Method for preparing graphene-like molybdenum disulfide-graphene composite material by reducing carbohydrate organic carbon

A technology of molybdenum disulfide and composite materials, which is applied in the fields of molybdenum sulfide, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as pollution and complicated preparation process, and achieve the goal of expanding application range, high preparation efficiency and large output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

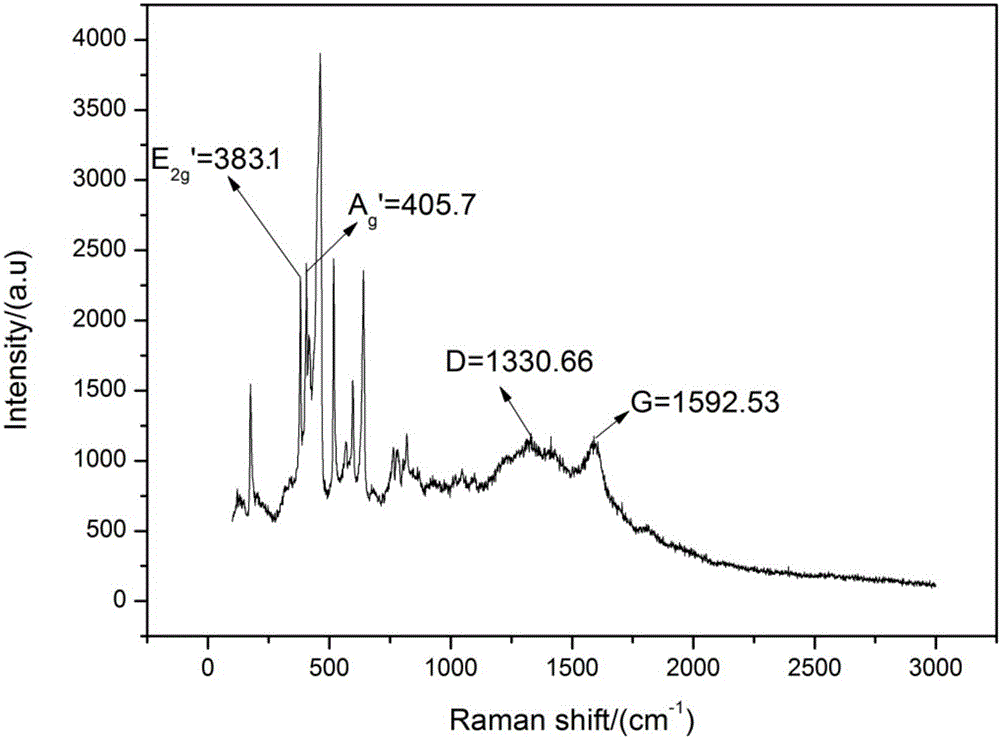

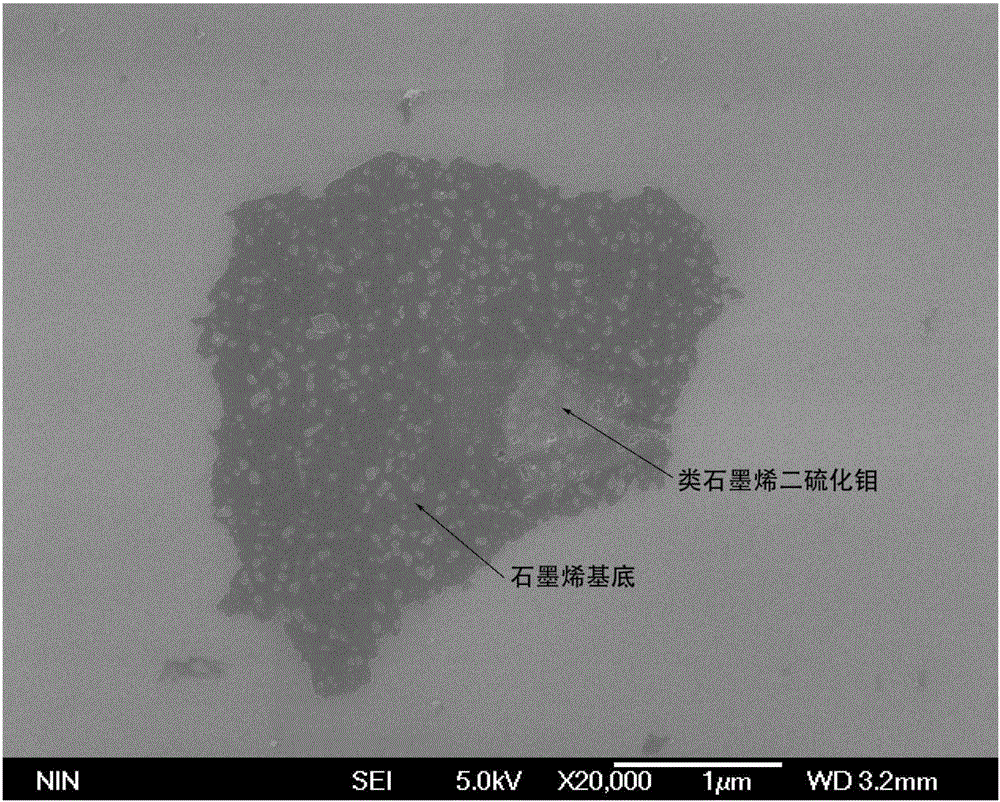

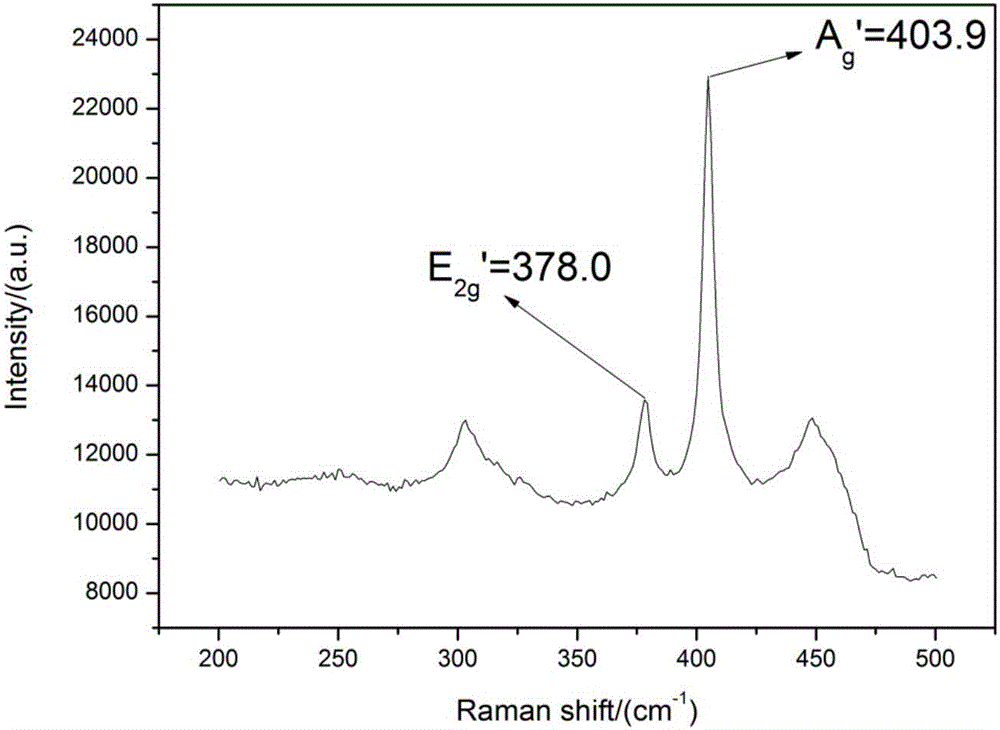

Embodiment 1

[0044] The present embodiment provides a method for preparing graphene-like molybdenum disulfide-graphene composite material by reduction of sugar organic carbon, the method may further comprise the steps:

[0045] Step 1, the molybdenum disulfide powder is ground to 200 mesh and sieved, and 10 g of the molybdenum disulfide powder under the sieve is added to the intercalation solution. The composition of the intercalation solution is 20 g of potassium chlorate, 10 g of sodium nitrate, and a mass concentration of 98%. 230mL of concentrated sulfuric acid and 70mL of hydrogen peroxide with a mass concentration of 30%;

[0046] Heat in a water bath to 15°C for 2 hours, then stir at 30°C for 30 minutes to carry out intercalation reaction, then heat to 75°C and stir for 30 minutes to react, filter the solution obtained after the reaction and dry the filter cake, grind to 200 mesh sieve, The intercalated molybdenum disulfide powder was obtained.

[0047] Step 2: Take 4.0g of maltose...

Embodiment 2

[0052] The present embodiment provides a method for preparing graphene-like molybdenum disulfide-graphene composite material by reduction of sugar organic carbon, the method may further comprise the steps:

