Preparation method and application of nitrogen defect/boron doped tubular carbon nitride photocatalyst

A boron doping and catalyst technology is applied in the field of preparation of tubular carbon nitride photocatalysts, which can solve the problems of weak oxidation performance, inability to obtain catalytic effect, insufficient light absorption performance, etc., achieve large interlayer distance, and improve photocatalytic oxidation. performance, and the effect of enhancing the hydrogen production activity of decomposing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

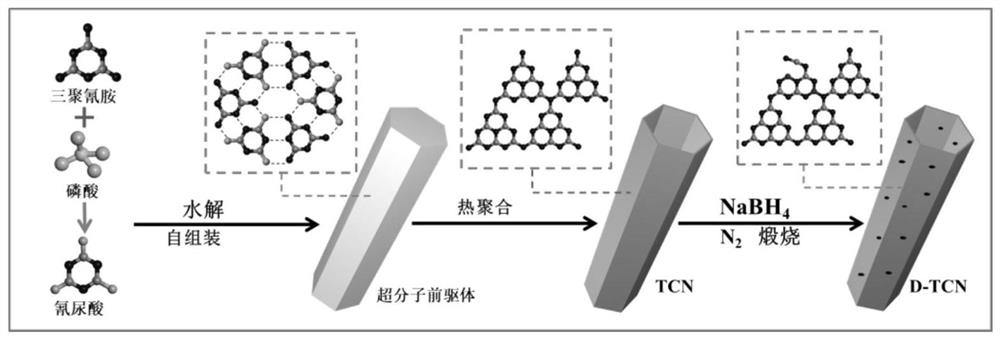

[0037] (1) Preparation of TCN photocatalyst:

[0038] Weigh 3 g of melamine and 0.5 g of phosphoric acid into 70 mL of deionized water and stir vigorously for 0.5 h; then transfer the solution to a 100 mL autoclave and react at 190 °C for 8 h; wash the resulting supramolecular precursor with deionized water until Phosphoric acid was thoroughly washed and then dried at 60°C. Finally, the obtained supramolecular precursor was heated to 500°C at a heating rate of 2.3°C / min in a muffle furnace, and calcined for 4 hours to obtain TCN;

[0039] (2) Preparation of D-TCN photocatalyst:

[0040] 0.2g TCN and 160mg NaBH 4 After mixing and grinding evenly, put it in a corundum porcelain boat, cover the porcelain boat cover, keep the porcelain boat in a semi-closed state, and place it in a tube furnace. Under a nitrogen atmosphere, raise the temperature to 450 ℃, the heating rate is 2.3°C / min, the calcination time is 0.5h, after the calcination is finished, it is naturally cooled to ro...

Embodiment 2

[0042] (1) Preparation of TCN photocatalyst:

[0043]Weigh 4 g of melamine and 1 g of phosphoric acid into 70 mL of deionized water and stir vigorously for 0.5 h; then transfer the solution to a 100 mL autoclave and react at 200 °C for 12 h; wash the resulting supramolecular precursor with deionized water until phosphoric acid was thoroughly washed and then dried at 60°C. Finally, the obtained supramolecular precursor was heated to 500°C at a heating rate of 2.3°C / min in a muffle furnace, and calcined for 4 hours to obtain TCN;

[0044] (2) Preparation of D-TCN photocatalyst:

[0045] 0.4g TCN and 80mg NaBH 4 After mixing and grinding evenly, put it in a corundum porcelain boat, cover the porcelain boat cover, keep the porcelain boat in a semi-closed state, and place it in a tube furnace. Under a nitrogen atmosphere, raise the temperature to 450 °C, the heating rate is 2.3 °C / min, and the calcination time is 0.5 h. After the calcination, it is naturally cooled to room tempe...

Embodiment 3

[0047] (1) Preparation of TCN photocatalyst:

[0048] Weigh 5 g of melamine and 2 g of phosphoric acid into 70 mL of deionized water and stir vigorously for 0.5 h; then transfer the solution to a 100 mL autoclave and react at 180 °C for 10 h; wash the resulting supramolecular precursor with deionized water until phosphoric acid It was completely washed, and then dried at 60°C; finally, the obtained supramolecular precursor was heated to 500°C in a muffle furnace at a heating rate of 2.3°C / min, and calcined for 4 hours to obtain TCN;

[0049] (2) Preparation of D-TCN photocatalyst:

[0050] 0.6g TCN and 40mg NaBH 4 After mixing and grinding evenly, place it in a corundum porcelain boat, cover the porcelain boat cover, keep the porcelain boat in a semi-closed state, and place it in a tube furnace, and raise the temperature to 450°C at a heating rate of 2.3°C / min under a nitrogen atmosphere , the heating rate is 2.3°C / min, and the calcination time is 0.5h. After the calcination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com