Flexible sulfur-nitrogen co-doped porous carbon fiber composite electrode material, preparation method and application thereof

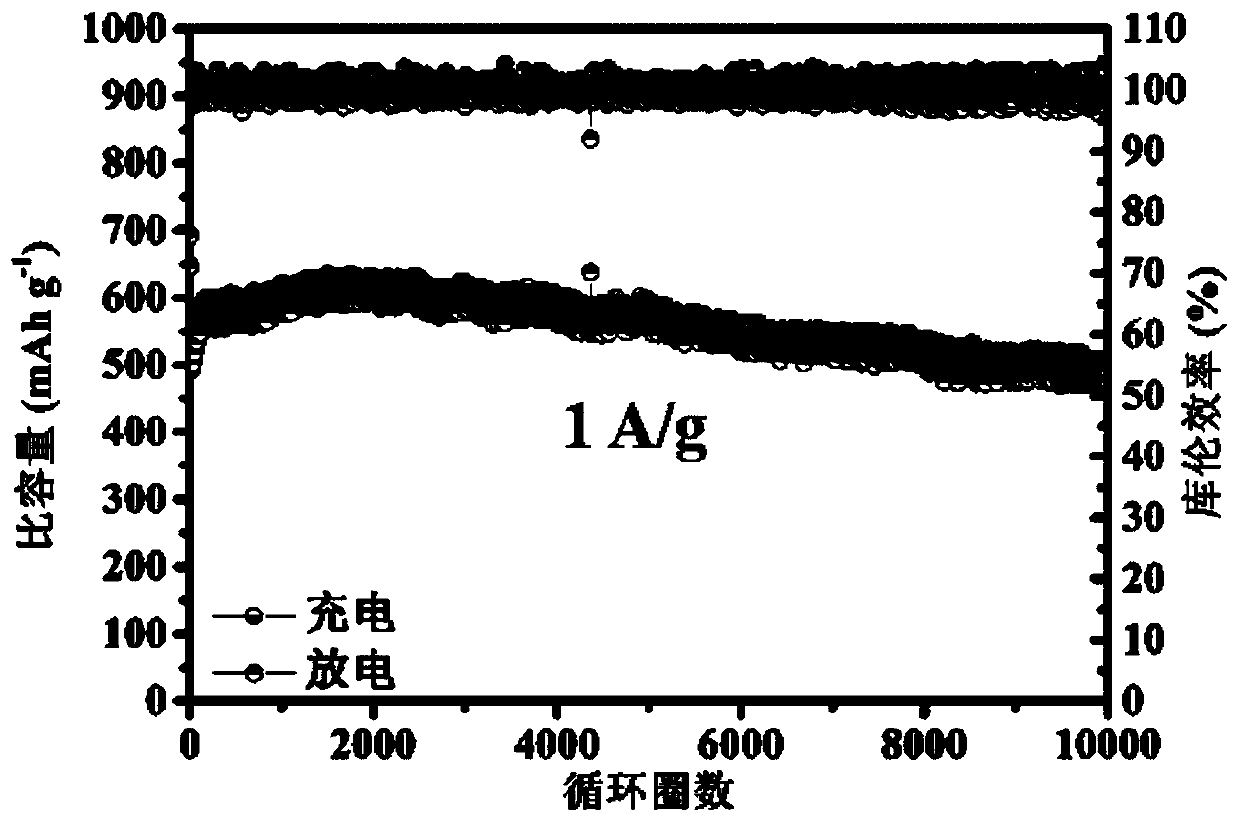

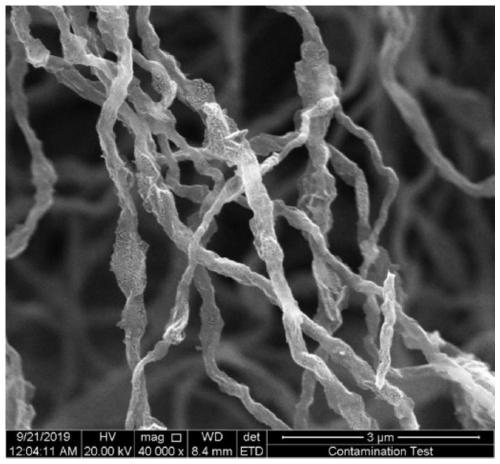

A porous carbon fiber, composite electrode technology, applied in the field of materials science, can solve the problems of electrode material structure collapse, less active sites, low rate performance, etc., and achieve the effect of increasing the interlayer distance, large amount of ions, and high cycle capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a flexible sulfur-nitrogen co-doped porous carbon fiber composite electrode material, comprising the steps of:

[0032] (1) Preparation of zinc oxide nanofibers (ZnO@PAN):

[0033] At room temperature, 1.2g ZnO was dissolved in 8mL N,N-dimethylformamide (DMF) and firstly ultrasonicated for 0.5h to obtain a homogeneous solution, then 0.6g PAN powder was added to the above mixed solution and stirred for 6h, followed by electrospinning Instrument, specific parameters Spinning is performed at a voltage of 10kV, a temperature of 25°C, and a bolus injection speed of 0.1mm / min, and finally flexible oxide nanofibers (ZnO@PAN) are obtained.

[0034] (2) Preparation of zinc sulfide nanocarbon fibers (ZnS@NCF):

[0035] The mass ratio of ZnO@PAN and sublimated sulfur is mixed at 1:1. 2 The high-temperature heat treatment was carried out under the atmosphere, and the heating control program was as follows: the temperature was raised to 600°C at a rate of 2°...

Embodiment 2

[0041] A method for preparing a flexible sulfur-nitrogen co-doped porous carbon fiber composite electrode material, comprising the steps of:

[0042] (1) Preparation of nickel oxide nanofibers (NiO@PAN):

