Layered structure molybdenum disulfide/carbon composite material and preparation method and application thereof

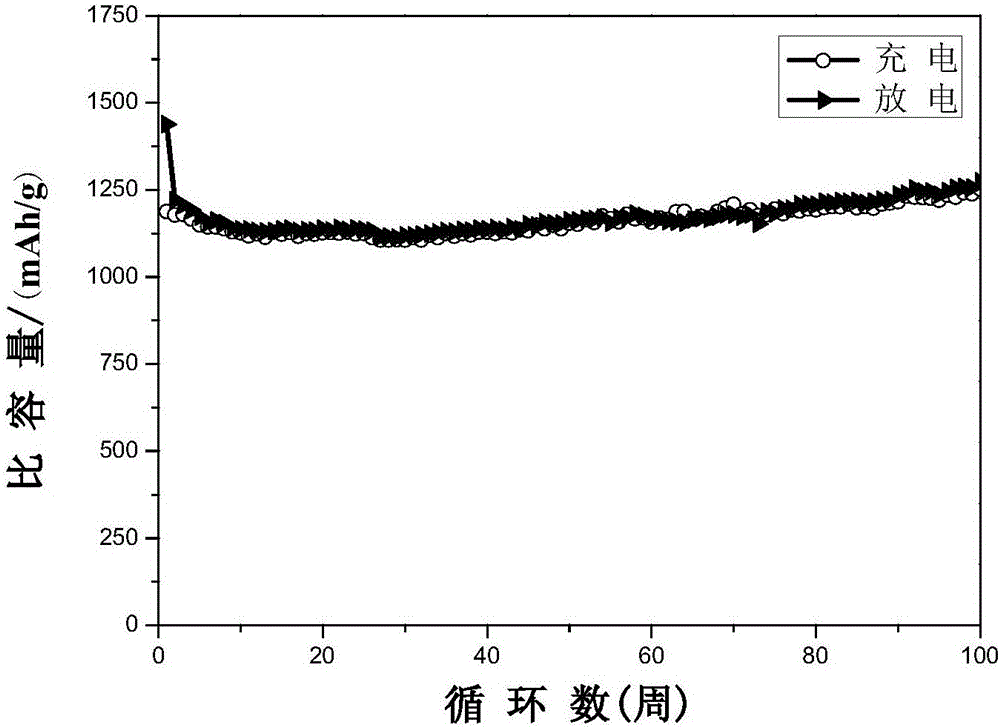

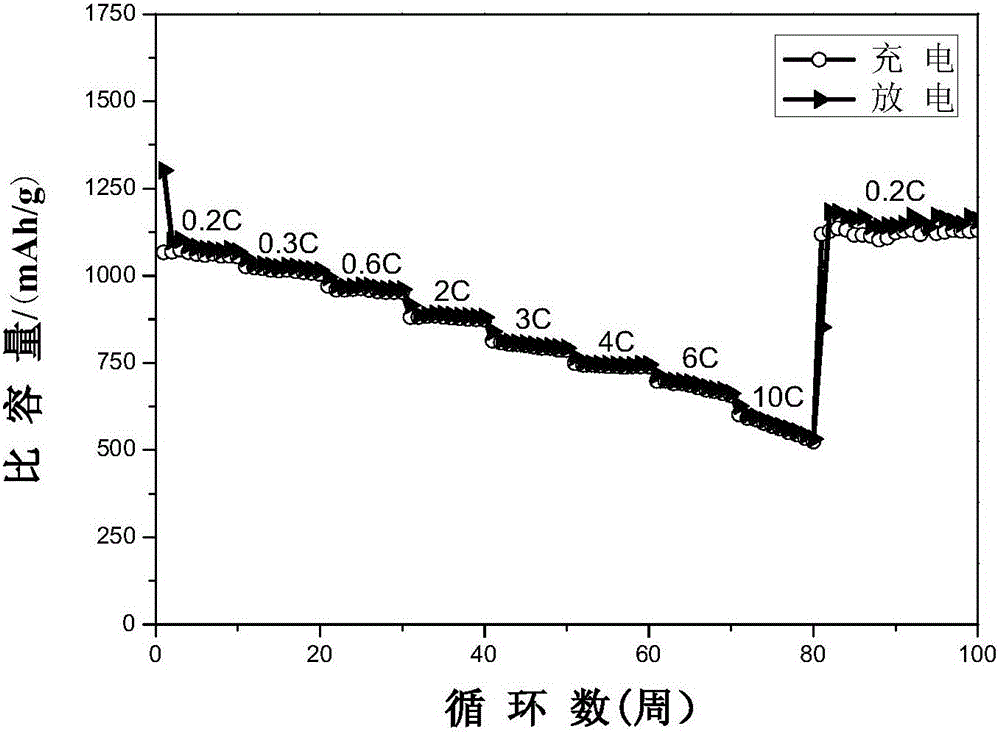

A technology of carbon composite materials and molybdenum disulfide, applied in structural parts, secondary batteries, electrochemical generators, etc., can solve problems such as poor stability, achieve the effect of increasing layer spacing and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

