Hydrophobic air purifying composite catalyst and preparing method thereof

A composite catalyst and air purification technology, which is applied in the fields of hydrophobic air purification composite catalyst and its preparation, air purification material and its modification preparation, can solve the problems of difficult operation and implementation, complicated activation method, etc., and achieves long service life and dispersion. The effect of good performance and simple modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

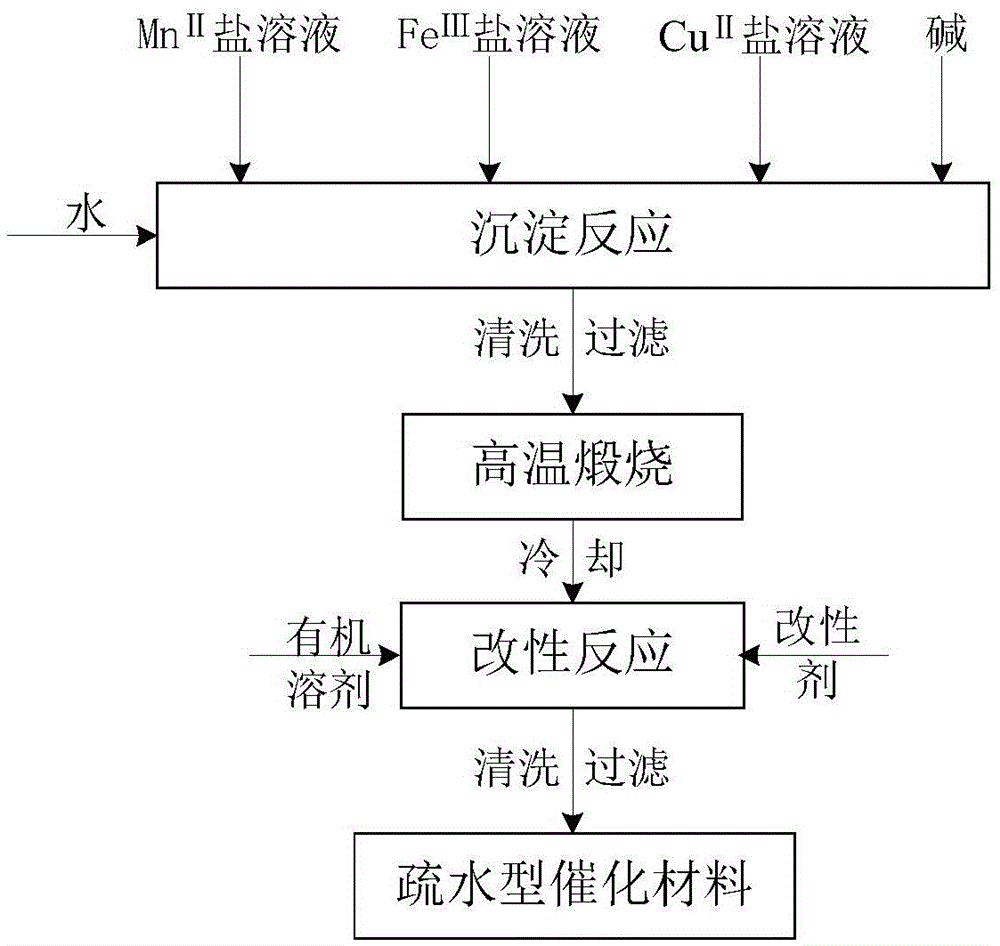

Method used

Image

Examples

Embodiment 1

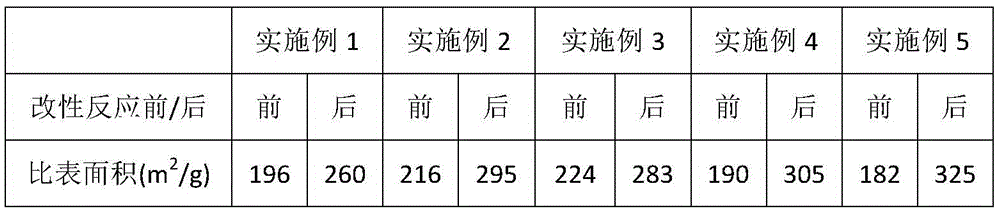

[0036] Add 27.875g of manganese sulfate tetrahydrate, 12.078g of copper nitrate trihydrate and 20.2g of ferric nitrate nonahydrate to 500mL of pure water in turn, stir well until they are completely dissolved, then add appropriate amount of sodium hydroxide to adjust the pH of the solution to 9, at room temperature After stirring and reacting for 20 hours, wash and suction filter to obtain the precursor filter residue for use; put the filter residue obtained above into a high-temperature furnace for roasting, set it in it for calcination at 200°C for 10 hours, cool down, and take it out quickly after cooling down to 80°C. Pour it into 300mL of absolute ethanol solution containing 20wt% octadecyltriethoxysilane, add a few drops of pure water, stir and react at 30°C for 30h, then wash with absolute ethanol, filter and dry to obtain Hydrophobic air purification composite catalyst.

[0037] The specific surface area (BET) test shows that the specific surface area of the synthesi...

Embodiment 2

[0040] Add 18.0g of manganese chloride tetrahydrate, 1.14g of copper sulfate pentahydrate and 4.78g of ferric sulfate hexahydrate into 500mL of pure water in sequence, stir well until completely dissolved, then add an appropriate amount of potassium hydroxide to adjust the pH of the solution to 7.5, at 0 After stirring and reacting at ℃ for 30 hours, wash and suction filter to obtain the precursor filter residue for use; put the filter residue obtained above into a high-temperature furnace for roasting, set it in it for calcination at 400°C for 1 hour, and then cool it down. After cooling down to 50°C, quickly Take it out and pour it into 300mL of absolute ethanol solution containing 30wt% dodecyltriethoxysilane, add a few drops of pure water, stir and react at 50°C for 15h, then wash with absolute ethanol, filter and dry , to obtain a hydrophobic air purification composite catalyst.

[0041] The specific surface area (BET) test shows that the specific surface area of the sy...

Embodiment 3

[0044] Add 28.7g of manganese nitrate hexahydrate, 1.71g of copper chloride dihydrate and 21.04g of ferric sulfate hexahydrate to 500mL of pure water in turn, stir well until completely dissolved, then add an appropriate amount of calcium hydroxide to adjust the pH of the solution to 11, at 90 Stir and react at ℃ for 1 hour, then wash and filter to obtain the precursor filter residue for use; put the filter residue obtained above into a high-temperature furnace for roasting, set it in it for calcination at 300°C for 6 hours, and then cool it down. After cooling down to 60°C, quickly Take it out and pour it into 300mL of absolute ethanol solution containing 10wt% tetradecyltriethoxysilane, add a few drops of pure water, stir and react at 75°C for 10h, then wash with absolute ethanol, filter and dry , to obtain a hydrophobic air purification composite catalyst.

[0045] The specific surface area (BET) test shows that the specific surface area of the synthesized hydrophobic air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com