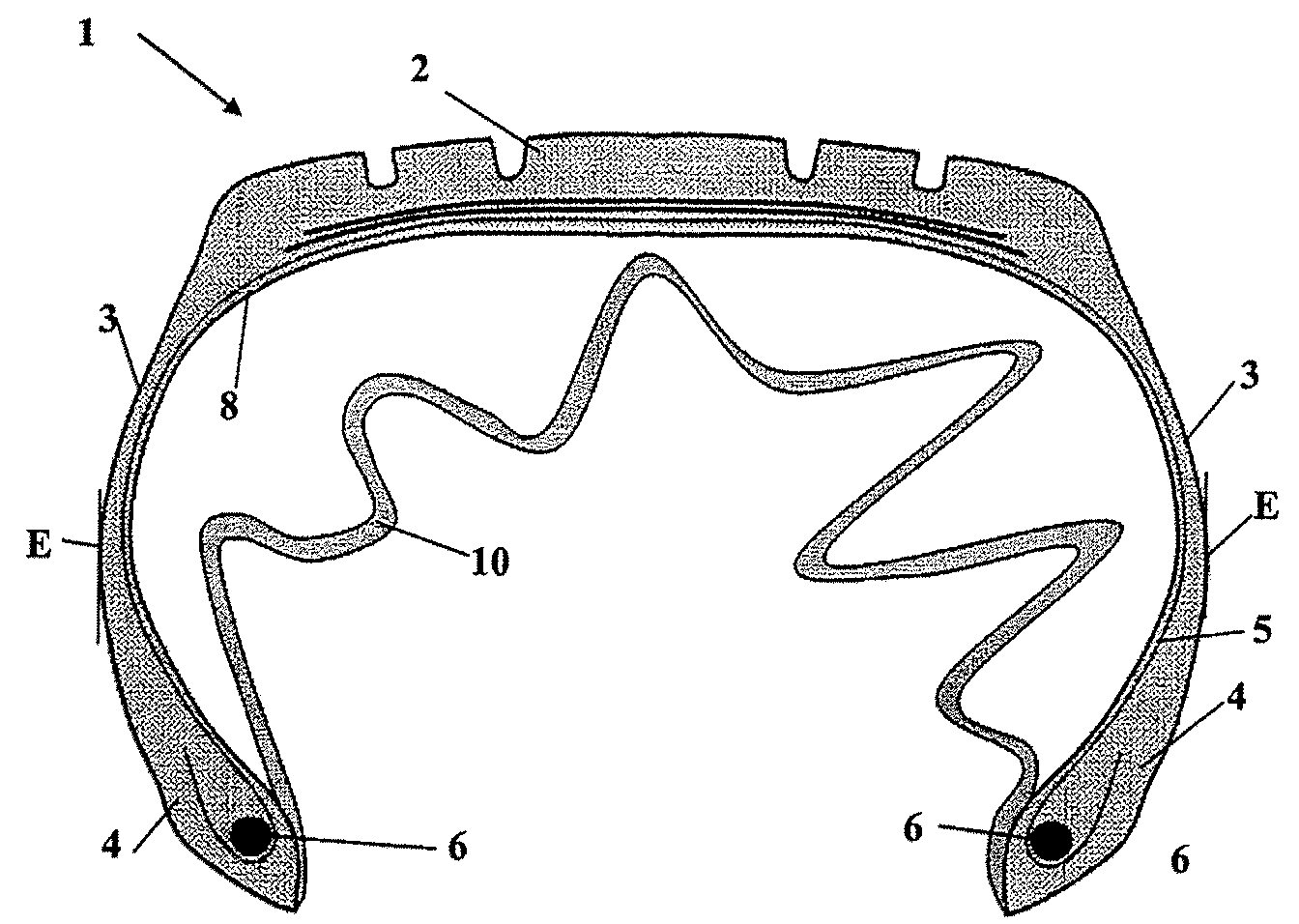

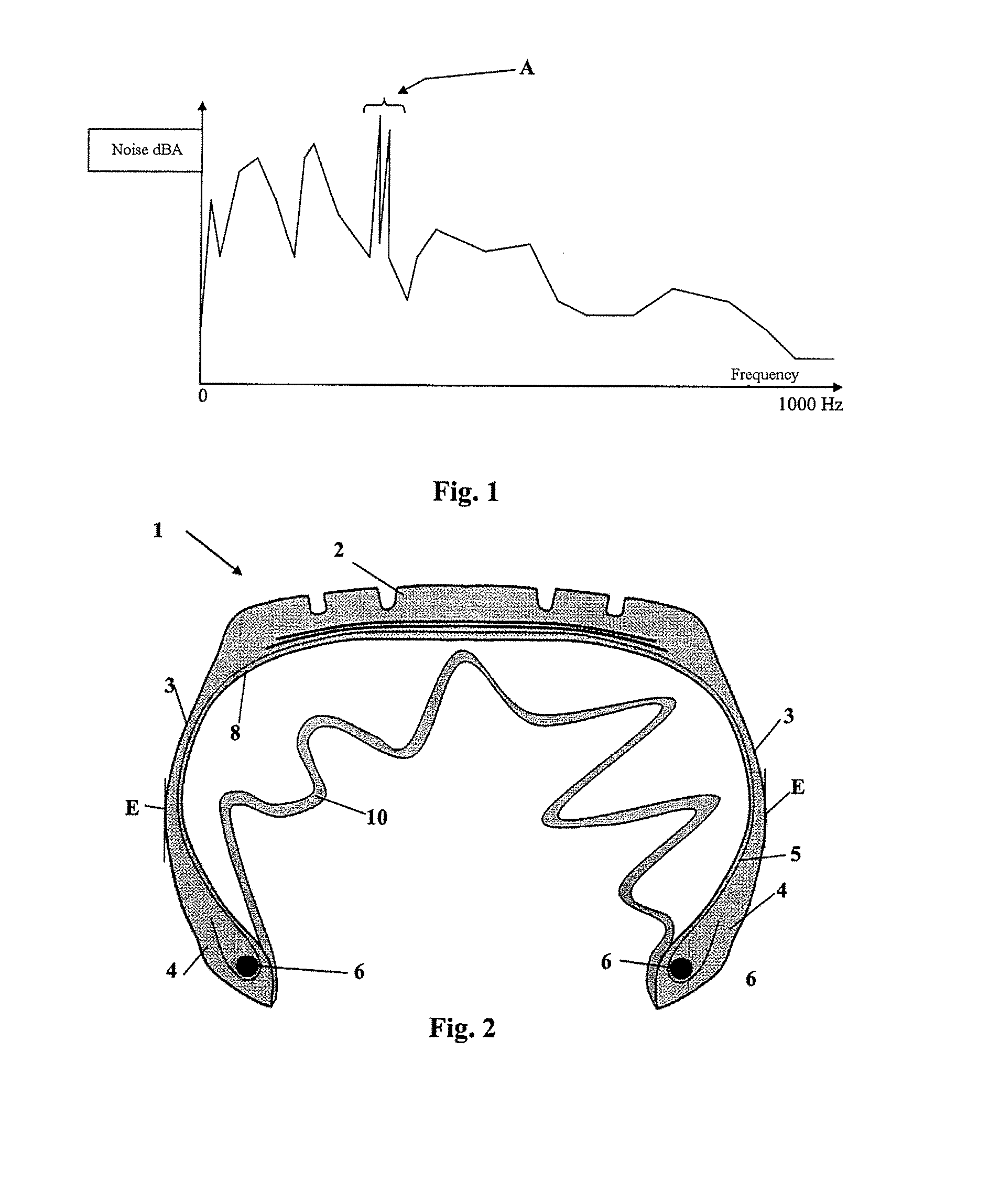

Tire with a cellular layer

InactiveUS20080264538A1Reduce noiseImprove noiseWith multiple inflatable chambersTyresEngineeringCellular material

A tire with a cellular layer is provided. The tire includes a tire structure formed of at least one crown extended by two sidewalls and two beads. A base of each of the two beads is configured to be mounted onto a rim seat. The tire also includes a carcass-type reinforcing structure anchored into the two beads, and a layer that includes a cellular material, also referred to as a cellular layer. The cellular layer is positioned on an inner wall of the tire structure, such that the cellular layer is bonded to the tire structure over at most over 20% of a surface of the cellular layer and is not bonded to the tire structure elsewhere on the surface.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Electronic device and method for manufacturing the same, and method for shielding printed circuit board

InactiveUS20030043563A1Reduce noiseGround can be reinforcedCross-talk/noise/interference reductionRack/frame constructionElectromagnetic shieldingEngineering

An electronic device having a printed circuit board having a ground, an electrically insulating layer provided on a face of the printed circuit board, and an electromagnetic shielding layer adhered to the face of the printed circuit board through the electrically insulating layer. The ground of the printed circuit board and the electromagnetic shielding layer are conducted electrically.

