Rapid preparation methods of graphene oxide and graphene

A graphene and graphene dispersion technology, applied in the field of graphene, can solve problems such as hindering the commercial application of graphene oxide and graphene, unfavorable industrial production, long production cycle, etc., to avoid heating and cooling operations, and to achieve complete lamellae. High degree and complete lattice effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The invention provides a kind of preparation method of graphene oxide, comprises the following steps:

[0055] A) under airtight conditions, react after graphite, intercalation agent and oxidizing agent are mixed, obtain reaction mixture;

[0056] B) after the reaction mixture obtained in the above steps is separated, a reaction product is obtained;

[0057] C) Exfoliating the reaction product obtained in the above steps in a dispersant to obtain a graphene oxide dispersion.

[0058] In the present invention, graphite, intercalation agent and oxidant are mixed and then reacted under airtight conditions to obtain a reaction mixture.

[0059] The present invention does not have special limitation to described graphite, gets final product with the graphite that is well known to those skilled in the art and is used for preparing graphene, and those skilled in the art can select and adjust according to actual production situation, product requirement and quality requirement...

Embodiment 1

[0091] Mix 1.0 g of 1000-mesh natural flake graphite with 3.5 g of potassium permanganate, add it into a 100 mL polytetrafluoroethylene pressure vessel, add a magnetic rotor, and add 30 mL of concentrated sulfuric acid (98%) at 0°C. Put the autoclave into the autoclave, seal the autoclave under normal pressure, and install a magnetic stirrer under the autoclave. Stirring was started for 5 min to allow the reactants to be fully mixed. Then the reaction vessel was heated to 60° C. for 1 h, then cooled to room temperature, and the pressure vessel was released to obtain a reaction mixture.