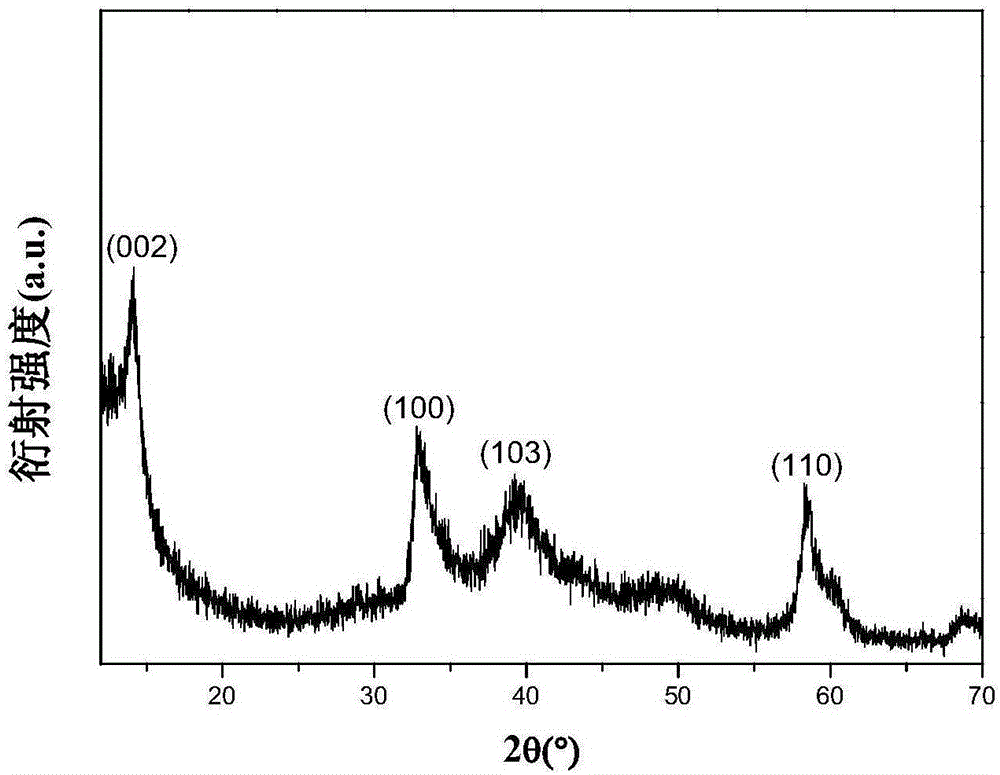

[0056] A layered structure molybdenum disulfide / carbon composite material, the composite material presents the morphology of nanosheets, the carbon material is between the laminates of the layered structure of molybdenum disulfide, and one or more layers of molybdenum disulfide Composite in-situ with the carbon layer in a layer-by-layer manner.

[0057] The preparation method of this composite material is as follows:

[0058] 1) Measure 30 mL of dodecylamine (analytical pure) and dissolve it in 200 mL of ethanol solvent. After the dodecylamine is fully dissolved, weigh 2 g of molybdenum trioxide (analytical pure) and add it to the above mixed solution, and stir in a water bath at 70 ° C. After reacting for 24 hours, a white precipitate was formed, which was filtered by suction and washed with ethanol solvent, and dried in vacuum at 70°C for 48 hours to obtain a dodecylamine-intercalated molybdenum trioxide organic / inorganic hybrid;

[0059] 2) Take 0.5g of dodecylamine-interc...

Embodiment 2

[0066] A layered structure molybdenum disulfide / carbon composite material, the composite material presents the morphology of nanosheets, the carbon material is between the laminates of the layered structure of molybdenum disulfide, and one or more layers of molybdenum disulfide Composite in-situ with the carbon layer in a layer-by-layer manner.

[0067] The preparation method of this composite material is as follows:

[0068] 1) Measure 1 mL of ethylenediamine (analytical pure) and dissolve it in 30 mL of ethanol solvent. After the ethylenediamine is fully dissolved, weigh 0.37 g of molybdenum trioxide (analytical pure) and add it to the above mixed solution. Stirring and reacting for 24 hours, a white precipitate was formed, which was filtered with suction and washed with ethanol solvent, and vacuum-dried at 60°C for 24 hours to obtain a molybdenum trioxide organic / inorganic hybrid intercalated with ethylenediamine;

[0069] 2) Take 0.5 g of molybdenum trioxide organic / inorg...

Embodiment 3

[0072] A layered structure molybdenum disulfide / carbon composite material, the composite material presents the morphology of nanosheets, the carbon material is between the laminates of the layered structure of molybdenum disulfide, and one or more layers of molybdenum disulfide Composite in-situ with the carbon layer in a layer-by-layer manner.

[0073] The preparation method of this composite material is as follows:

[0074] 1) Dissolve 5 mL of n-octylamine (analytical pure) in 100 mL of propanol solvent. After the n-octylamine is fully dissolved, weigh 0.50 g of molybdenum trioxide (analytical pure) and add it to the above mixed solution. The reaction was stirred in medium temperature for 36 h, and a white precipitate was formed. The filter cake was filtered by suction and washed with propanol solvent, and vacuum-dried at 70 °C for 24 h to obtain a molybdenum trioxide organic / inorganic hybrid intercalated with n-octylamine;

[0075] 2) Take 0.2g of n-octylamine-intercalated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com