Owner:KONICA CORP

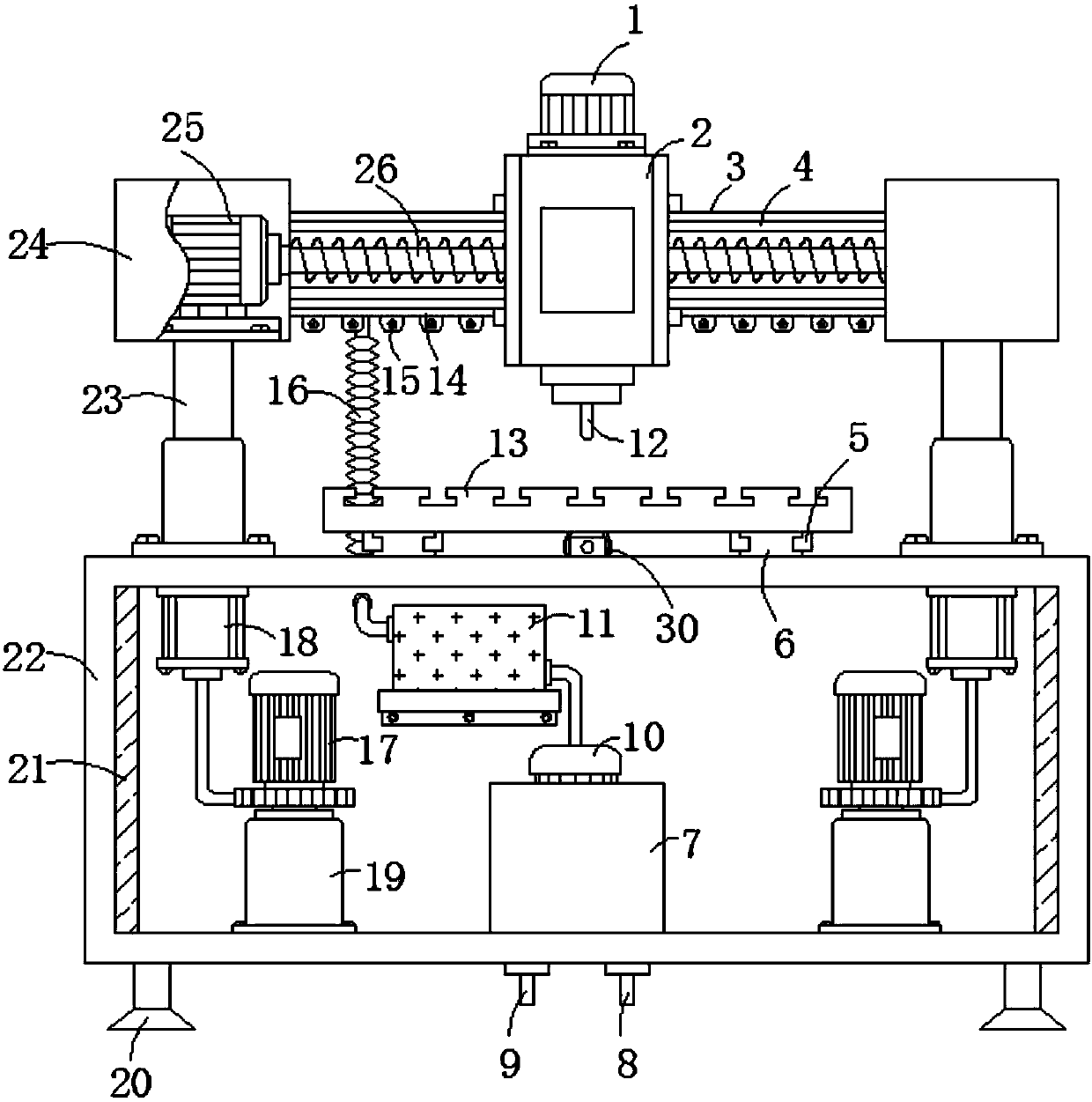

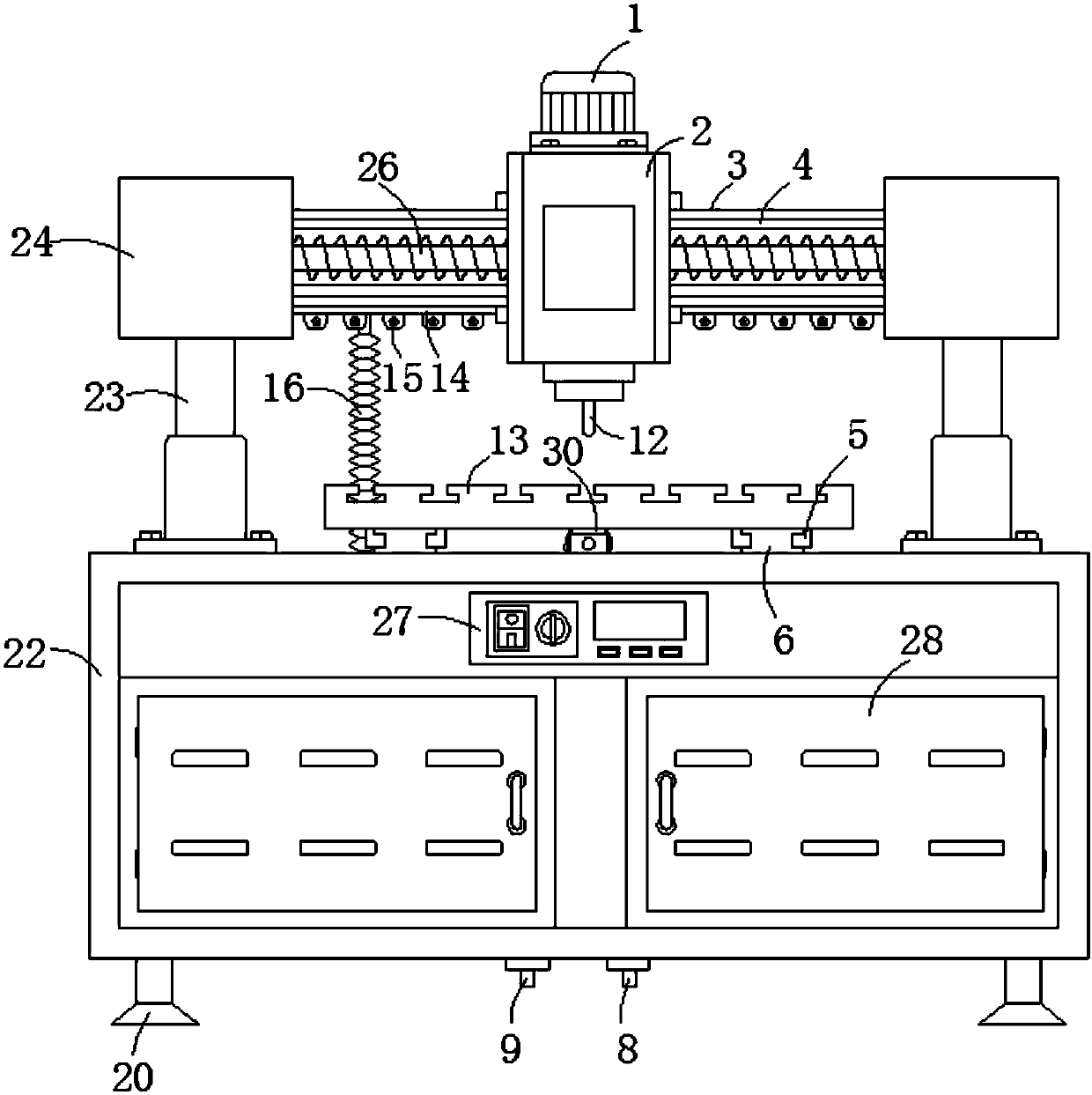

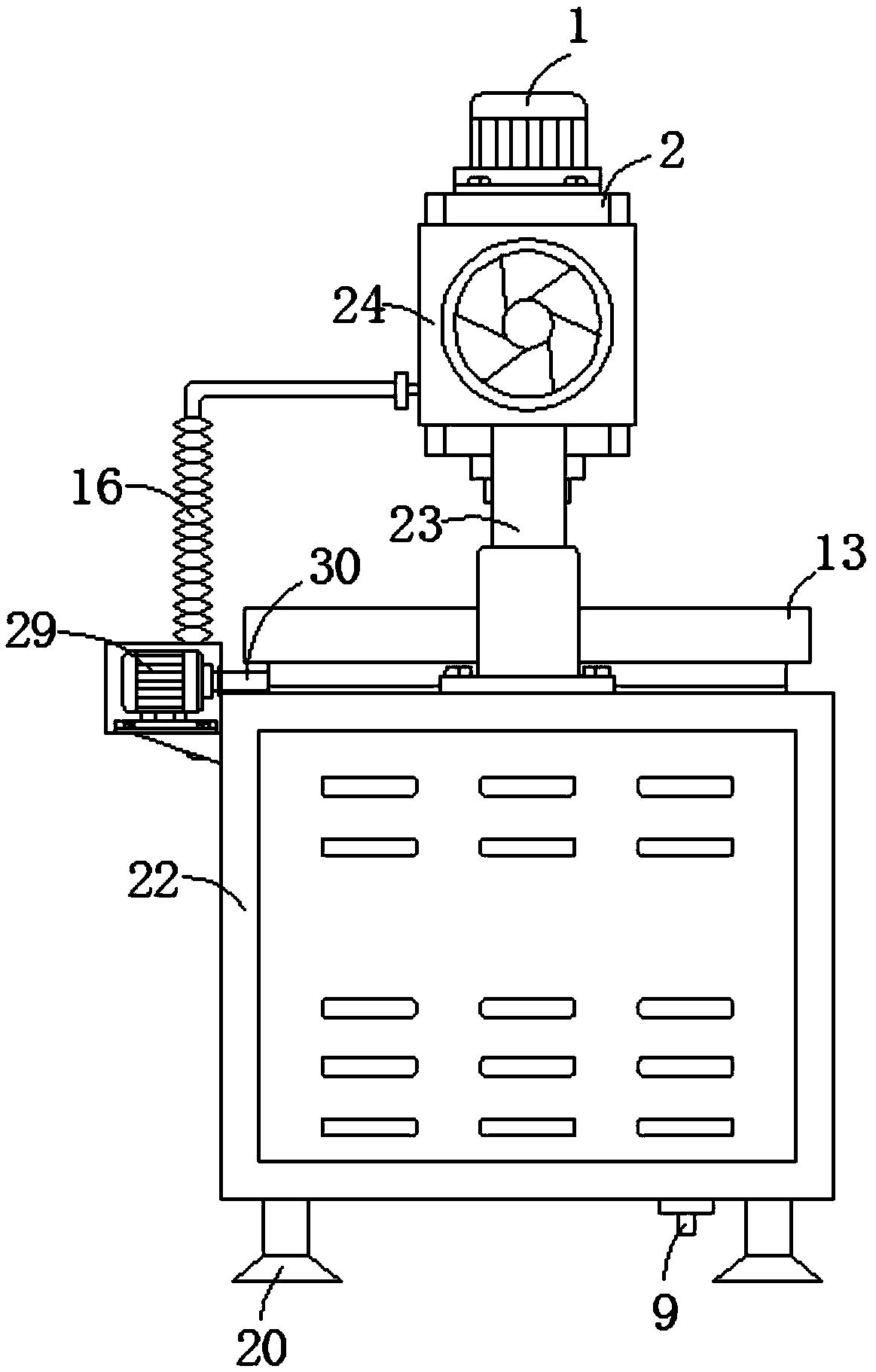

Numerically-controlled slot broaching device for furniture board processing

InactiveCN107718191AImprove air qualityAvoid noise pollutionWood mortising machinesBark-zones/chip/dust/waste removalSpray nozzleNoise pollution

The invention discloses a numerically controlled grooving device for furniture plate processing, which comprises a cabinet body. Two telescopic columns are symmetrically installed on the upper surface of the cabinet body through a mounting seat, and two sound-absorbing columns are symmetrically installed on both sides of the inner wall of the cabinet body. plate, the tops of the two telescopic columns are equipped with fixed seats, and a crossbeam is connected between the two fixed seats, the middle position of the crossbeam is installed with a headstock, and the bottom of the crossbeam is close to the two sides of the headstock There are two spray pipes symmetrically installed at the center. The present invention sets a spray device composed of an atomizer, a spray pipe and a spray nozzle to realize the dust-free slotting operation of the equipment, prevent the dust from distributing in the air and cause air pollution, and improve the working environment. The air quality is improved, and the sound-absorbing board is installed to absorb the noise generated by the electrical equipment inside the chassis in real time, avoiding noise pollution, ensuring the physical and mental health of the workers, and improving the work efficiency of the workers.

