Patents

Literature

80results about How to "Increase the distance between layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite clay material and method for producing the same, blend material and composite clay rubber using the same and production method thereof

InactiveUS6103817ASufficiently disperseImprove dynamic propertyPigmenting treatmentSpecial tyresMolecular levelSide chain

A composite clay material with the interlayer distance sufficiently expanded by dispersing clay mineral in a low polar polymer on a molecular level and the method for producing the same, blend material and composite clay rubber material using the same and the production method thereof. The composite clay material is formed of a clay mineral rendered compatible with an organic material through ionic bonding to an organic onium ion having 6 or more carbon number and a main guest molecule having a polar group in its main chain and side chain and molecular length equal to or larger than that of said organic onium ion. The main guest molecule is incorporated at least partially into an interlayer section of the clay mineral which has a hydrogen bonding with the polar group of the main guest molecule. The main guest molecule preferably has a molecular weight ranging from about 100 to 100000. Alternatively a first guest molecule having a polar group and molecular length equal to or smaller than that of the organic onium ion and a second guest molecule having no polar group therein and molecular length larger than that of the organic onium ion are incorporated into the interlayer section of the clay mineral instead of the main guest molecule. The above obtained clay composite material may be mixed with the rubber material.

Owner:DENSO CORP

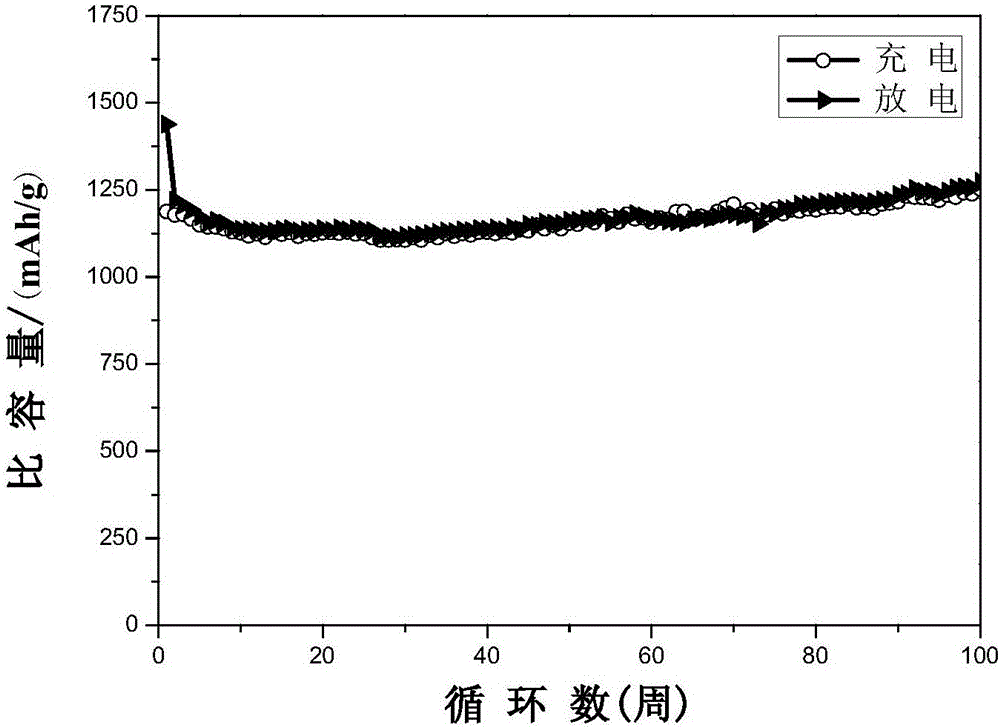

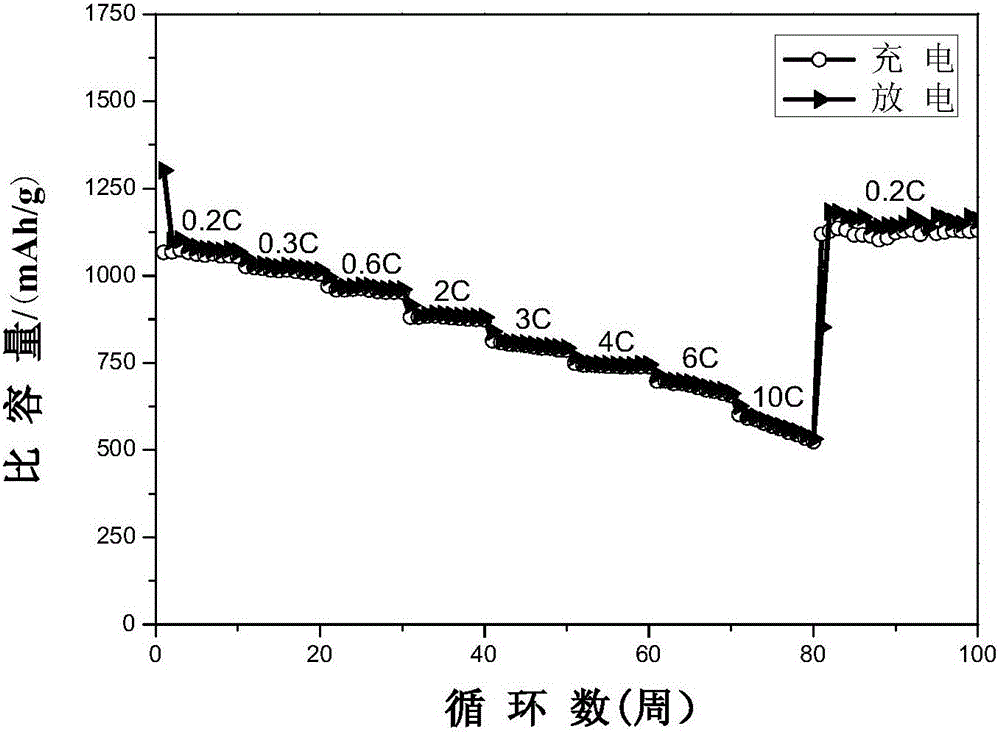

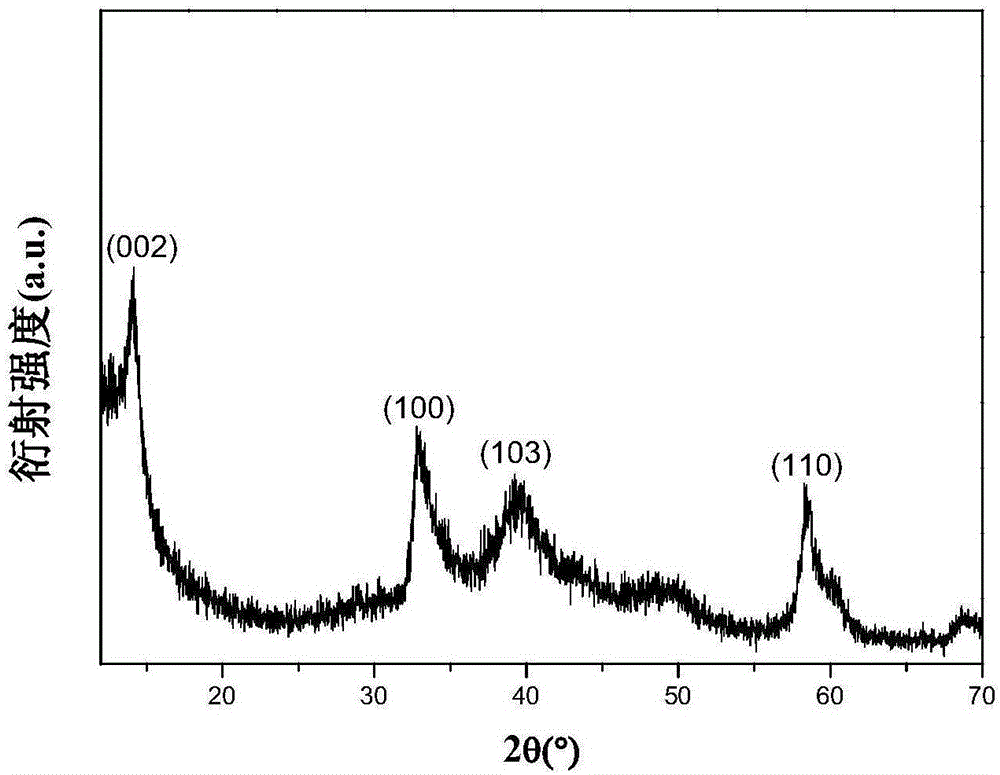

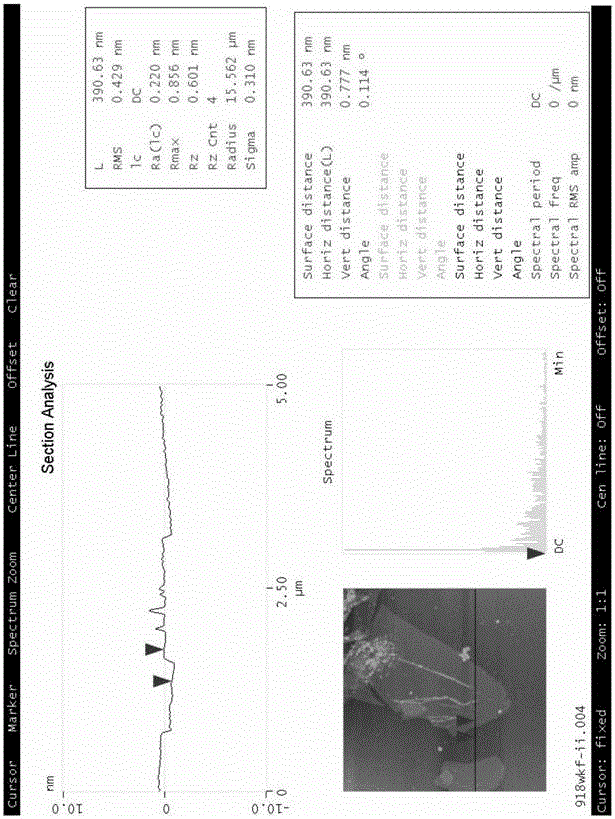

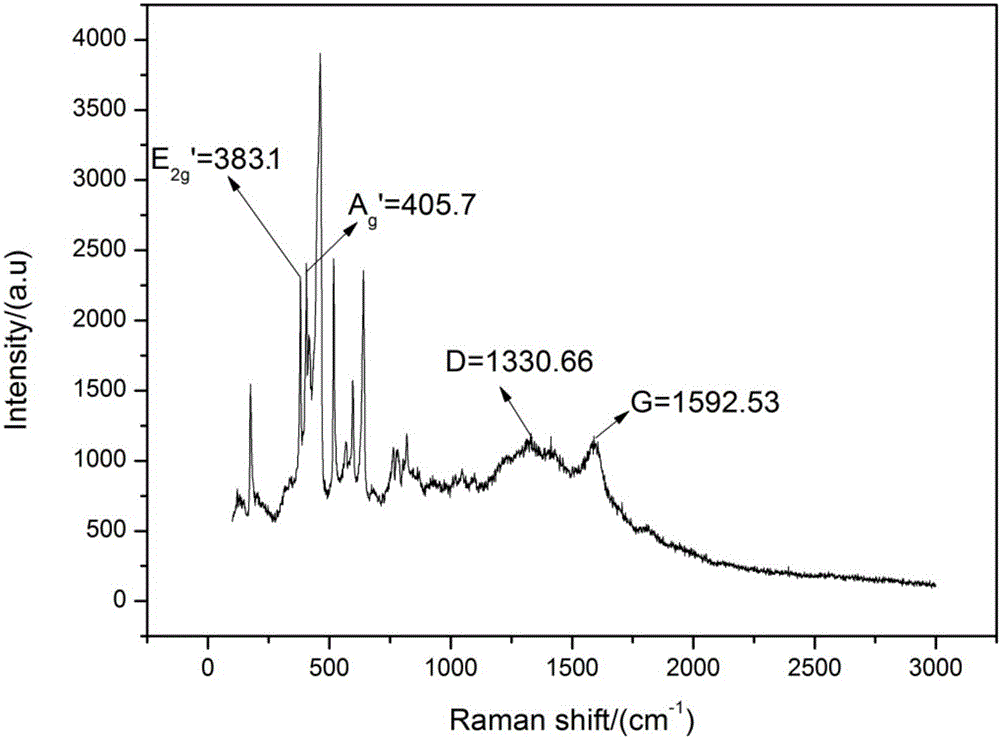

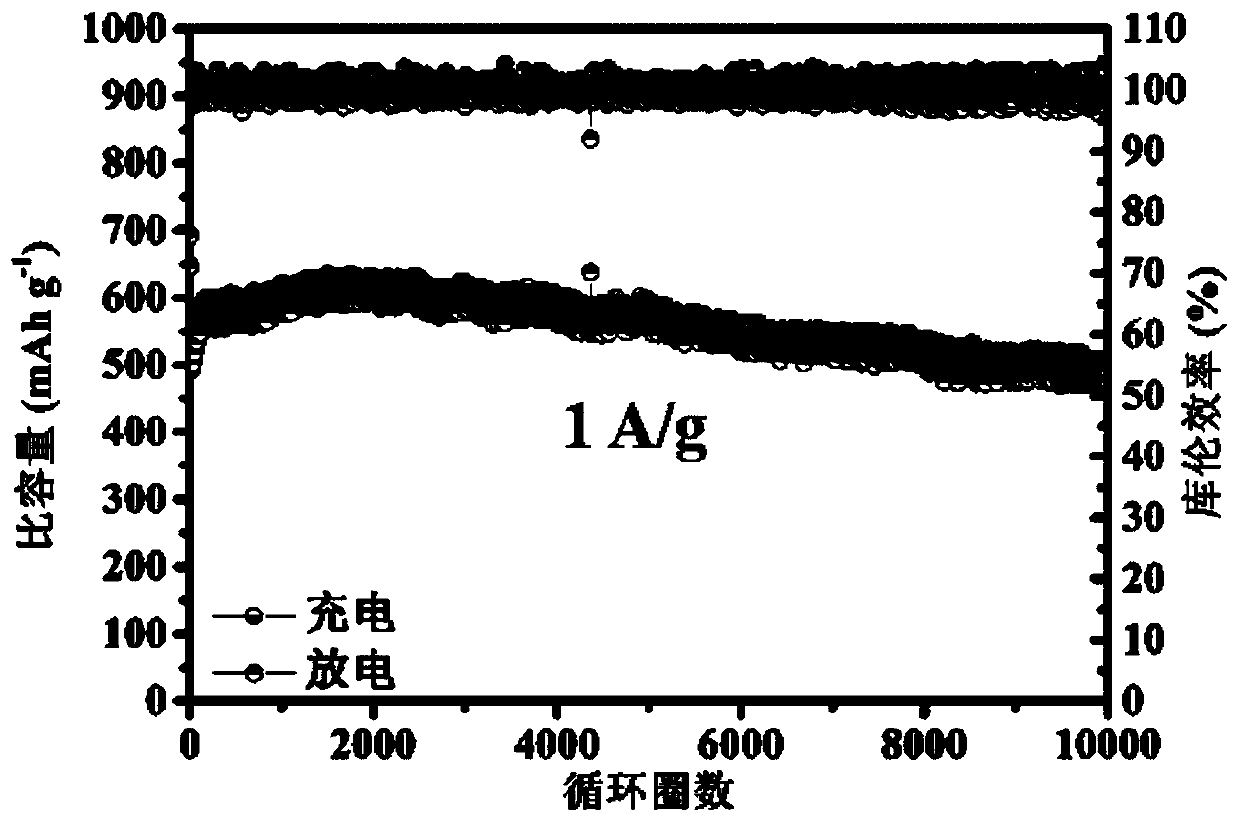

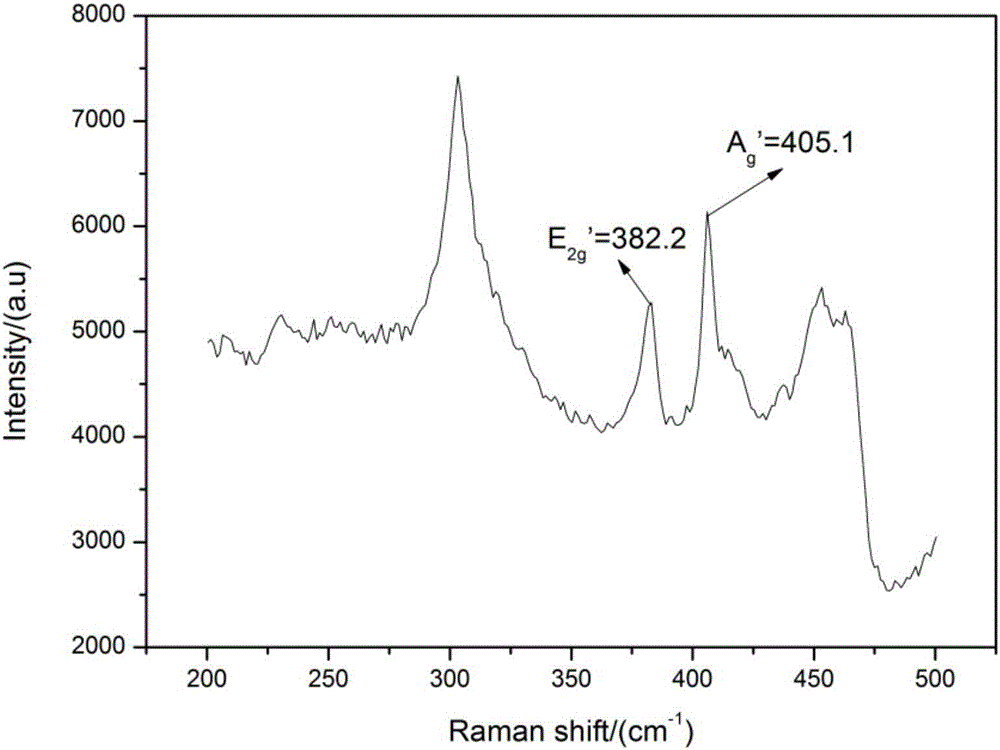

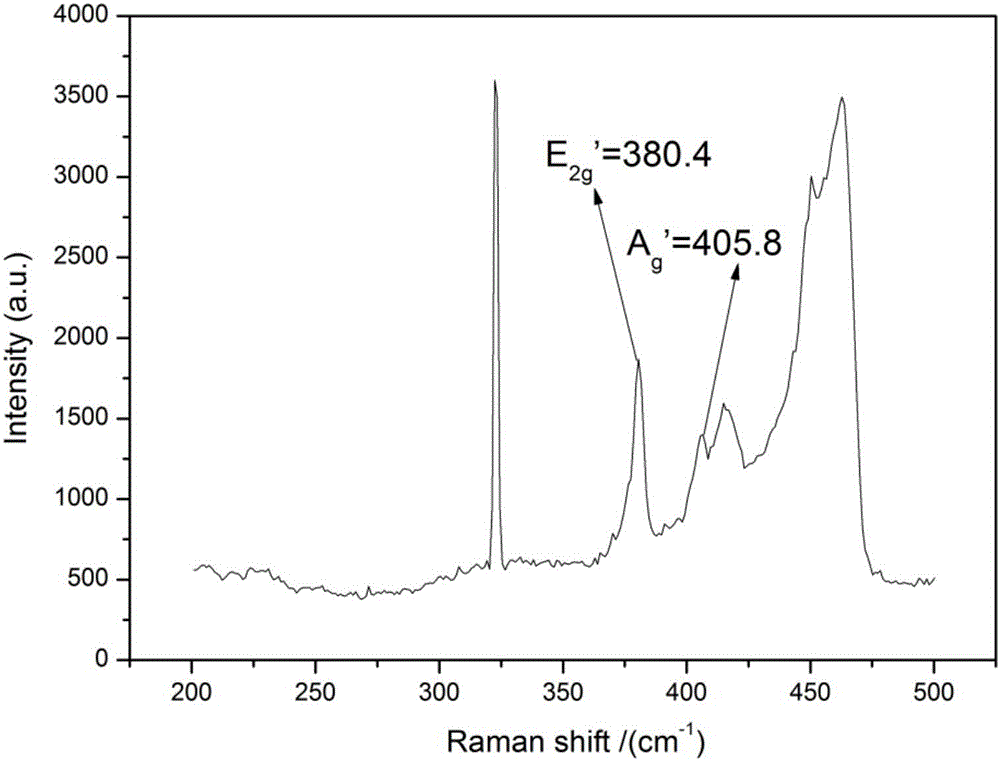

Layered structure molybdenum disulfide/carbon composite material and preparation method and application thereof

