A kind of sterilizing and antifouling melt-blown cloth and its processing technology

A processing technology and technology of melt-blown cloth, applied in fiber processing, textile and papermaking, biochemical fiber processing, etc., can solve the problem of inability to melt-blown cloth with excellent isolation, filtering effect and sterilization effect, complex preparation process of antibacterial materials, and no anti-fouling. performance and other issues, to achieve the effects of excellent sterilization and antifouling performance, low production cost, and increased molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

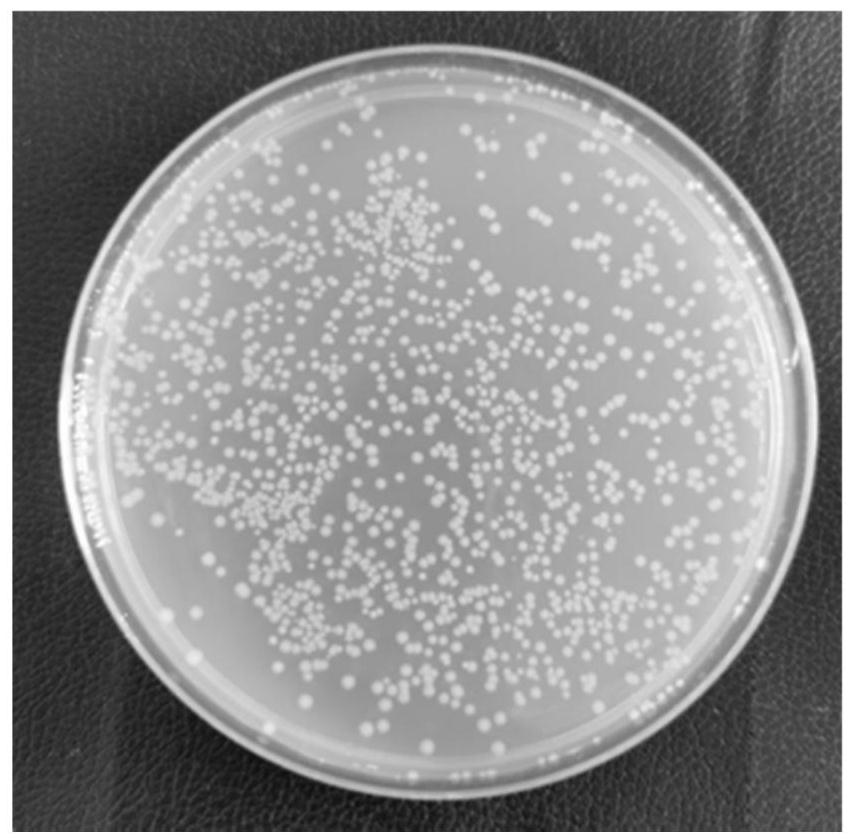

Embodiment 1

[0050] (1) Add methacryloyloxyethyltrimethylammonium chloride, 2-methacryloyloxyethylphosphorylcholine and ammonium persulfate to deionized water respectively to obtain a solution, methacryloyloxyethyl The molar ratio of trimethylammonium chloride, 2-methacryloyloxyethylphosphorylcholine and ammonium persulfate is 100:100:5. Immerse the polypropylene melt-blown cloth in the prepared solution, and then take it out Press between the pads to remove excess solution before drying at 80°C.

[0051] (2) Place the dried material in step (1) in a glow discharge radio frequency oxygen plasma with a gas flow rate of 100 sccm, a chamber pressure of 40 Pa, and a discharge power of 100 W for 5 minutes, then wash with deionized water, and dry at 80°C. That is, the sterilized antifouling melt-blown cloth is obtained.