Owner:安吉县创鸿家具有限公司

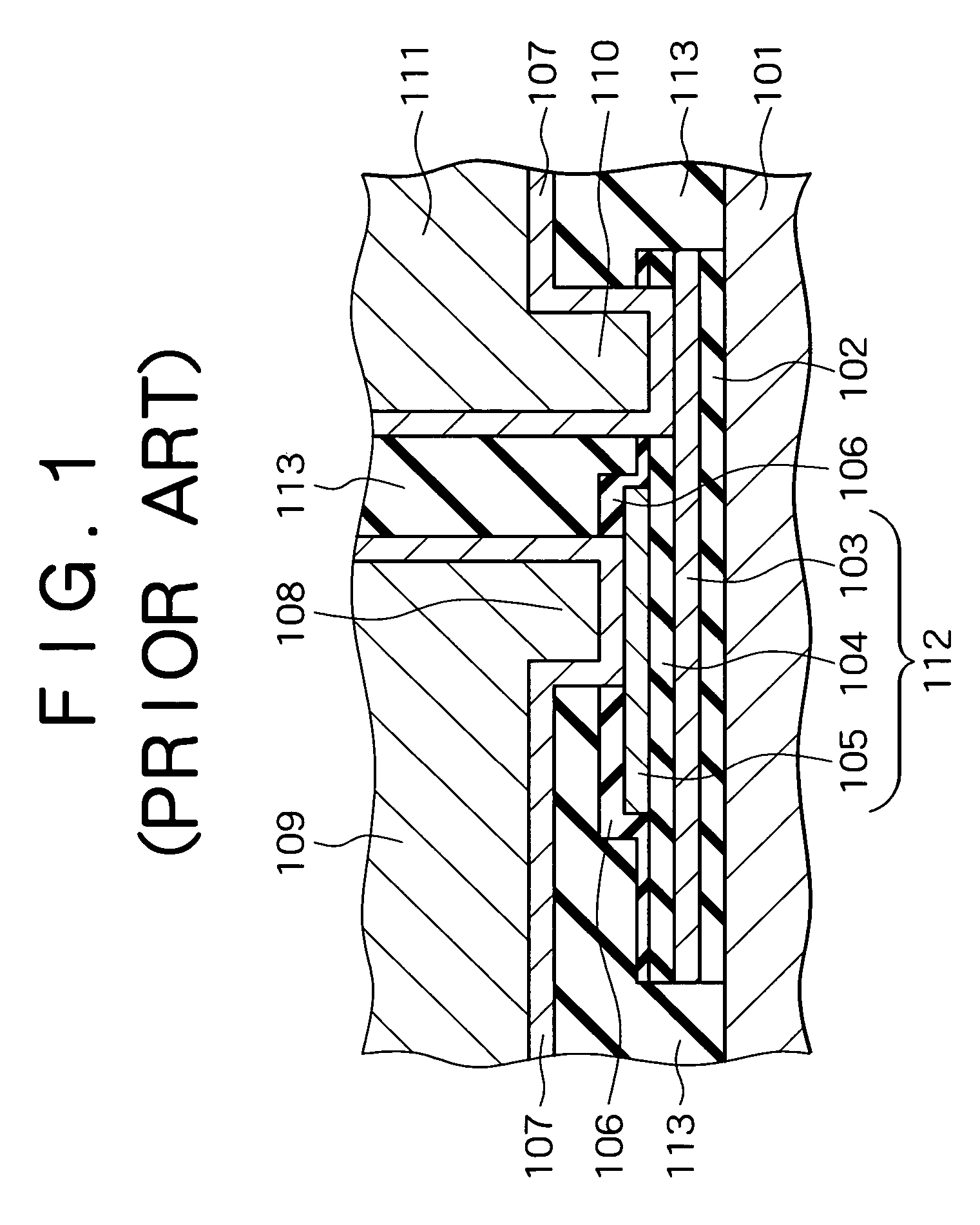

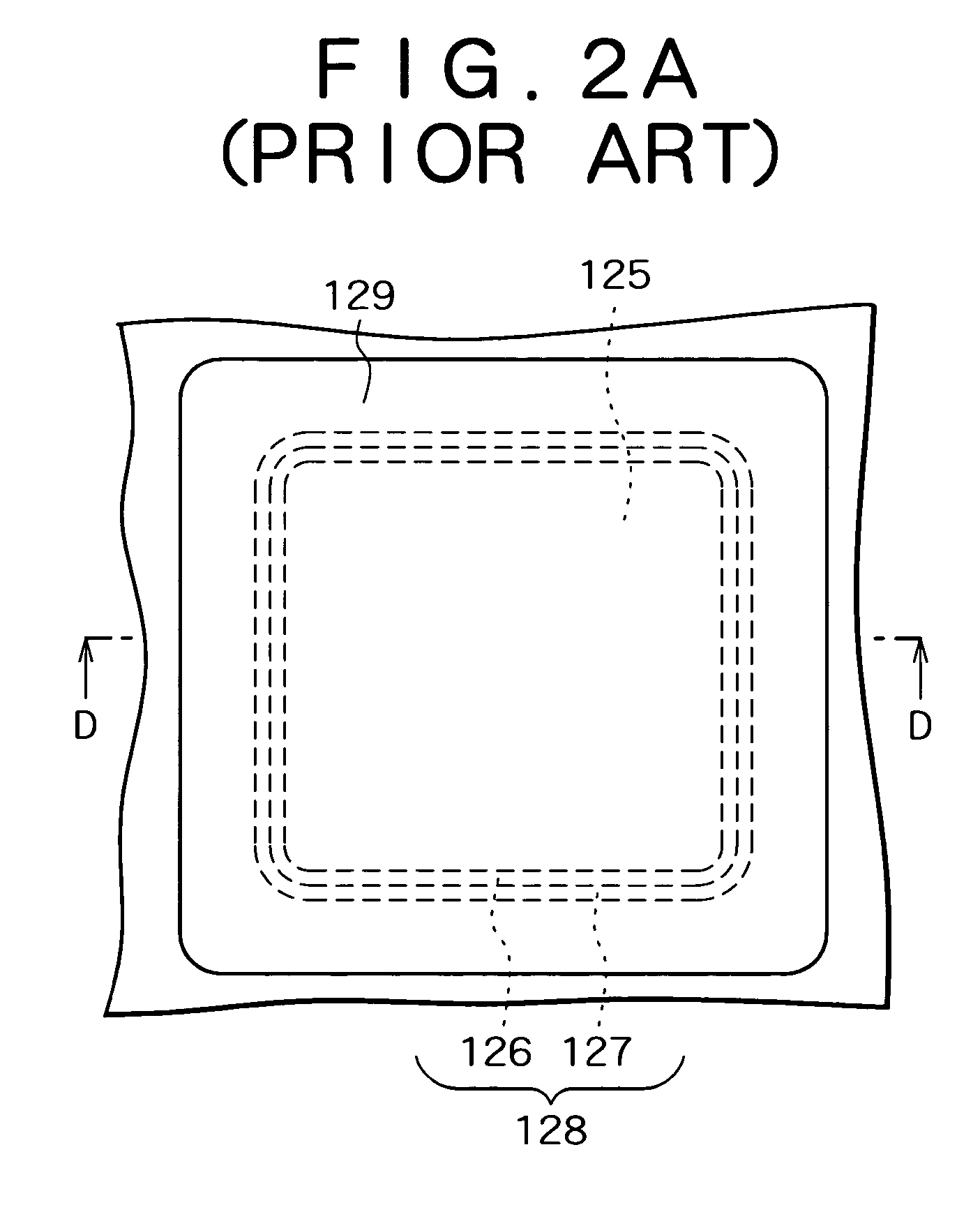

Semiconductor device with wiring layers forming a capacitor

ActiveUS7095072B2Capacitance valueLarge caliberTransistorSemiconductor/solid-state device detailsCapacitorSemiconductor

A semiconductor device, in which four pieces of strip-shaped electrodes, whose longitudinal directions are the same, are formed in each layer of a plurality of wiring layers that are provided by a same design rule with each other, simultaneously with regular wirings. In each wiring layer, two pieces each of first electrode and second electrode are formed parallelly with each other, alternately, and remote from each other. Then, the first electrodes formed in each layer are connected to each other by a first via, the second electrodes formed in each layer are connected to each other by a second via, a first structure body formed by connecting the first electrodes and the first via to each other is connected to a ground wiring, and a second structure body formed by connecting the second electrodes and the second via to each other is connected to a power source wiring.