ActiveCN106410136AIncrease layer spacingWell formedCell electrodesSecondary cellsCarbon compositesElectronic transmission

The invention discloses a preparation method of a layered structure molybdenum disulfide / carbon composite material and an application. The composite material is prepared by adopting a molybdenum oxide organic / inorganic hybrid compound of an organic amine intercalation layer as a precursor, putting the precursor into a high-temperature area, putting a sulfur source into a low-temperature area and simultaneously carrying out high-temperature vulcanization and carbonization treatment under inert gas protection. The composite material has a layered structure; carbon is located between laminated plates of a few of molybdenum disulfide layers; the composite material can serve as an electronic transmission channel to improve the conductivity of the electrode material; and furthermore, the interlayer distance is expanded and the diffusion ability of Li<+>between the layers is improved. The composite electrode material has relatively high specific capacity and good cycle performance and rate capability, and is simple in process and low in raw material cost; and large-scale industrial production is easy to implement.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

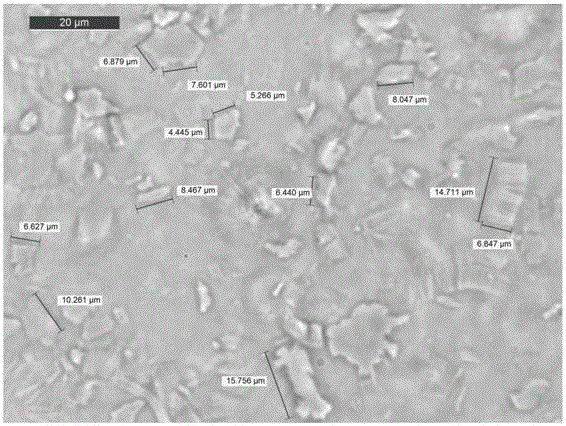

Rapid preparation methods of graphene oxide and graphene

InactiveCN106430175AImprove integrityReduced interlayer forceSingle layer grapheneCvd grapheneEnergy consumption

The invention provides a preparation method of graphene oxide. The method comprises the following steps: firstly, mixing graphite, an intercalator and an oxidizing agent under an airtight condition and then carrying out a reaction to obtain a reaction mixture; separating the reaction mixture obtained in the previous step to obtain a reaction product; finally, stripping the reaction product, obtained in the previous step, in a dispersing agent to obtain graphene oxide dispersion liquid. According to the preparation method, the intercalator is inserted into the parts among graphene sheet layers under the action of pressure and under the airtight condition, so that the acting force among layers is reduced, and the distances among the layers are increased; then, the oxidizing agent enters the parts among the graphene sheet layers and has an oxidation reaction, so that the graphene oxide is formed; due to the action of the pressure, the intercalator and the oxidizing agent are enabled to enter the parts among graphene layers more rapidly, and the reaction is promoted to be completed within a short time, so that first-order intercalating for the graphite is realized; furthermore, the preparation method is less in energy consumption in a reaction process, environmentally-friendly, convenient and fast to operate as well as safe and controllable, thus being more suitable for industrial mass production.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

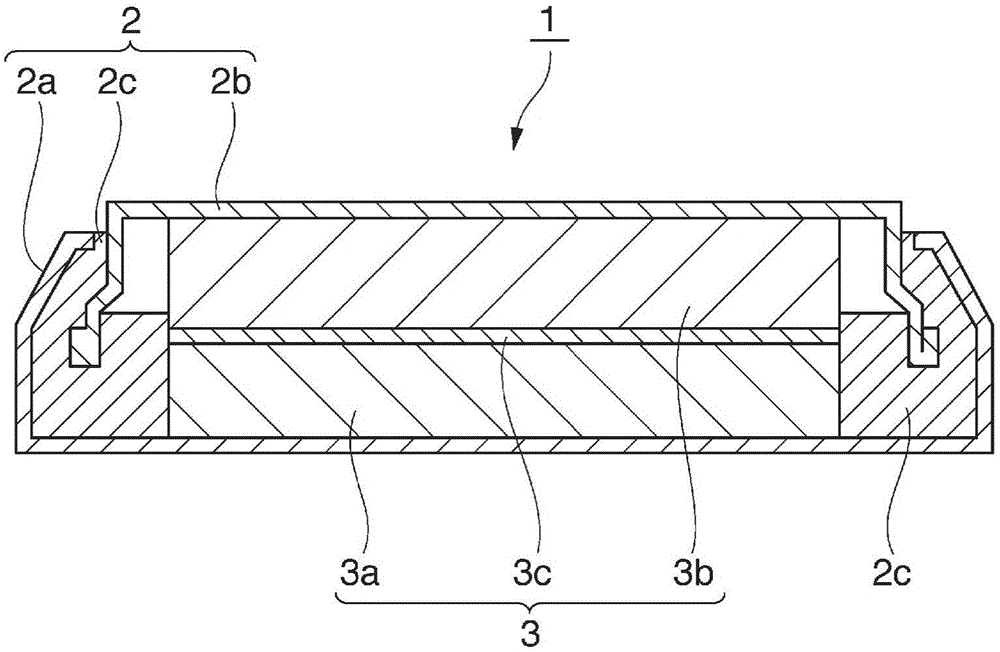

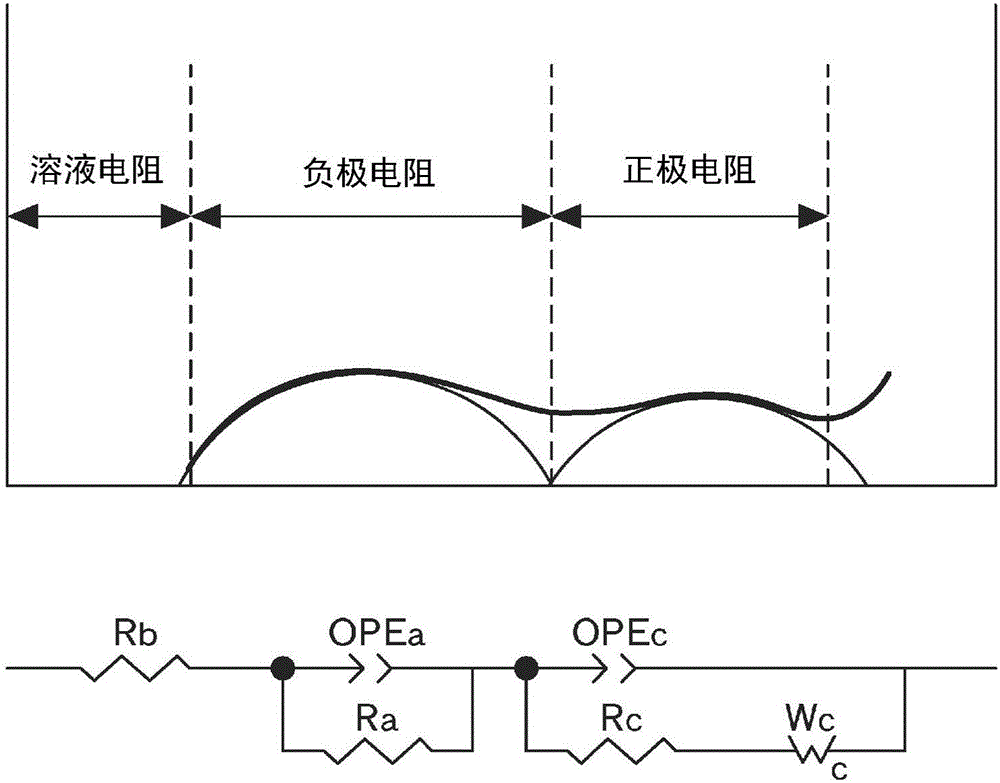

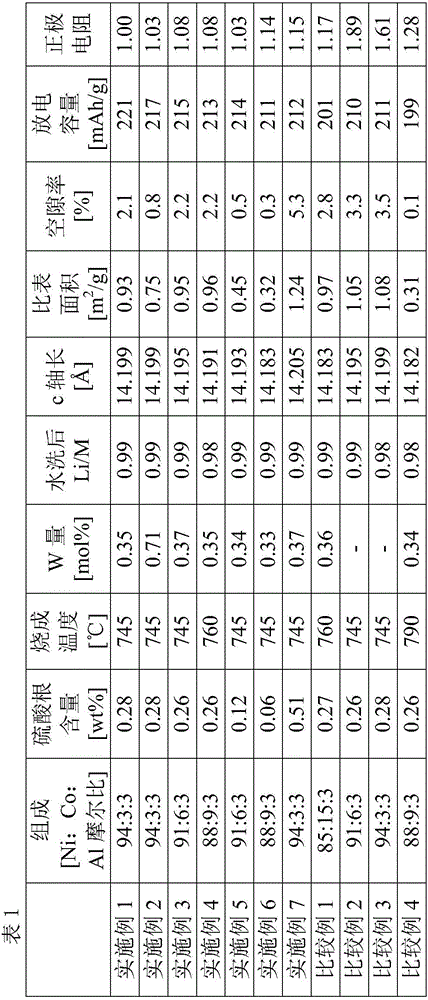

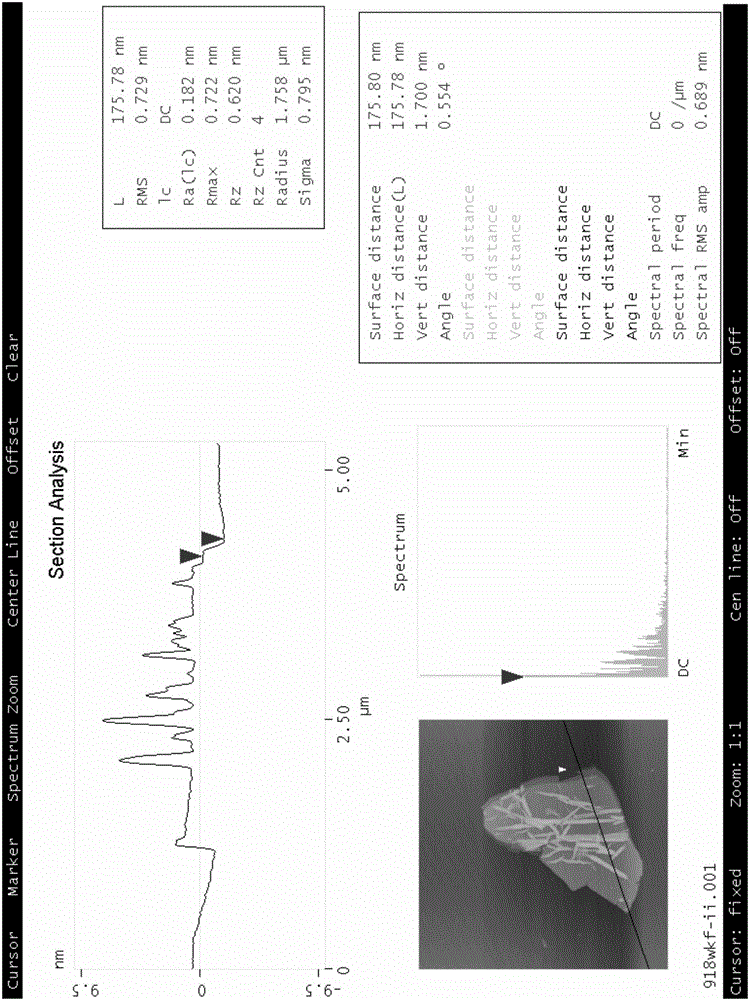

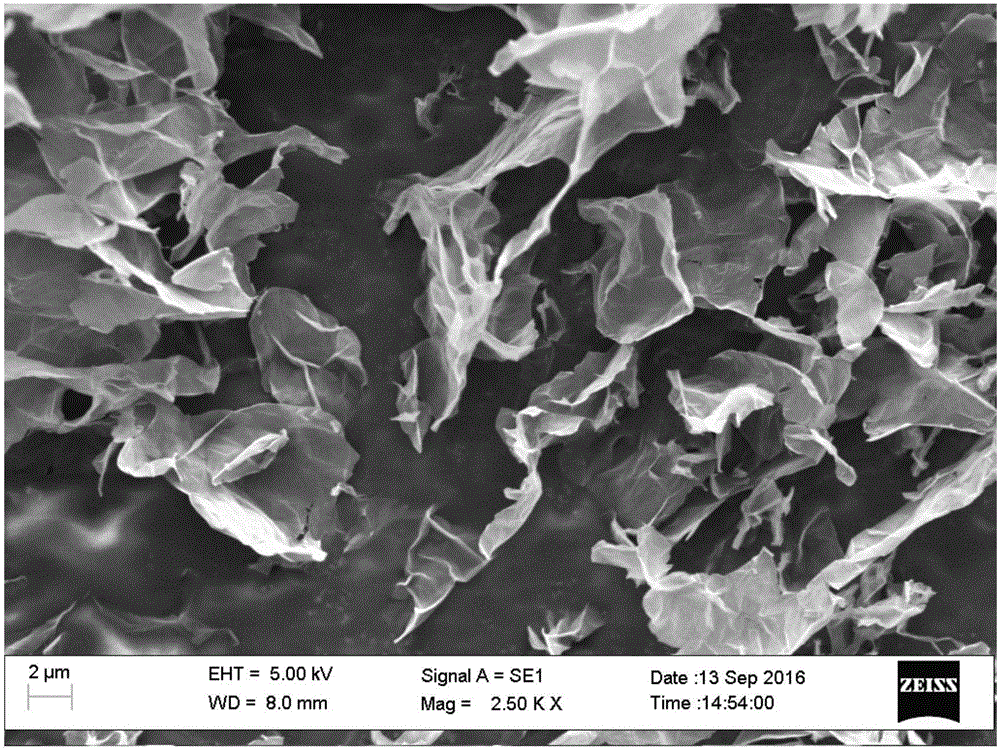

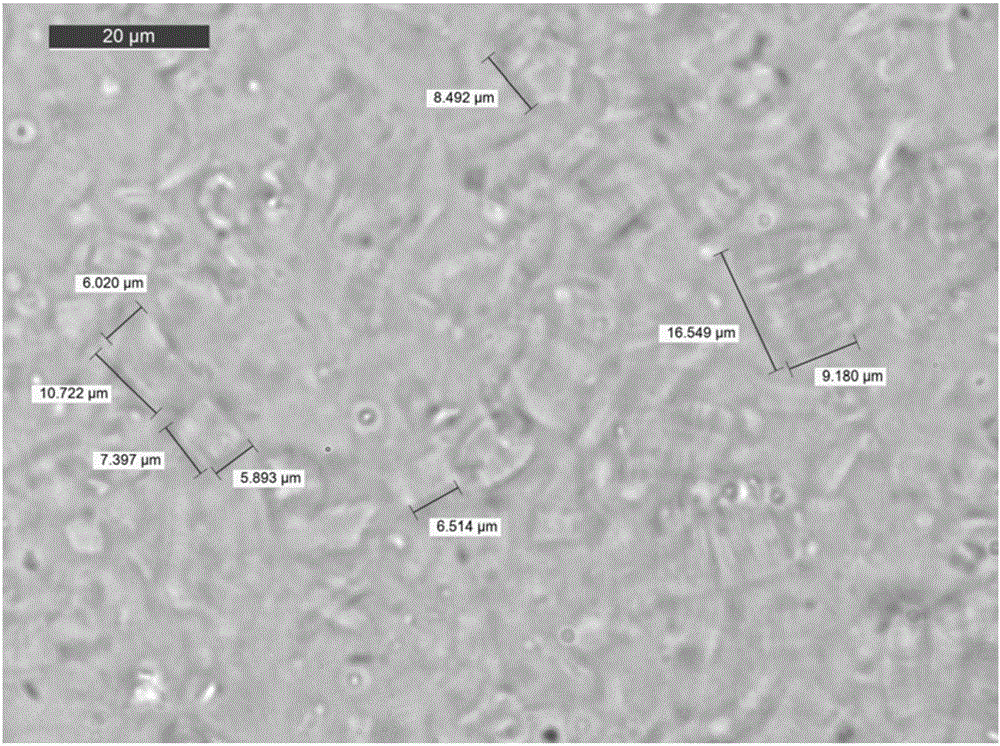

Positive electrode active material for non-aqueous electrolyte secondary battery and method for producing same, and non-aqueous electrolyte secondary battery manufactured using said positive electrode active material

ActiveCN106256036AImproved pluggabilityImprove output characteristicsElectrode thermal treatmentFinal product manufactureComposite oxideNickel

The purpose of the present invention is to provide a positive electrode active material for a non-aqueous electrolyte secondary battery which can have both a high capacity and a high output. A positive electrode active material for a non-aqueous electrolyte secondary battery, said positive electrode active material being characterized by comprising primary particles of a lithium nickel composite oxide represented by general formula: LibNi1-x-yCoxMyO2 (wherein M represents at least one element selected from Mg, Al, Ca, Ti, V, Cr, Mn, Nb, Zr and Mo; b represents a numerical value satisfying the requirement represented by the formula 0.95 <= b <= 1.03; and x represents a numerical value satisfying the requirement represented by the formula 0 < x <= 0.15 and y represents a numerical value satisfying the requirement represented by the formula 0 <y <= 0.07, wherein the sum total of x and y is 0.16 or smaller, i.e., x+y <= 0.16) and secondary particles that are aggregates of the primary particles, wherein microparticles containing W and Li are present on the surface of each of the primary particles, and the length of axis-c of the lithium nickel composite oxide is 14.183 angstroms or more as determined by a Rietveld analysis of X-ray diffraction data on the oxide.

