Anti-cracking zinc acrylate antifouling paint and preparation method thereof

A technology of zinc acrylate, antifouling paint, applied in antifouling/underwater paint, coating, paint containing biocide, etc., can solve the problem of unsatisfactory sterilization and antifouling performance, easy drying and cracking of the coating, and increase the cost of use, etc. problem, to achieve the effect of excellent sterilization and antifouling performance, excellent flexibility and anti-cracking performance, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

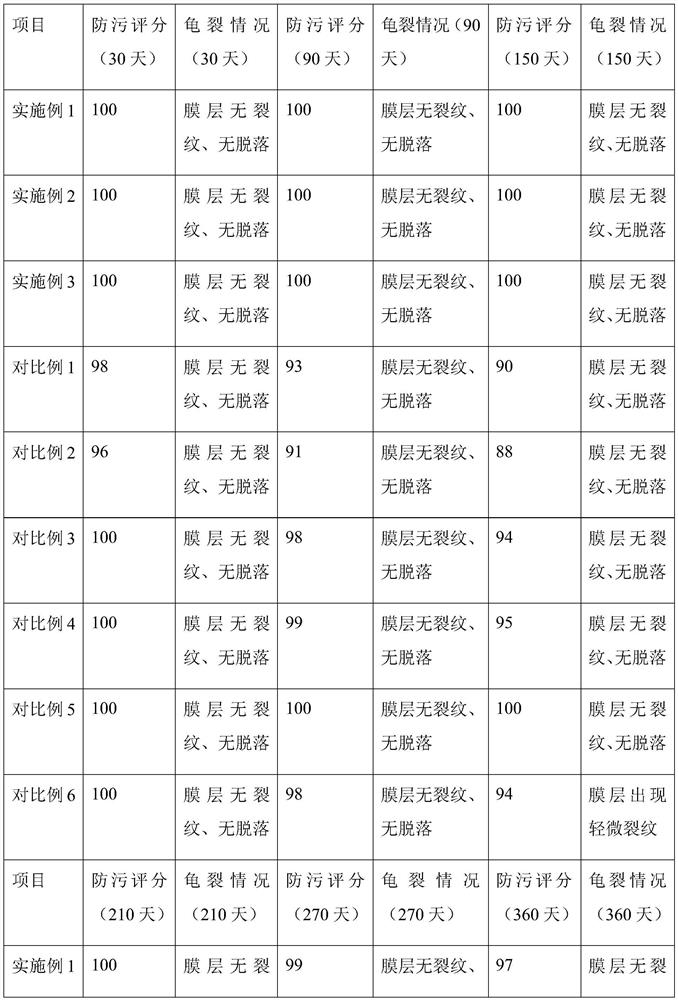

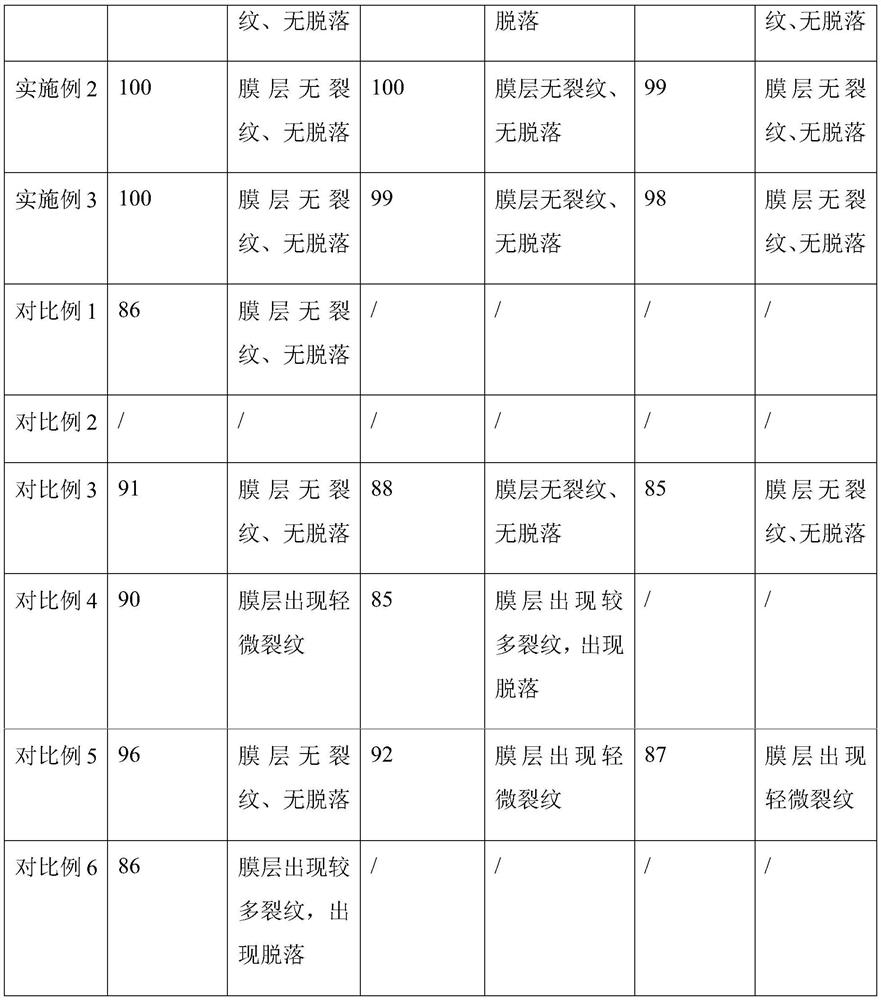

Examples

Embodiment 1

[0047] A preparation method of anti-cracking acrylate zinc antifouling paint, comprising the following steps:

[0048] (1) Prepare materials;

[0049] (2) Preparation of modified graphene:

[0050] Take hydroxylated graphene and dimethylformamide, ultrasonically disperse for 20 minutes, keep stirring while ultrasonically dispersing, add methacrylic anhydride, stir and react for 8 hours under nitrogen atmosphere, the reaction temperature is 110°C, wash, and dry in vacuum to obtain modified graphite alkene;

[0051] (3) Preparation of modified montmorillonite:

[0052] Take montmorillonite and deionized water, mix and stir for 20 minutes, add surfactant, stir and react in a water bath at 60°C for 4 hours, let stand for 10 hours, centrifuge, wash and dry, and grind through a 200-mesh sieve to obtain material A;

[0053] Take material A, acetone and silane coupling agent, stir and react at 45°C for 40 minutes, let stand to volatilize acetone, cool, dry, and grind through a 200-...

Embodiment 2

[0061] A preparation method of anti-cracking acrylate zinc antifouling paint, comprising the following steps:

[0062] (1) Prepare materials;

[0063] (2) Preparation of modified graphene:

[0064] Take hydroxylated graphene and dimethylformamide, ultrasonically disperse for 25 minutes, keep stirring while ultrasonically dispersing, add methacrylic anhydride, stir and react for 9 hours under nitrogen environment, the reaction temperature is 105°C, wash, and dry in vacuum to obtain modified graphite alkene;

[0065] (3) Preparation of modified montmorillonite:

[0066] Take montmorillonite and deionized water, mix and stir for 25 minutes, add surfactant, stir and react in a water bath at 63°C for 3.5 hours, let stand for 12 hours, centrifuge, wash and dry, and grind through a 200-mesh sieve to obtain material A;

[0067] Take material A, acetone and silane coupling agent, stir and react at 48°C for 35 minutes, let stand to volatilize acetone, cool, dry, and grind through a 2...

Embodiment 3

[0075] A preparation method of anti-cracking acrylate zinc antifouling paint, comprising the following steps:

[0076] (1) Prepare materials;

[0077] (2) Preparation of modified graphene:

[0078] Take hydroxylated graphene and dimethylformamide, ultrasonically disperse for 30min, keep stirring while ultrasonically dispersing, add methacrylic anhydride, stir and react for 10h under nitrogen environment, the reaction temperature is 100°C, wash and vacuum dry to obtain modified graphite alkene;

[0079] (3) Preparation of modified montmorillonite:

[0080] Take montmorillonite and deionized water, mix and stir for 30 minutes, add surfactant, stir and react in a water bath at 65°C for 3 hours, let stand for 15 hours, centrifuge, wash and dry, and grind through a 200-mesh sieve to obtain material A;

[0081] Take material A, acetone and silane coupling agent, stir and react at 50°C for 30 minutes, let stand to volatilize acetone, cool, dry, and grind through a 200-mesh sieve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com