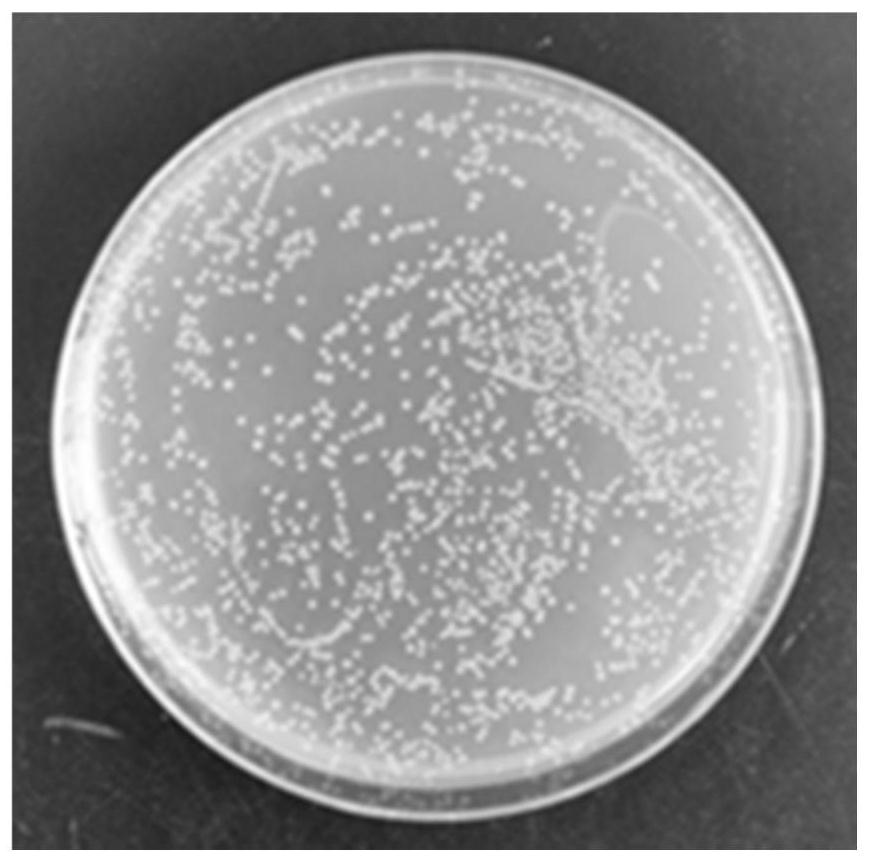

Embodiment 2

[0053] (1) Add methacryloyloxyethyltrimethylammonium chloride, 2-methacryloyloxyethylphosphorylcholine and 2-hydroxyl-2-methyl-1-phenylmethanone respectively In deionized water, a solution was obtained, methacryloyloxyethyltrimethylammonium chloride, 2-methacryloyloxyethylphosphorylcholine and 2-hydroxy-2-methyl-1-phenylmethanone The molar ratio is 100:100:5. The polypropylene melt-blown cloth is immersed in the prepared solution, then taken out and pressed between the pads to remove excess solution, and then dried at 80°C.

[0054] (2) Place the dried material in step (1) in a photochemical reactor. The light source used is an ultraviolet lamp with a power of 500W. The material is polymerized under ultraviolet light for 1 hour, then washed with deionized water, and dried at 80°C. A sterilized anti-fouling melt-blown cloth was obtained.

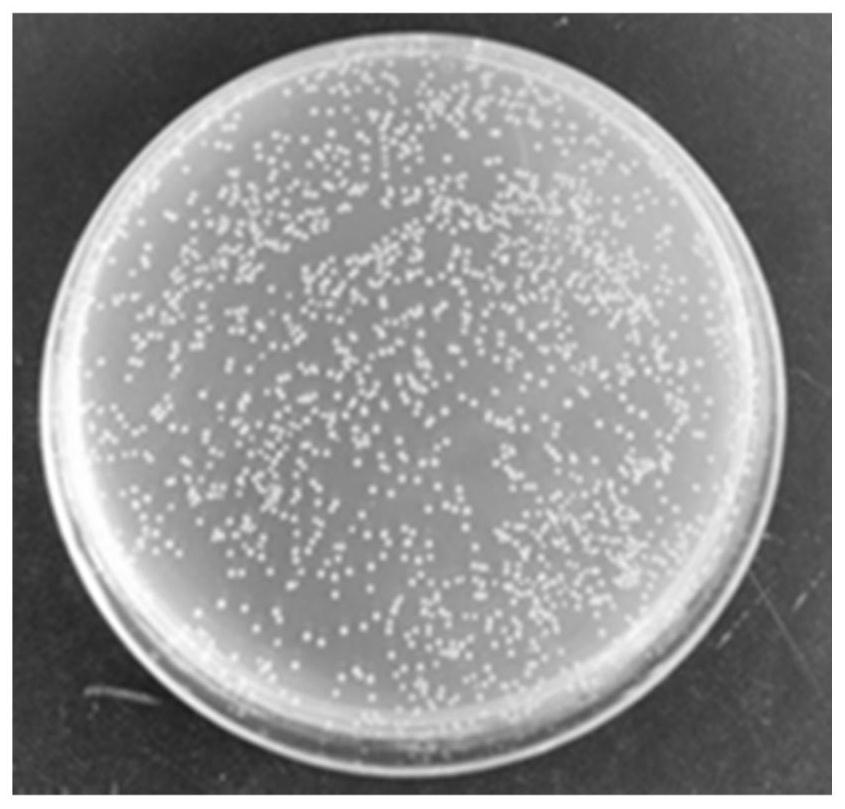

Embodiment 3

[0056] In this example, the sterilizing and antifouling melt-blown cloth material was prepared according to the same method as in Example 1, the only difference being that polylactic acid was used instead of polypropylene melt-blown cloth in step (1) to obtain a sterilized and anti-fouling melt-blown cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com