Modified polyurethane coating and preparation method thereof

A polyurethane coating and modification technology, applied in the field of coatings, can solve the problems of lack of temperature insulation performance and limit the application scope of polyurethane coatings, and achieve the effects of broadening the scope of use, increasing the spacing between layers, and improving affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

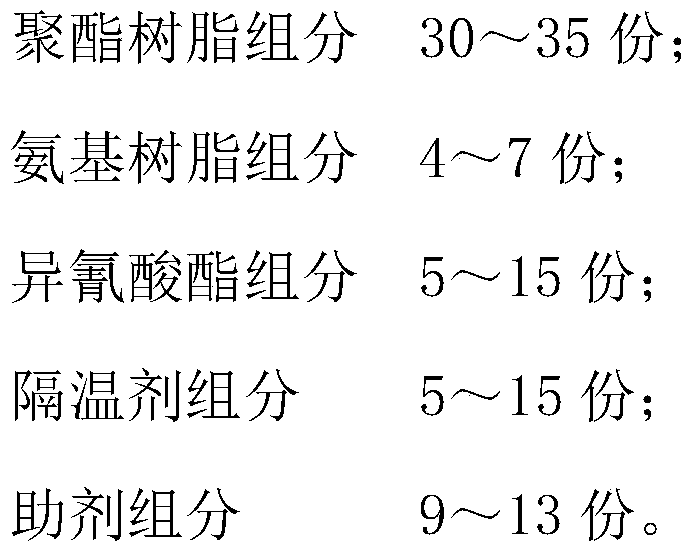

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Preparation of Organic Sepiolite

[0022] Disperse the sepiolite in deionized water under stirring to form a sepiolite suspension, let it stand for 24 hours, use ultrasonic waves to disperse the sepiolite suspension for 20 minutes, add octadecyltrimethylammonium chloride, and stir to dissolve Finally, put it into an ultrasonic cleaner, react at a temperature of 60°C for 3 hours, let it stand for stratification to remove the upper layer solution, filter it with suction, use deionized water to clean the product, dry it, and crush it to prepare organic sea foam stone;

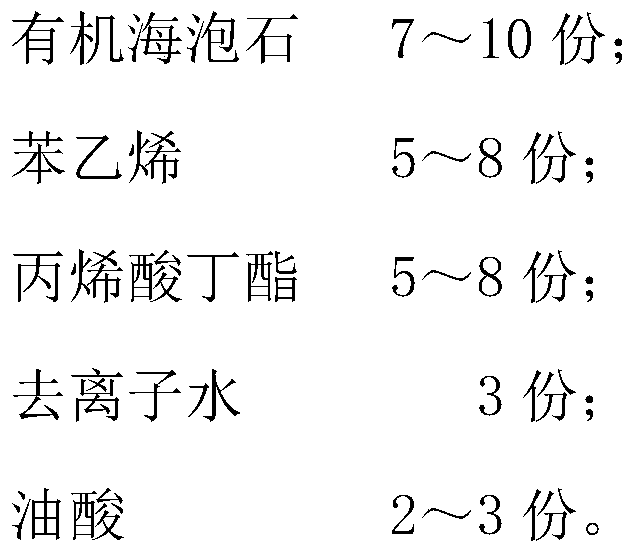

[0023] Step 2: Prepare Insulation Components

[0024] Stir 5 parts of styrene, 5 parts of butyl acrylate, 7 parts of organic sepiolite, 3 parts of deionized water and 2 parts of oleic acid at a temperature of 20°C for 1 hour, then raise the temperature to 40°C, and slowly add the initiator dropwise An aqueous solution of potassium persulfate was reacted for 1 hour to obtain the temperature insulat...

Embodiment 2

[0032] Step 1: Preparation of Organic Sepiolite

[0033] Disperse the sepiolite in deionized water under stirring to form a sepiolite suspension, let it stand for 24 hours, use ultrasonic waves to disperse the sepiolite suspension for 23 minutes, add octadecyltrimethylammonium chloride, and stir to dissolve Finally, put it into an ultrasonic cleaner, react at a temperature of 60°C for 3 hours, let it stand for stratification to remove the upper layer solution, filter it with suction, use deionized water to clean the product, dry it, and crush it to prepare organic sea foam stone;

[0034] Step 2: Prepare Insulation Components

[0035] Stir 6 parts of styrene, 6 parts of butyl acrylate, 8 parts of organic sepiolite, 3 parts of deionized water and 2 parts of oleic acid at a temperature of 22°C for 1 hour, then raise the temperature to 43°C, and slowly add the initiator dropwise An aqueous solution of potassium persulfate was reacted for 1 hour to obtain the temperature insulat...

Embodiment 3

[0043] Step 1: Preparation of Organic Sepiolite

[0044] Disperse the sepiolite in deionized water under stirring to form a sepiolite suspension, let it stand for 24 hours, use ultrasonic waves to disperse the sepiolite suspension for 26 minutes, add octadecyltrimethylammonium chloride, and stir to dissolve Finally, put it into an ultrasonic cleaner, react at a temperature of 60°C for 3 hours, let it stand for stratification to remove the upper layer solution, filter it with suction, use deionized water to clean the product, dry it, and crush it to prepare organic sea foam stone;

[0045] Step 2: Prepare Insulation Components

[0046] Stir 7 parts of styrene, 7 parts of butyl acrylate, 9 parts of organic sepiolite, 3 parts of deionized water and 3 parts of oleic acid at a temperature of 23°C for 1 hour, then raise the temperature to 46°C, and slowly add the initiator dropwise An aqueous solution of potassium persulfate was reacted for 1 hour to obtain the temperature insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com