Owner:SUMITOMO METAL MINING CO LTD

Preparing method of oxidized graphene and high-conductivity graphene

InactiveCN106564891AAchieving a self-boosting reactionReduced interlayer forceSingle layer grapheneGraphiteGraphene

The invention provides a preparing method of oxidized graphene. The preparing method comprises the following steps that at first, on the condition of pressurization of protective gas, graphite, an intercalator and an oxidizing agent are subjected to low-temperature reaction after being mixed, and a reaction mixture is obtained; then the reaction mixture obtained in the above step is separated, and then a reaction product is obtained; finally, the reaction product obtained in the above step is stripped in a dispersing agent, and oxidized graphene dispersing liquid is obtained. By the adoption of the low-temperature condition, the defect rate is reduced obviously, under the effect of pressure, the intercalator is inserted between graphene sheet layers, the acting force between the layers is reduced, and the distance between the layers is increased; then the oxidizing agent enters the portions between the graphene sheet layers, the oxidizing reaction is carried out, and thus oxidized graphene is formed; and due to the effect of the pressure, the intercalator and the oxidizing agent enter the portions between the graphene sheet layers faster, the reaction is promoted to be more complete within a short time, one-step intercalation to graphene is achieved, and then graphene powder with the low defect rate and high quality is obtained and prepared.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

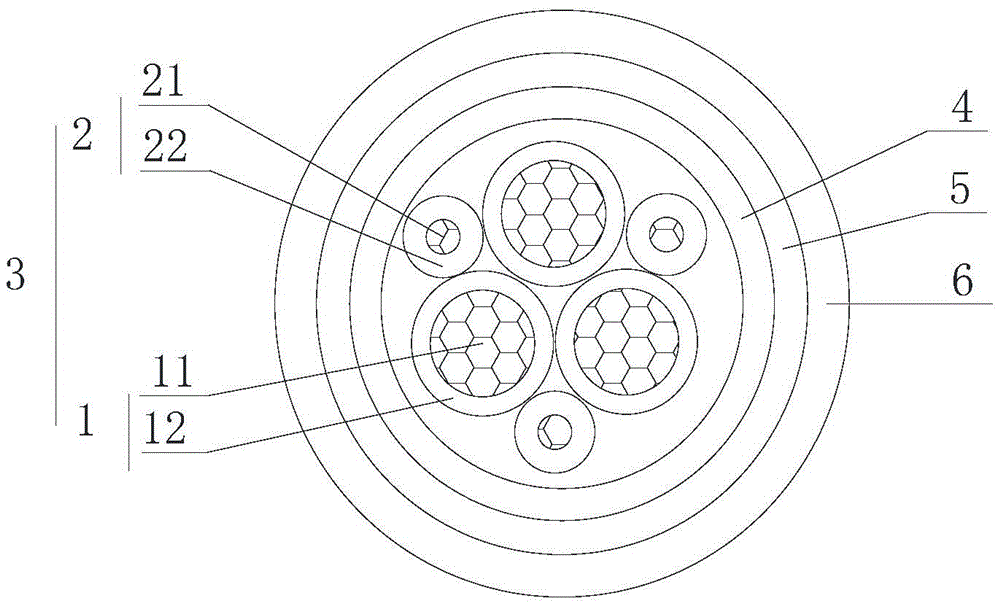

Tear-resistant and heat-resistant silicone rubber cable

InactiveCN105623275AGood high and low temperature resistanceImprove corrosion resistanceRubber insulatorsFire retardantDibutyltin dilaurate

The invention discloses a tear-resistant and heat-resistant silicone rubber cable. The silicon rubber cable comprises a jacket layer. The jacket layer is prepared from silicone rubber, ethylene propylene diene monomer, composite filler, hydroxyl silicone oil, paraffin oil, epoxidized soybean oil, fire retardant, dicumyl peroxide, bi25, accelerant M, accelerant BZ, dibutyl tin oxide, dibutyltin dilaurate, antioxygen 1010, antioxygen 168 and silicone powder. The composite filler is prepared from vinyl triethoxysilane, nanosilicon dioxide, nanometer titania and modified expanded vermiculite. The tear-resistant and heat-resistant silicone rubber cable is good in heat resistance, high in tear resistance and good in mechanical performance.

Owner:王社兵

High-strength anti-puncturing graphene modified plastic

The invention provides high-strength anti-puncturing graphene modified plastic which comprises the following materials in parts by weight: 40-80 parts of PA66, 30-60 parts of glass fiber, 0.8-3 parts of graphene, 0.5-1.5 parts of nanometer zinc oxide, 0.3-2 parts of surface active agent, 0.1-1 part of dispersing agent, 0.5-2.5 parts of coupling agent and 0.1-0.6 part of antioxidant. According to the invention, PA66 is used as a plastic substrate and the graphene is utilized to modify, so that the mechanical property of the plastic is promoted; the graphene is subjected to nanometer zinc oxide intercalated modification, so that the dispersing performance of the graphene is obviously promoted; the other auxiliary additives jointly have a cross-linking effect on the plastic, so that the toughness of the plastic is greatly promoted; and the plastic has an excellent anti-puncturing property and is light and practical.

Owner:JIANGSU HUASHENG PLASTIC

Attapulgite sewage treatment agent and preparation method thereof

InactiveCN106865655AGood dispersionGood suspensionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionIron sulfateAluminium chloride

The invention discloses an attapulgite sewage treatment agent and a preparation method thereof, and relates to the technical field of attapulgite processing. The attapulgite sewage treatment agent is prepared from the following raw materials in parts by weight: 150 to 200 parts of attapulgite, 200 to 250 parts of hollow glass beads, 80 to 100 parts of deionized water, 20 to 25 parts of a sulfuric acid solution, 20 to 25 parts of cross-linked rectorite, 2 to 5 parts of ferric trichloride, 2 to 5 parts of ferrous sulfate, 2 to 5 parts of magnesium sulfate, 2 to 5 parts of polyacrylamide, 2 to 5 parts of aluminium chloride, 2 to 5 parts of polyferric sulfate, 2 to 5 parts of sodium hydroxide, 2 to 5 parts of sodium benzoate, 2 to 5 parts of corn starch, 2 to 5 parts of straw, 1 to 3 parts of cottonseed shell residue, 1 to 3 parts of modified diatomite, 1 to 3 parts of citric acid, 1 to 3 parts of aids and a proper amount of water. The attapulgite serves as the raw material and is subjected to modification treatment, so high dispersibility, high suspension property and good adsorption effect are achieved.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

Preparation method of modified hydrotalcite-like concrete sulfate-corrosion-resistant preservative

ActiveCN110255963AImprove adsorption capacityHas a structural memory effectUltrasonic dispersionSodium hydroxide

The invention discloses a preparation method of a modified hydrotalcite-like concrete anti-sulfate-corrosion preservative. The method comprises the following steps: mixing calcium nitrate, barium nitrate, aluminum nitrate, sodium carbonate, sodium hydroxide and distilled water to prepare a solution, and stirring, suction-filtering, washing and drying the solution to obtain hydrotalcite-like compounds; and mixing the obtained hydrotalcite-like compound with nano silicon dioxide, ultrafine mica powder and a silane coupling agent, carrying out ultrasonic dispersion, drying and grinding the mixture, sieving the ground mixture with a 200-mesh sieve, and calcining the mixture to obtain the preservative. When the preservative is applied to concrete, the diffusion of sulfate ions can be reduced, the generation of sulfate corrosive products is prevented, and the sulfate corrosion resistance of the concrete is improved.

Owner:HOHAI UNIV

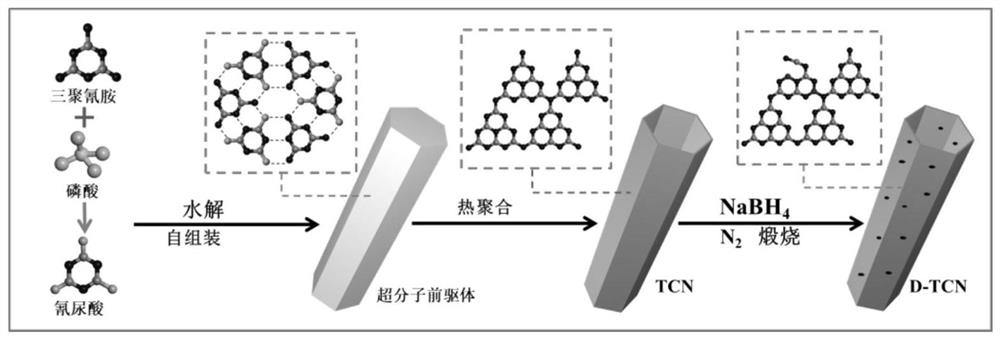

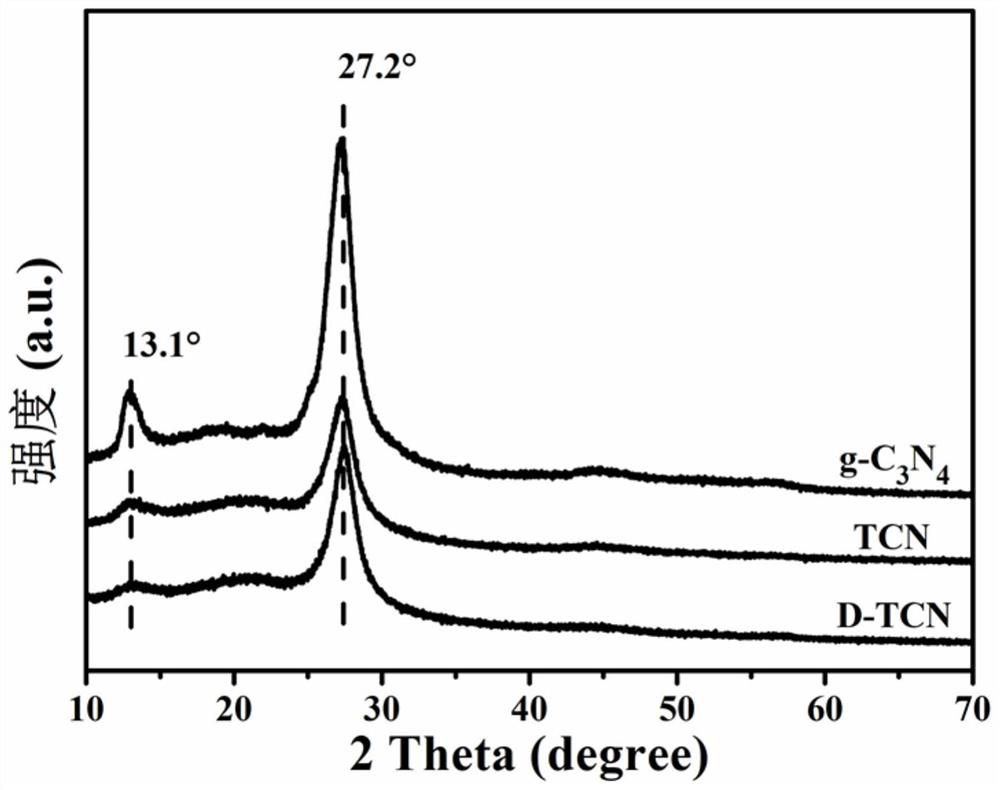

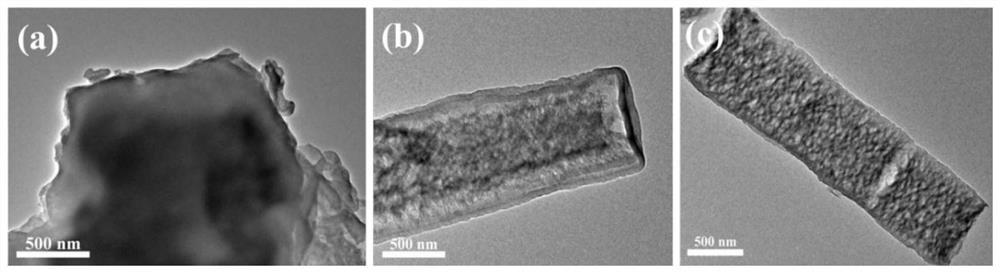

Preparation method and application of nitrogen defect/boron doped tubular carbon nitride photocatalyst

InactiveCN113318764AIncrease exposurePromote absorptionWater/sewage treatment by irradiationWater treatment compoundsPtru catalystPhosphoric acid

The invention belongs to the technical field of semiconductor photocatalysts, and particularly relates to a preparation method and application of a nitrogen defect / boron doped tubular carbon nitride photocatalyst. The preparation method comprises the following steps: putting melamine and phosphoric acid into a high-pressure kettle containing deionized water to carry out hydrothermal reaction, washing the reacted product with deionized water, carrying out vacuum drying to obtain a substance which is a supramolecular precursor, conducting calcining again, naturally conducting cooling and conducting grinding to obtain tubular carbon nitride; mixing tubular carbon nitride and NaBH4, then conducting uniform grinding, and putting the mixture into a porcelain boat for calcination; and washing the calcined product with HCl and distilled water, and carrying out vacuum drying to obtain the nitrogen defect / boron doped tubular carbon nitride photocatalyst, which is marked as a D-TCN photocatalyst. The synergistic effect of nitrogen defect / boron doping and the tubular structure can effectively promote light capture, accelerate charge transfer and promote exposure of more active sites, and the effects of photocatalytic degradation of antibiotics and decomposition of water to produce hydrogen activity can be remarkably enhanced.

Owner:JIANGSU UNIV

Vegetable insecticide and preparation method thereof

InactiveCN106900768AThoroughly modifiedHigh activityBiocideAnimal repellantsBacillus thuringiensisBiology

The invention discloses a vegetable insecticide and a preparation method thereof and relates to the technical field of insecticides. The vegetable insecticide is prepared from 80-90 parts of attapulgite, 55-75 parts of sepiolite powder, 55-65 parts of natural plant extracts, 45-50 parts of kieselguhr, 15-30 parts of bacillus thuringiensis, 10-20 parts of veratrine, 10-15 parts of additive and 250-300 parts of water. The vegetable insecticide is good in insecticidal efficacy and long in action time, the raw materials are easy to obtain, and the vegetable insecticide is safe, environmentally friendly and harmless to the human body.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

