Graphene preparation method and mass production device

A technology of graphene and graphene powder, which is applied in the field of graphene preparation, can solve the problems of increasing the interlayer spacing of graphite powder, incapable of mass production, poor safety and environmental protection, etc., and achieve mass production problems, stable product quality, and large-scale expansion produced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

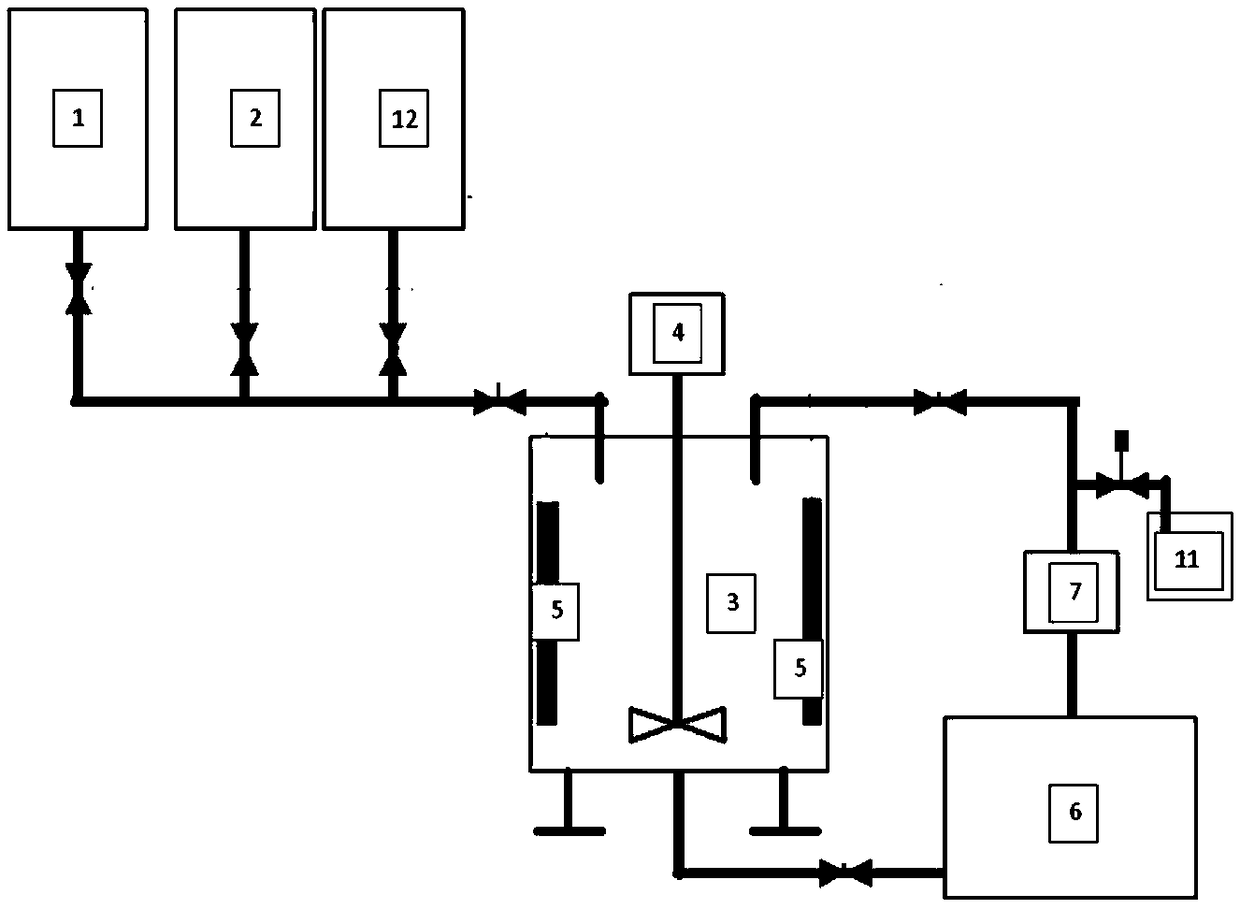

[0052] A graphene mass production equipment of this embodiment, such as figure 1 As shown, it includes a microwave reactor 3, a high-speed shear 6, a cleaning and drying device 7 and a graphene tank 11 connected in sequence. The microwave reactor 3 has a stirrer 4 and a microwave generator, and the microwave reactor There are two microwave tubes 5, the capacity of the microwave reactor 3 is 800L, the top is respectively connected with the graphite powder tank 1, the weak acid / weak base tank 2 and the deionized water tank 12, and the bottom outlet is connected with the inlet of the high-speed shearing machine 6. The outlet of the high-speed shear 6 is connected to the inlet of the cleaning and drying device 7, and the outlet of the cleaning and drying device 7 is connected to the circulation inlet of the microwave reactor 3 and the graphene tank 11, respectively.

