Epoxy silane surface modified microcrystal muscovite active filler and its preparation method

A technology of microcrystalline muscovite and epoxy silane, which is applied in the treatment of fibrous fillers and dyed organosilicon compounds, can solve undiscovered problems, achieve obvious effects, enhance mechanical properties, electrical properties and moisture-proof properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

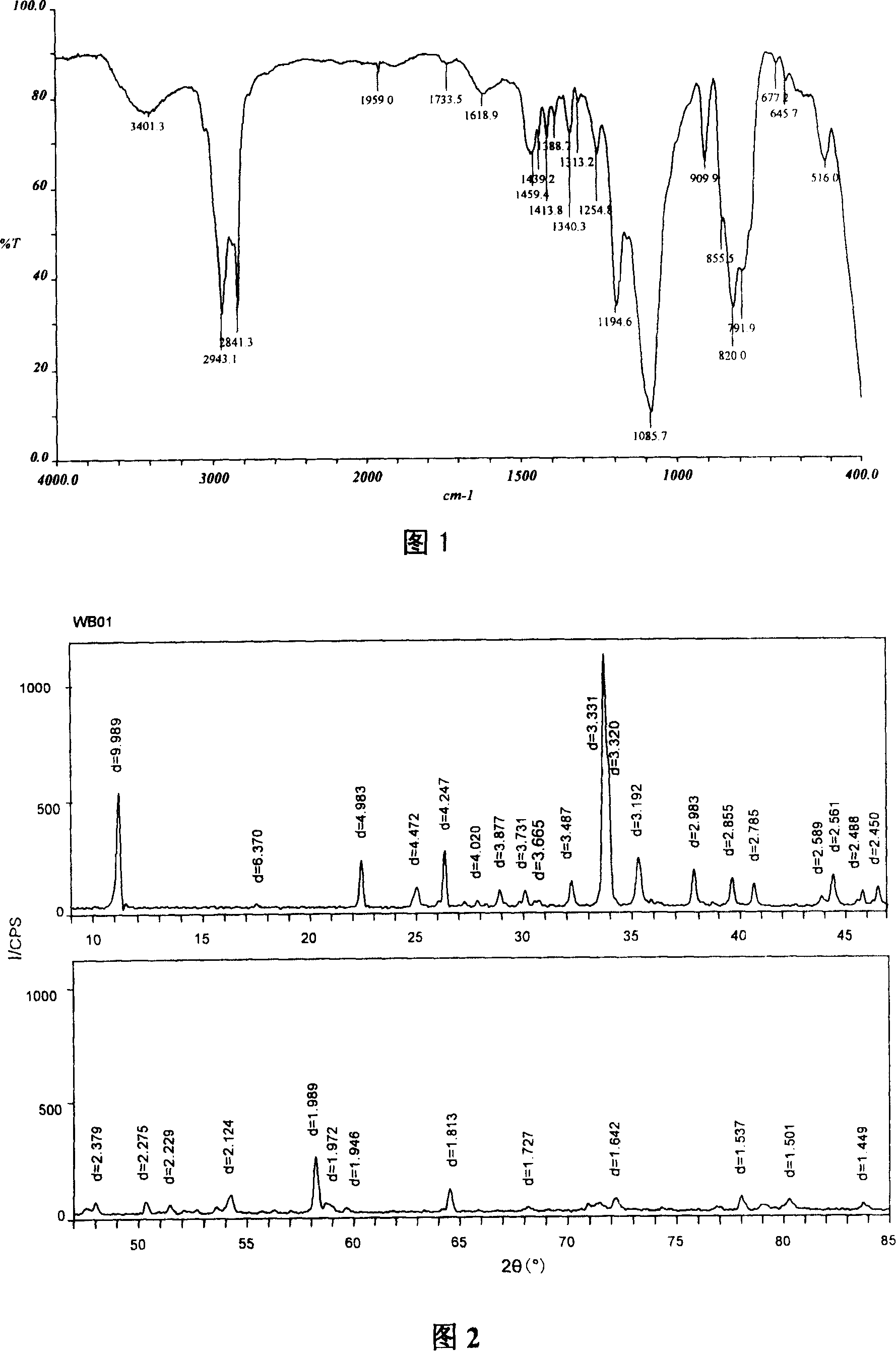

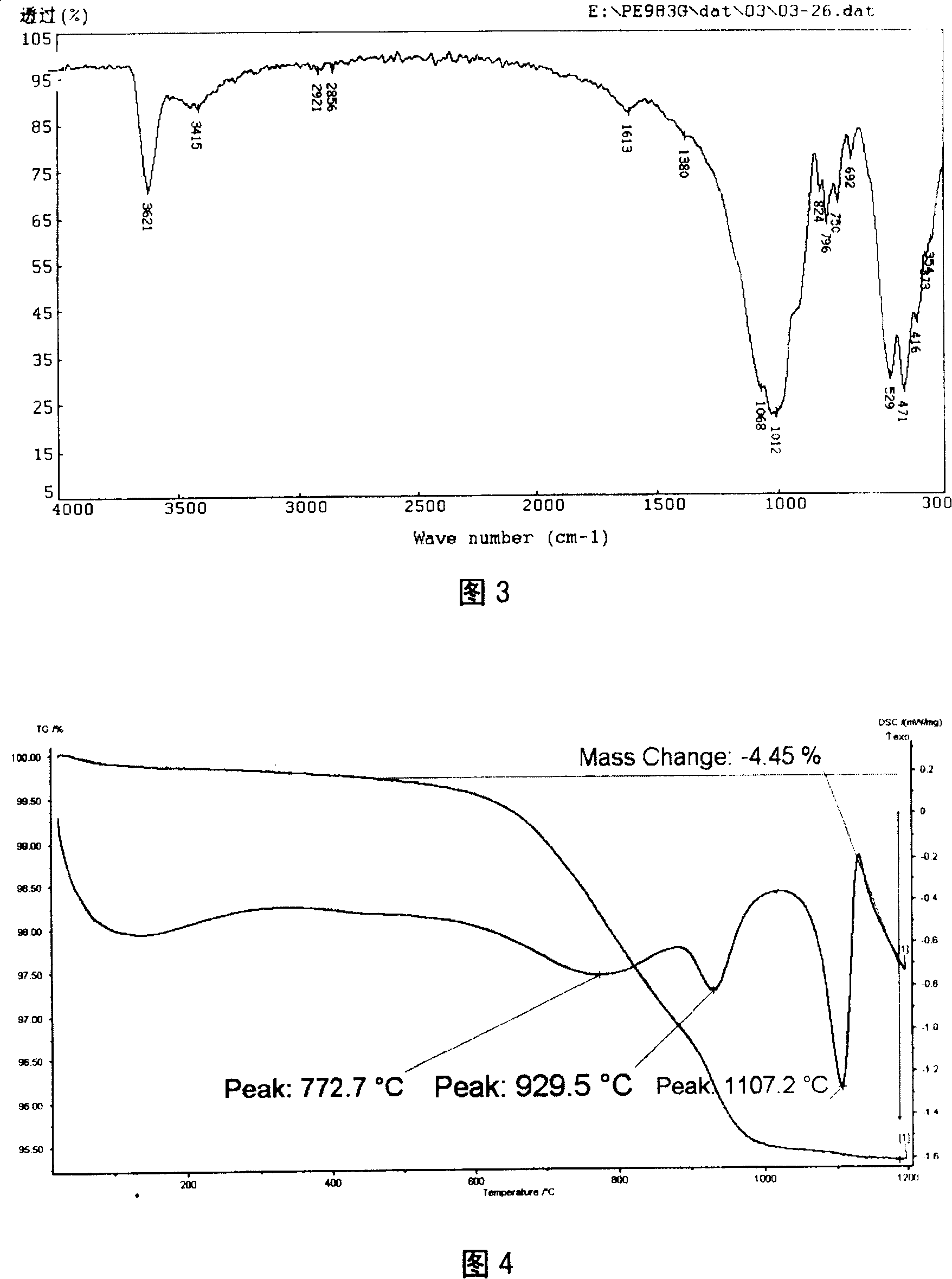

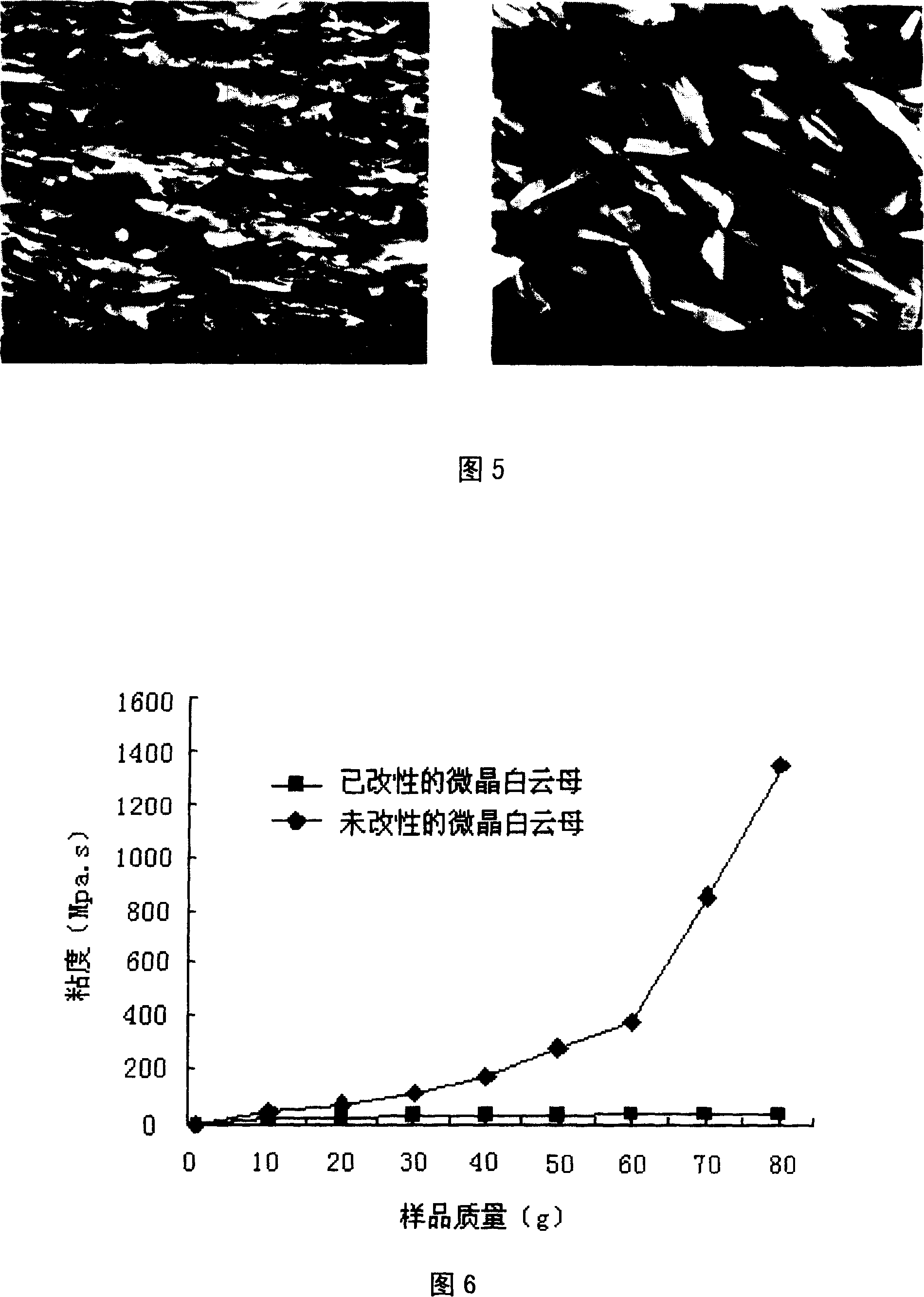

example 1

[0076] A preparation method of epoxy silane surface modified microcrystalline muscovite active filler (600 mesh). The microcrystalline muscovite powder sample used in this example was produced from a large microcrystalline muscovite deposit in a certain area in Sichuan. As mentioned above, the deposit was first discovered by the author in 1997. In the past few years, the scientific and technical personnel of Sichuan Xinju Mining Resources Development Co., Ltd. and Chengdu University of Technology have done certain work on the type, chemical composition, mineral composition, structure and beneficiation experiment of Sichuan microcrystalline