Hybrid organic silicon-phosphorus type epoxy modifying agent used for copper clad laminate of printed circuit board, preparation method and application thereof

A technology of organosilicon and modifier, which is applied in the field of hybrid organosilicon-phosphorus epoxy modifier and its preparation, can solve the problems of brittleness, decreased heat resistance, poor heat resistance, etc., and achieve modification The effect of simple process, improved heat resistance, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

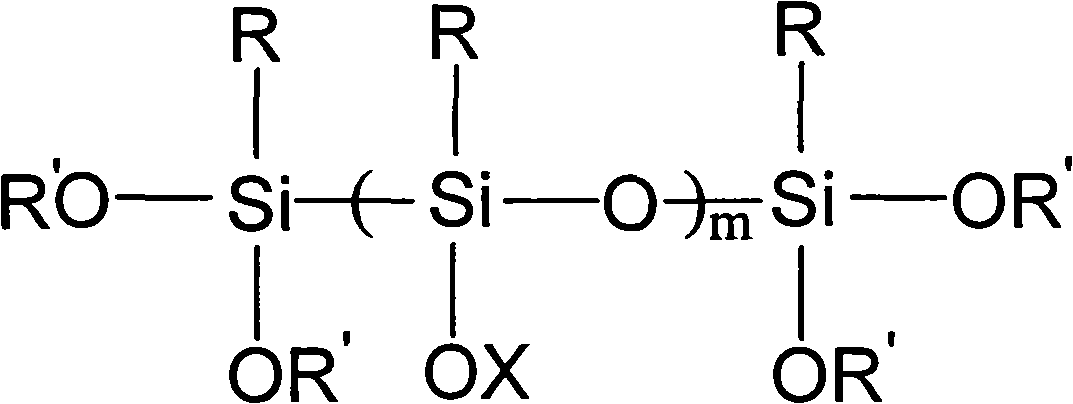

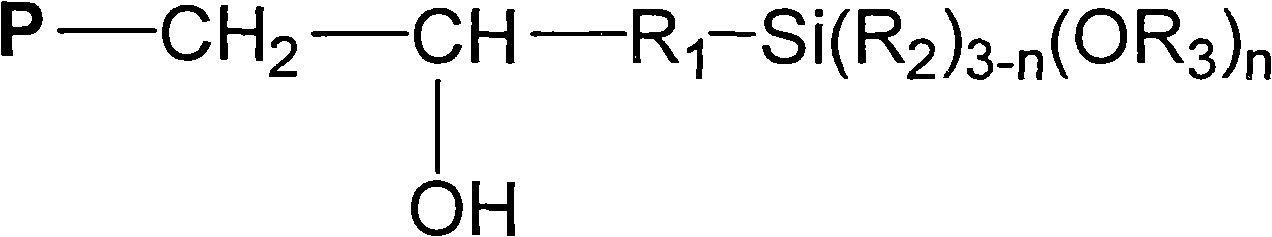

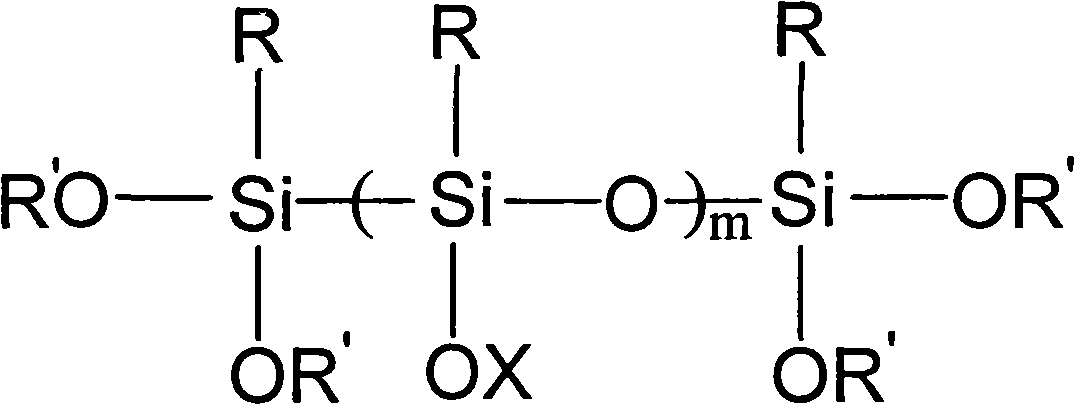

Method used

Image

Examples

Embodiment 1

[0036] Add 236g of glycidoxypropyltrimethylsilane, 138g of diethyl phosphite, and 2g of triphenylphosphine into a three-necked flask, stir it electrically, reflux at 150°C for 3h, and then cool to prepare a phosphorus-containing active agent.

[0037] Take another 200g of methyltriethoxysilane, 20g of deionized water, and 0.5g of dibutyltin dilaurate, stir, reflux and hydrolyze at 80°C for 8 hours, and remove small molecules of water after the reaction to obtain polymethyltriethyl triethyl Oxysilane.

[0038] Add 475g of phosphorus-containing active agent, 105g of polymethyltriethoxysilane, 18g of deionized water, and 2g of dibutyltin dilaurate into the reactor in sequence, stir, and reflux at 100°C for 6h, and cool to obtain the hybrid organic Silicon phosphorus epoxy modifier.

[0039] Take 100g of bisphenol A epoxy resin (E54) with an epoxy value of 0.54mol / g, add 25g of the above-mentioned modifier, stir evenly, and then vacuumize in a vacuum oven at 80°C for 1h, then add...

Embodiment 2