[0053] The frequency of the microwave conduit 5 is 800-1200W, the stirring speed of the stirrer is 50-200r / min, and th...

Embodiment 2

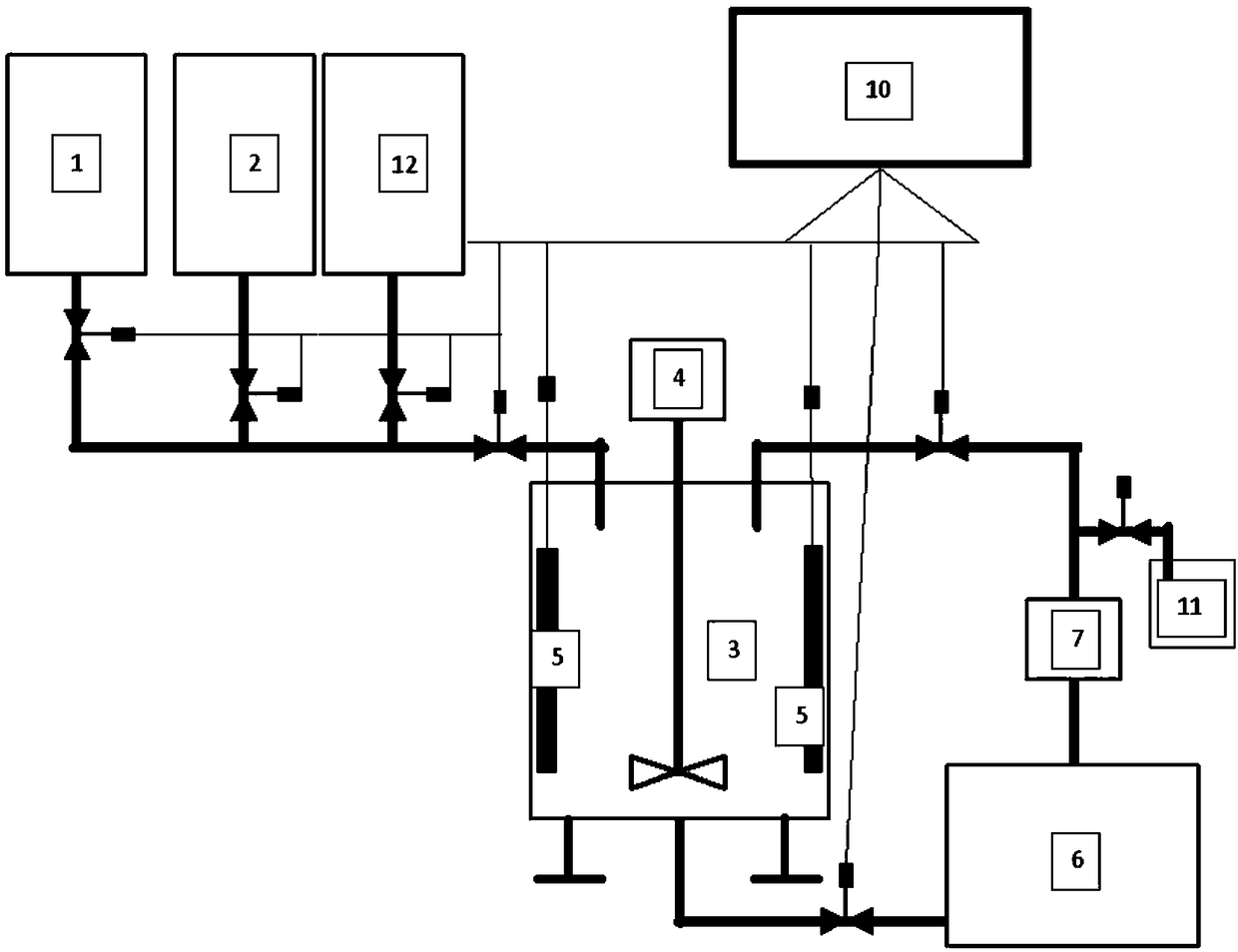

[0055] On the basis of Embodiment 1, the graphene mass production equipment of this embodiment also includes a program controller 10, such as figure 2 As shown, they are connected to the graphite powder tank 1, the weak acid / weak base tank 2, the deionized water tank 12, the microwave reactor 3, the high-speed shear 6, the cleaning and drying device 7, and the graphene tank 11. According to the product graphene layer According to the requirements, the program controller 10 sets the ratio of raw materials, wetting conditions, peeling steps and peeling conditions, and sends them to each device connected to it to automatically control its opening and closing, thereby efficiently and automatically controlling the production of graphene from graphite The whole process.