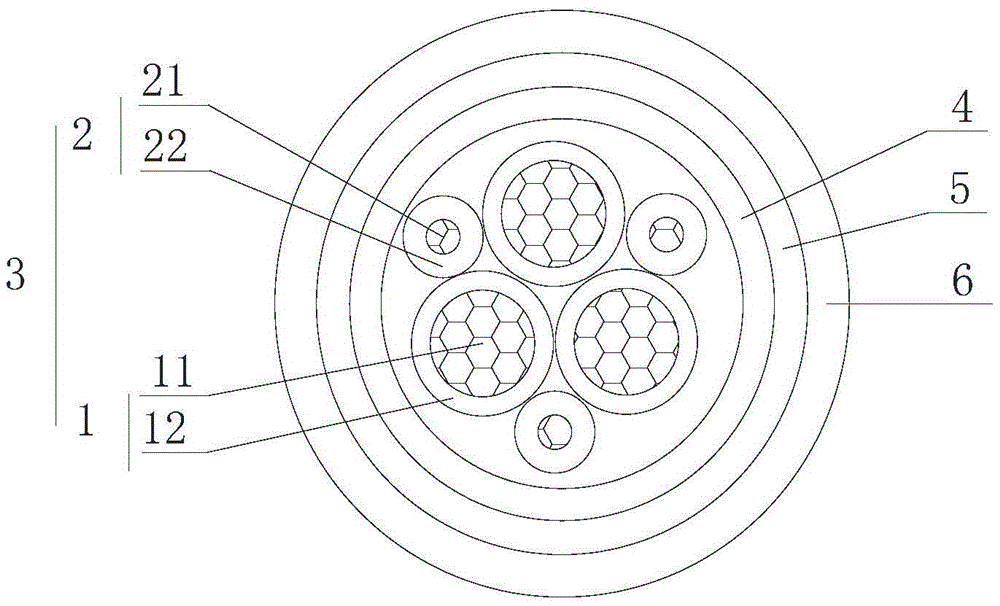

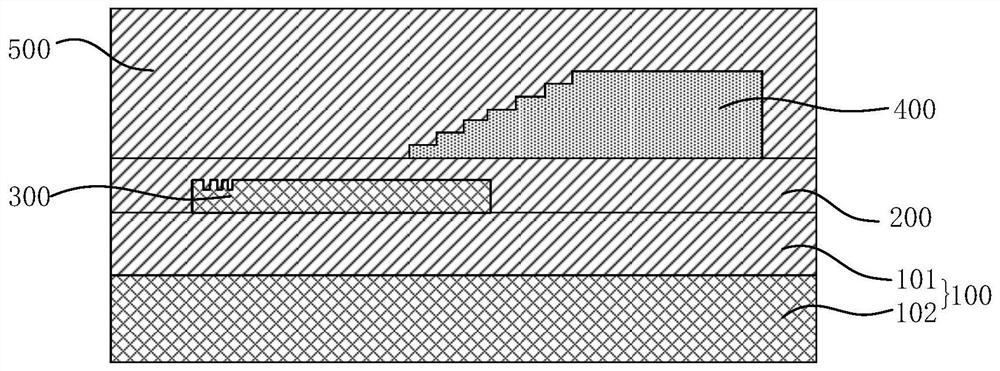

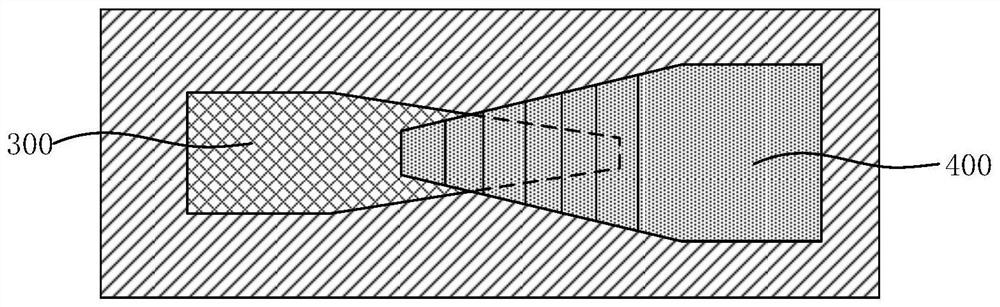

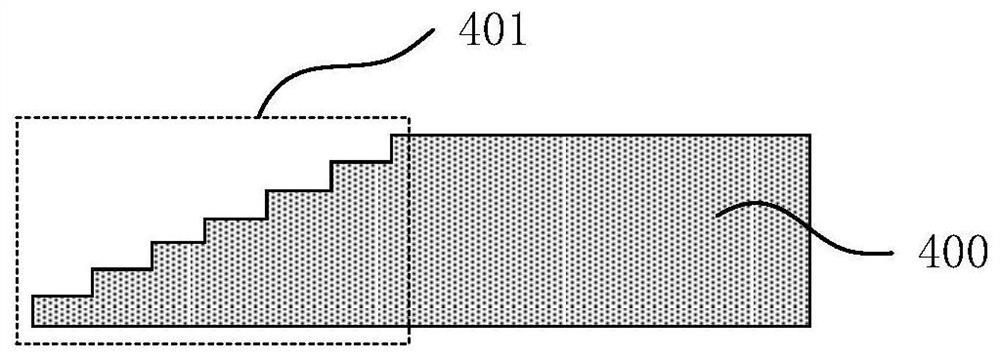

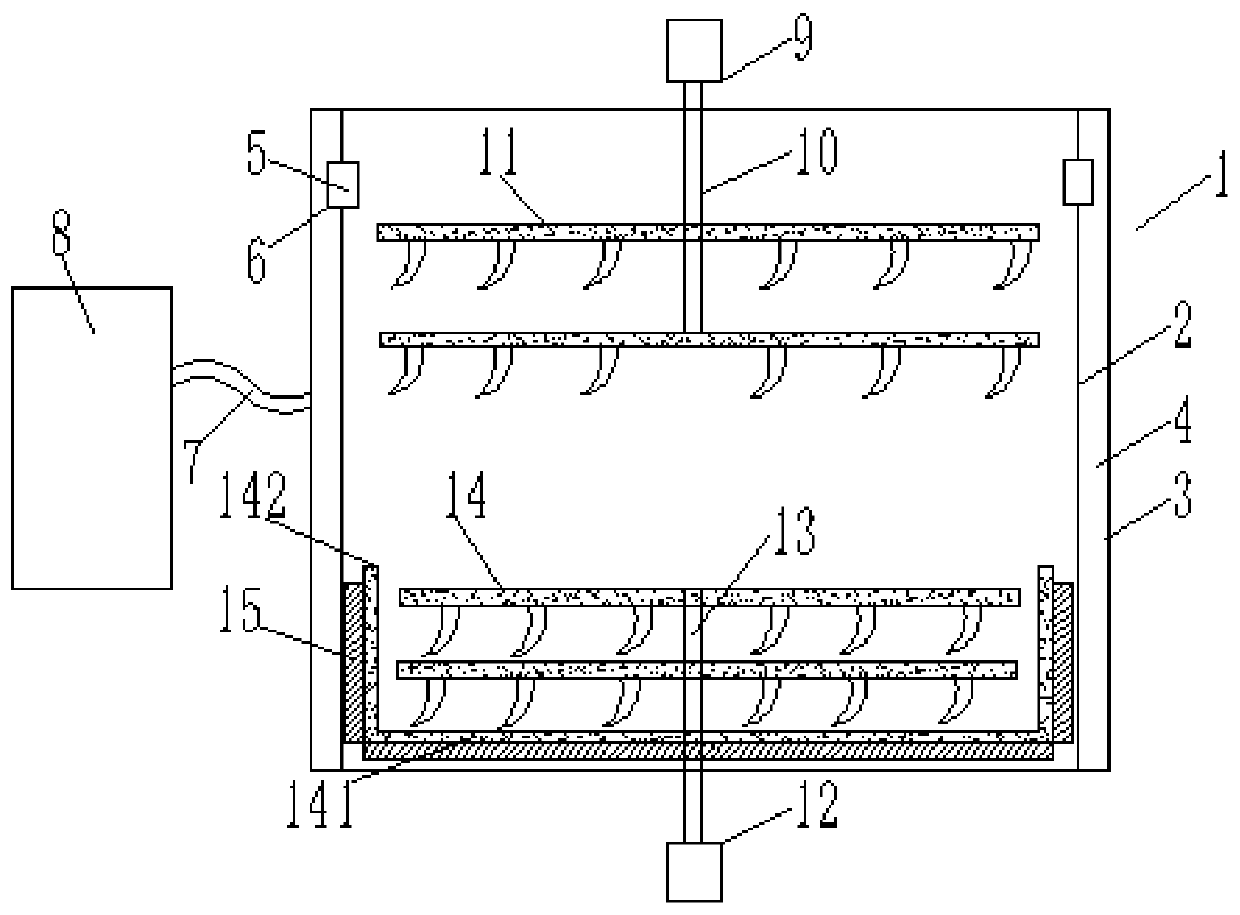

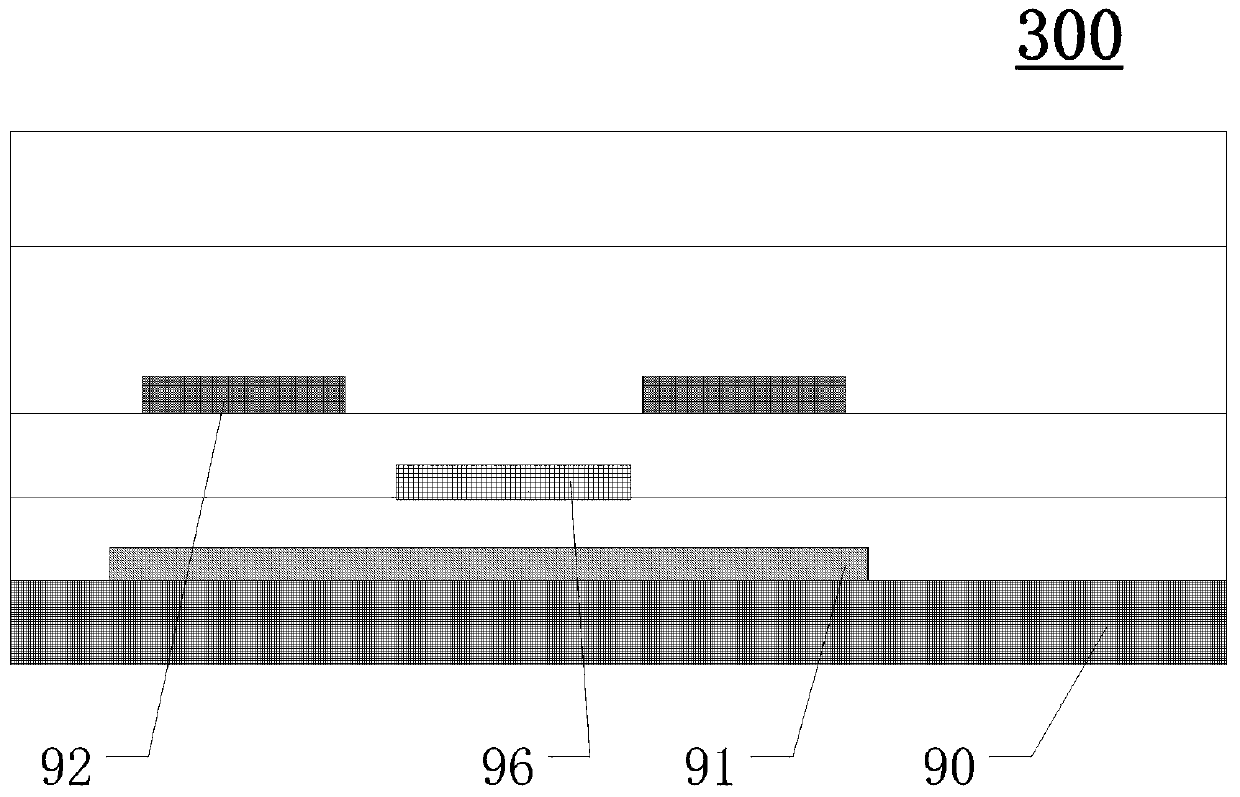

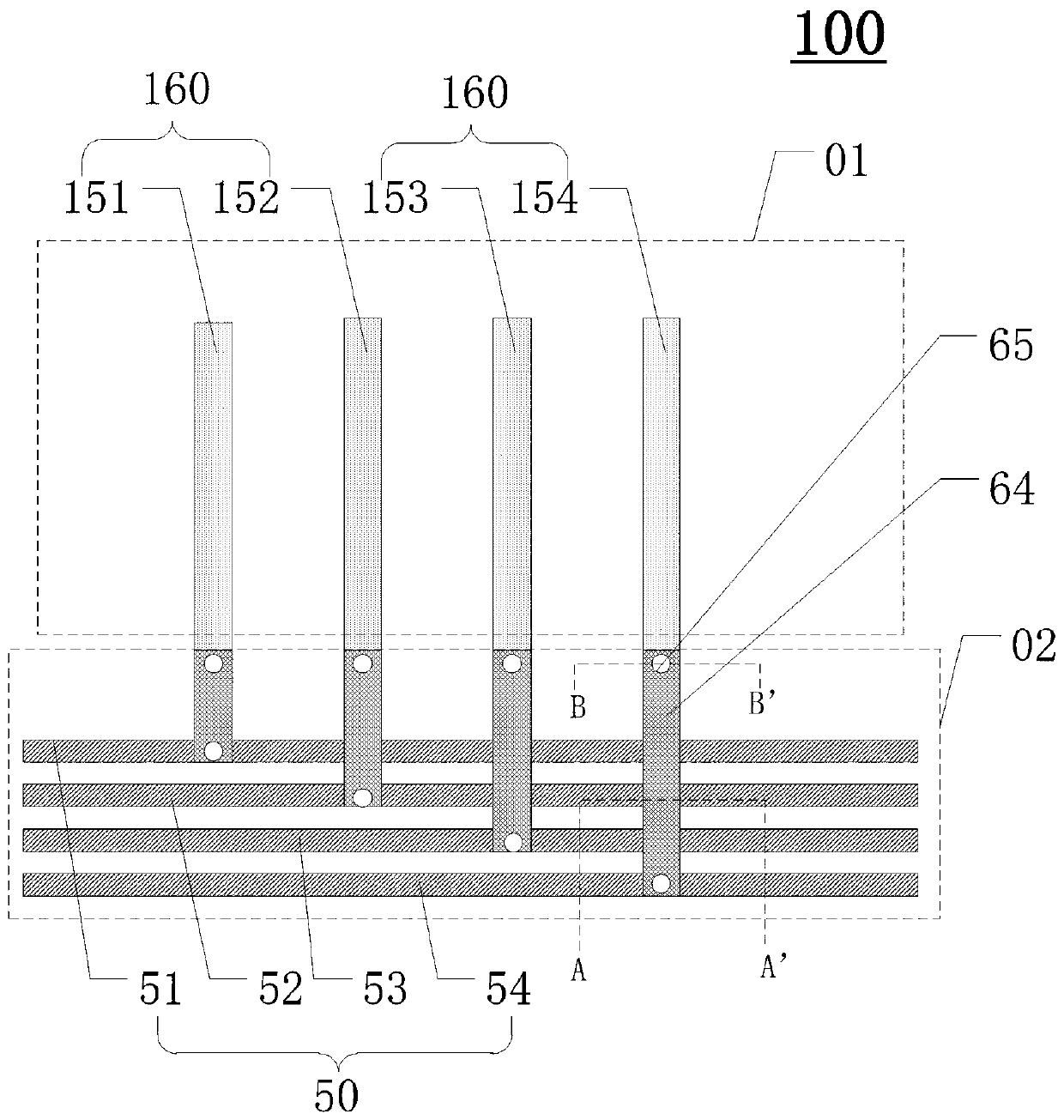

Waveguide interlayer coupling structure and preparation method thereof

PendingCN113568105AIncrease the distance between layersGuaranteed Coupling EfficiencyCoupling light guidesCoupling lossDielectric layer

The invention discloses a waveguide interlayer coupling structure and a preparation method thereof, relates to the technical field of silicon optical devices, and aims to solve the technical problem that an existing coupling structure is high in interlayer coupling loss. The waveguide interlayer coupling structure comprises: a substrate. a first waveguide formed on the substrate, wherein a first waveguide is located in the first area of the substrate; a first dielectric layer which is formed on the substrate and covers the first waveguide; and a second waveguide formed on the first dielectric layer, wherein the second waveguide is located in the second area of the substrate, and the projection of the first waveguide on the substrate and the projection of the second waveguide on the substrate have an overlapped area, so that light emitted from the second waveguide enters the first waveguide in a coupling manner. The end, close to the first waveguide, of the second waveguide is provided with a step-shaped structure, and the thicknesses of steps in the step-shaped structure are sequentially increased in the direction from the first waveguide to the second waveguide.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

