Borate intercalation modified graphene oxide composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and borate technology, which is applied in the field of nanofiltration membranes, achieves good industrial production and application prospects, low cost, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

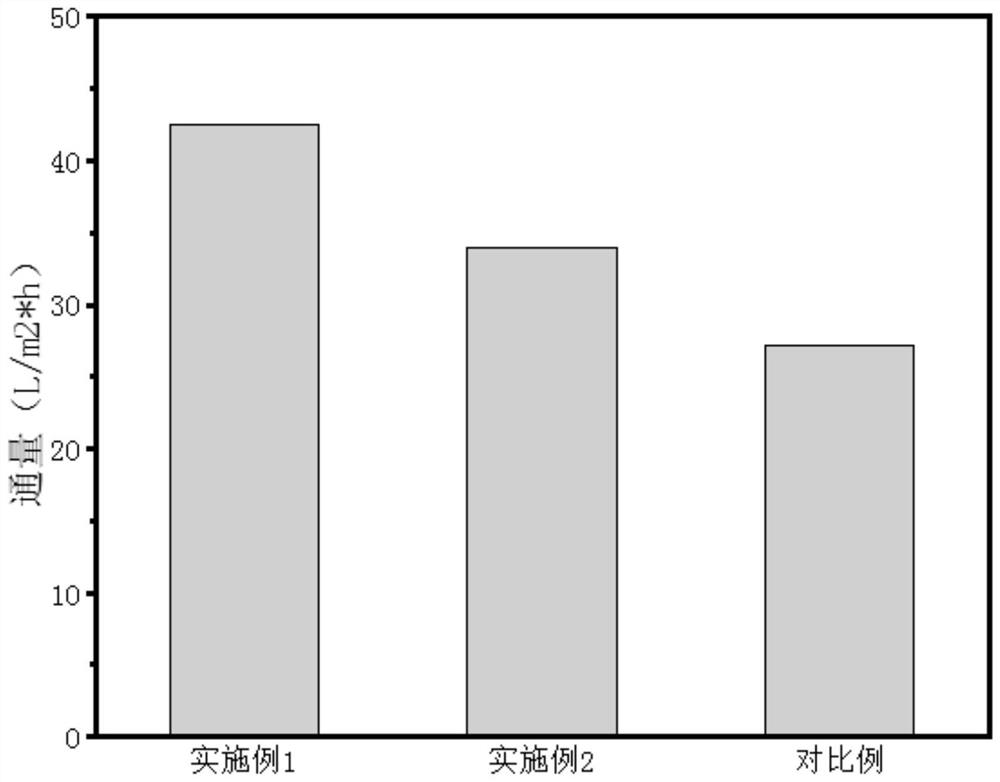

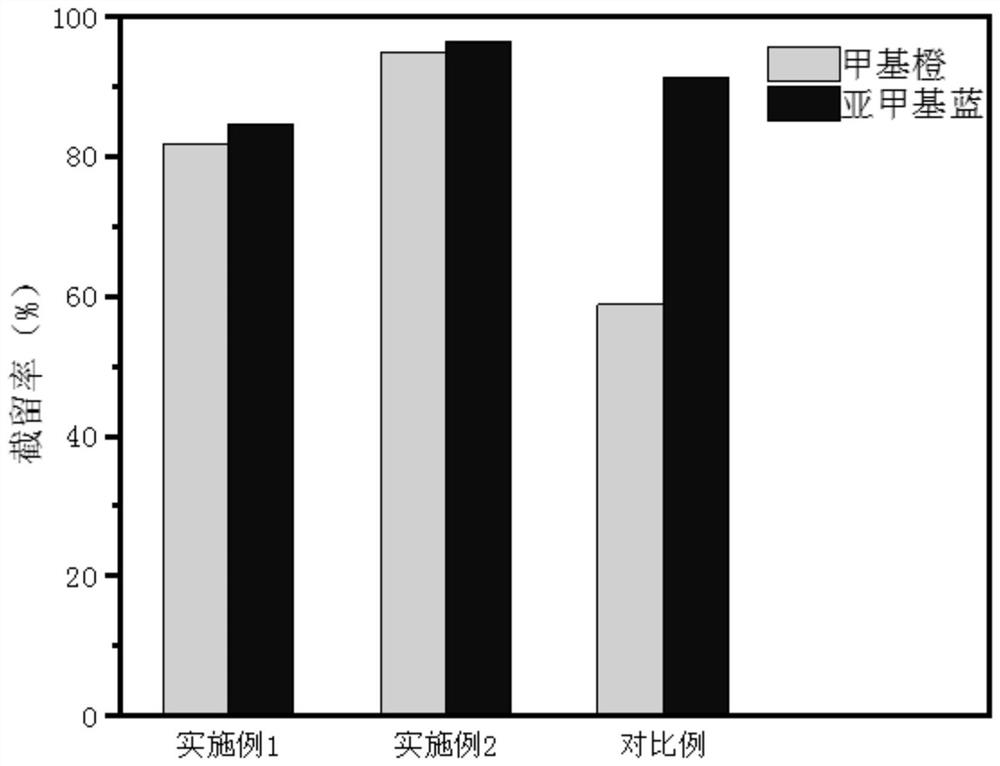

Embodiment 1

[0035] (1) Immerse the polypropylene cyanide membrane in the sodium hydroxide solution, let it stand at 40°C for 2 hours, rinse the excess sodium hydroxide solution with deionized water, and obtain the hydrolyzed polypropylene cyanide membrane, wherein the concentration of sodium hydroxide is 2mol / L .

[0036] (2) Immerse the hydrolyzed polypropylene cyanide film obtained in step (1) in the polyethyleneimine solution, let it stand at 40°C for 1 hour, rinse the excess polyethyleneimine solution with deionized water, and obtain the base film, wherein polyethyleneimine The imine concentration was 1 g / L.

[0037] (3) Graphene oxide was dissolved in deionized water, ultrasonicated for 1 h to obtain a graphene oxide dispersion, sodium tetraborate was added, and shaken at 60° C. for 12 h to obtain a sodium tetraborate intercalation-modified graphene oxide solution. Wherein, the concentration of graphene oxide is 1 g / L, and the concentration of sodium tetraborate is 0.2 g / L.

[0038...

Embodiment 2

[0044] (1) Immerse the polypropylene cyanide membrane in the sodium hydroxide solution, let it stand at 40°C for 2 hours, rinse the excess sodium hydroxide solution with deionized water, and obtain the hydrolyzed polypropylene cyanide membrane, wherein the concentration of sodium hydroxide is 2mol / L .

[0045] (2) Immerse the hydrolyzed polypropylene cyanide film obtained in step (1) in the polyethyleneimine solution, let it stand at 40°C for 1 hour, rinse the excess polyethyleneimine solution with deionized water, and obtain the base film, wherein polyethyleneimine The imine concentration was 1 g / L.

[0046] (3) Graphene oxide was dissolved in deionized water, ultrasonicated for 1 h to obtain a graphene oxide dispersion, sodium tetraborate was added, and shaken at 60° C. for 12 h to obtain a borate intercalation modified graphene oxide solution. Wherein, the concentration of graphene oxide is 1 g / L, and the concentration of sodium tetraborate is 0.4 g / L.

[0047] (4) Immers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com