Embodiment 3

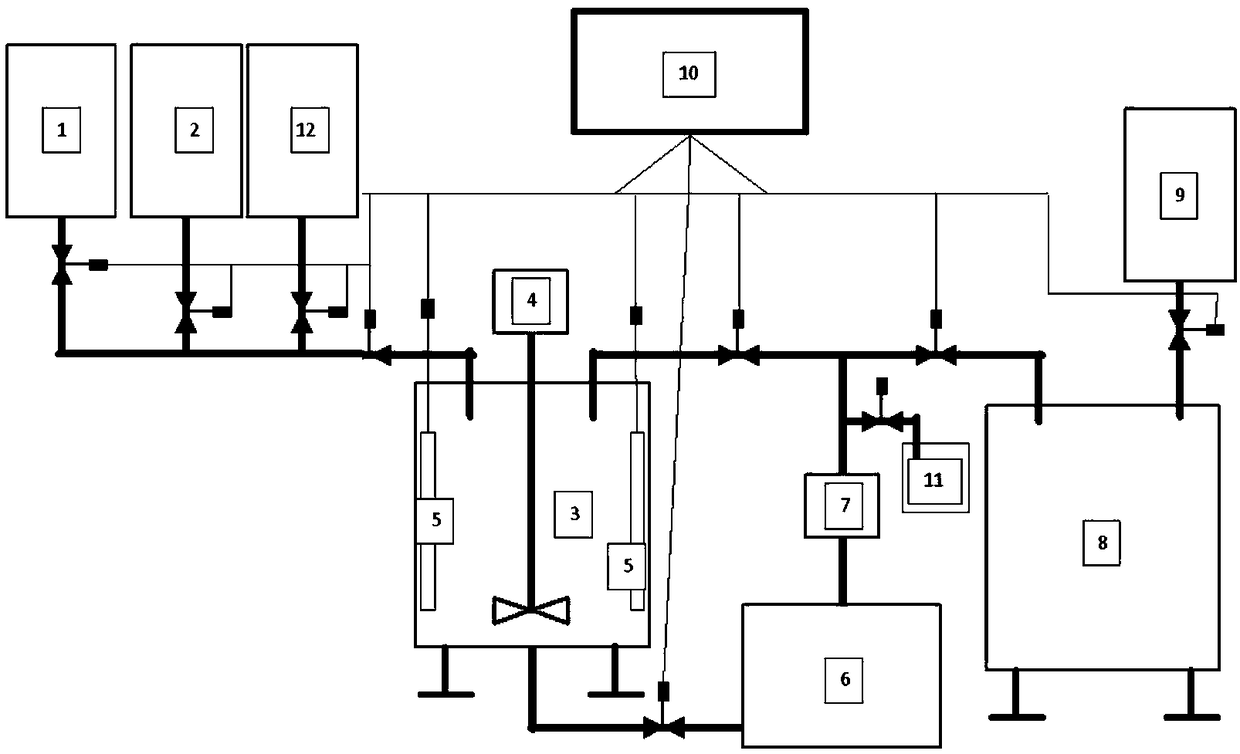

[0057] On the basis of Embodiment 1 or 2, the graphene mass production equipment of this embodiment also includes graphene application devices, such as image 3 As shown, the graphene application device includes a graphene dispersion tank 8 and a graphene solvent tank 9, and the graphene dispersion tank 8 is connected to the graphene tank 11 and the graphene solvent tank 9 respectively. The dried graphene and the solvent liquid enter the graphene dispersion tank 8 separately for stirring, and are dispersed into graphene slurry, which is used for conductive slurry, graphene coating, and the like. In addition, when the program controller 10 is included, the graphene dispersion tank 8 and the graphene solvent tank 9 are respectively connected to the program controller 10, and the above process is automatically performed by the program control.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com