Preparation method of expanded perlite sulfur-loading modified patina adsorbent

An expanded perlite and adsorbent technology, which is applied in the field of preparation of green rust adsorbents, can solve the problems of reducing the adsorption performance of green rust heavy metals, unable to remove heavy metals efficiently at the same time, unfavorable for popularization and application, etc., so as to reduce the influence and expand the interlayer distance. , Improve the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

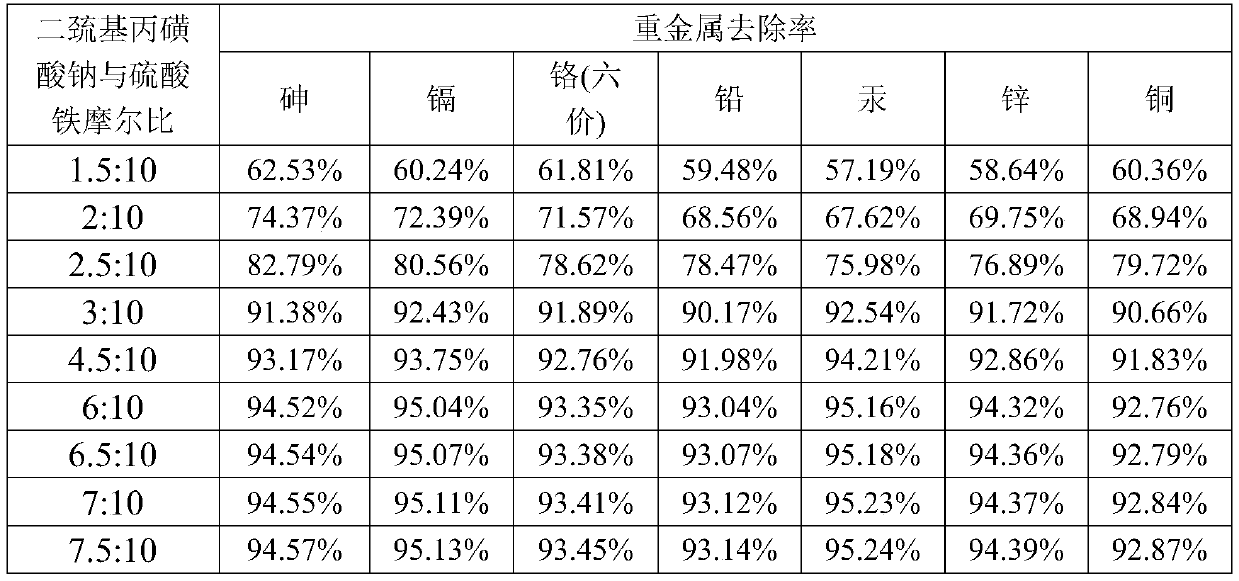

[0018] Effect of molar ratio of sodium dimercaptopropane sulfonate to iron sulfate on adsorption performance of expanded perlite sulfur-loaded green rust adsorbent