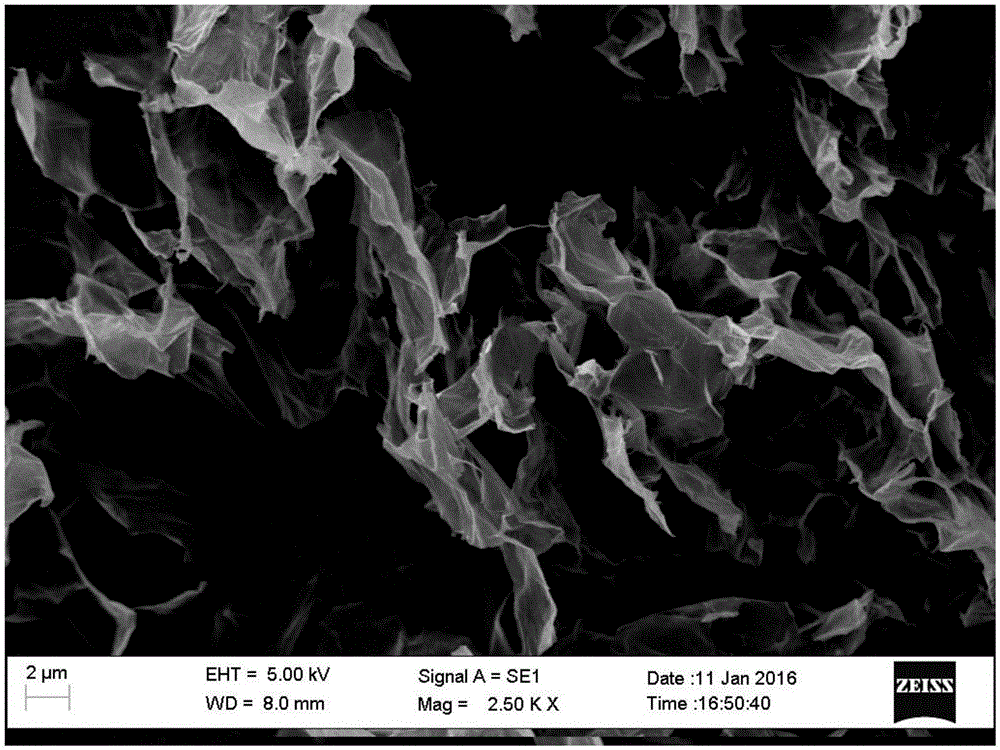

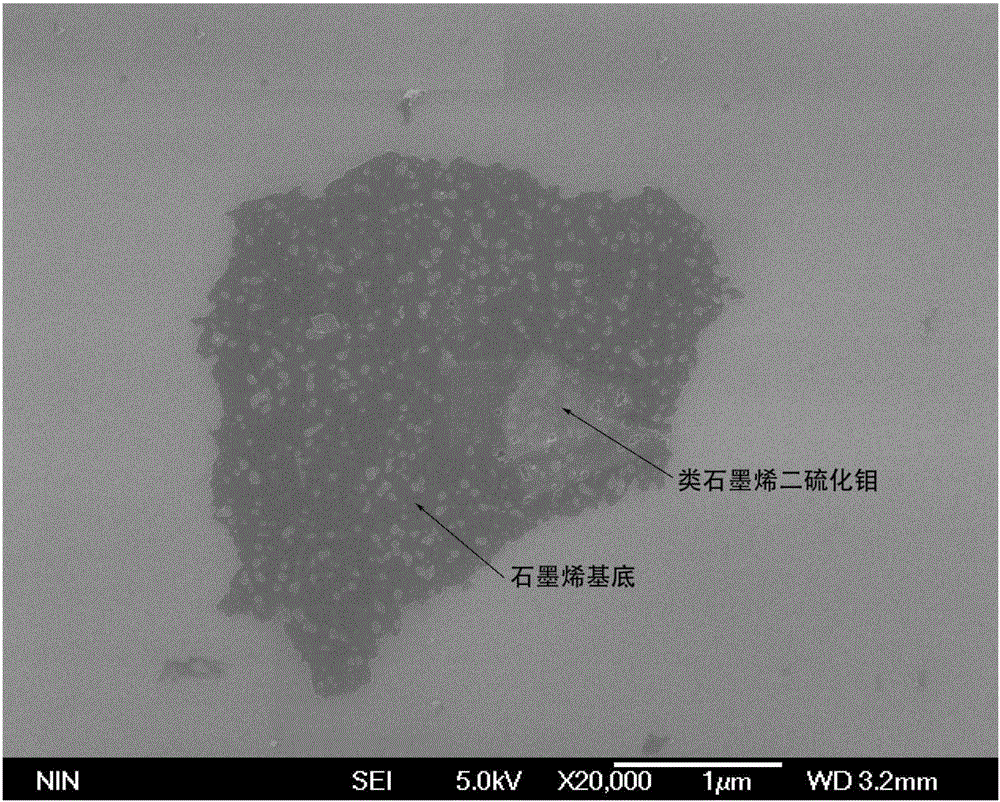

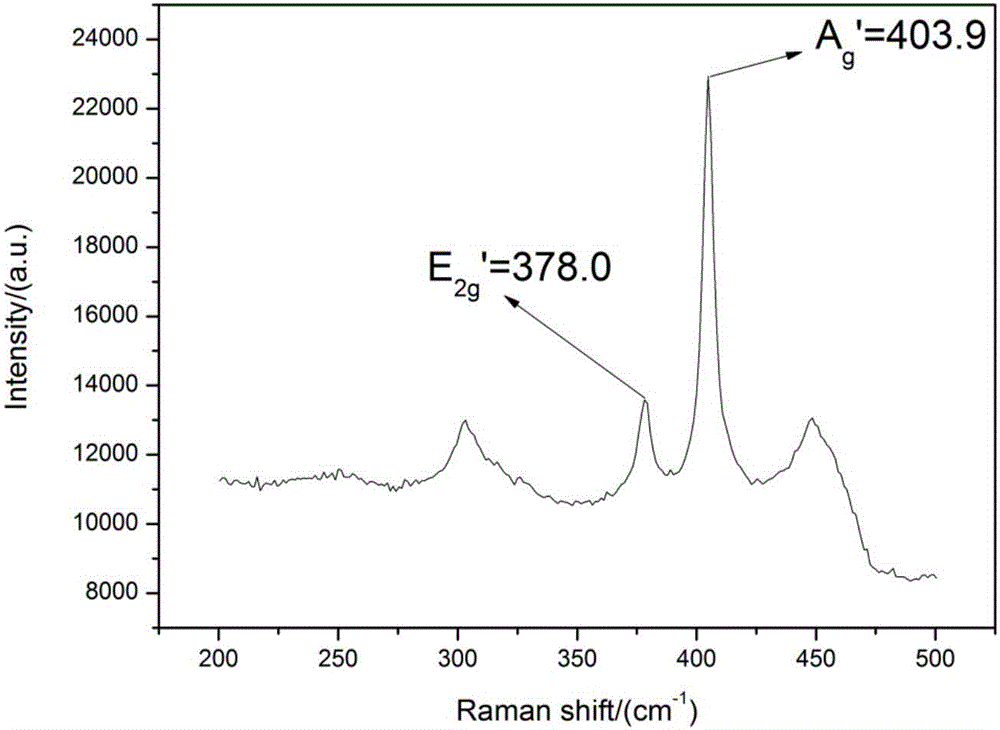

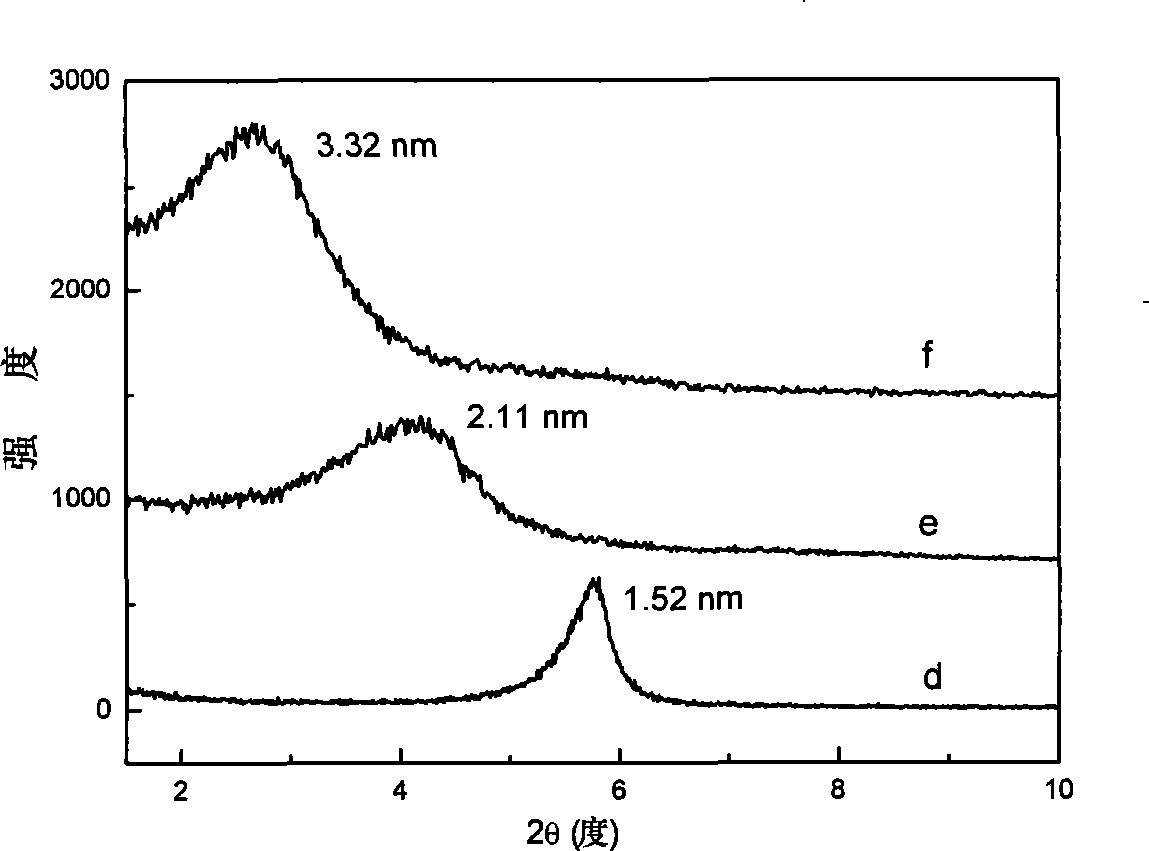

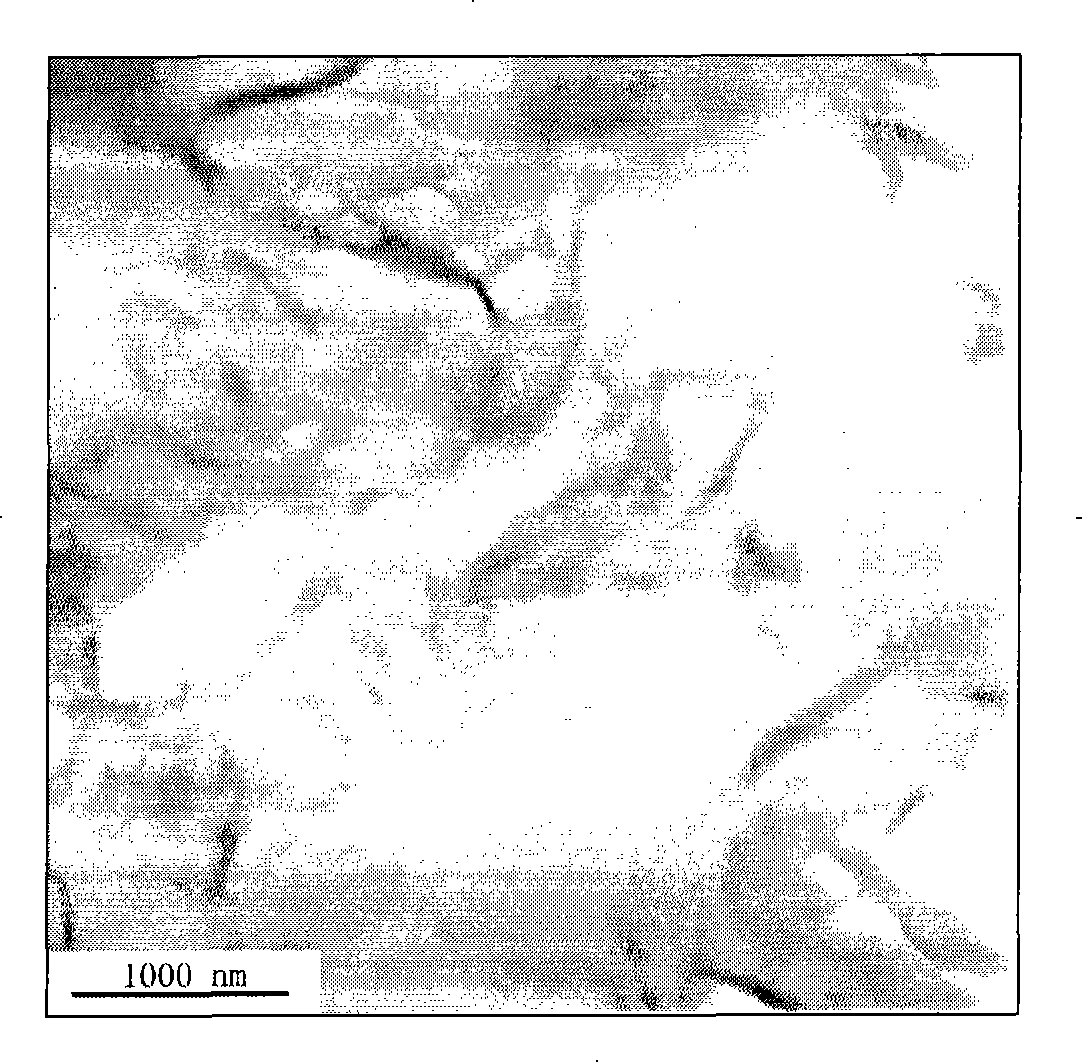

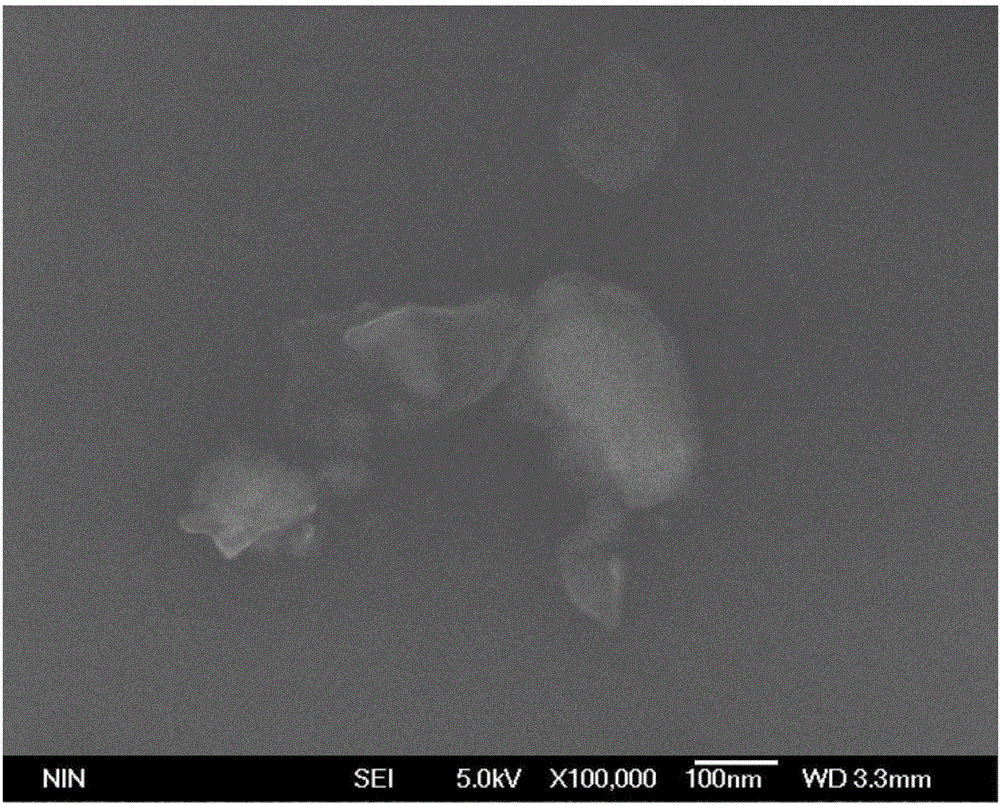

Method for preparing graphene-like molybdenum disulfide-graphene composite material by reducing carbohydrate organic carbon

ActiveCN106564952AImprove photocatalytic performanceHigh carrier mobilityPhysical/chemical process catalystsMolybdenum sulfidesIntercalation reactionShielding gas

The present invention provides a method for preparing a graphene-like molybdenum disulfide-graphene composite material by reducing carbohydrate organic carbon. The method is as follows: 1, adding molybdenum disulfide powder into an intercalation solution for intercalation reaction, and filtering and drying after the reaction is complete to obtain intercalation molybdenum disulfide powder; 2, mixing the intercalation molybdenum disulfide powder obtained by the step 1 with the carbohydrate organic carbon and water in the proportion of intercalation molybdenum disulfide powder to carbohydrate organic carbon to water of 2g: (2-12) g: (20-120) g, stirring evenly, drying and grinding to obtain precursor powder; and 3, performing reduction reaction of the precursor powder under a protective gas, after the reaction is complete, cooling, and taking a reaction product for grinding to obtain the graphene-like molybdenum disulfide-graphene composite material. Through combination of intercalation reduction synthesizing of graphene-like molybdenum disulfide and synthesizing of graphene, the stripping of intercalation molybdenum disulfide and the production of graphene are completed in one step.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

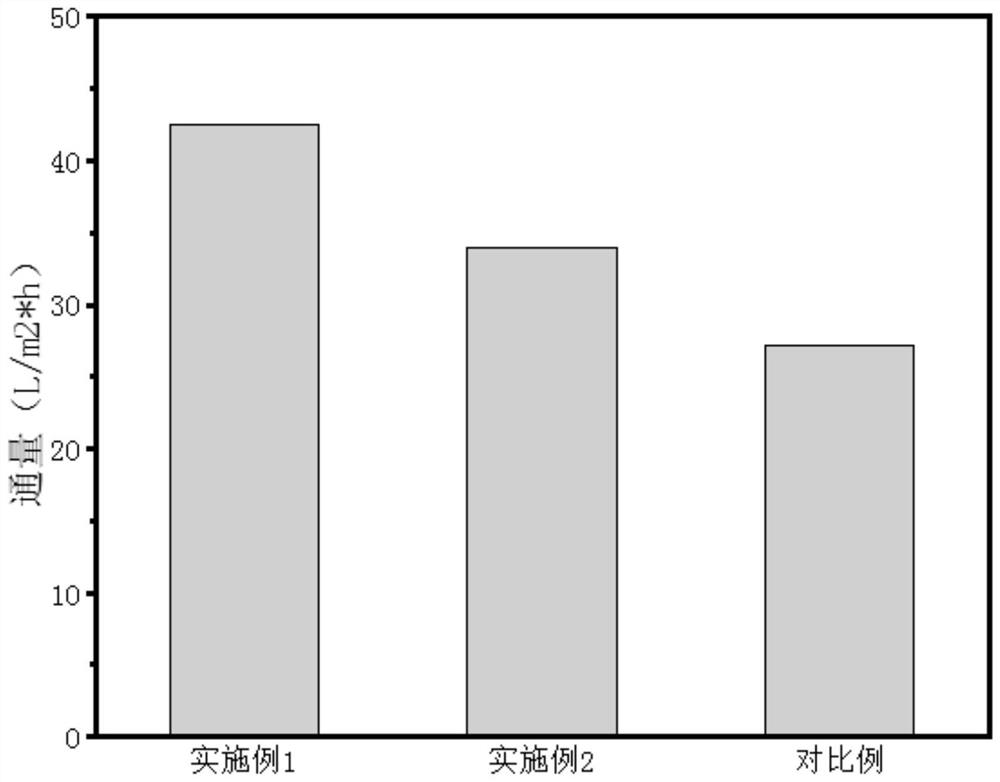

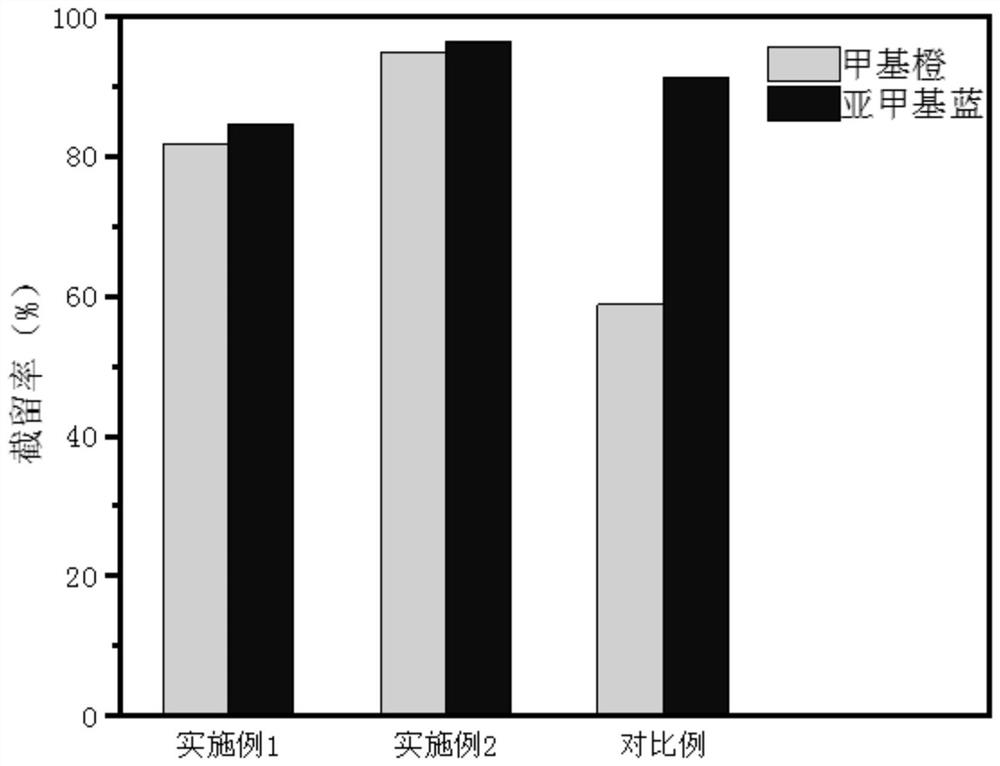

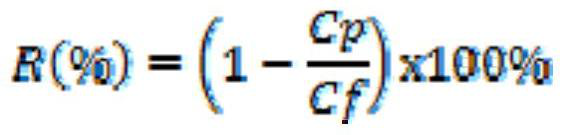

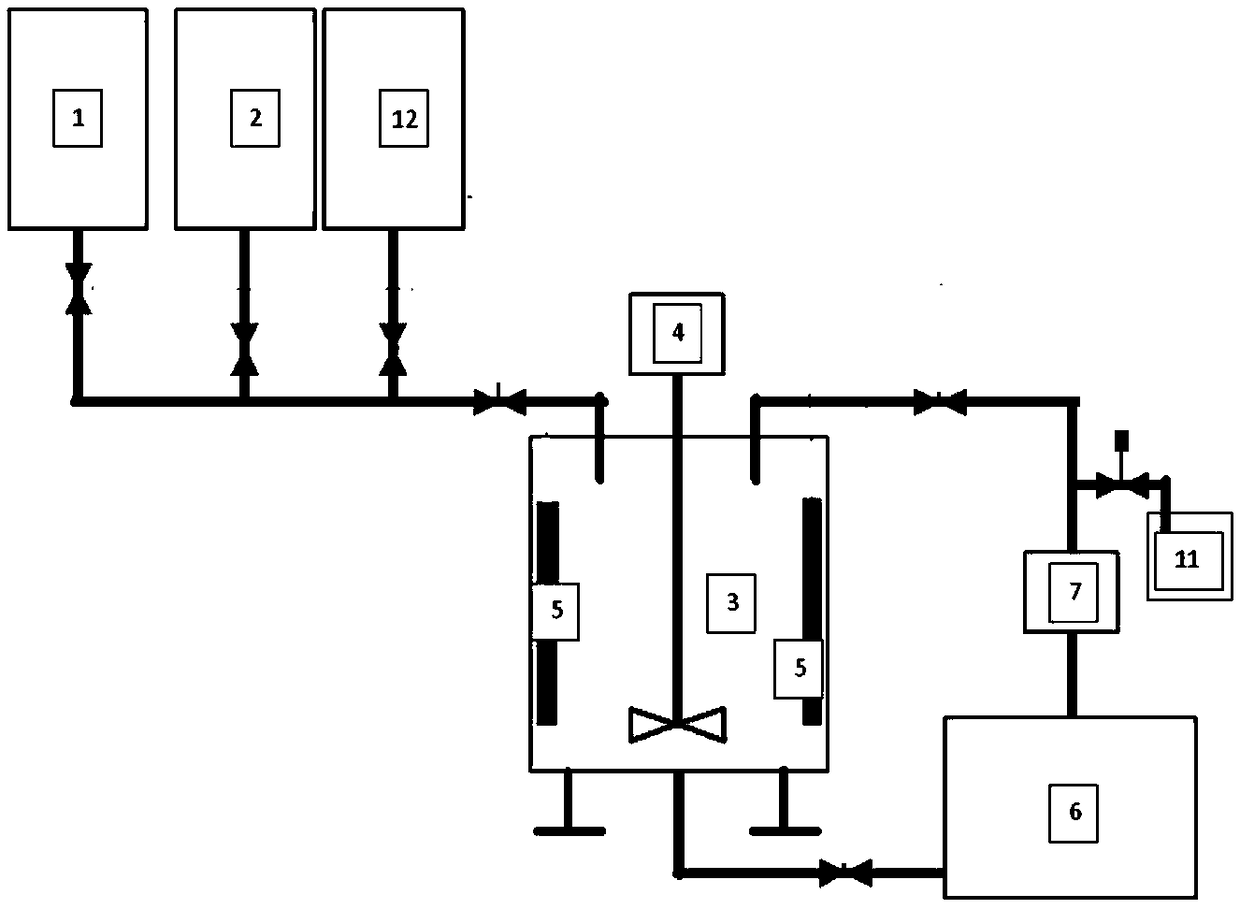

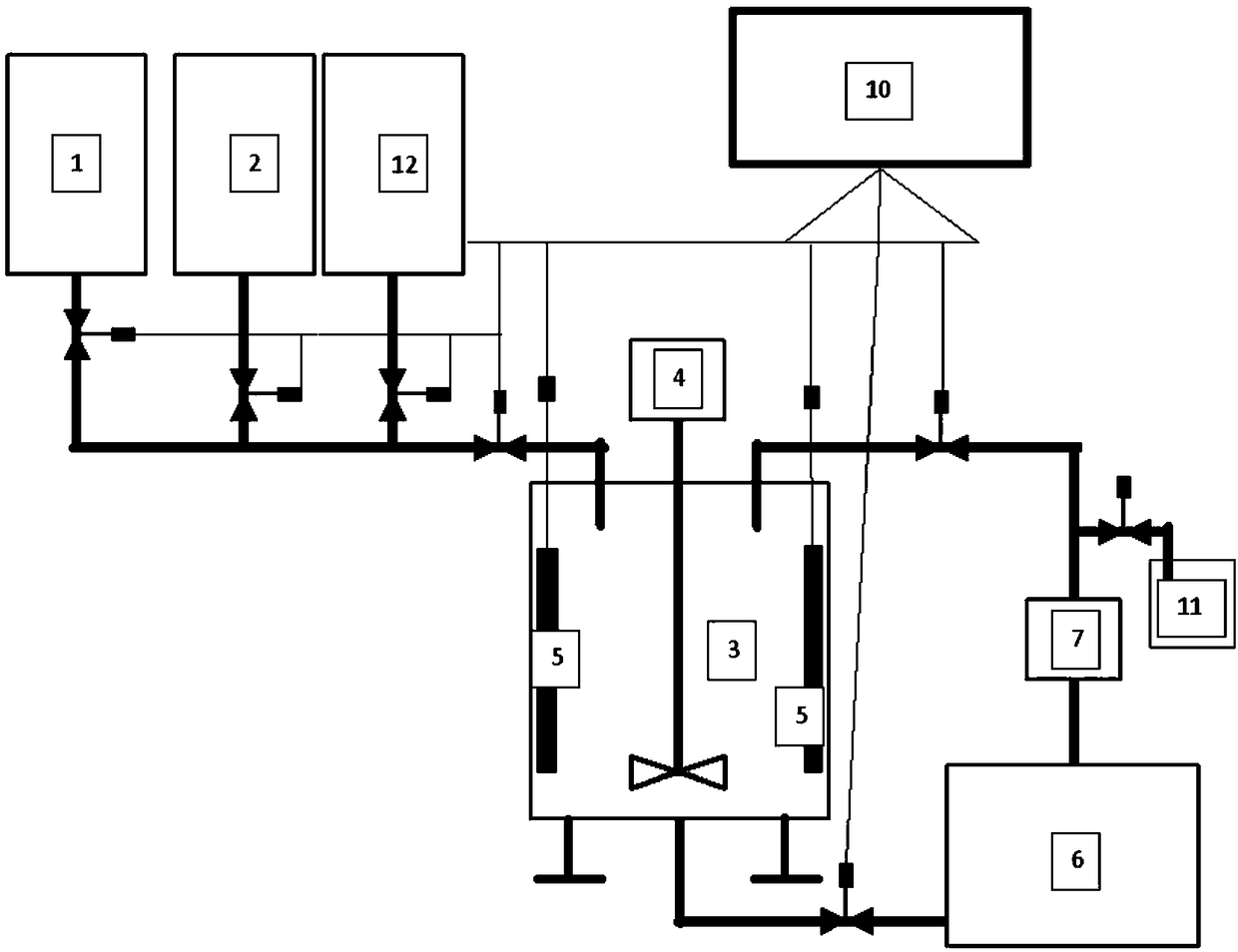

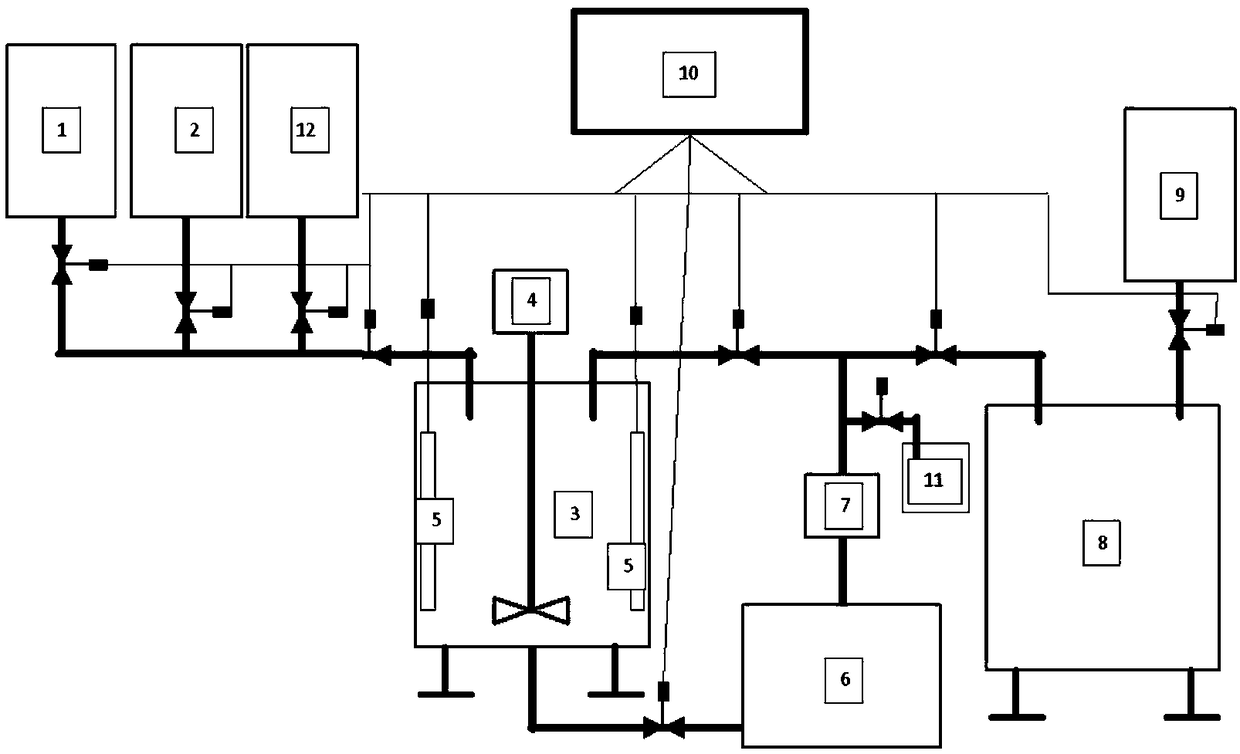

Borate intercalation modified graphene oxide composite nanofiltration membrane and preparation method thereof

