Tear-resistant and heat-resistant silicone rubber cable

A silicone rubber and tear-resistant technology, used in rubber insulators, organic insulators, etc., can solve the problems of affecting use, low strength of silicone rubber, and poor tear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

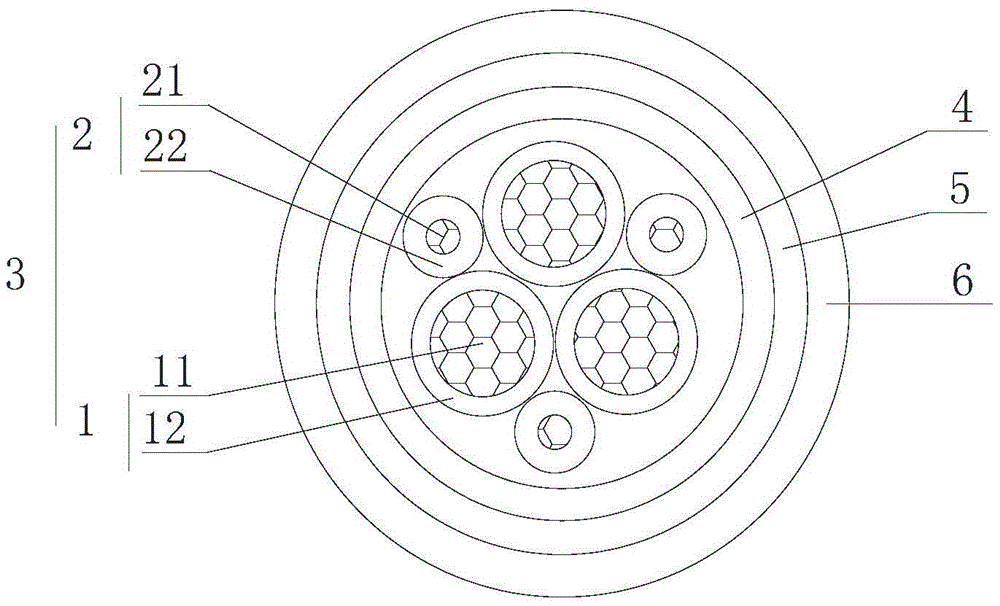

Image

Examples

Embodiment 1

[0020] A tear-resistant and heat-resistant silicone rubber cable. The silicone rubber cable includes a sheath layer. The raw materials of the sheath layer include 90 parts by weight of silicone rubber, 15 parts of EPDM rubber, 70 parts of composite filler, and 5 parts of hydroxy silicone oil. Parts, 2.5 parts of paraffin oil, 2 parts of epoxy soybean oil, 40 parts of flame retardant, 1.5 parts of dicumyl peroxide, 250.5 parts of double, 0.3 part of accelerator M, 0.4 part of accelerator BZ, dibutyl 2 parts of tin oxide, 1.5 parts of dibutyltin dilaurate, 10100.3 parts of antioxidants, 1680.2 parts of antioxidants, 2 parts of silicone powder; composite filler materials include: vinyl triethoxy silane, nano silica, Nano titanium dioxide, modified expanded vermiculite.

Embodiment 2

[0022] A tear-resistant and heat-resistant silicone rubber cable. The silicone rubber cable includes a sheath layer. The raw materials of the sheath layer include, in parts by weight: 100 parts of methyl vinyl silicone rubber with a vinyl content of 0.4% by weight, EPDM 10 parts of rubber, 80 parts of compound filler, 4 parts of hydroxy silicone oil, 3 parts of paraffin oil, 1 part of epoxy soybean oil, 50 parts of flame retardant, 1 part of dicumyl peroxide, double 250.6 parts, accelerator M0.2 Parts, 0.5 parts of accelerator BZ, 1 part of dibutyl tin oxide, 2 parts of dibutyl tin dilaurate, 10100.2 parts of antioxidant, 1680.3 parts of antioxidant, 1 part of silicone powder;

[0023] The raw materials of the composite filler include: vinyl triethoxy silane, nano silica, nano titanium dioxide, modified expanded vermiculite, among which vinyl triethoxy silane, nano silica, nano titanium dioxide, modified expanded vermiculite The weight ratio is 1:3:4:80;

[0024] The flame retarda...

Embodiment 3

[0028] A tear-resistant and heat-resistant silicone rubber cable. The silicone rubber cable includes a sheath layer. The raw materials of the sheath layer include 80 parts by weight of methyl vinyl silicone rubber with a vinyl content of 0.6 wt%, and EPDM Rubber 20 parts, composite filler 60 parts, hydroxy silicone oil 6 parts, paraffin oil 2 parts, epoxy soybean oil 3 parts, flame retardant 30 parts, dicumyl peroxide 2 parts, double 250.4 parts, accelerator M0.4 Parts, 0.3 parts of accelerator BZ, 3 parts of dibutyl tin oxide, 1 part of dibutyl tin dilaurate, 10100.4 parts of antioxidant, 1680.1 parts of antioxidant, 3 parts of silicone powder;

[0029] The raw materials of the composite filler include: vinyl triethoxy silane, nano silica, nano titanium dioxide, modified expanded vermiculite, among which vinyl triethoxy silane, nano silica, nano titanium dioxide, modified expanded vermiculite The weight ratio is 1:10:4:240;

[0030] The flame retardant is a mixture of ammonium po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com