Design method, structure and application of perforated sound absorber inside waste heat boiler

A technology of waste heat boiler and design method, which is applied to the components of steam boilers, steam boilers, steam boiler accessories, etc., and can solve the problems of high cost, general noise reduction effect, and inability to find out the noise of waste heat boilers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

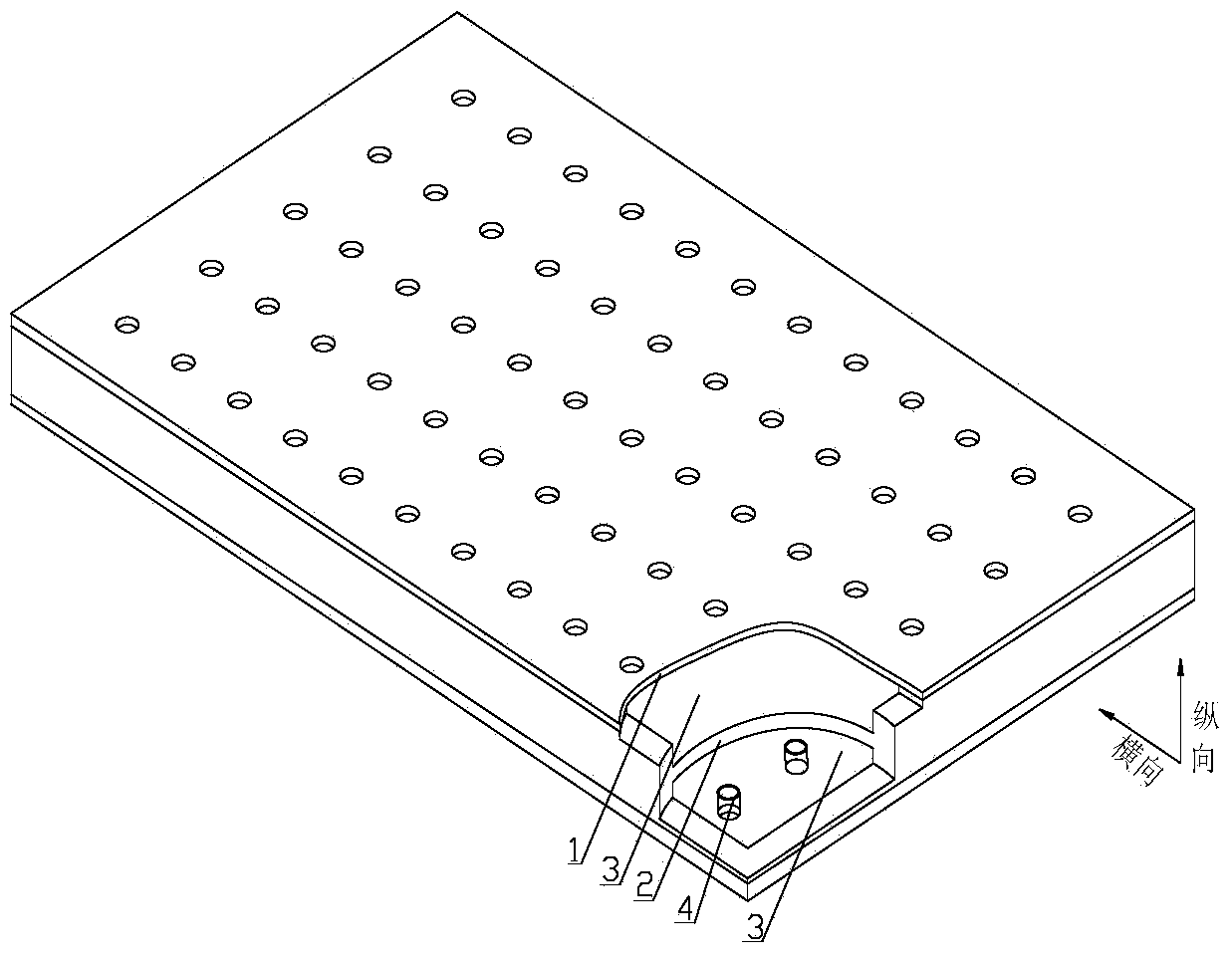

[0057] Embodiment 1 of the present invention: the design method of the perforated sound absorbing body used inside the waste heat boiler, such as Figure 1 ~ Figure 3 shown, including the following steps:

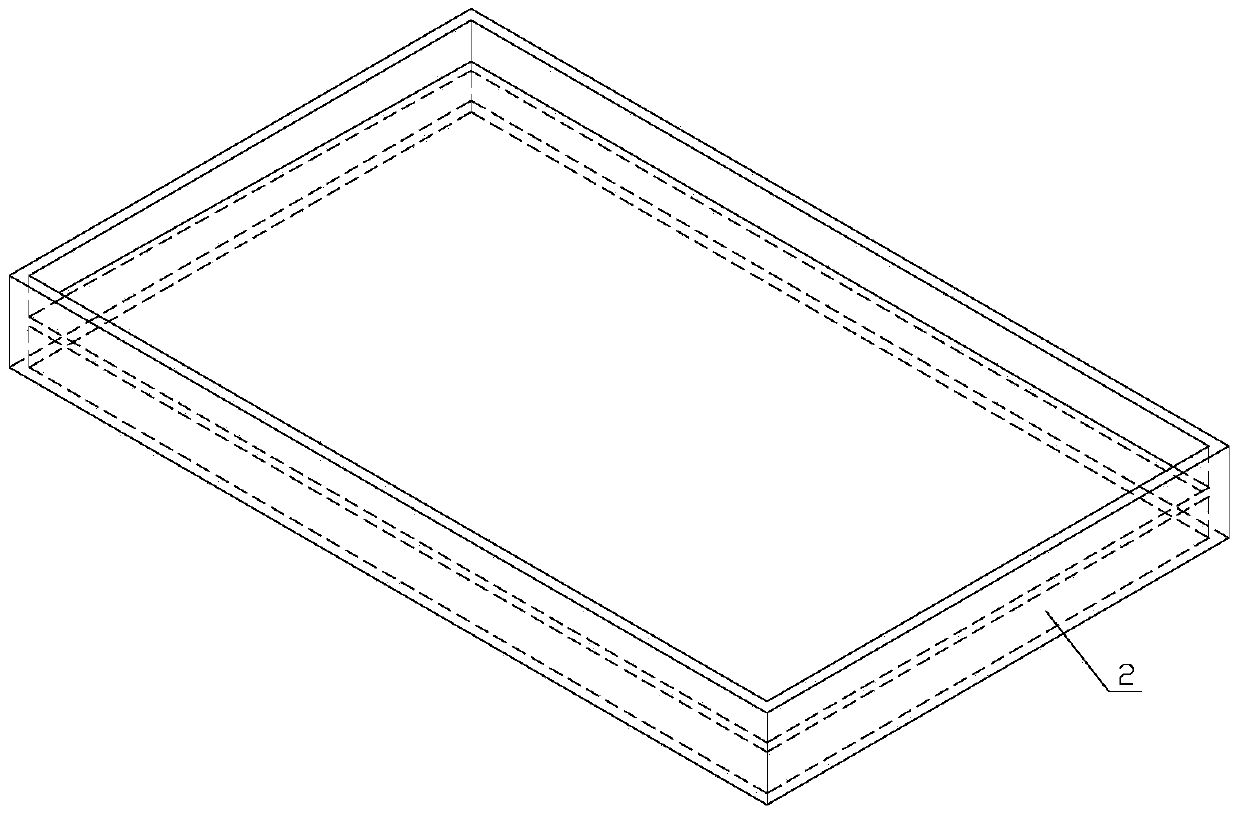

[0058] a. Two perforated plates 1 and one liner 2 are provided, and the two perforated plates 1 are attached to both sides of the liner 2 respectively; A rectangular sound-absorbing cavity 3 is formed between 1 and the liner 2; an inner liner 4 with a thickness of 1mm is added to the perforated part of the perforated plate to obtain a perforated sound-absorbing body;