ActiveCN111921388AIncrease the distance between layersImprove permeabilityMembranesWater/sewage treatment bu osmosis/dialysisOxide compositeCross linker

The invention discloses a borate intercalation modified graphene oxide composite nanofiltration membrane and a preparation method thereof. Borate is used as an intercalation molecule to modify graphene oxide, and then the modified graphene oxide is connected with a hydrolyzed polypropylene cyanide membrane through polyethyleneimine to obtain the composite nanofiltration membrane. According to thepreparation method, borate is used as an inorganic covalent cross-linking agent for intercalation modification of layered graphene oxide nano sheets, and the interlayer distance of graphene oxide is increased before membrane formation, so that the problem of environmental pollution caused by small organic molecule intercalation is solved, and the interlayer distance of graphene oxide is increasedto improve the permeation flux and separation performance of the membrane; and the preparation process is mild in reaction conditions and low in cost.

Owner:HOHAI UNIV

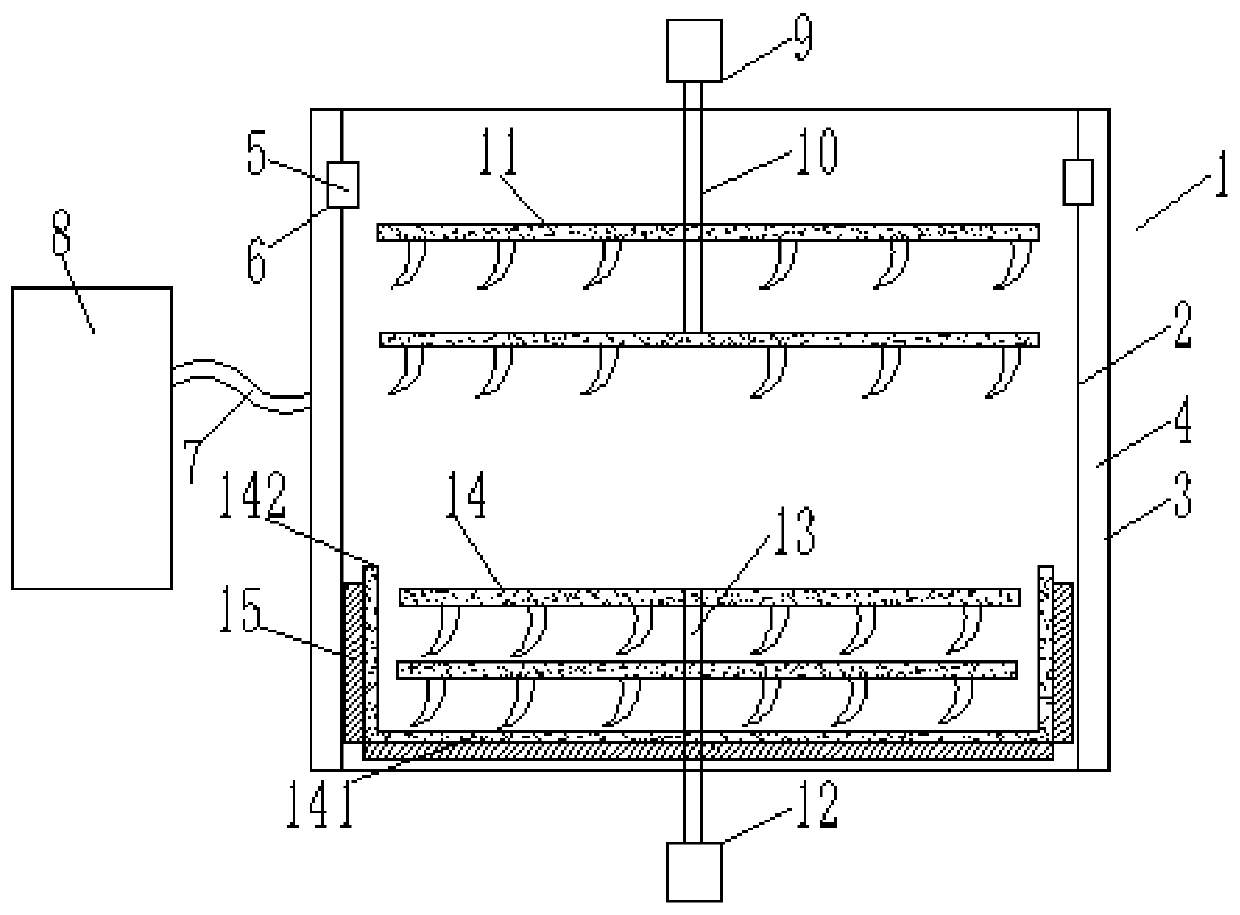

Graphene preparation method and mass production device

The invention discloses a graphene preparation method and a mass production device. The graphene preparation method comprises the following steps: adding graphite powder, a weak acid or a weak alkaliand water into a microwave reaction kettle, stirring, and wetting to obtain a graphite turbid liquid; carrying out microwave peeling in the microwave reaction kettle, carrying out mechanical peeling in a mechanical peeling device, circulating microwave and / or mechanical peeling according to demands to obtain a graphene turbid liquid; carrying out suction filtration, washing and drying by using a cleaning and drying device to obtain graphene powder, wherein the weak acid or the weak alkali is one or more of tannic acid, sodium gluconate and hydrogen peroxide; the ratio of the graphite powder tothe weak acid or the weak alkali to the water is (1-10g):(0.1-1g):(0.5-1L); and the temperature of mechanical peeling is 60 DEG C or less. No strong acid, strong alkali or strong oxidant is needed tobe introduced to oxidize or intercalate graphite / graphene; raw materials are safe and environmentally-friendly, wide in source and low in cost; no waste acid, wastewater, waste gas or pollution is generated in the preparation process, in addition, on-scale production is achieved, and the equipment cost is low.

Owner:北京若水金枫科技有限公司

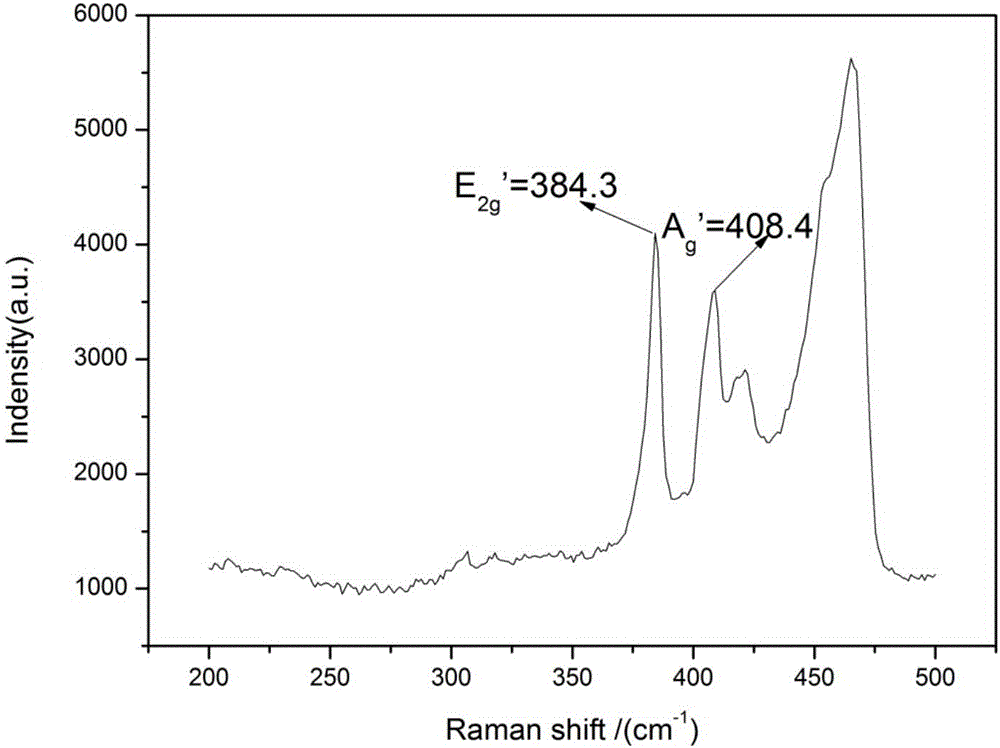

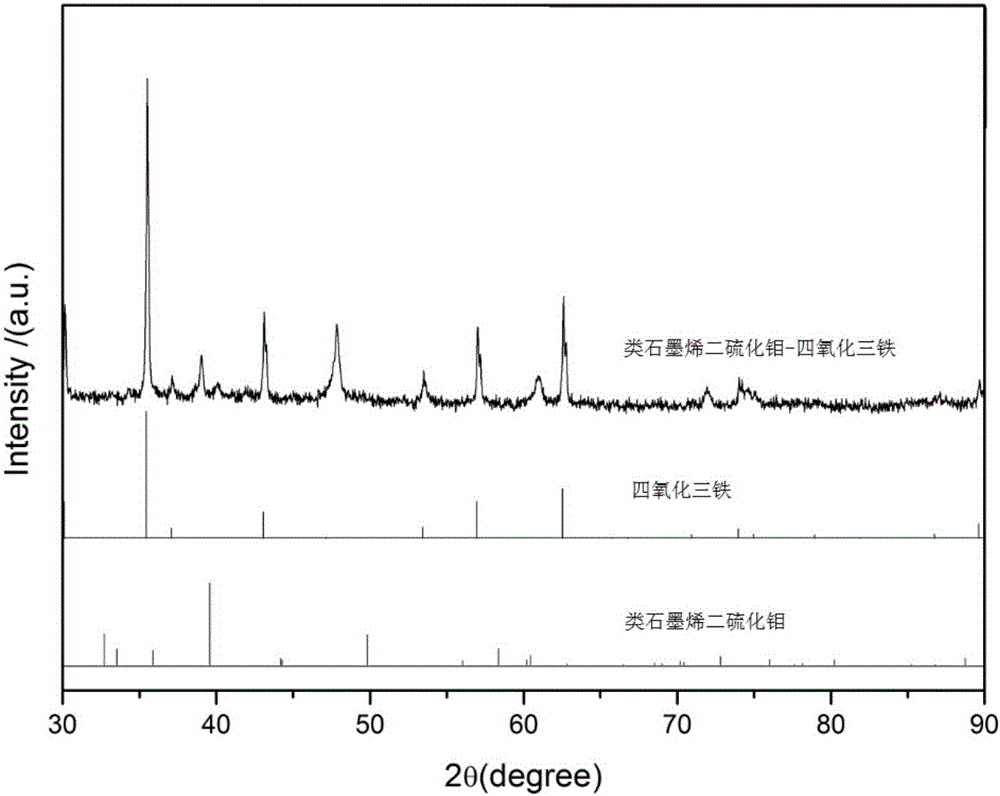

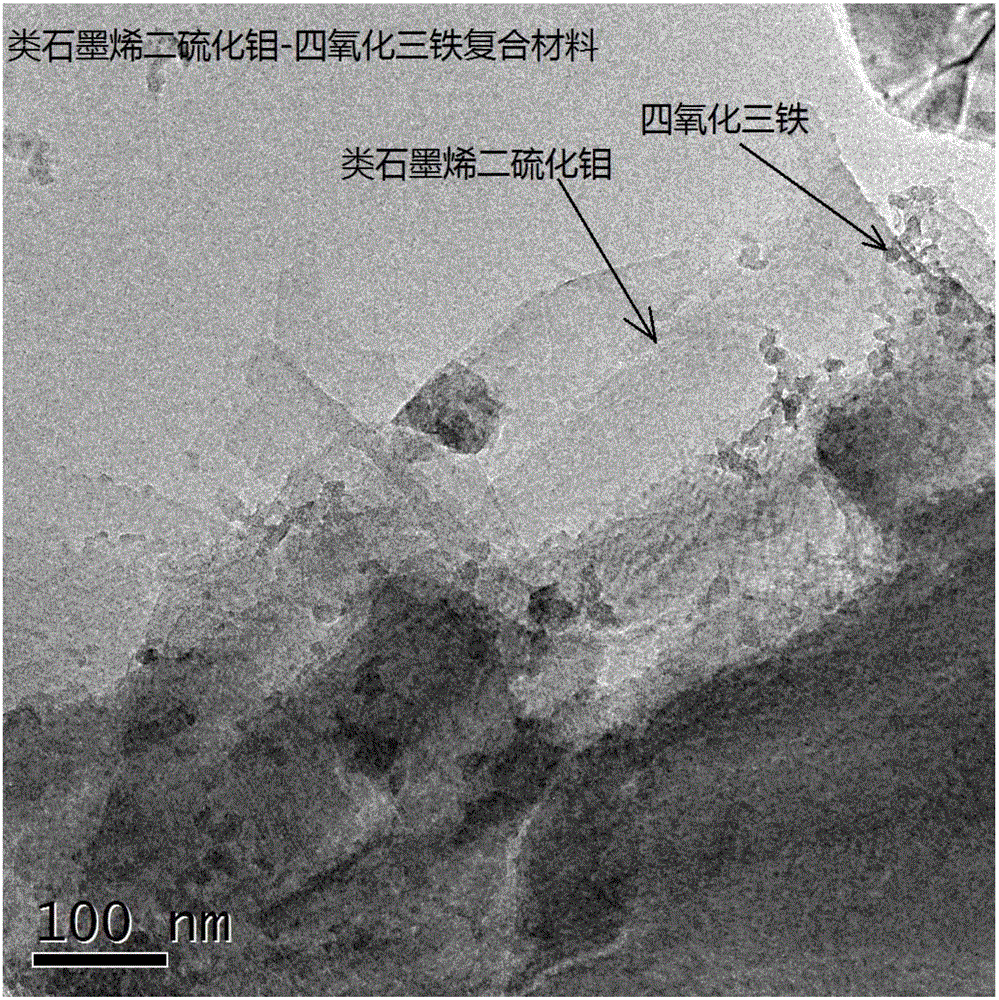

Method for preparing graphene-like molybdenum disulfide-ferroferric oxide composite material through reduction for proteic substances

ActiveCN106564962AAchieve strippingRealize generationOther chemical processesFerroso-ferric oxidesIntercalation reactionNitrate

The invention provides a method for preparing a graphene-like molybdenum disulfide-ferroferric oxide composite material through reduction for proteic substances. The method comprises the following steps: adding a molybdenum disulfide powder in an intercalation solution and carrying out an intercalation reaction, and filtering and drying after the reaction is finished to obtain an intercalation molybdenum disulfide powder; mixing the intercalation molybdenum disulfide powder prepared in the step 1 with the proteic substances and water, uniformly stirring, drying and grinding to obtain a precursor powder; mixing ferric nitrate with citric acid and then adding the mixture in water, and carrying out a chelation reaction to obtain a yellow sol solution; adding the precursor powder in the yellow sol solution, stirring and mixing to obtain a mixed gel, drying and grinding to obtain a dry gel powder; and carrying out a reduction reaction on the dry gel powder under a protective gas, cooling after the reaction is complete, and taking out a reaction product. The method provided by the invention realizes peeling for molybdenum disulfide and generation for ferroferric oxide simultaneously, and finishes a compounding process of graphene-like molybdenum disulfide and ferroferric oxide in one step.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation technology of flame-resistant glass flake

InactiveCN109705702AImprove anti-corrosion performanceImprove heat resistanceFireproof paintsLiquid surface applicatorsEpoxyUnsaturated polyester

The invention discloses preparation technology of flame-resistant glass flake. The preparation technology comprises following steps: 1, a base surface is coated with a primary coat through spraying successively, and a primary coat surface is subjected to polishing so as to form a rough surface, wherein the primary coat is composed of vinyl ester resin, unsaturated polyester resin, urea-formaldehyde resin, organic silicon resin, and epoxy resin at a mass ratio of 4:2:1:1:1 through mixing; 2, the primary coat surface is coated with a structure layer through spraying, and a structure layer surface is subjected to polishing so as to form a rough surface, wherein the structure layer is composed of modified montmorillonite, modified bentonite, meerschaum, and epoxy resin through mixing at a massratio of 3:2:2:1; and 3, the structure layer surface is coated with a surface coat through spraying so as to obtain the target product flame-resistant glass flake, wherein the surface coat is composed of zinc borate, nanometer silver particle, epoxy resin, and glass flake at a mass ratio of 0.5:0.5:1:3 through mixing. The flame-resistant glass flake is excellent in anti-corrosive property, heat resistance, and flame resistance.

Owner:武汉博奇玉宇环保股份有限公司

High temperature resistance and impact resistance variable frequency cable

InactiveCN105585851AGood high and low temperature resistanceImprove corrosion resistanceRubber insulatorsInsulated cablesPhosphateStearic acid

The invention discloses a high temperature resistance and impact resistance variable frequency cable which comprises a sleeve layer. The sleeve layer is prepared from silicone rubber, composite filler, hydroxyl silicone oil, acetyl tributyl citrate, trioctyl phosphate, fire retardant, vinyltriethoxysilane, dicumyl peroxide, sulphur, zinc oxide, stearic acid, accelerant DETU, lauric acid dibutyltin maleate, octyl tin mercaptide, an anti-aging agent 4020, an anti-aging agent TMQ, an anti-aging agent RD and polyethylene wax. The composite filler is prepared from superfine glass fiber cotton, nanometer silicon carbide and modified expanded vermiculite. The high temperature resistance and impact resistance variable frequency cable is good in high temperature resistance and high in mechanical performance.