Owner:RENESAS ELECTRONICS CORP

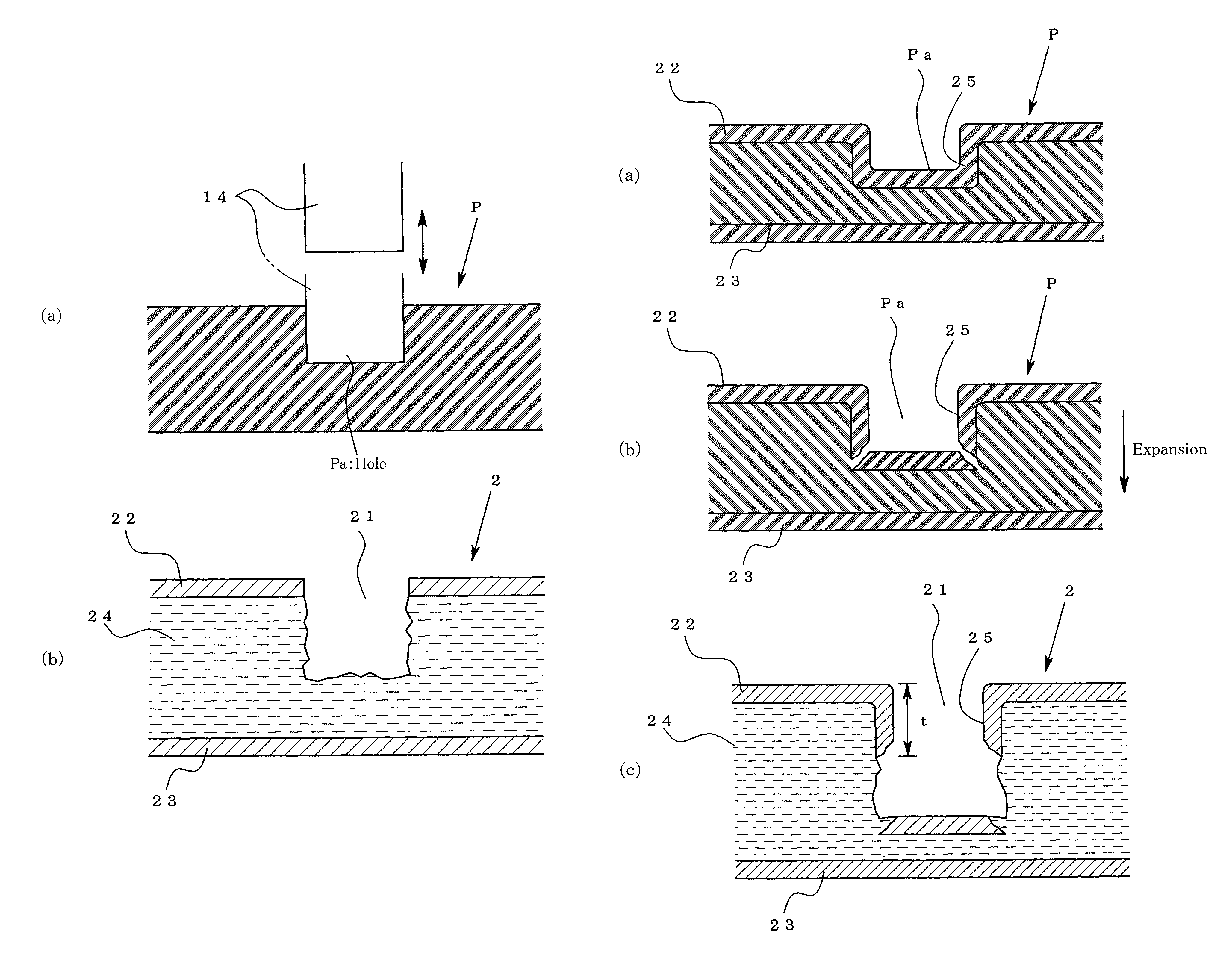

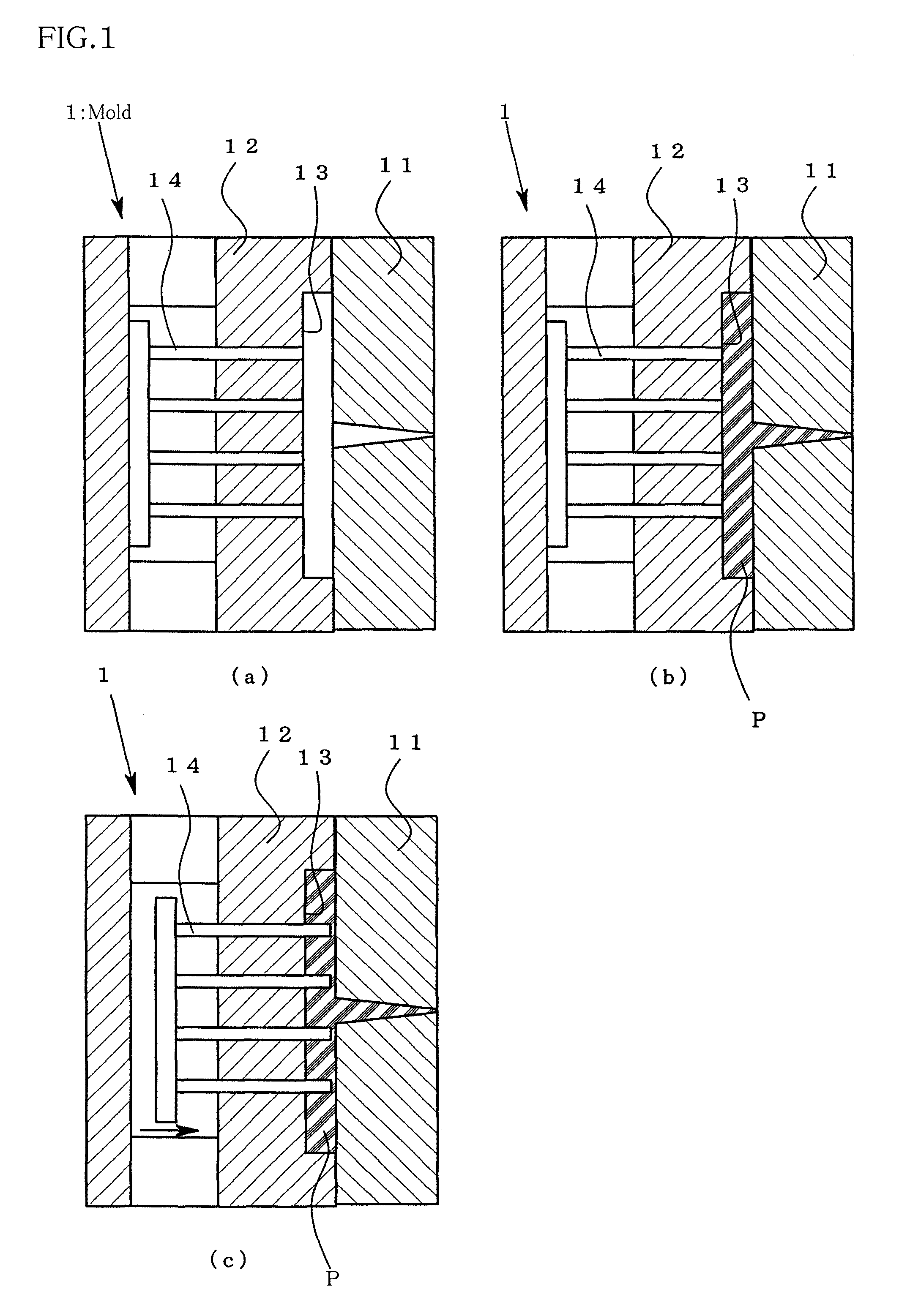

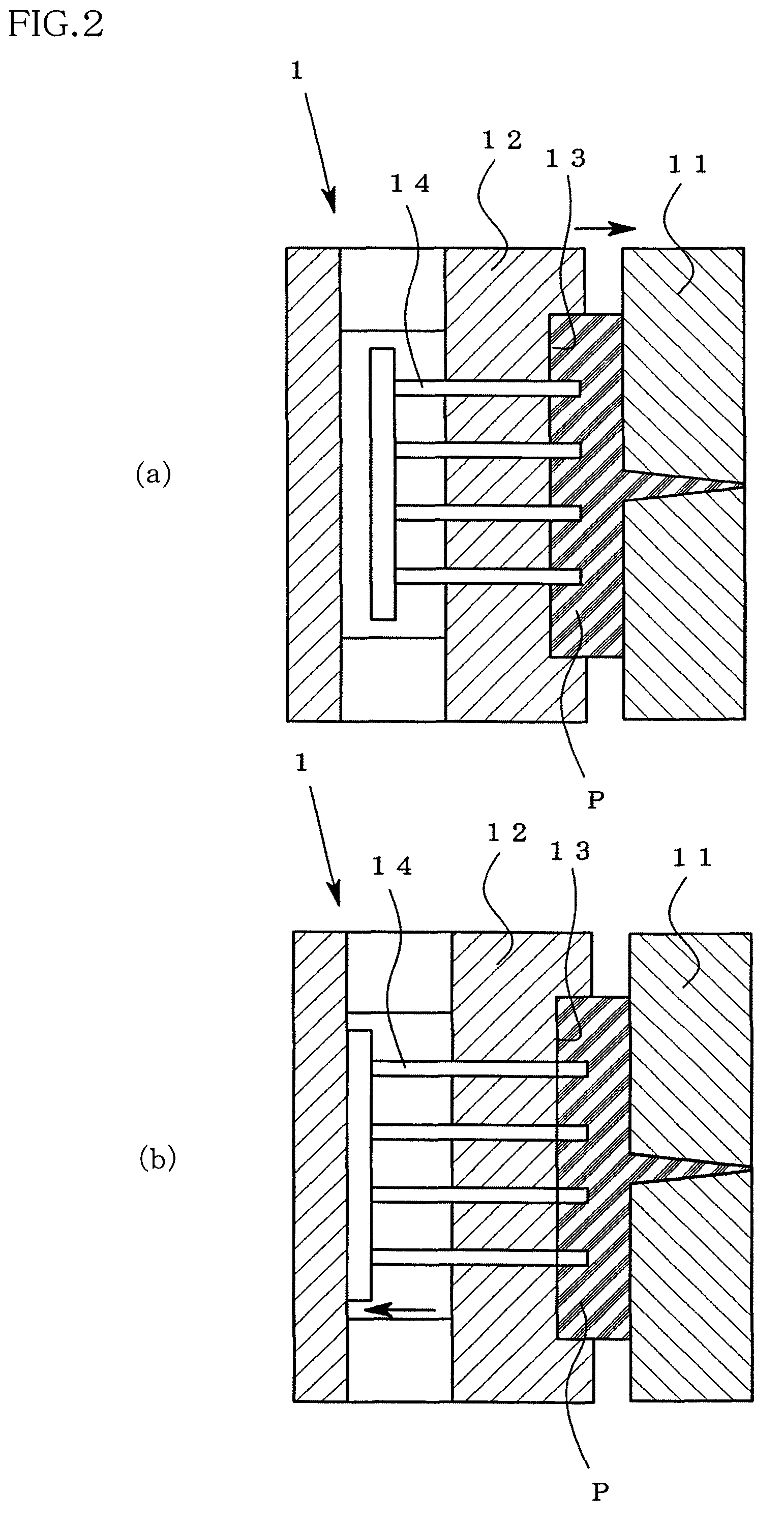

Process for producing sound absorber and produced by the process, sound absorber and sound absorbing structure

A process for producing a sound absorber having skin layers constituting front and back surfaces and, interposed between the skin layers, a void layer having a plurality of pin formed holes, each hole having a depth which is enough to penetrate one of the skin layers and is not enough to reach the other skin layer. The sound absorber is formed of a resin material containing 2 to 60 wt % of reinforcing fibers with a length of 2 to 100 mm.

