Chemical reaction equipment used for material preparation

A chemical reaction and equipment technology, applied in the field of chemical reaction equipment for material preparation, can solve the problems of affecting material preparation efficiency, inconvenient equipment cleaning, slow stirring efficiency, etc., to shorten the preparation time, avoid poor heat preservation, and improve the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

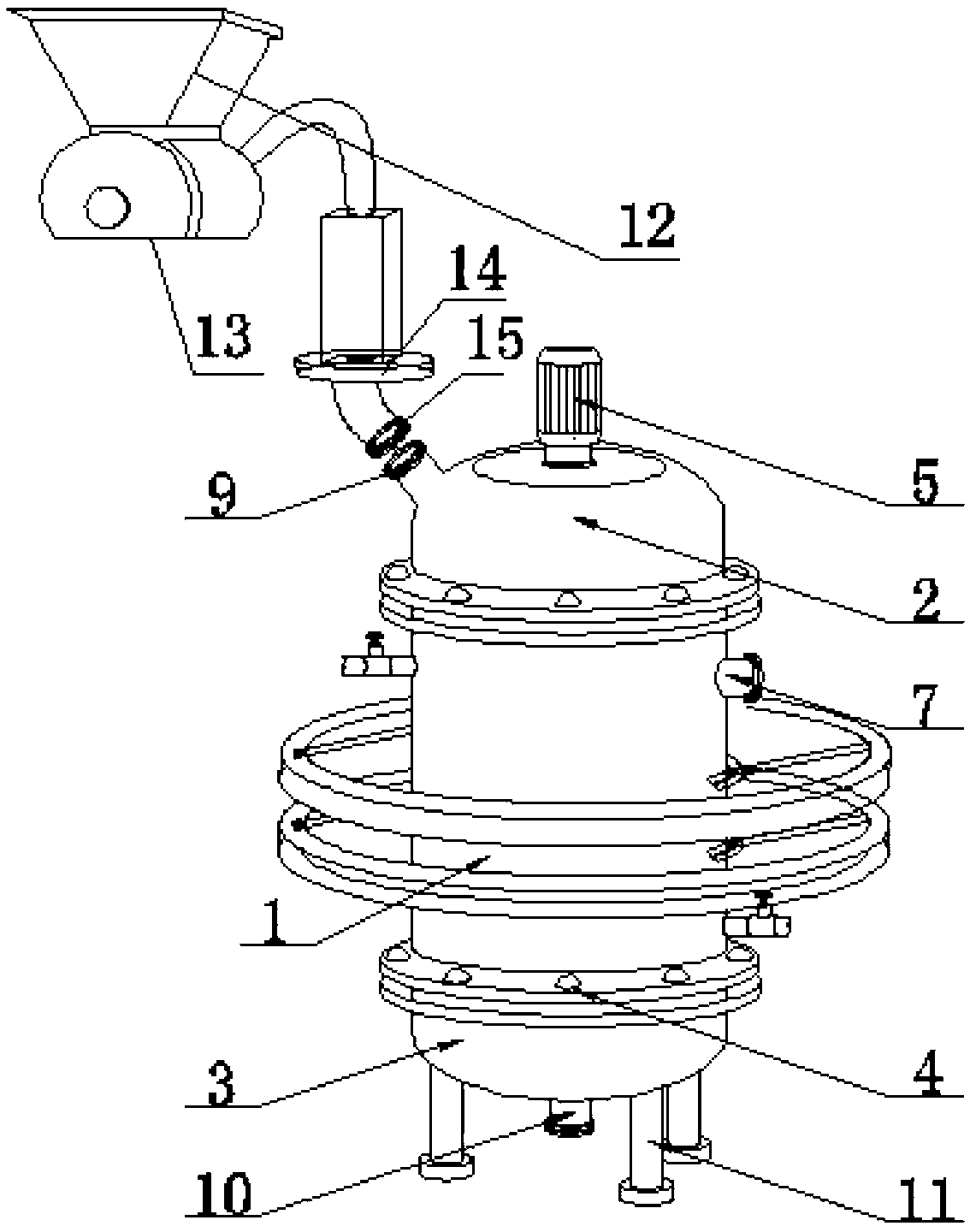

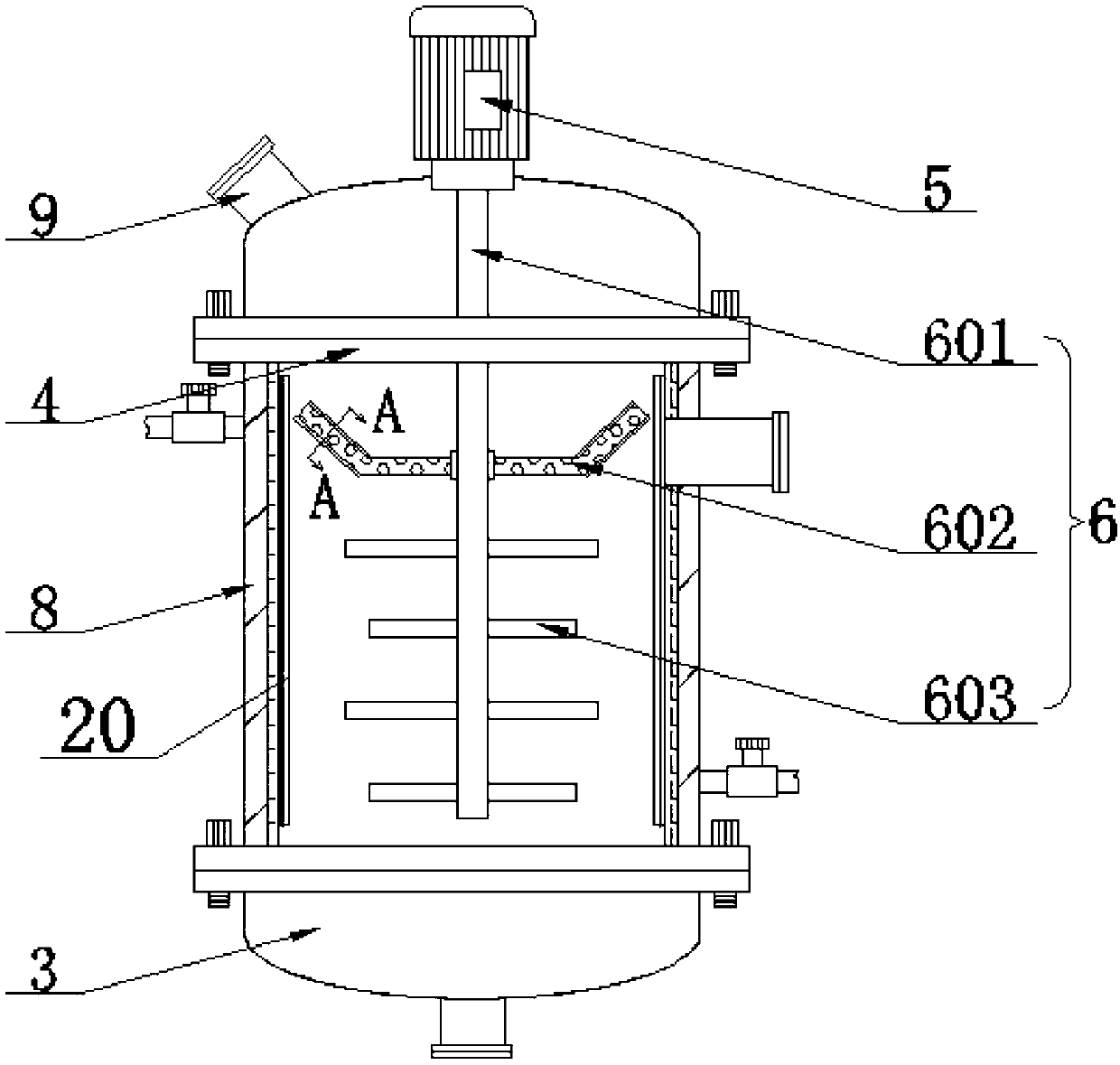