[0041]Add 22 g of methyl (γ-glycidoxy) diethoxysilane, 14 g of dimethyl phosphate, and 0.2 g of triethylamine into a three-necked flask, stir it electrically, and reflux at 120°C for 6 hours to obtain a phosphorus-containing Active agent; then add 10 g of commercially available polymethyltrimethoxysilane, 0.5 g of deionized water, and 0.2 g of tin tetrachloride, continue to stir, and reflux at 60 ° C for 8 hours, and cool to obtain a hybrid organosilicon phosphorus ring Oxygen modifier.

[0042] Take 10g of novolac epoxy with an epoxy value of 0.48mol / g, add 2.5g of the above-mentioned modifier, then add 6.3g of novolak resin and 0.2g of triphenylphosphine, stir well and vacuumize at 60°C for 2h, then Inject into the mold, keep the vacuum, 1h at 90°C, 2h at 150°C, 3h at 200°C. The Tg of the obtained epoxy cured product is 172.50°C, the limiting oxygen index (LOI) is 24.3, and the tensile strength is 51.93 MPa.

Embodiment 3

[0044] Glycidoxypropyltriethylsilane 260g, 10-oxygen-(9,10-2H-9-oxo-10phospho)phenanthrene (DOPO) 216g, ethyl triphenylphosphonium ester / acetate complex Add 3g of the compound into a three-necked flask, stir electrically, and reflux at 130°C for 5h to obtain a phosphorus-containing active agent; cool, then add 50g of commercially available polymethyltriethoxysilane, 10g of deionized water, and 2g of stannous octoate , continue to stir, and reflux at 80 ° C for 4 hours, and cool to obtain a hybrid organic silicon phosphorus epoxy modifier.

[0045] Get 100g of bisphenol A epoxy resin (E51) with an epoxy value of 0.51mol / g, add 25g of the above-mentioned modifier, add 83g of novolac resin, 0.05g of 2-ethyl-4-methylimidazole, and stir evenly Then vacuumize at 80°C for 2h, then inject into the mold, keep the vacuum, 120°C for 3h, 220°C for 3h. The Tg of the obtained epoxy cured product is 155.88°C, the limiting oxygen index (LOI) is 24.9, and the tensile strength is 71.36MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com