Owner:PRIME POLYMER CO LTD +1

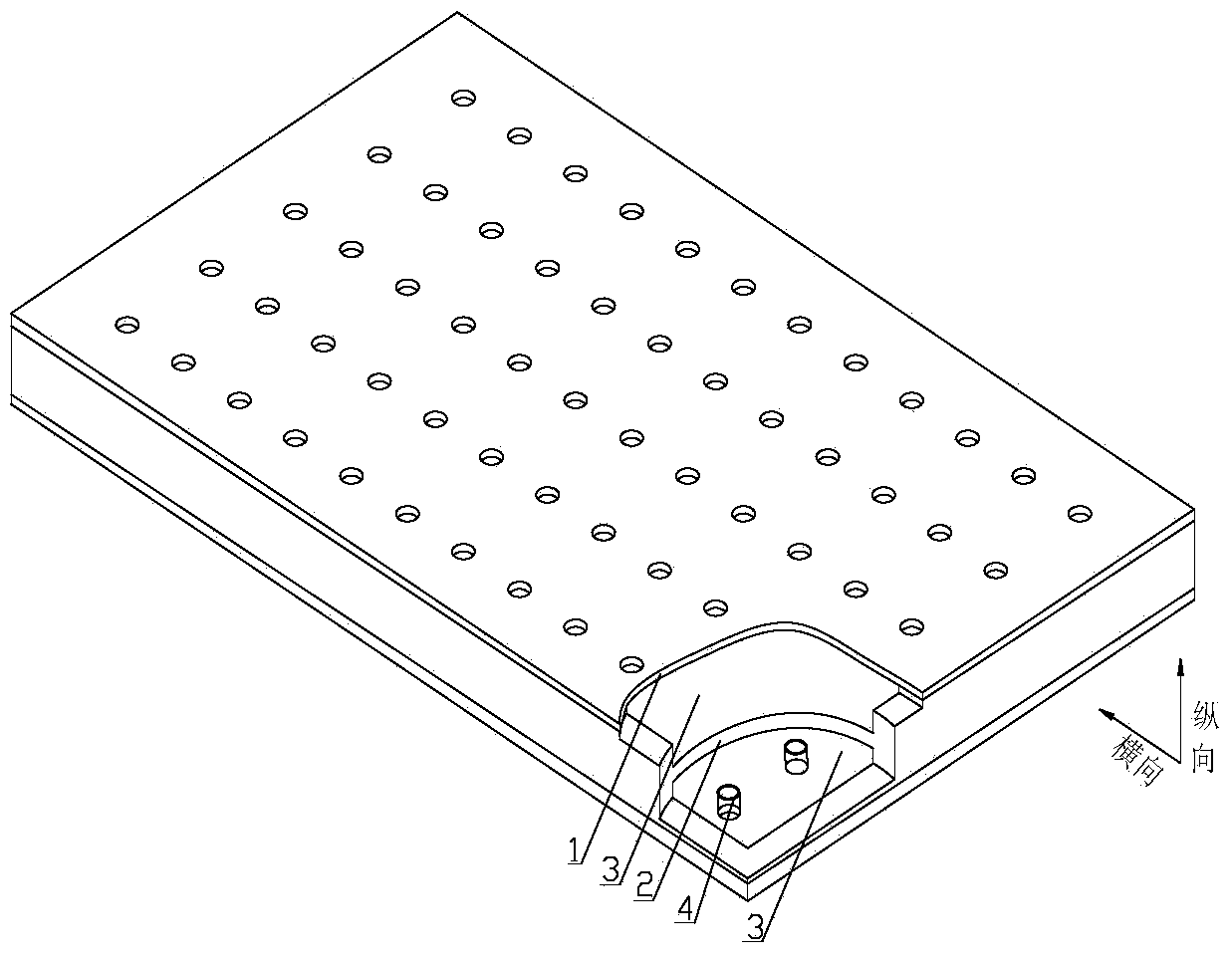

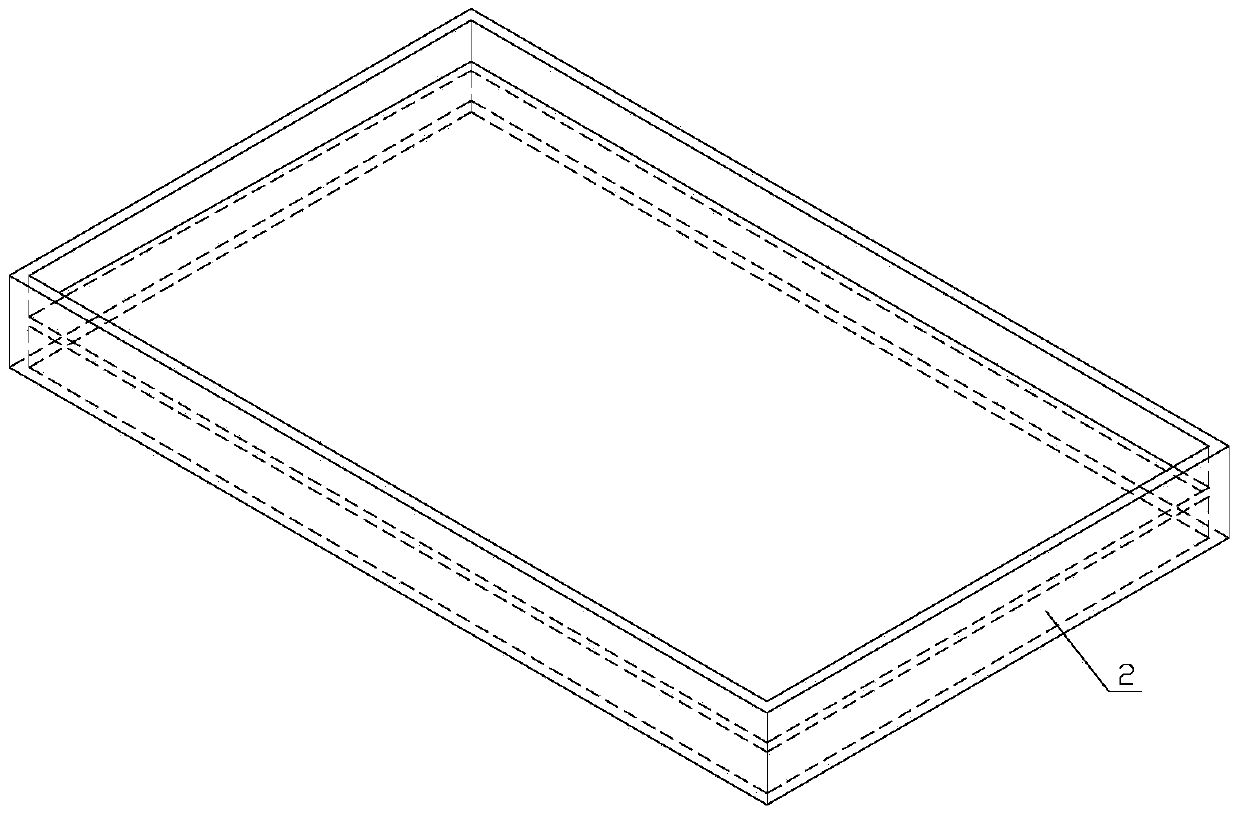

Design method, structure and application of perforated sound absorber inside waste heat boiler

ActiveCN103968362AReduce consumptionAccurate and efficient calculationSteam boilersSteam boilers componentsSound AbsorberEngineering

The invention discloses a design method, structure and application of a perforated sound absorber inside a waste heat boiler. The perforated sound absorber comprises two perforated plates 1 and a liner plate 2. The two perforated plates 1 are attached to the two sides of the liner plate 2 respectively; the two sides, tightly attached to the perforated plates 1, of the linear plate 2 are respectively of a groove type structure, so that sound absorption cavities 3 are formed between the perforated plates 1 and the linear plate 2; liner pipes 4 are arranged in holes in the perforated plates 1. According to the perforated sound absorber inside the waste heat boiler, the perforated plates are provided with the liner pipes and the small holes, the problem that a traditional multi-hole sound absorber material is prone to blocking is effectively solved, the resonance absorber is formed by the sound absorption cavities formed by the perforated plates and the linear plate, noise produced inside the waste heat boiler can be effectively absorbed, and a part of the noise can be reflected to a noise source.

Owner:HUADIAN HEAVY IND CO LTD

Structure for and method of fixing elastic resin sheet

InactiveUS20070215264A1Eliminate depressionPromote meltingLaminationLamination apparatusEngineeringSynthetic resin

A structure is disclosed for fixing an elastic resin sheet on a base member made of a synthetic resin so that the base member is covered with the elastic resin sheet. The structure includes a welding protrusion formed so as to protrude from a part covered with the elastic resin sheet in the base member. The welding protrusion has a distal end face to which the elastic resin sheet is vibration-welded.