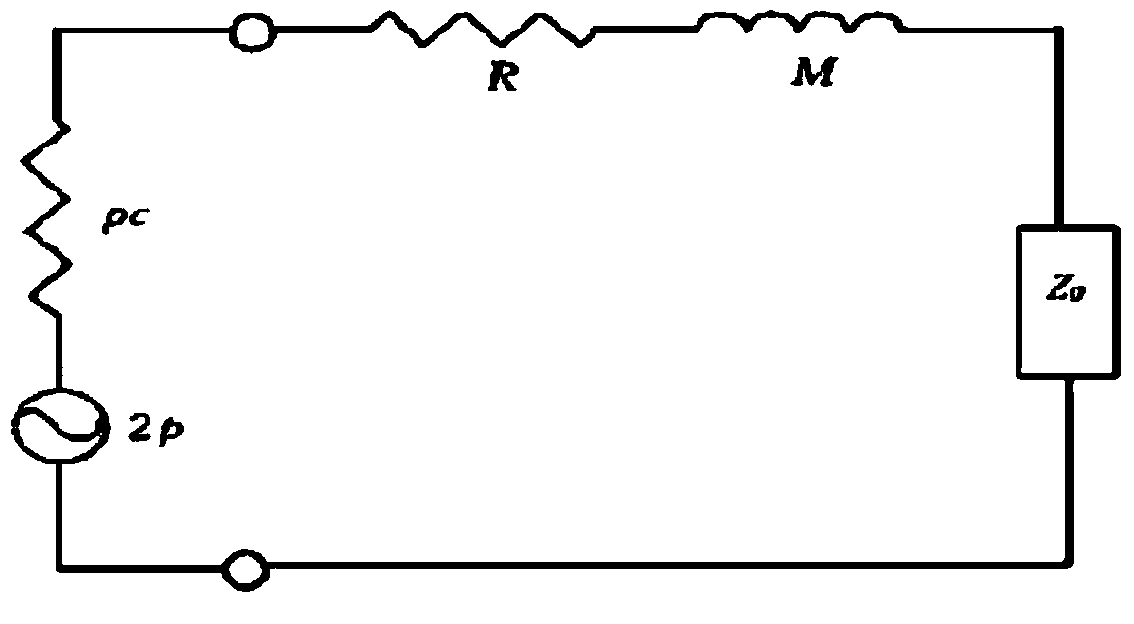

[0059] b. According to the principle of acoustic-electric analogy, construct the equivalent circuit when the sound wave is vertically incident on the perforated sound-absorbing body;

[0060] c. Match and calculate the relative acoustic impedance rate of the perforated plate and the sound-absorbing cavity according to the noise characteristics; wherein, the relative acoustic impedance rate of the perforated ...

experiment example

[0069] Experimental example: The perforated sound-absorbing body used in the waste heat boiler of the present invention is composed of a perforated plate with a large number of small holes and a sound-absorbing cavity formed by the lining plate. It is a resonant sound-absorbing body, which can be regarded as having Acoustic elements of acoustic resistance and reactance, constructed as figure 1 As shown, the equivalent circuit is as image 3 as shown, image 3 Among them, R and M are the sound resistance and sound quality of the perforated plate respectively, and Z D is the sound capacity of the sound-absorbing cavity behind the plate, the acoustic impedance rate of the perforated plate is R+jwM, and the acoustic impedance rate of the sound-absorbing cavity is Z S空腔 , the sound source is the incident sound wave, according to Thevenin's law, the equivalent sound source is the sound pressure and internal impedance of the open circuit (the flow is zero, that is, in front of the ...

Embodiment 2

[0102] Example 2: Identification of Noise Sources

[0103] Due to the coupling of flow, heat, and sound in the furnace, the tube array itself is composed of finned tubes with spiral fins, and its geometric characteristics are complex. The resources required for complete modeling and calculation are too large, so the analysis model is made as follows Simplifications and assumptions:

[0104] 1. According to the relationship between the components of the flue gas, use the gas state equation to calculate the physical characteristics of the flue gas, and find that the difference between its various indicators and air is not more than 5%, and use air instead of flue gas in the calculation;

[0105] 2. Since the heat exchange process itself does not generate noise, it only indirectly affects the physical properties of the flue gas, so the heat exchange between the furnace wall and the pipe wall during the flue gas flow is not considered, and the thermodynamic parameters of the flue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Vertical depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com