Oil-water separator for compressed air and heatless regeneration type compressed air dryer

An oil-water separator and compressed air technology, applied in separation methods, dispersed particle separation, gas treatment, etc., can solve the problems of increased maintenance workload, wear of pneumatic equipment, complex structure, etc., and achieve simple structure, cost reduction, and drying effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

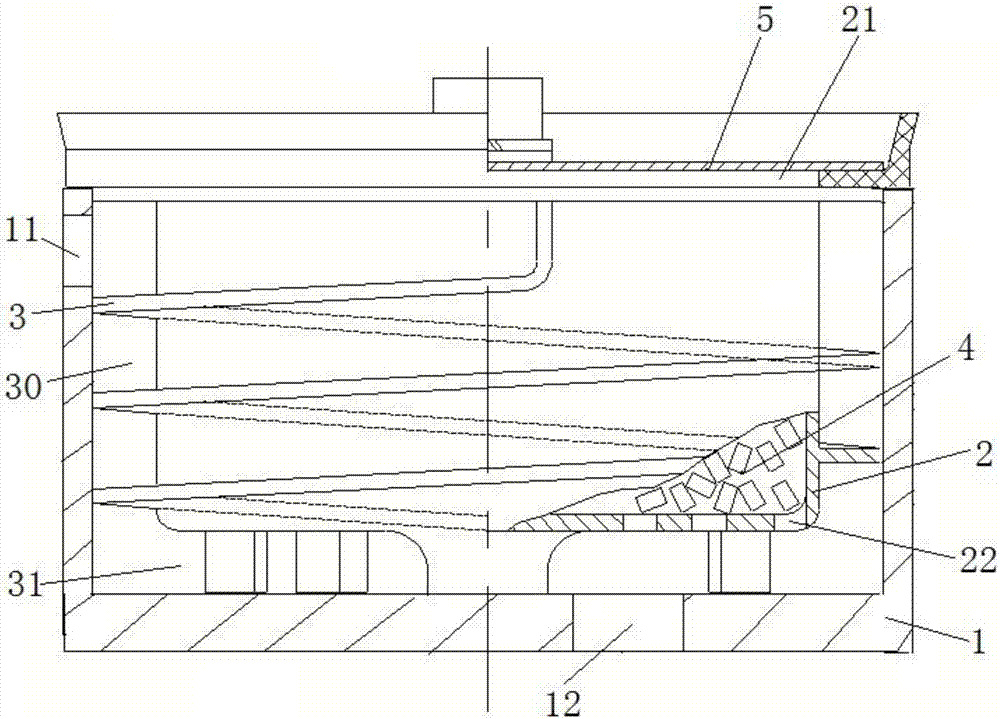

[0033] see figure 1 The oil-water separator for compressed air includes an outer shell 1 and an inner shell 2. The outer shell is arranged on the periphery of the inner shell, and the height of the outer bottom surface of the inner shell is higher than the inner bottom surface of the outer shell. The gas enters or exits the entrance 21 and the entrance 2 22. A guide bar 3 in a spiral structure is arranged between the inner wall of the outer shell and the outer wall of the inner shell. The guide bar 3 of the spiral structure forms a spiral between the outer shell and the inner shell. The upper part of the outer casing is provided with a connection port 11, one end of the connection port 1 is used to directly or indirectly connect compressed air, the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com