Owner:PACIFIC INDUSTRIAL CO LTD

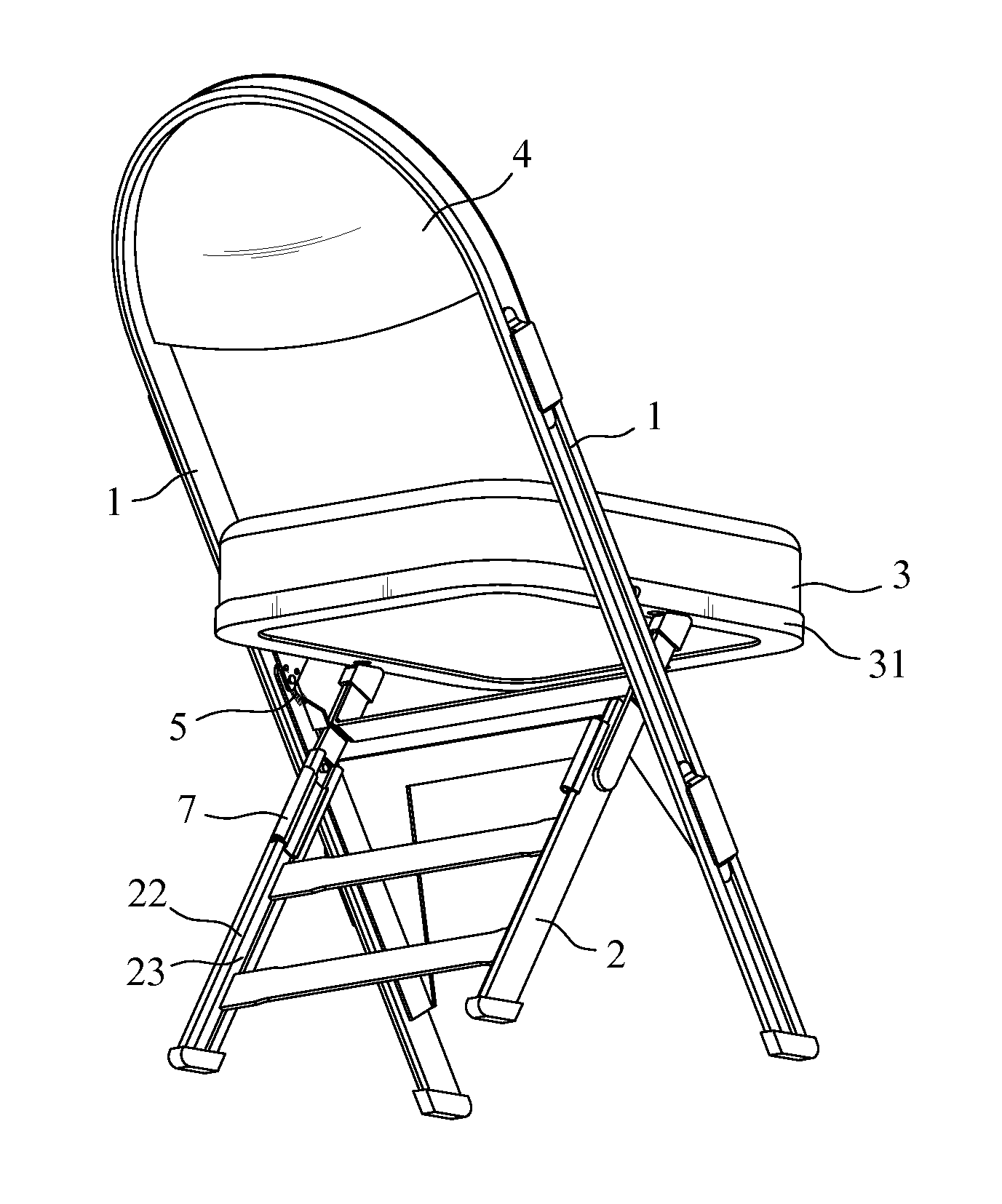

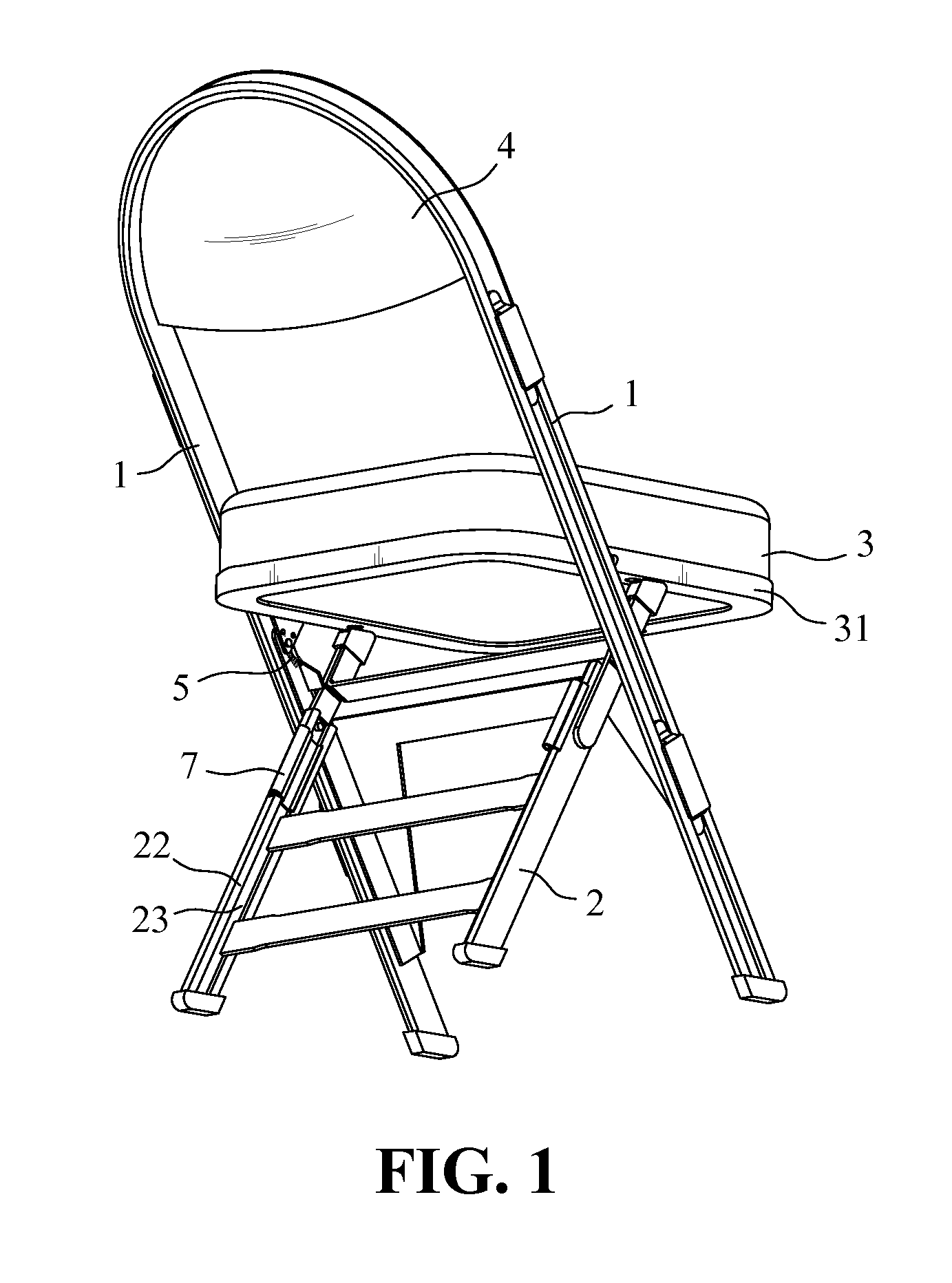

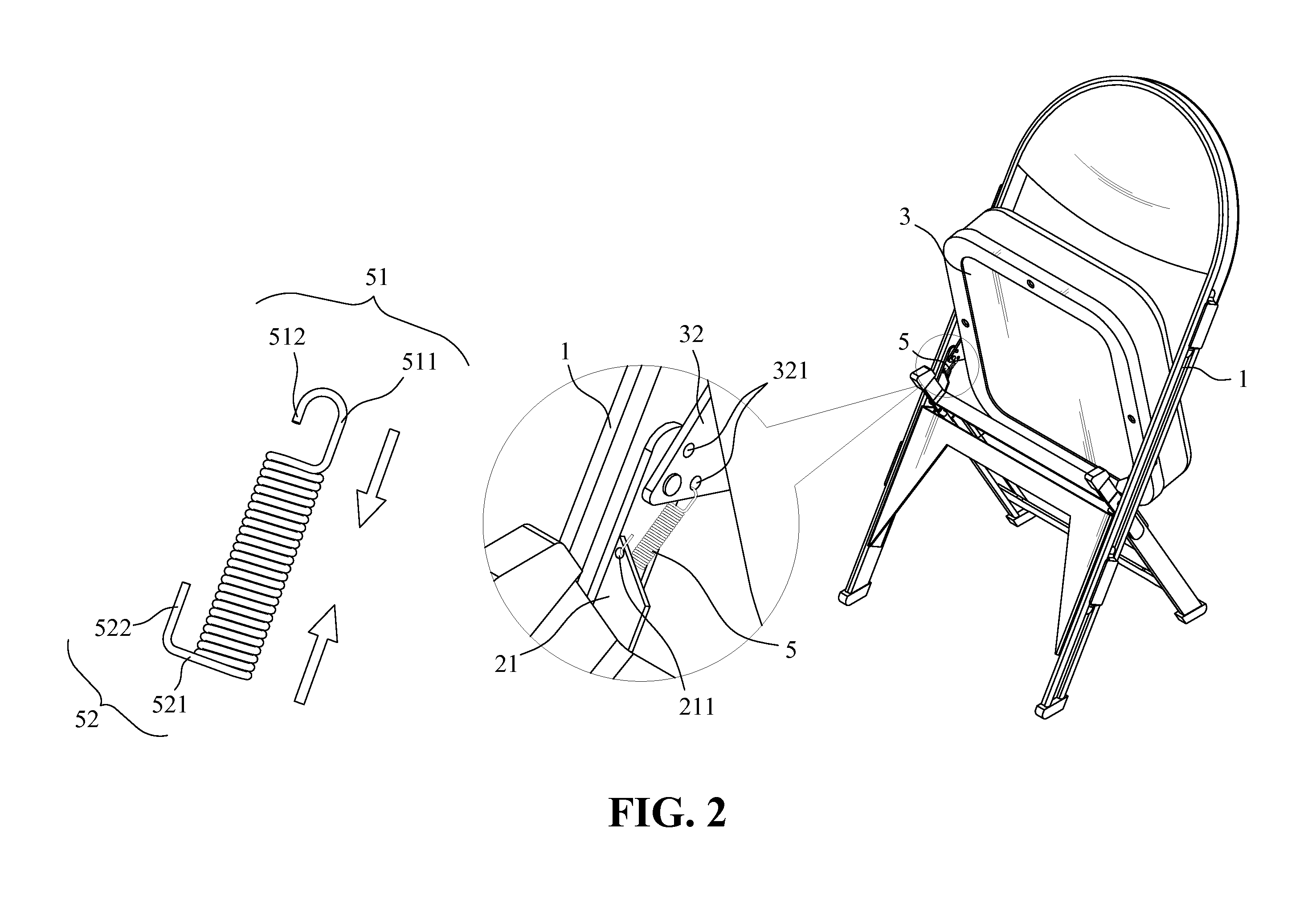

Mechanism for self folding up and cushing a seat of portable chair

A portable chair has a mechanism for self folding up and cushioning a seat. The mechanism includes a tension spring assembled between a seat frame and a rear leg for collapsing the seat, and a cushioning pad affixed on the rear leg. The tension spring has first and second hook elements disposed on different orientations and engaged with holes. The hook elements are easy to install, and reduce the risk of disengagement after assembly. The length of the spring is substantially equal to the length of the space in which it is assembled, so that it is not excessively stretched during assembly, thereby preventing spring fatigue. The cushioning pad is integrally formed and includes retainer and insert portions through which it is affixed with the rear leg, and a cushion portion that can absorb noise and vibration when the seat is collapsed.

Owner:SPEC SEATS TECH

Compound semiconductor switching circuit device

InactiveUS7358788B2Absorb noiseAvoid oscillationTransistorSuperconductors/hyperconductorsCapacitorCompound semiconductor

Protecting elements are respectively connected between a control terminal Ctl and a ground terminal GND of a logic circuit L, between a point Cp and a ground terminal GND, and between a power supply terminal VDD and a ground terminal GND thereof. With this, an E-FET, constituting an inverter 70, and capacitors Ci and Cr can be protected from electrostatic breakdown due to external static electricity. Since the protecting element can be constituted by requisite components for the logic circuit, an additional step or structure is not especially required to provide the protecting element.

Owner:SEMICON COMPONENTS IND LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com