Easy assembling and disassembling type rattan bed

a rattan bed and easy-to-assemble technology, applied in the field of beds, can solve the problems of reducing air permeability, generating a larger noise when used, and bed is not firm or durable enough, so as to improve the service life of the bed, improve the service life, and be reasonable in structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment i

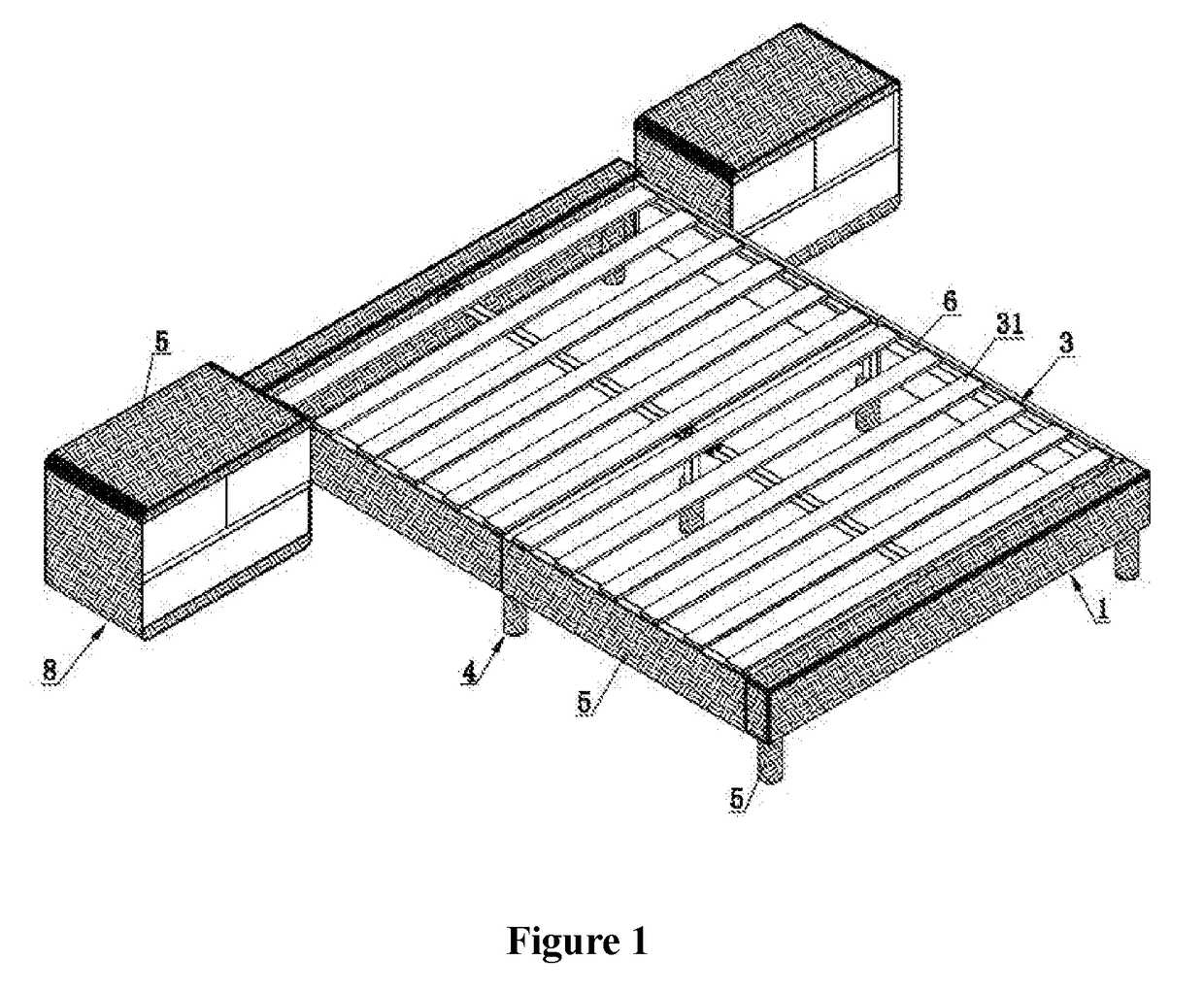

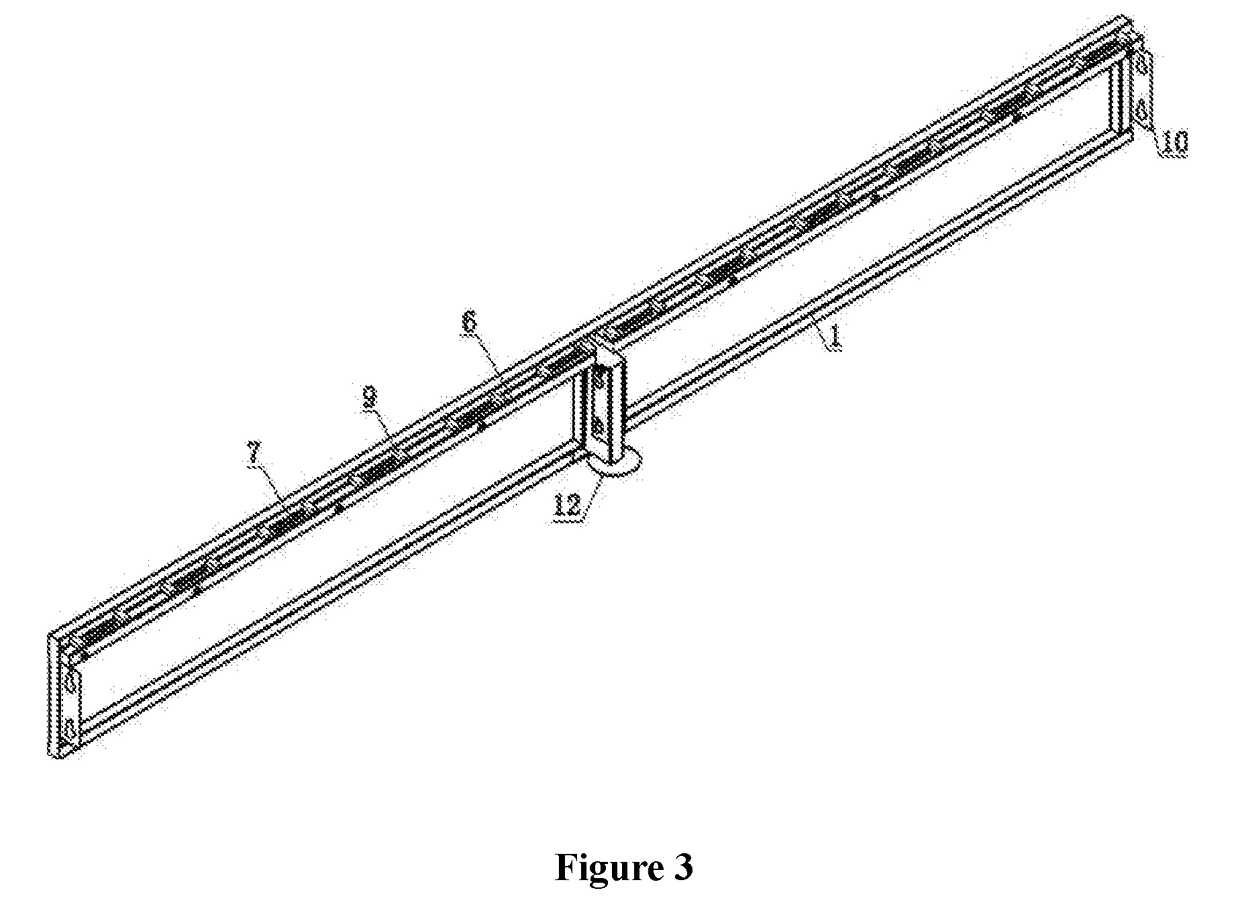

[0028]With reference to FIG. 1, FIG. 7, FIG. 8 and FIG. 9, an easy assembling and disassembling type rattan bed is provided, comprising six support frame boards 1, a detachable bedstead 2, a bed board 3 and a plurality of support legs 4. The six support frame boards 1, having rattan panels 5 covered on all outer surfaces thereof, are successively and detachably connected to each other end to end, with two being arranged on the left side, two being arranged on the right sides and one being respectively arranged on the front and rear sides. The rattan panel 5 is woven by a plurality of vertical rattans 51 arranged alternately and a plurality of horizontal rattans 52 which successively and alternately move up and down from one side of the well-arranged vertical rattans 51; the adjacent two horizontal rattans 52, which move up and down through the plurality of vertical rattans 51 in the reverse order, are arranged alternately. The six support frame boards 1 are successively connected en...