muscovite ore, and successfully developed them accordingly. Xinju brand microcrystalline muscovite powder series products with different particle sizes such as 200 mesh, 325 mesh, 400 mesh, 600 mesh, 800 mesh, 1250 mesh and 2500 mesh are produced. The microcrystalline muscovite samples of different particle sizes in all examples of this patent a...

example 2

[0100] A preparation method of epoxy silane surface modified microcrystalline muscovite active filler (200 mesh). The microcrystalline muscovite filler (200 mesh) used in this example has the same origin, mineral composition, chemical composition and mineral physical characteristics as in Example 1 of this patent; its physical and chemical properties are shown in Table 2.

[0101] The epoxy silane (KH-560) coupling agent and diluent used in this example are all the same as in Example 1 of this patent; the surface modification process is also the same as Example 1 of this patent, as shown in Table 3, the difference is The dosage of the coupling agent in this example is based on the microcrystalline muscovite powder material: epoxy silane (KH-560) = 100: 0.5 ~ 0.7, the calculated dosage and dosage range of epoxy silane (KH-560) ( %)as shown in Table 3.

[0102] This example uses the same method as Example 1 to characterize and evaluate the surface modification effect, which shows th...

example 3

[0104] A preparation method of epoxy silane (KH-560) surface modified microcrystalline muscovite active filler (325 mesh). The microcrystalline muscovite filler (325 mesh) used in this example has the same origin, mineral composition, chemical composition and mineral physical characteristics as in Example 1 of this patent; its physical and chemical properties are shown in Table 2.

[0105] The epoxy silane (KH-560) coupling agent and diluent used in this example are all the same as in Example 1 of this patent; the surface modification process is also the same as Example 1 of this patent, as shown in Table 3, the difference is The weight of the coupling agent in this example is based on the microcrystalline muscovite powder material: epoxy silane (KH-560) = 100: 0.9 ~ 1.3, the calculated dosage and dosage range of epoxy silane (KH-560) (% )as shown in Table 3.

[0106] This example uses the same method as Example 1 to characterize and evaluate the surface modification effect, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com