Method for finishing cotton cloth bandage through antibacterial antifouling micro-capsules

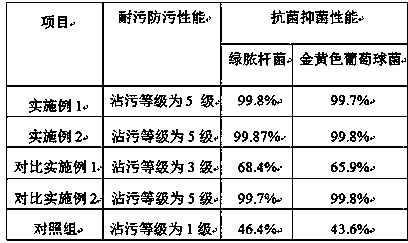

A technology for microcapsule finishing and microcapsules, applied in microcapsule preparations, anti-staining/anti-fouling fibers, preparation of microspheres, etc., can solve the problems of wound infection, easy to be polluted by stains, stain resistance, poor antibacterial effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for arranging cotton bandages with antibacterial and antifouling microcapsules is characterized in that it comprises the following steps, and the following raw materials are by weight:

[0029] (1) Fluorosilane treatment process for cotton bandages:

[0030] Mix 1 part of low surface energy finishing agent 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane, 99 parts of absolute ethanol and 100 parts of deionized water, add dropwise glacial acetic acid to adjust the pH to 3, After hydrolysis for 30 minutes, soak the cotton bandage treated with alkali reduction at a bath ratio of 1:40, shake it in a water bath at 90°C for 2 hours, and take out the cotton bandage treated with fluorosilane;

[0031] Among them, the alkali reduction treatment process of cotton bandages: heating the sodium hydroxide solution with a mass concentration of 25g / L to 75°C in a water bath, immersing the pretreated cotton bandages in it at a bath ratio of 1:30, and adding 1 part of accelerator 2g...

Embodiment 2

[0042] A method for arranging cotton bandages with antibacterial and antifouling microcapsules is characterized in that it comprises the following steps, and the following raw materials are by weight:

[0043] (1) Fluorosilane treatment process for cotton bandages:

[0044] Mix 2 parts of low surface energy finishing agent 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane, 198 parts of absolute ethanol and 200 parts of deionized water, add dropwise glacial acetic acid to adjust the pH to 3, After hydrolysis for 40 minutes, soak the cotton bandage treated with alkali reduction at a bath ratio of 1:40, shake it in a water bath at 95°C for 1 hour, and take out the cotton bandage treated with fluorosilane;

[0045] Among them, the alkali reduction treatment process of cotton bandages: heating the sodium hydroxide solution with a mass concentration of 25g / L to 90°C in a water bath, dipping the pretreated cotton bandages into it at a bath ratio of 1:40, and adding 2 parts of accelerator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com