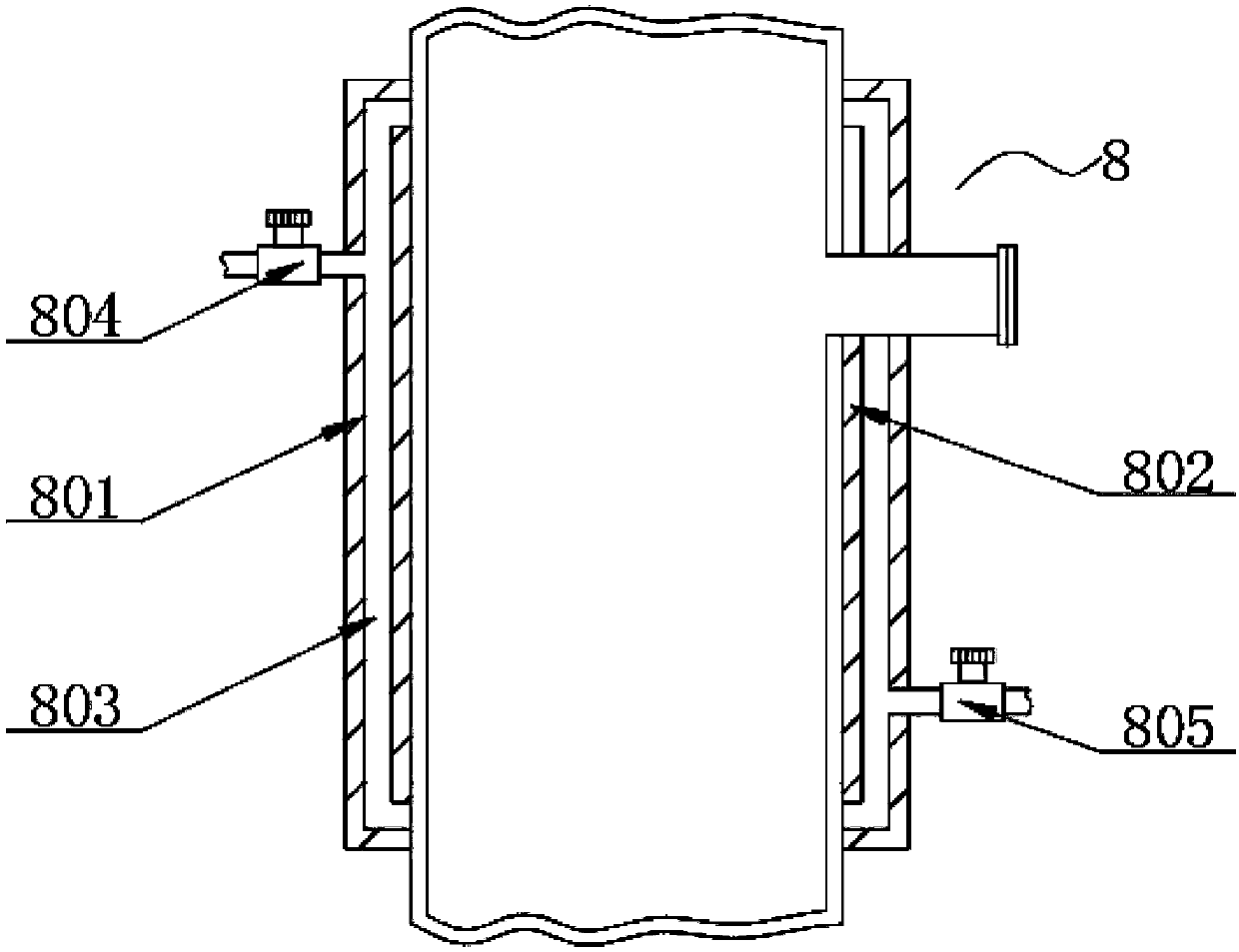

[0033] see Figure 1-7 , in an embodiment of the present invention, a chemical reaction equipment for material preparation, including a reaction kettle, a preheating feeding assembly, a stirring assembly and a cleaning assembly, wherein the reaction kettle is a split-type detachable structure, in order to facilitate the feeding and discharging of the equipment , the feed port 9 of the reactor is detachably connected to the preheating feeding assembly;

[0034] A stirring assembly is provided in the reaction kettle, and the stirring assembly includes a stirring plate 602 arranged on a stirring shaft 601 and a plurality of stirring paddles 603, wherein the stirring plate 602 is located above the stirring paddle 603;

[0035] The stirring plate 602 includes a vertical section and an inclined section vertically connected to the stirring shaft, the inclined section is integrally arranged on both sides of the vertical section, and both the vertical section and the inclined section i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com