Phase change temp controlling super magneto strictive extension microshifting actuator

A giant magnetostrictive and magnetostrictive rod technology, which is applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of magnetostrictive rod heating, etc. Achieve the effect of suppressing thermal elongation, simple driving power supply, and good output linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

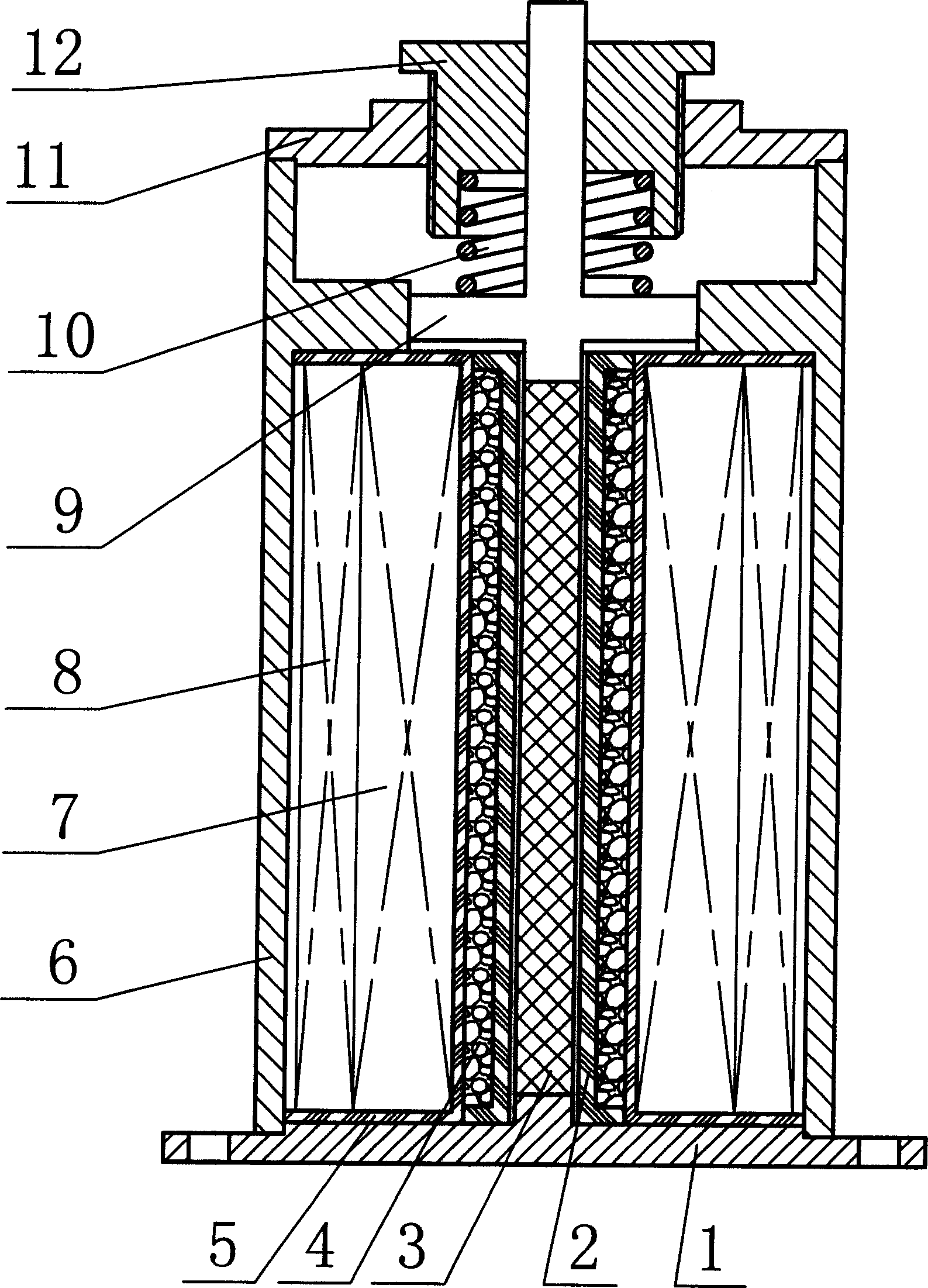

[0016] As shown in the drawings, the present invention includes a base 1, a temperature control sleeve 2, a magnetostrictive rod 3, a phase change material 4, a coil frame 5, a casing 6, a drive coil 7, a bias coil 8, an output push rod 9, Preload spring 10, upper end cover 11, preload nut 12. A magnetostrictive rod 3 is installed on the central small boss of the base 1, and a phase change temperature control device composed of a sleeve 2 and a phase change material 4 is installed outside the magnetostrictive rod 3. The coil skeleton 5 outside the phase change temperature control device is A drive coil 7 and a bias coil 8 are arranged sequentially from inside to outside. The joint between the temperature control sleeve 2 and the coil frame 5 is sealed, and a closed cavity containing phase change material is formed inside. The bias coil 8 is equipped with a shell 6, and the upper end of the magnetostrictive rod 3 is equipped with an output push rod 9, and the bosses on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com