Method for preparing agricultural plastic mulching film special for arachis hypogaea from automotive sound-absorbing cotton leftover waste material

A technology of agricultural mulch and scraps, which is applied in botany equipment and methods, applications, plant protection, etc., can solve the problems of waste of high-performance sound-absorbing materials, large amount of scraps of resources, and high recycling costs, so as to improve the efficiency of light Utilization rate, saving resource consumption, and improving the effect of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

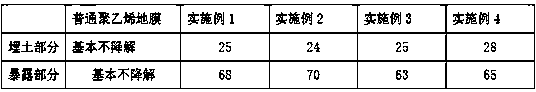

Embodiment 1

[0075] The method for preparing special agricultural mulch film for peanuts by using waste materials of sound-absorbing cotton for vehicles, including the following raw materials in parts by weight: 300 parts of waste materials for sound-absorbing cotton for vehicles, 35 parts of modified starch, 15 parts of peanut vine powder, and 20 parts of calcium carbonate 8 parts, 8 parts of polyethylene terephthalate, 5 parts of ethylene-acrylic acid copolymer, 5 parts of maleic anhydride, 2 parts of dicumyl peroxide, 5 parts of auxiliary agent;

[0076] The car sound-absorbing cotton is made of PET fiber and PP fiber as the main raw materials;

[0077] The peanut vine powder is 150 orders, and the calcium carbonate is nanometer calcium carbonate;

[0078] The auxiliary agent is an oxidation degradation agent, an antioxidant, an ultraviolet absorber, a lubricant, and a plasticizer, and the weight ratio is 1:2:1:3:5;

[0079] The oxidative degradation agent is titanium dioxide, the anti...

Embodiment 2

[0094] The method for preparing special agricultural mulch film for peanuts by using waste materials of sound-absorbing cotton for vehicles, including the following raw materials in parts by weight: 350 parts of waste materials for sound-absorbing cotton for vehicles, 45 parts of modified starch, 17 parts of peanut vine powder, and 30 parts of calcium carbonate Parts, 9 parts of polyethylene terephthalate, 7 parts of ethylene-acrylic acid copolymer, 6 parts of maleic anhydride, 3 parts of dicumyl peroxide, 7 parts of auxiliary agent;

[0095] The car sound-absorbing cotton is made of PET fiber and PP fiber as the main raw materials;

[0096] The peanut vine powder is 150 orders, and the calcium carbonate is nanometer calcium carbonate;

[0097] The auxiliary agent is an oxidation degradation agent, an antioxidant, an ultraviolet absorber, a lubricant, and a plasticizer, and the weight ratio is 1:2:1:3:5;

[0098] The oxidative degradation agent is iron oxide, the antioxidant ...

Embodiment 3

[0113] The method for preparing peanut special-purpose agricultural mulching film by using waste materials of sound-absorbing cotton for vehicles, including the following raw materials in parts by weight: 400 parts of waste materials for sound-absorbing cotton for vehicles, 50 parts of modified starch, 18 parts of peanut vine powder, and 35 parts of calcium carbonate 10 parts, 10 parts of polyethylene terephthalate, 7 parts of ethylene-acrylic acid copolymer, 7 parts of maleic anhydride, 3 parts of dicumyl peroxide, 8 parts of auxiliary agent;

[0114] The car sound-absorbing cotton is made of PET fiber and PP fiber as the main raw materials;

[0115] Described peanut vine powder is 200 orders, and described calcium carbonate is nano calcium carbonate;

[0116] The auxiliary agent is an oxidation degradation agent, an antioxidant, an ultraviolet absorber, a lubricant, and a plasticizer, and the weight ratio is 1:2:1:3:5;

[0117] The oxidative degradation agent is titanium di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com