[0053] Step 1: Grind molybdenum disulfide powder to 200 mesh and sieve, take 10g of undersize molybdenum disulfide powder and add it to the intercalation solution. The composition of the intercalation solution is 40g of potassium chlorate, 5g of sodium nitrate, and a mass concentration of 98%. The concentrated sulfuric acid is 300mL and the hydrogen peroxide of mass concentration 30% is 60mL.

[0054] Heat in a water bath to 10°C for 2 hours, then stir at 10°C for 30 minutes to carry out intercalation reaction, then heat to 95°C and stir for 25 minutes to react, filter the solution obtained after the reaction and dry the filter cake, grind to 200 mesh sieve, The intercalated molybdenum disulfide powder was obtained.

[0055] Step 2: Take 2.6g of maltose and add it to 26g ...

Embodiment 3

[0059] The present embodiment provides a method for preparing graphene-like molybdenum disulfide-graphene composite material by reduction of sugar organic carbon, the method may further comprise the steps:

[0060] Step 1, grind molybdenum disulfide powder to 200 mesh and sieve, take 10g of molybdenum disulfide powder under the sieve and add it to the intercalation solution. The composition of the intercalation solution is 10g of potassium chlorate, 8g of sodium nitrate, and a mass concentration of 98%. The concentrated sulfuric acid is 400mL and the hydrogen peroxide of mass concentration 30% is 45mL.

[0061] Heated in a water bath to 30°C for 1 hour, then stirred at 45°C for 50 minutes for intercalation reaction, then heated to 98°C and stirred for 15 minutes, filtered the solution obtained after the reaction and dried the filter cake, ground to 200 mesh and sieved, The intercalated molybdenum disulfide powder was obtained.

[0062] Step 2: Take 2g of maltose and add it to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com