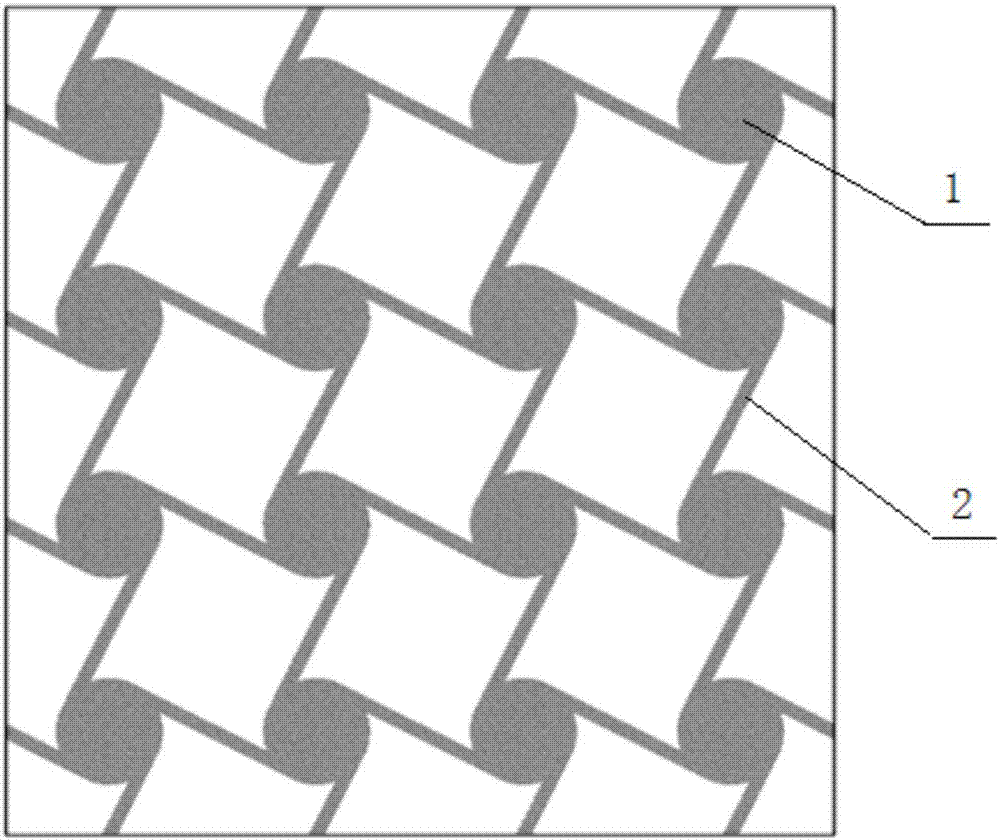

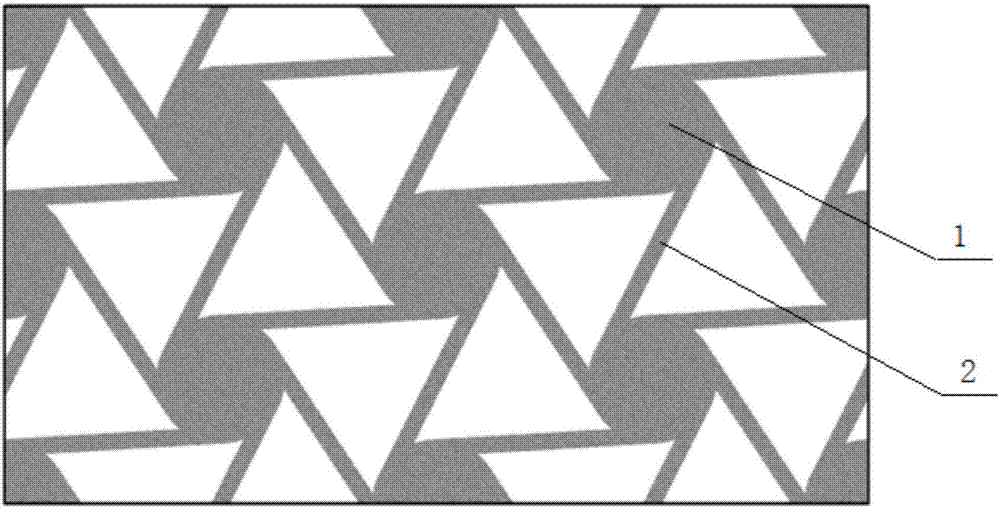

Metal glass metamaterial with chiral microstructure

A metal glass and microstructure technology, applied in the field of metamaterials, can solve the problem of poor plastic deformation ability of metal glass at room temperature, and achieve the effects of precise thermal forming ability, high elasticity, and improved mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Below at first principle of the present invention and working process are described as follows:

[0027] The invention combines the excellent mechanical properties of the metallic glass with the characteristics of the chiral structure itself, thereby improving the ability of the structure to withstand large deformation and large loads, and ultimately achieve the goals of sound absorption, energy absorption, and vibration reduction. Due to the high elasticity and high strength of metallic glass, the deformation limit and load bearing limit of metallic glass structural parts are several orders of magnitude larger than those of traditional alloys. And thanks to the ultra-high elastic limit of metallic glass, after unloading, as long as the degree of deformation does not reach the elastic limit, the structural part can quickly retu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com