Owner:王社兵

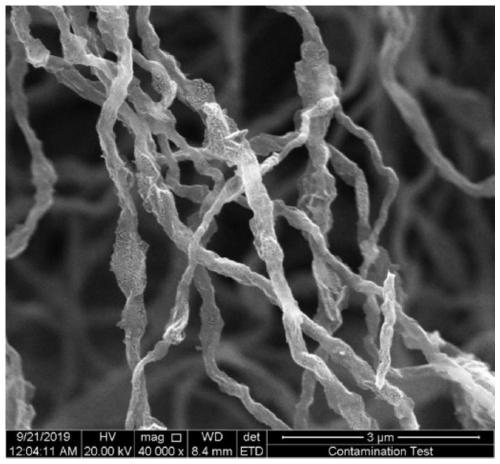

Flexible sulfur-nitrogen co-doped porous carbon fiber composite electrode material, preparation method and application thereof

ActiveCN111211307ALarge specific surface areaLarge amount of ionsNegative electrodesSecondary cellsCarbon fibersPorous carbon

The invention discloses a flexible sulfur-nitrogen co-doped porous carbon fiber composite electrode material and a preparation method thereof, and an application in an electrochemical energy storage device. The preparation method comprises the following steps: firstly, taking polyacrylonitrilePAN and metal oxide MOX as raw materials, carrying out electrostatic spinning to obtain flexible oxide nanofiberMOX@PAN; mixing with sublimed sulfur, heating in an inert atmosphere for heat treatment, and naturally cooling to obtain flexible metal sulfide nano carbon fiber MSx@NCF; and finally, etching metal sulfide by using an acid to obtain the flexible sulfur-nitrogen co-doped porous carbon fiber (SNCF) composite electrode material. The flexible sulfur-nitrogen co-doped porous carbon fiber composite electrode material obtained by adopting electrostatic spinning, high-temperature treatment and an etching method not only has a large specific surface area, but also enables surface charges to be stored and reacted quickly due to sulfur-nitrogen doping, obviously improves cycling stability of an energy device, and can be used as a lithium, sodium and potassium ion battery negative electrode material.

Owner:SOUTHEAST UNIV

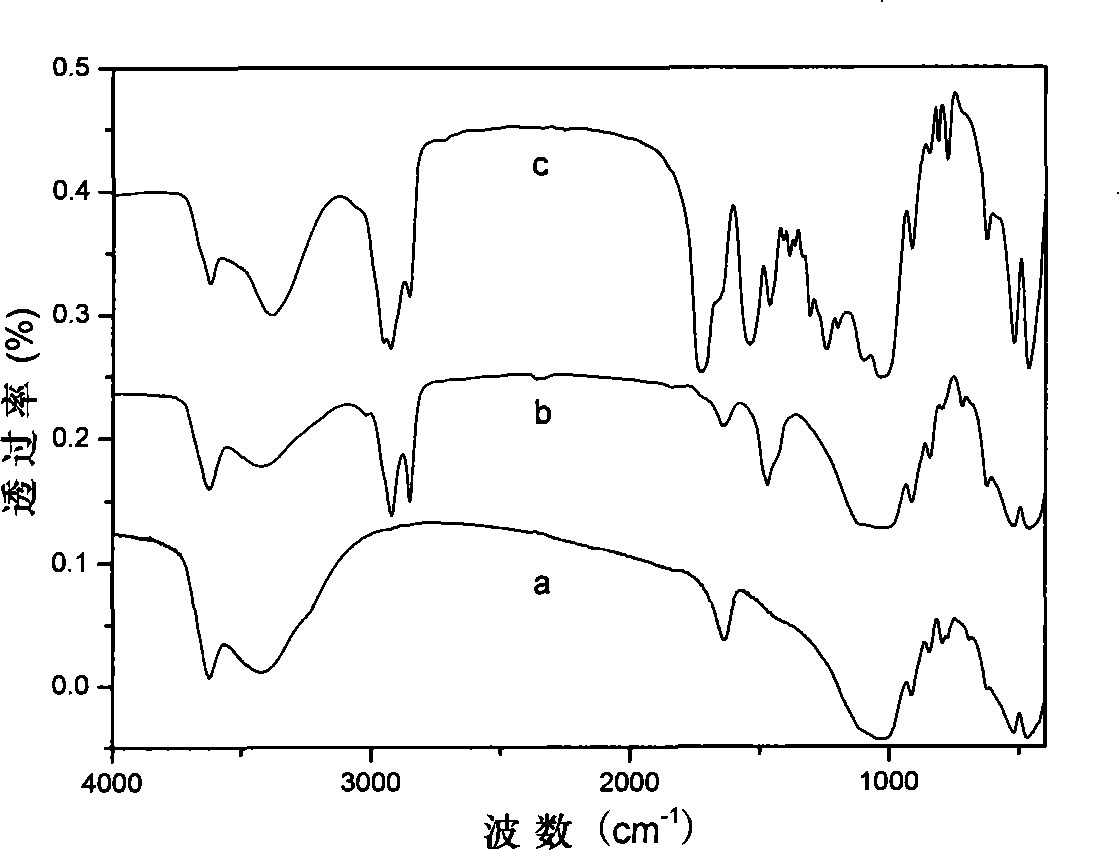

Ultraviolet curing acrylic ester/modified montmorillonite nano composite material and preparation thereof

InactiveCN101255219BOvercome Synthetic DifficultiesIncrease layer spacingPigment treatment with non-polymer organic compoundsUltraviolet lightsMechanical property

The invention relates to an ultraviolet light solidified acrylate / modified montmorillonite nanometre composite material and preparation method thereof, comprising montmorillonite being subjected to cation exchange modifying using longchain alkyl quaternary ammonium salts; extending the distance between the montmorillonite layers and improving the chemistry microenvironment; the surface hydroxy group of the montmorillonite being decorated using acrylate modifier with carbimide group and grafted with a large amount of acrylate groups of high response to further extend the interlayer distance;finally mixing the decorated montmorillonite, acrylate monomer, acrylate oligomer and ultraviolet light initiator to produce the ultraviolet light solidified acrylate / modified montmorillonite nanometre composite material. The method is simply and easily operated to realize high delamination and good dispersion pf montmorillonite in polymer substrate. Compared with the pure acrylate material, the material of the invention has greatly improved mechanical property and thermal endurance, with high intension after ultraviolet light solidifying, high hardness, good thermal stability and wide industrial application foreground.

Owner:常州华钛化学有限公司

Method for reducing preparation of graphene-like molybdenum disulfide from protein substance

ActiveCN106629851AAchieve restorationAchieve strippingNanotechnologyMolybdenum sulfidesPhysical chemistryCarbonization

The invention provides a method for reducing preparation of graphene-like molybdenum disulfide from a protein substance. The method comprises the following steps: adding molybdenum disulfide powder into an intercalation solution for intercalation reaction, and after the reaction is finished, performing filtering and drying to obtain intercalated molybdenum disulfide powder; mixing and uniformly stirring the intercalated molybdenum disulfide powder prepared by step 1, the protein substance and water, and performing drying and grinding to obtain precursor powder; performing reducing reaction on the precursor powder under protective gas, performing cooling after complete reaction, and extracting and grinding a reaction product to obtain the graphene-like molybdenum disulfide. According to the method, a protein organic carbon source and molybdenum disulfide are mixed to form a precursor, then the organic carbon source is intercalated between molybdenum disulfide powder layers to increase the distance between the layers and weaken the action of van der waals force between the molybdenum sulfide powder layers, and heating carbonization of the protein organic carbon source is combined to promote reduction and stripping of the molybdenum disulfide.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

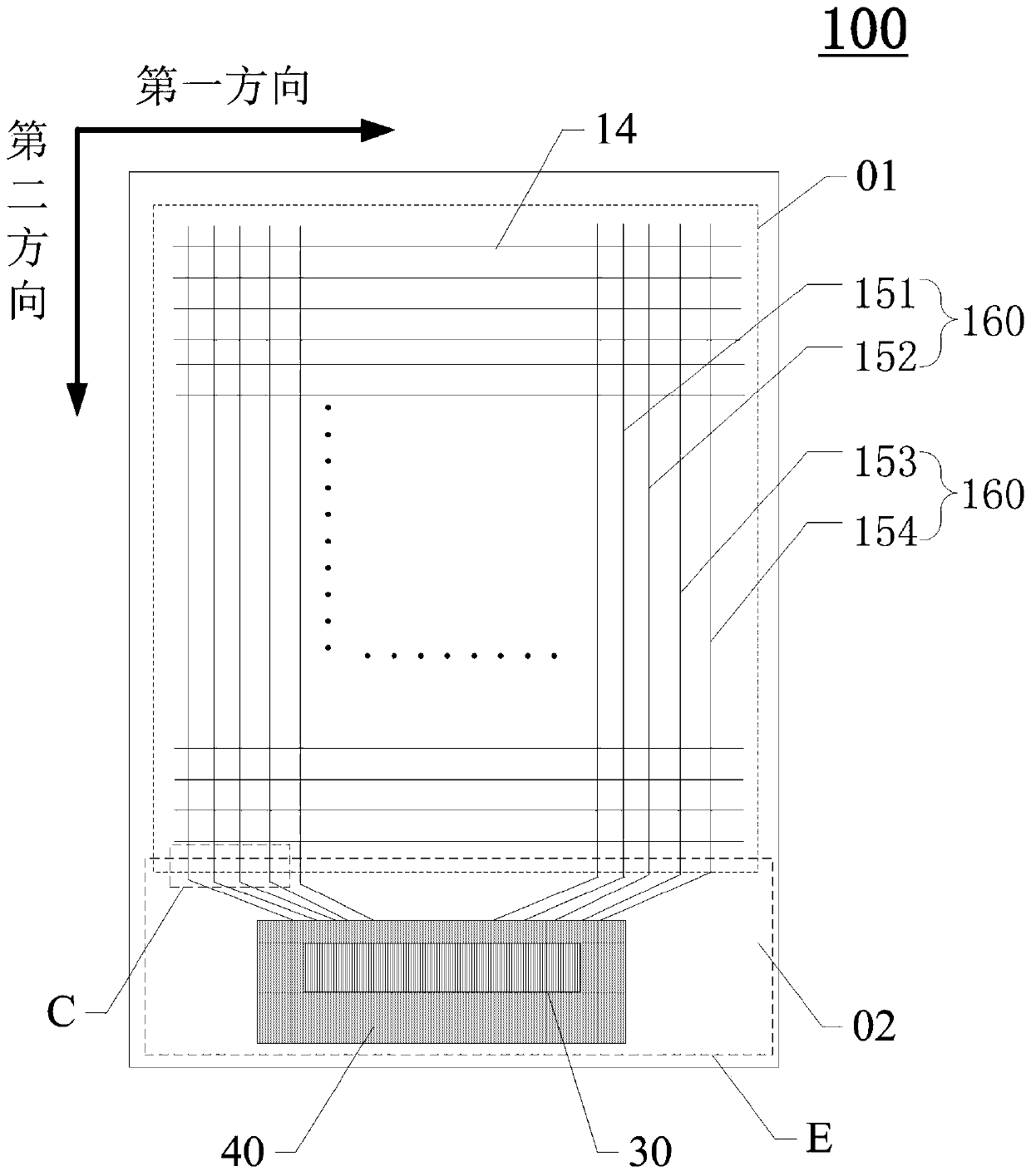

Display panel and display device

PendingCN111240059AIncrease charging rateIncrease the distance between layersStatic indicating devicesNon-linear opticsDisplay deviceElectrical connection

The invention discloses a display panel and a display device, and relates to the technical field of display. The display panel comprises a substrate, a first metal layer, a second metal layer and a third metal layer arranged in sequence, and also comprises a data line group extending along a second direction. The non-display area of the display panel comprises a switch unit and a switch control line unit extending in the first direction, and any data line set at least comprises a first data line and a second data line. The first pole of any switch unit is electrically connected with the firstdata line or the second data line in a one-to-one correspondence manner. The control end of any switch unit is electrically connected with the switch control line unit through a first connecting wire, the first connecting wire is at least partially overlapped with the orthographic projection of the switch control line unit on the substrate, the switch control line unit is arranged on the second metal layer, and the first connecting wire is arranged on the third metal layer. By increasing the interlayer distance between the switch control line unit and the first connecting line, the charging rate of the display panel can be increased.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

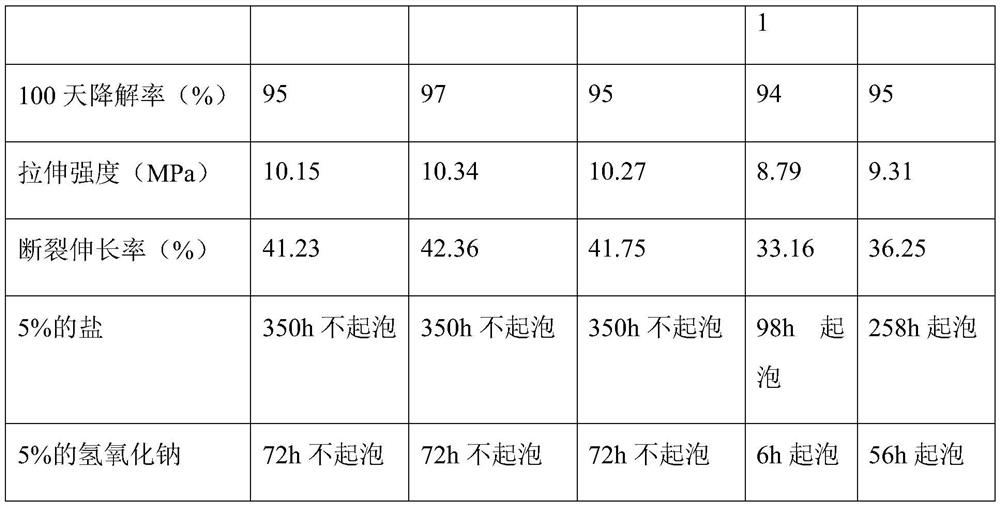

High-strength degradable environment-friendly plastic and preparation method thereof

InactiveCN112358638AImprove water resistanceGood water resistanceAnti-corrosive paintsEpoxy resin coatingsEthyleneglycol monobutyl etherCorn starch

The invention discloses a high-strength degradable environment-friendly plastic and a preparation method thereof. The environment-friendly plastic comprises a modified substrate and an anticorrosive coating coated on the surface of the modified substrate; the modified substrate is mainly prepared by surface modification of a pretreatment matrix and a silane coupling agent A; the anticorrosive coating is prepared from the following raw materials, by weight: 60-70 parts of epoxy resin, 25-30 parts of ethylene glycol monobutyl ether, 30-40 parts of a silane coupling agent B and 10-15 parts of modified graphene. The invention discloses a high-strength degradable environment-friendly plastic and a preparation method thereof, the process design is reasonable, the operation is simple, and the prepared environment-friendly plastic is co-extruded by taking polyethylene, corn starch and other components as raw materials; the plastic has excellent biodegradability as well as excellent water resistance and corrosion resistance; and the plastic has excellent comprehensive performance, can be applied to multiple fields, and has high practicability.

Owner:张小兰

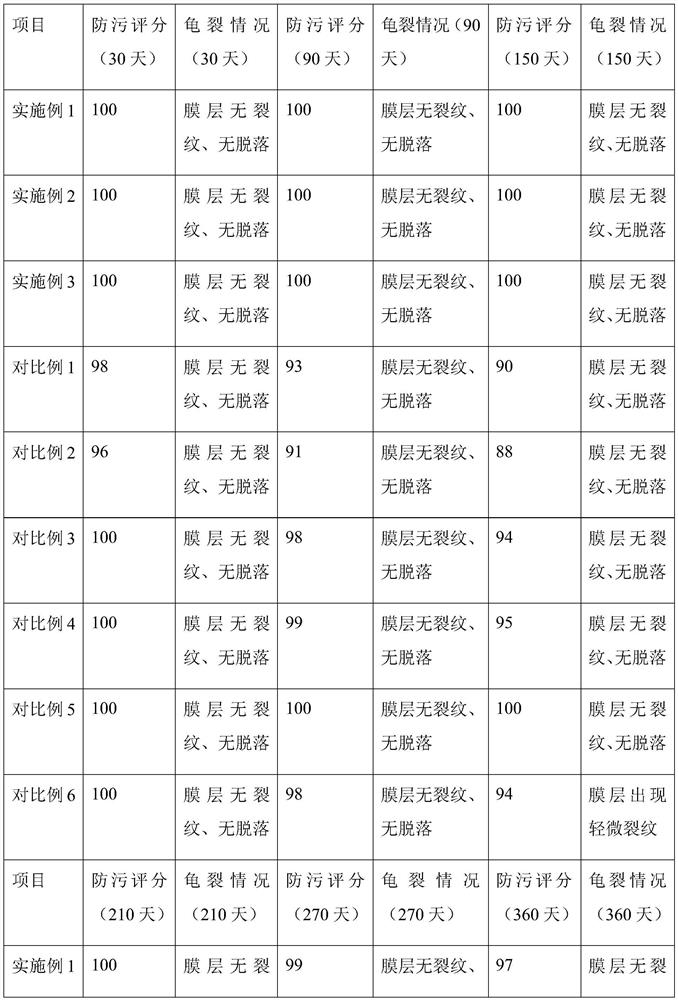

Anti-cracking zinc acrylate antifouling paint and preparation method thereof

PendingCN112375436AExcellent antibacterial and antifouling propertiesGood flexibilityAntifouling/underwater paintsPaints with biocidesTitanium chlorideOrganosolv

The invention discloses an anti-cracking zinc acrylate antifouling paint and a preparation method thereof, and the antifouling paint comprises the following raw materials by weight: 30-40 parts of zinc acrylate resin, 15-20 parts of a pigment, 10-15 parts of an organic solvent, 25-35 parts of a modified antifouling agent, 4-8 parts of an auxiliary agent, and 8-10 parts of amino silicone oil. The modified antifouling agent is mainly prepared by reacting modified graphene, modified montmorillonite, isopropanol, titanium tetrachloride, sodium citrate, a copper acetate solution, sodium hydroxide and hydrazine hydrate. According to the anti-cracking zinc acrylate antifouling paint and the preparation method thereof, the process design is reasonable, the operation is simple, the prepared antifouling paint not only has excellent bactericidal antifouling performance, but also has excellent flexibility and anti-cracking performance, can be applied to the field of marine antifouling, and has high practicability.