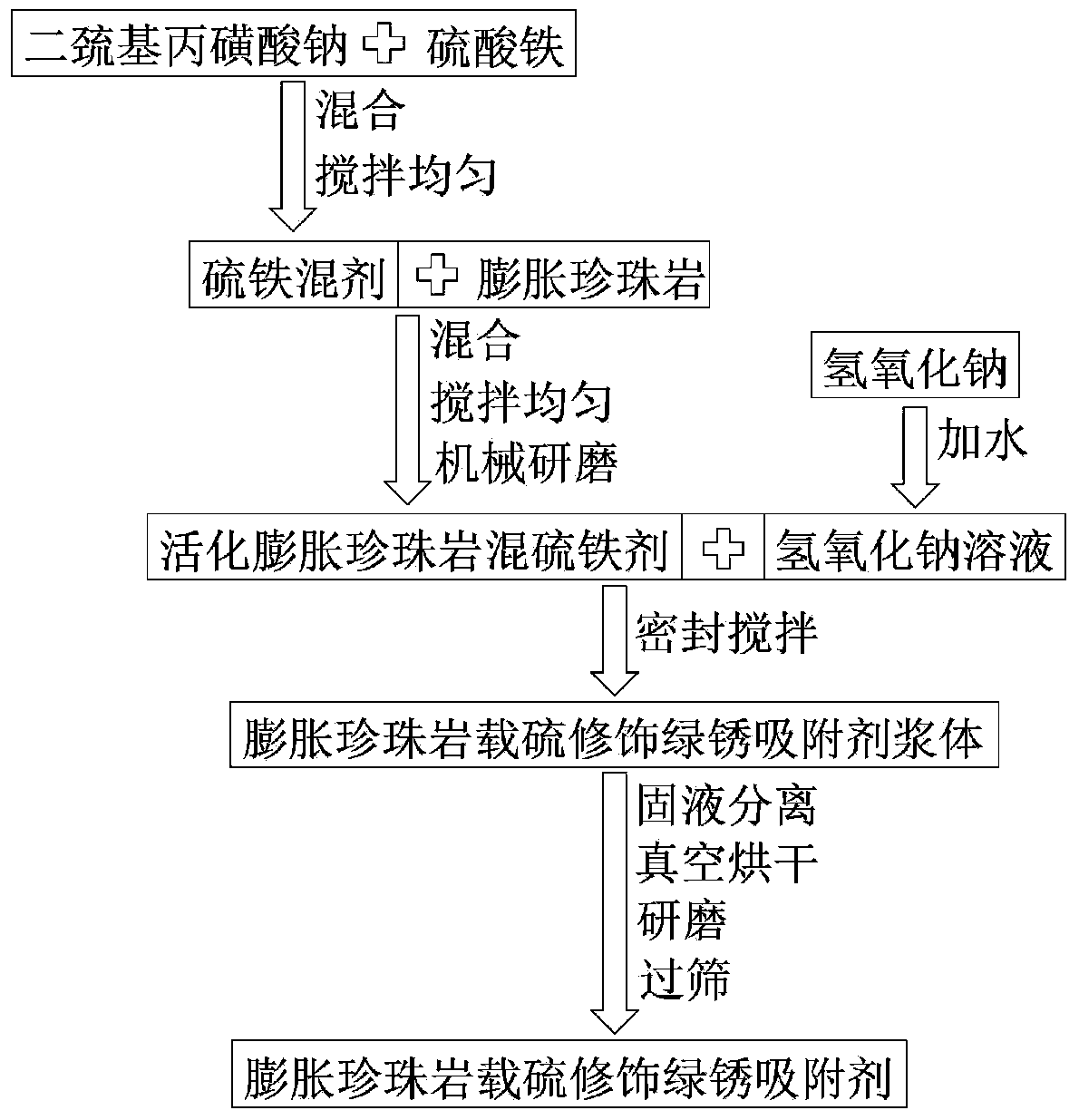

[0019] Preparation of expanded perlite sulfur-loaded green rust adsorbent: such as figure 1 As shown, according to the molar ratio of sodium dimercaptopropanesulfonate to iron sulfate 1.5:10, 2:10, 2.5:10, 3:10, 4.5:10, 6:10, 6.5:10, 7:10, 7.5:10 Weigh sodium dimercaptopropanesulfonate and ferric sulfate respectively, mix, stir evenly, obtain sulfur-iron mixture; take expanded perlite and sulfur-iron mixture according to the mass ratio of expanded perlite and sulfur-iron mixture 3:6, mix , stir evenly, and then mechanically grind at 120rpm for 6h to obtain activated expanded perlite mixed sulfur ferrite; weigh sodium hydroxide, dissolve it in water, and prepare 4mol / L sodium hydroxide solution; according to the solid-liquid ratio of 1:2 (mg :mL) the activated expanded perlite mixed sulfur ferric agent is added in...

Embodiment 2

[0027] Effect of mass ratio of expanded perlite and sulfur-iron mixture on the adsorption performance of the prepared expanded perlite sulfur-loaded green rust adsorbent

[0028] Preparation of expanded perlite sulfur-loaded green rust adsorbent: Weigh sodium dimercaptopropanesulfonate and iron sulfate according to the molar ratio of sodium dimercaptopropanesulfonate and iron sulfate 6:10, mix and stir evenly to obtain sulfur-iron mixture ; Take by weighing respectively according to the mass ratio of expanded perlite and sulfur-iron mixture 1.5:6, 2:6, 2.5:6, 3:6, 4.5:6, 6:6, 6.5:6, 7:6, 7.5:6 Expanded perlite and sulfur-iron mixture, mixed, stirred evenly, and then mechanically ground at 240rpm for 9 hours to obtain activated expanded perlite mixed with sulfur-iron; weigh sodium hydroxide, dissolve it in water, and prepare 7mol / L sodium hydroxide solution ; According to the solid-liquid ratio of 1:2.5 (mg:mL), the activated expanded perlite mixed sulfur iron agent was added t...

Embodiment 3

[0035] Effect of sodium hydroxide concentration on the adsorption performance of the prepared expanded perlite sulfur-loaded green rust adsorbent

[0036] Preparation of expanded perlite sulfur-loaded green rust adsorbent: Weigh sodium dimercaptopropanesulfonate and iron sulfate according to the molar ratio of sodium dimercaptopropanesulfonate and iron sulfate 6:10, mix and stir evenly to obtain sulfur-iron mixture Take expanded perlite and sulfur-iron mixture according to the mass ratio of expanded perlite and sulfur-iron mixture 6:6, mix, stir, and then mechanically grind 12h with 360rpm rotating speed to obtain activated expanded perlite mixed sulfur-iron agent; weigh Take sodium hydroxide, dissolve it in water, and prepare 2mol / L, 3mol / L, 3.5mol / L, 4mol / L, 7mol / L, 10mol / L, 10.5mol / L, 11mol / L, 12mol / L hydroxide respectively Sodium solution; according to the solid-liquid ratio of 1:3 (mg:mL), the activated expanded perlite mixed sulfur iron agent was added to the sodium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com