[0043] At room temperature, 1.8g NiO was dissolved in 10mL N,N-dimethylformamide (DMF) and ultrasonicated for 1h to obtain a homogeneous solution, then 0.8g PAN powder was added to the above mixed solution and stirred for 36h, and then electrospinning equipment was used to , the specific parameters were spun at a voltage of 15kV, a temperature of 40°C, and a bolus injection speed of 0.15mm / min, and finally flexible oxide nanofibers (NiO@PAN) were obtained.

[0044] (2) Preparation of zinc sulfide nanocarbon fibers (NiS@NCF):

[0045] Mix NiS@PAN and sublimated sulfur at a mass ratio of 1:2, and perform high-temperature heat treatment in an Ar atmosphere. The heating control program is: the temperature is raised to 700°C at a rate of 4°C / min, and then kept for 3 hours, and f...

Embodiment 3

[0051] A method for preparing a flexible sulfur-nitrogen co-doped porous carbon fiber composite electrode material, comprising the steps of:

[0052] (1) Preparation of ferric oxide nanofibers (Fe 2 o 3 @PAN):

[0053] At room temperature, 2.4g Fe 2 o 3 Dissolved in 12mL N,N-dimethylformamide (DMF) and ultrasonicated for 1.5h to obtain a homogeneous solution, then 1.0g PAN powder was added to the above mixed solution and stirred for 24h, then using an electrospinning instrument, the specific parameters were in the voltage Spinning was carried out at 18kV, temperature 50°C and injection speed 0.2mm / min, and finally flexible oxide nanofibers (Fe 2 o 3 @PAN).

[0054] (2) Preparation of zinc sulfide nanocarbon fibers (FeS@NCF):

[0055] Fe 2 o 3 Mix @PAN and sublimed sulfur at a mass ratio of 1:2, and perform high-temperature heat treatment in an argon-hydrogen mixed atmosphere. The heating control program is: the temperature is raised to 800°C at a rate of 5°C / min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com