embodiment ii

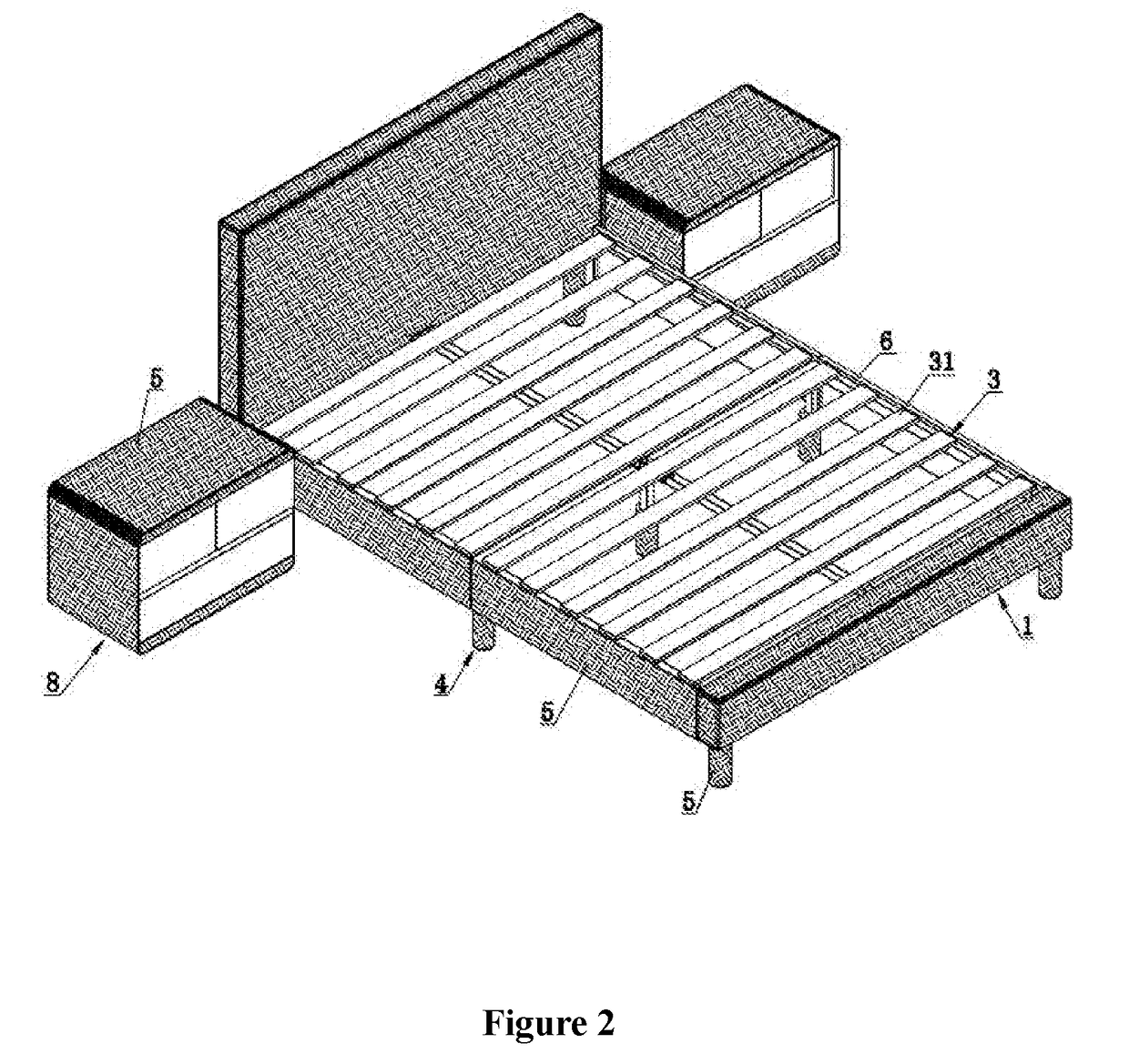

[0036]With reference to FIG. 2, FIG. 6 and FIG. 9, the preferred embodiments of this Embodiment are substantially the same as those of the Embodiment I, in which the differences are as follows: a backrest 14 covered with the rattan panels 15 is connected to an upper portion of the support frame board 1 on the rear side, and an accommodating chamber 15, configured to accommodate the support frame boards 1, the bedstead 2, the bed board 3 and the support legs 4, is arranged on a rear side face of the backrest 14. A piece of non-woven fabrics 16, configured to cover a chamber opening of the accommodating chamber 15, is also arranged on the rear side face of the backrest 14 and is provided with Velcro sub-tapes 18 which are adapted to Velcro master tapes 17 arranged on the periphery of the rear side face of the backrest 14. The human body can effectively rest against the backrest 14, and the accommodating chamber 15 is able to effectively accommodate the cross rod 22, the vertical rod, ...

embodiment iii

[0037]With reference to FIG. 4 and FIG. 5, the preferred embodiments of this Embodiment are substantially the same as those of the Embodiment II, in which the differences are as follows: the bed board 3 comprises a plurality of support boards 31; the plurality of rattan panels 31, left and right ends of which are placed on the top surfaces of the corresponding support bars respectively 6, are arranged closely and successively from front to back. The bed board 3 comprises a plurality of support boards 31, so that such arrangement is conducive to improving the sleeping comfort. At the same time, the air permeability and stability of the bed board can also be improved, so that the sleeping of the user is more relaxed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com