Owner:张学忠

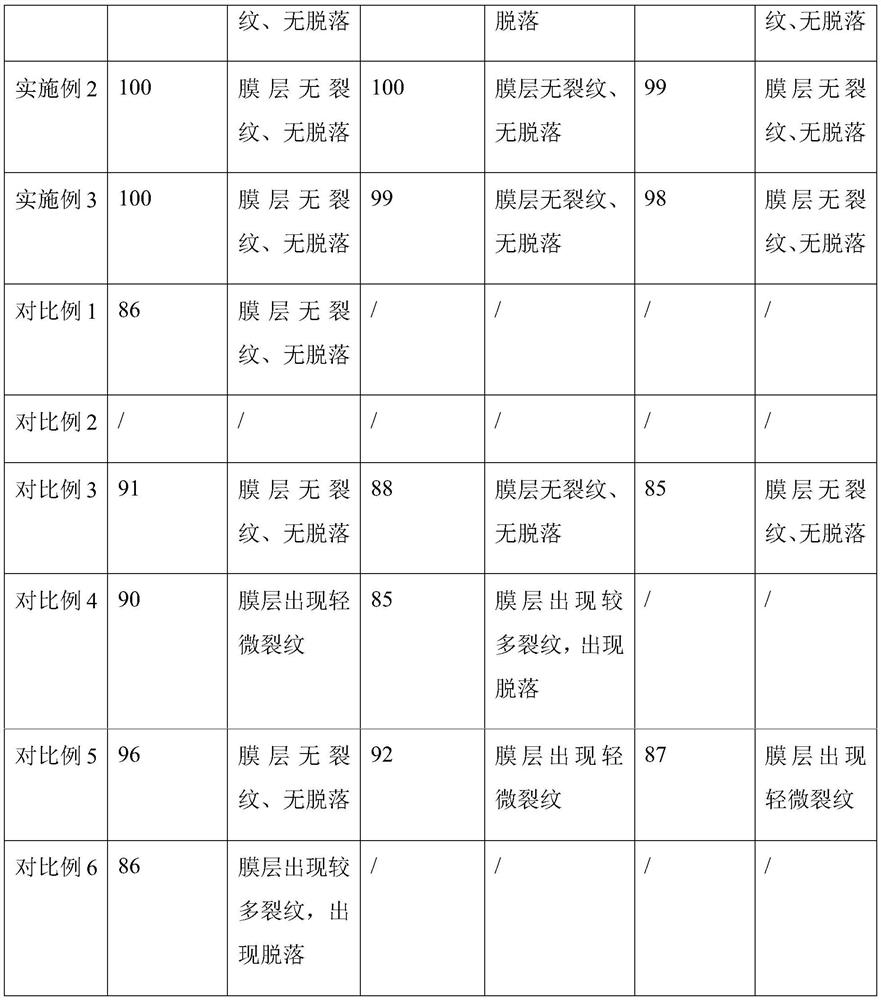

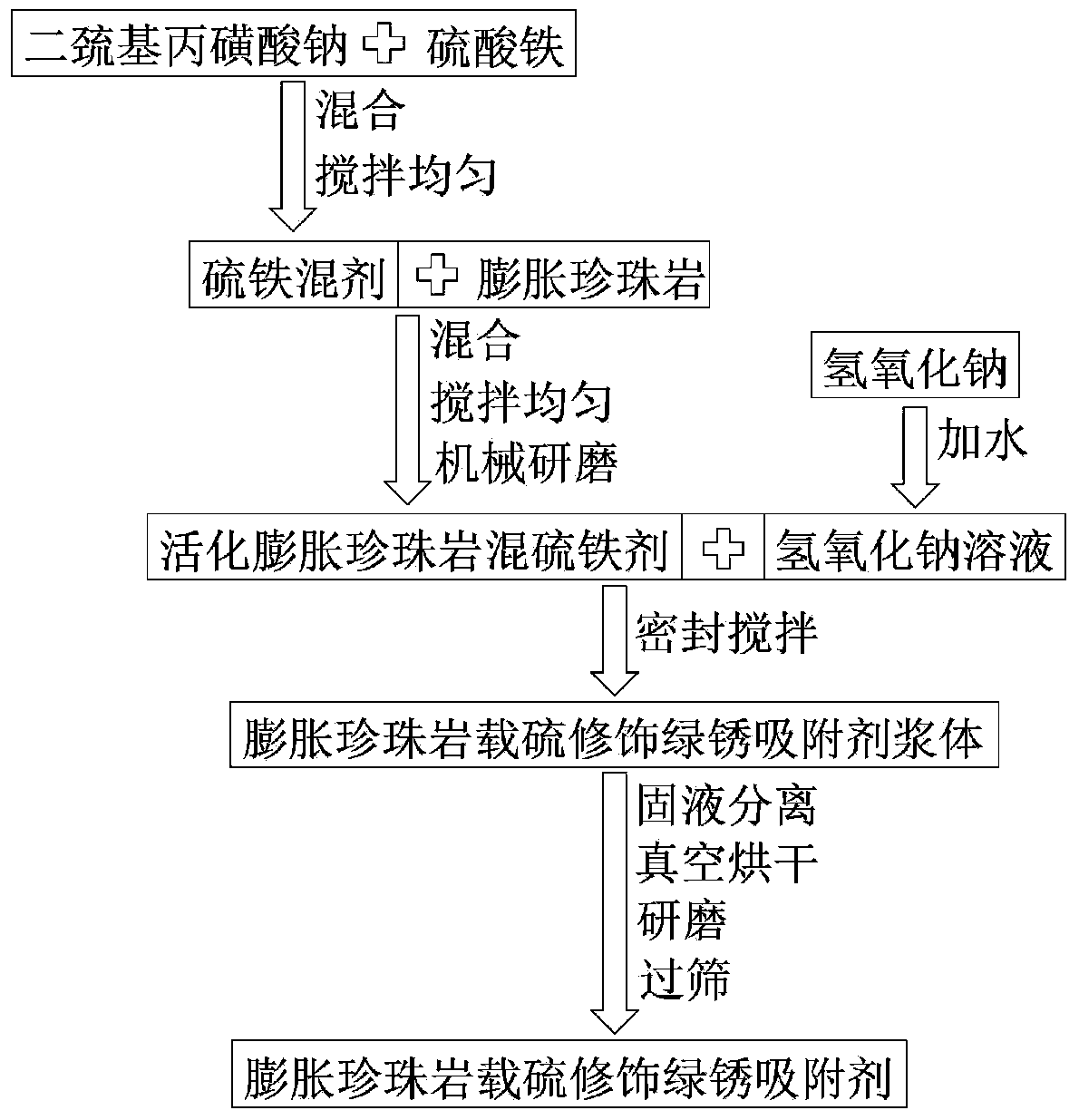

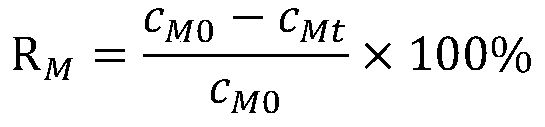

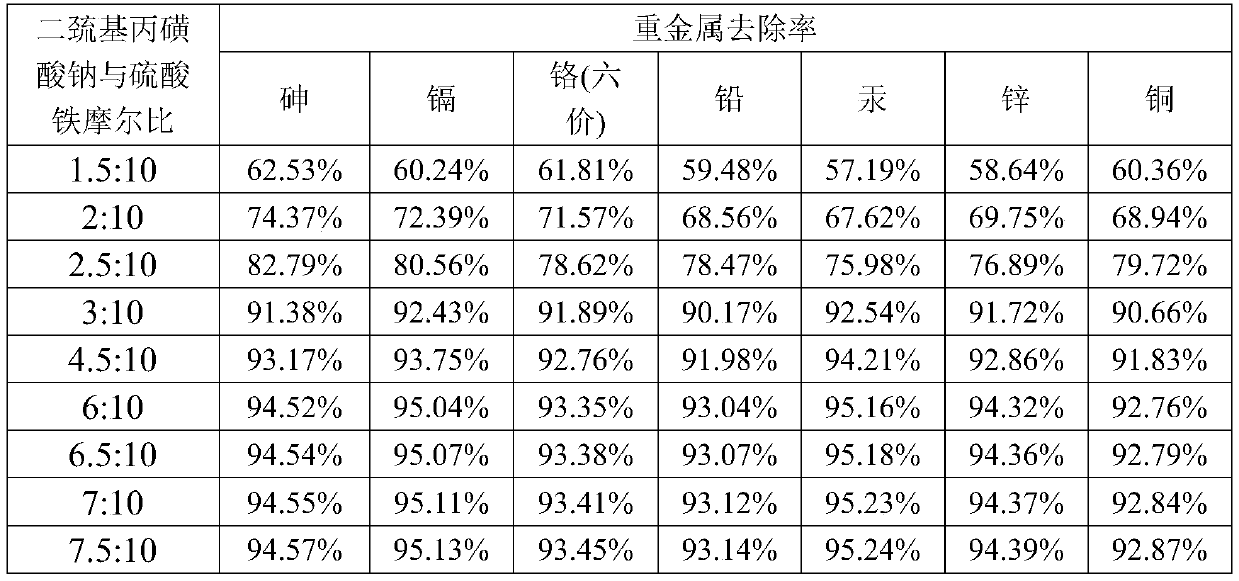

Preparation method of expanded perlite sulfur-loading modified patina adsorbent

ActiveCN110756170ALarge specific surface areaReduce the impactOther chemical processesWater/sewage treatment by sorptionIron sulfateSorbent

The invention discloses a preparation method of an expanded perlite sulfur-loading modified patina adsorbent. The preparation method comprises the following preparation steps: mixing sodium dimercaptopropanesulfonate and iron sulfate evenly so as to obtain a sulfur-iron mixture, then mixing the obtained sulfur-iron mixture with expanded perlite evenly, performing mechanical grinding so as to obtain an activated expanded perlite sulfur-iron-doped agent, then adding the activated expanded perlite sulfur-iron-doped agent to a sodium hydroxide solution, performing sealing and stirring so as to obtain expanded perlite sulfur-loading modified patina absorbent slurry, performing solid-liquid separation on the slurry, and finally performing drying, grinding and sieving so as to obtain the expandedperlite sulfur-loading modified patina adsorbent. Simultaneous and efficient removal of multiple heavy metal ions in sewage can be achieved through the patina adsorbent within a wide pH range of 2-12, and the removal rate of all the heavy metal ions is greater than 97%.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Weather-resistant building waterproof coating and preparation method thereof

The invention discloses a weather-resistant building waterproof coating and a preparation method thereof. The weather-resistant building waterproof coating comprises the following raw materials in parts by weight: 100-200 parts of organosiloxane, 8-10 parts of an emulsifier, 10-20 parts of nanoparticles, 4-8 parts of a curing agent, 100-150 parts of water and 20-30 parts of nano metal oxide modified graphene oxide. In the nano metal oxide modified graphene oxide, a nano metal oxide is embedded into an interlayer structure of the graphene oxide, and the nano metal oxide accounts for 10-50% of the mass of the graphene oxide; and the nano metal oxide is any one of nano aluminum oxide, nano magnesium oxide, nano titanium dioxide, nano manganese dioxide, nano zirconium oxide and nano iron oxide. The obtained product has excellent weather resistance, and the service life of the waterproof function of the product can be effectively prolonged.

Owner:成都亢倡菱涂料科技有限公司

Nutrient and fertilizer-retaining culture substrate and preparation method thereof

InactiveCN107082721AImprove lightnessImprove fat retention capacityMagnesium fertilisersAlkali orthophosphate fertiliserBiologyLightness

The invention discloses a nutrient and fertilizer-retaining culture substrate and a preparation method thereof, and relates to the technical field of culture substrates. The nutrient and fertilizer-maintenance culture substrate is prepared from the following raw materials in parts: 70 to 80 parts of attapulgite, 55 to 60 parts of perlite, 45 to 55 parts of micro-porus starch, 25 to 30 parts of inorganic fertilizer, 15 to 25 parts of organic fertilizer, 10 to 15 parts of straw powder, 2 to 4 parts of micro-components and 100 to 120 parts of water. The nutrient and fertilizer-retaining culture substrate and the preparation method thereof have the advantages of high lightness, fertilizer retention capacity and gas permeability, and is easy to obtain raw materials, simple in preparation method, safe and environmentally friendly.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

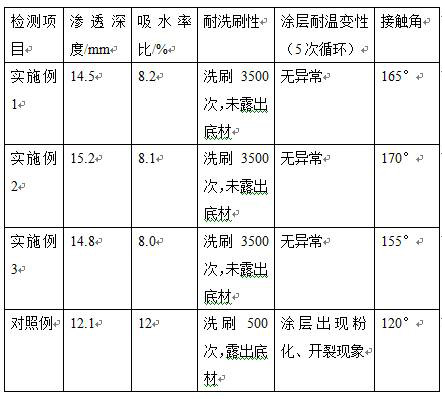

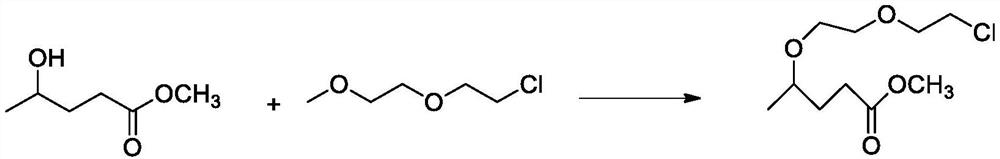

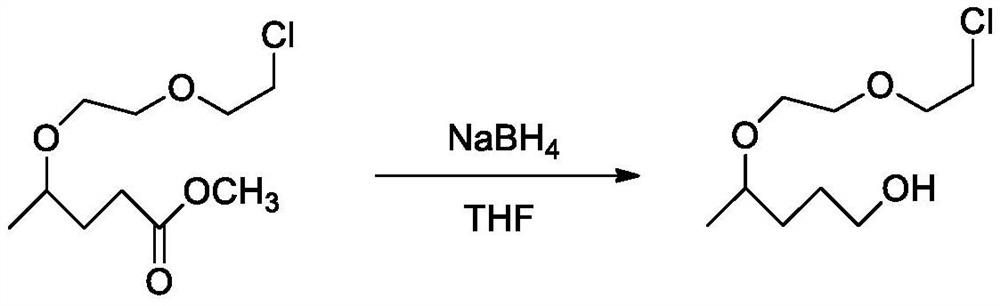

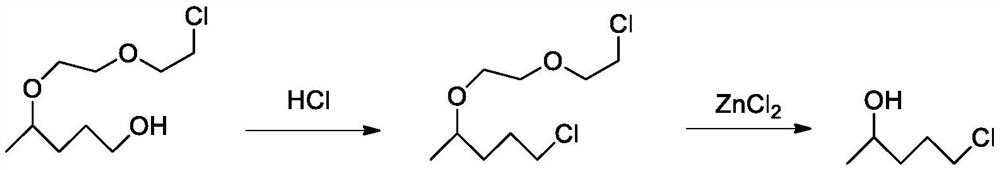

Synthesis process of 5-chloro-2-pentanone

PendingCN114591157AHigh yieldSimple and fast operationOrganic compound preparationCarboxylic acid esters preparationPtru catalystValerate

The invention relates to a synthesis process of 5-chloro-2-pentanone, and belongs to the technical field of medicine synthesis, the synthesis process comprises the following steps: S1, dissolving methyl 4-hydroxyvalerate in tetrahydrofuran, and adding 1-(2-chloroethoxy)-2-methoxyethane to obtain a composition A; s2, dissolving the composition A in tetrahydrofuran, adding zinc chloride, and adding sodium borohydride to obtain a composition B; s3, mixing the composition B with concentrated hydrochloric acid, and adding anhydrous zinc chloride to obtain a composition C; and S4, dissolving the composition C in tetrahydrofuran, adding a composite catalyst, introducing oxygen, filtering, extracting, drying and distilling to obtain the 5-chloro-2-pentanone. According to the technical scheme, 4-hydroxyl methyl valerate is used as an initial raw material for synthesizing 5-chloro-2-pentanone, and a target compound is prepared through five steps of reaction including hydroxyl protection, ester group'one-pot method 'deprotection, chlorination and hydroxyl oxidation.

Owner:ANHUI JIXI COUNTY HUIHUANG CHEM

Anti-cracking UHPC open caisson structure and construction method thereof

ActiveCN110528549AImprove tensile propertiesSolve the problem of easy crackingCaissonsCrack resistanceStructural engineering

The invention discloses an anti-cracking UHPC open caisson structure and a construction method thereof. The anti-cracking UHPC well sinking structure comprises a first layer UHPC layer which is positioned in a potential cracking area at the bottom of an open caisson. According to the anti-cracking UHPC open caisson structure, UHPC is used in a bottom area with greater tensile stress in the sinkingprocess of the open caisson, so that the cracking resistance of the bottom of the open caisson is greatly enhanced and the problem that the open caisson is easy to crack in the sinking process is solved.

Owner:CCCC SECOND HARBOR ENG +1

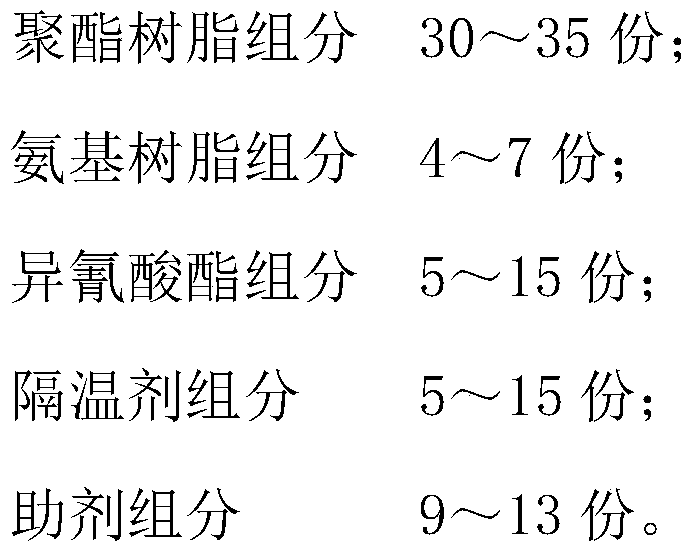

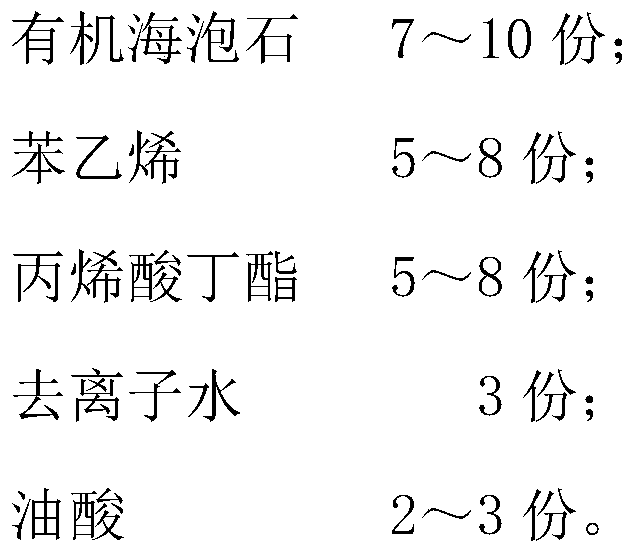

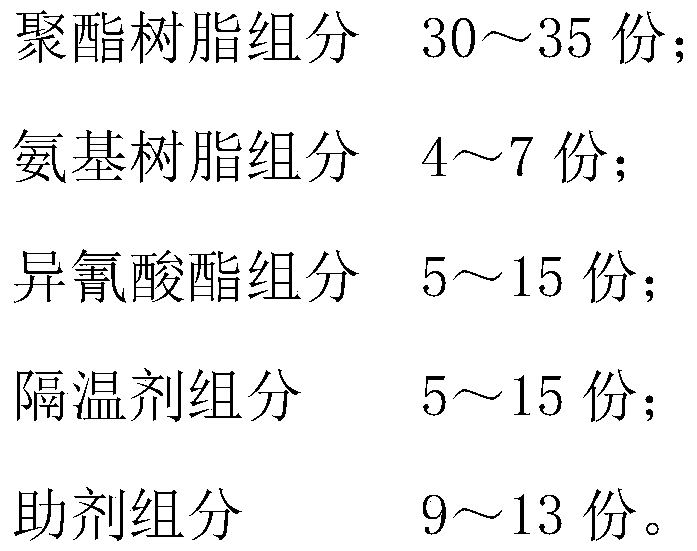

Modified polyurethane coating and preparation method thereof

InactiveCN110776823AImprove performanceStrong temperature insulationPolyurea/polyurethane coatingsPolymer scienceThermal insulation

The invention belongs to the technical field of coatings, and particularly relates to a modified polyurethane coating and a preparation method thereof. The modified polyurethane coating comprises thefollowing raw materials: a polyester resin component, an amino resin component, an isocyanate component, a thermal insulation agent component and an auxiliary agent component, wherein the thermal insulation agent component is composed of organic sepiolite, styrene, butyl acrylate, deionized water and oleic acid. According to the invention, styrene and butyl acrylate monomers generate styrene-butylacrylate under the action of an initiator, and styrene and butyl acrylate enter the space between organic sepiolite layers, so the thermal insulation agent component is obtained; oleic acid is unsaturated fatty acid and is environmentally friendly and harmless, and the addition of oleic acid is beneficial for polymerization between the styrene and butyl acrylate monomers, enables the styrene andbutyl acrylate monomers to react under lower preset conditions and functions as a surfactant for the styrene and butyl acrylate monomers, thereby realizing more thorough polymerization of the styreneand butyl acrylate monomers; and due to the addition of the thermal insulation agent component, the original performance of the polyurethane coating is improved, and the polyurethane coating has relatively strong thermal insulation performance.

Owner:斯博锐精细化学品(广东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com