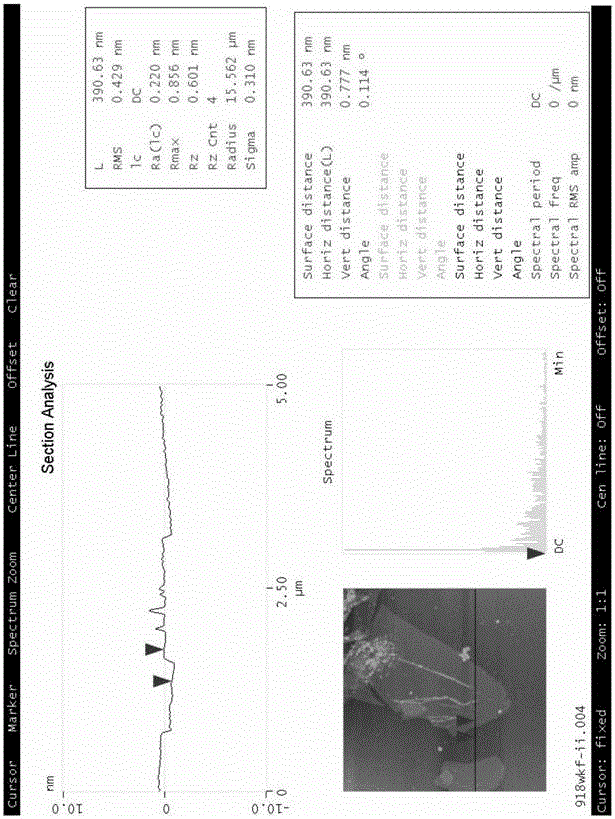

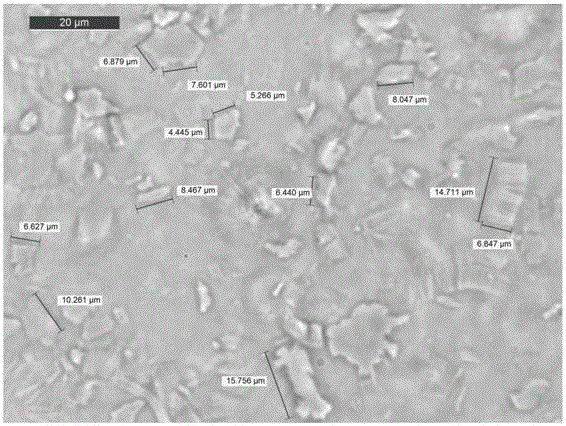

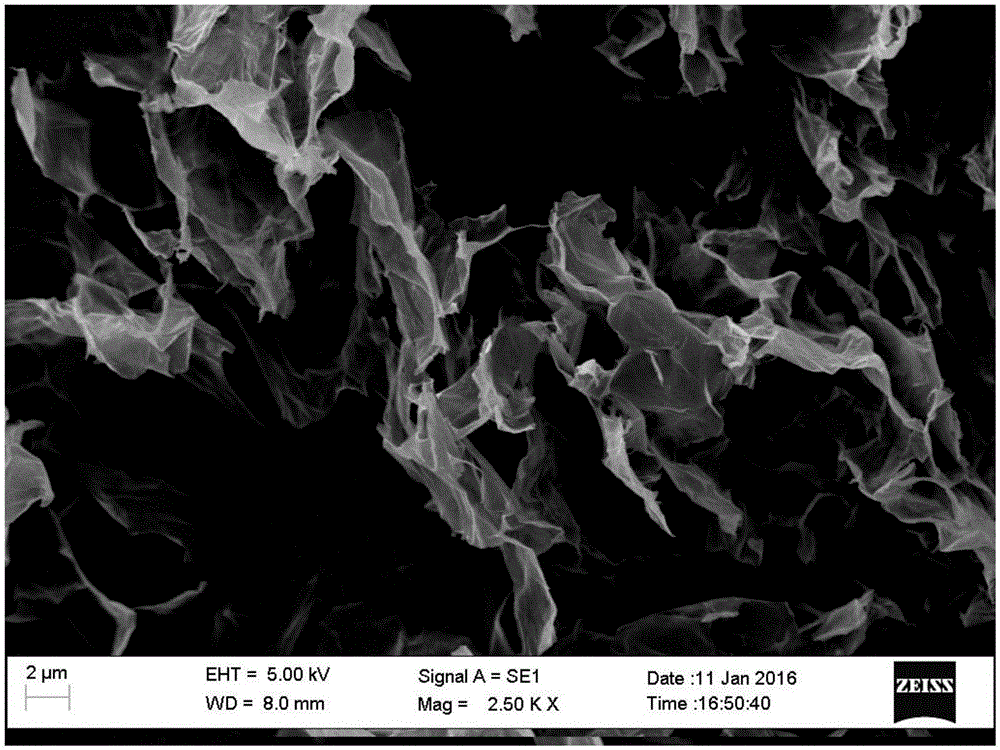

[0092] The obtained reaction mixture was centrifuged at 5000rmp for 5min, the clarified intercalation agent in the upper layer was recovered for use, the muddy product in the lower layer was poured into 50mL deionized water for dilution, and 5mL of 30% hydrogen peroxide was added to remove high-valent oxides, and the clear liquid was removed by centrifugation. Deionized water was centrifuged ...

Embodiment 2

[0100] Mix 1.0g of 5000-mesh natural flake graphite with 4.0g of potassium manganate and 1.0g of phosphorus pentoxide, add it to a 100mL polytetrafluoroethylene pressure vessel, add a magnetic rotor, and add 30mL of concentrated sulfuric acid (98%) at 0°C . Put the autoclave into the autoclave, seal the autoclave under normal pressure, and install a magnetic stirrer under the autoclave. Stirring was started for 5 min to allow the reactants to be fully mixed. Then the reaction vessel was heated to 50° C. for 1.5 h, and then cooled to room temperature. After the pressure was released, the pressure vessel was opened to obtain a reaction mixture.

[0101] The obtained reaction mixture was centrifuged at 5000rmp for 5min, the clarified intercalation agent in the upper layer was recovered for use, the muddy product in the lower layer was poured into 50mL deionized water for dilution, and 5mL of 30% hydrogen peroxide was added to remove high-valent oxides, and the clear liquid was r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com