High-strength degradable environment-friendly plastic and preparation method thereof

An environmentally friendly plastic, high-strength technology, applied in the field of plastics, can solve the problems of poor corrosion resistance, hard and brittle plastics, inconvenience, etc., and achieve the effects of excellent water resistance, improved water resistance, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

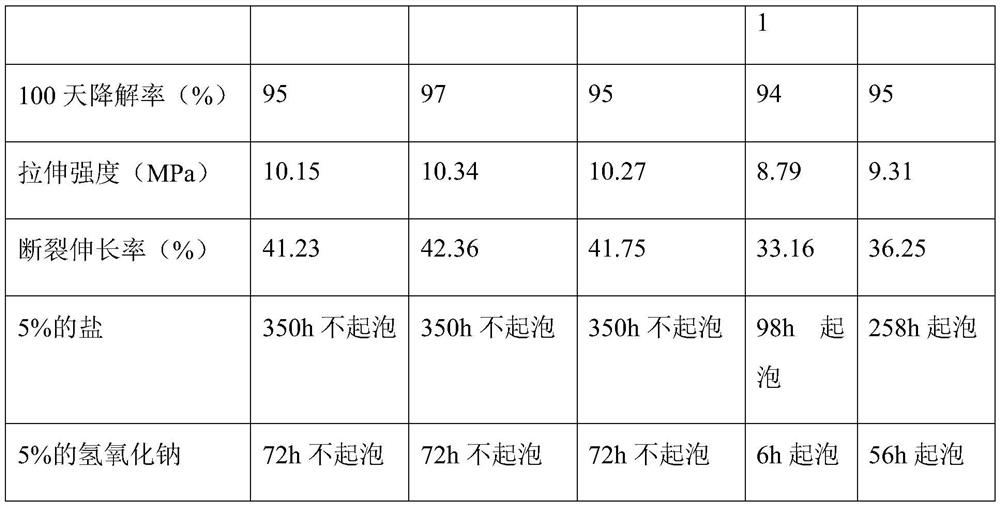

Examples

Embodiment 1

[0039] A preparation method of high-strength degradable environmentally friendly plastics, comprising the following steps:

[0040] (1) Prepare materials;

[0041] (2) Preparation of modified matrix:

[0042] Take zirconium phosphate and n-butylamine, ultrasonically disperse for 1 hour, stir and react after ultrasonic for 20 hours, and dry to obtain modified zirconium phosphate; take modified zirconium phosphate, cationic starch, corn starch and glycerin, stir and mix for 30 minutes, extrude and granulate to obtain modified zirconium phosphate Starch;

[0043] Take modified starch, compatibilizer, polyethylene and corn starch, stir and mix for 40 minutes, extrude and granulate, process and shape to obtain a pretreated substrate; put the pretreated substrate in acetone solution, ultrasonically treat it for 20 minutes, take it out and perform surface treatment Mechanically grind, wash and dry, then place in silane coupling agent A solution, soak for 20min at 110°C to obtain a mo...

Embodiment 2

[0050] A preparation method of high-strength degradable environmentally friendly plastics, comprising the following steps:

[0051] (1) Prepare materials;

[0052] (2) Preparation of modified matrix:

[0053] Take zirconium phosphate and n-butylamine, ultrasonically disperse for 1.1h, stir and react after ultrasonic for 21h, and dry to obtain modified zirconium phosphate; take modified zirconium phosphate, cationic starch, corn starch and glycerin, stir and mix for 35min, extrude and granulate to obtain modified starch;

[0054] Take modified starch, compatibilizer, polyethylene and corn starch, stir and mix for 45 minutes, extrude and granulate, process and shape to obtain a pretreated substrate; place the pretreated substrate in acetone solution, ultrasonically treat it for 25 minutes, take it out and perform surface treatment Mechanically grind, wash and dry, then place in silane coupling agent A solution, soak at 115°C for 25min to obtain a modified matrix;

[0055] (3)...

Embodiment 3

[0061] A preparation method of high-strength degradable environmentally friendly plastics, comprising the following steps:

[0062] (1) Prepare materials;

[0063] (2) Preparation of modified matrix:

[0064] Take zirconium phosphate and n-butylamine, ultrasonically disperse for 1.2 hours, stir and react for 22 hours after ultrasonic, and dry to obtain modified zirconium phosphate; take modified zirconium phosphate, cationic starch, corn starch and glycerin, stir and mix for 40 minutes, extrude and granulate to obtain modified starch;

[0065] Take modified starch, compatibilizer, polyethylene and corn starch, stir and mix for 50 minutes, extrude and granulate, process and shape to obtain a pretreated substrate; place the pretreated substrate in acetone solution, ultrasonically treat it for 30 minutes, take it out and perform surface treatment Mechanical grinding, washing and drying, then placing in the silane coupling agent A solution, soaking at 120°C for 30min, to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com