High temperature resistance and impact resistance variable frequency cable

A frequency conversion cable and impact resistance technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of high temperature resistance and mechanical properties of frequency conversion cables that cannot meet the requirements of high temperature environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

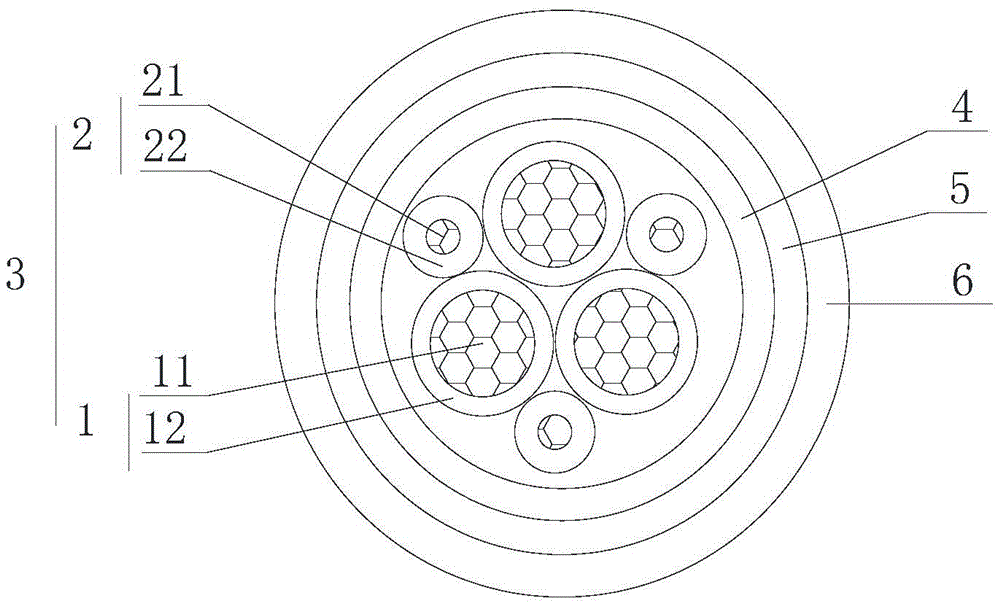

[0021] A high-temperature-resistant and impact-resistant frequency conversion cable, the frequency conversion cable includes a sheath layer, and the raw materials of the sheath layer include by weight: 100 parts of silicone rubber, 60 parts of composite filler, 2 parts of hydroxyl silicone oil, 1.5 parts of acetyl tributyl citrate, 3 parts of trioctyl phosphate, 30 parts of flame retardant, 2 parts of vinyl triethoxysilane, 2.5 parts of dicumyl peroxide, 0.2 parts of sulfur, 0.5 parts of zinc oxide, 0.8 parts of stearic acid, accelerator DETU0 .7 parts, 3 parts of dibutyltin maleate laurate, 1.5 parts of tin octyl mercaptide, 40200.15 parts of anti-aging agent, 0.3 parts of anti-aging agent TMQ, 0.3 parts of anti-aging agent RD, 3 parts of polyethylene wax; Raw materials include: ultra-fine glass fiber cotton, nano-silicon carbide, and modified expanded vermiculite.

Embodiment 2

[0023] A high-temperature-resistant and impact-resistant frequency conversion cable, the frequency conversion cable includes a sheath layer, and the raw materials of the sheath layer include: 90 parts of methyl vinyl silicone rubber, 70 parts of composite filler, 1 part of hydroxyl silicone oil, tributyl acetyl citrate 2 parts of ester, 2 parts of trioctyl phosphate, 40 parts of flame retardant, 1 part of vinyltriethoxysilane, 3 parts of dicumyl peroxide, 0.1 part of sulfur, 0.6 part of zinc oxide, 0.5 part of stearic acid , 0.8 parts of accelerator DETU, 2 parts of dibutyltin maleate laurate, 2 parts of tin octyl mercaptide, 40200.1 parts of anti-aging agent, 0.4 parts of anti-aging agent TMQ, 0.2 parts of anti-aging agent RD, 4 parts of polyethylene wax ;

[0024] The raw materials of the composite filler include: alkali-free ultra-fine glass fiber cotton, nano-silicon carbide, and modified expanded vermiculite, wherein the weight ratio of alkali-free ultra-fine glass fiber ...

Embodiment 3

[0029]A high-temperature-resistant and impact-resistant frequency conversion cable, the frequency conversion cable includes a sheath layer, and the raw materials of the sheath layer include: 110 parts of methyl vinyl silicone rubber, 50 parts of composite filler, 3 parts of hydroxyl silicone oil, tributyl acetyl citrate 1 part of ester, 4 parts of trioctyl phosphate, 20 parts of flame retardant, 3 parts of vinyltriethoxysilane, 2 parts of dicumyl peroxide, 0.3 part of sulfur, 0.4 part of zinc oxide, 1 part of stearic acid , 0.6 parts of accelerator DETU, 4 parts of dibutyltin maleate laurate, 1 part of tin octyl mercaptide, 0.2 parts of anti-aging agent, 0.2 parts of anti-aging agent TMQ, 0.4 parts of anti-aging agent RD, 2 parts of polyethylene wax ;

[0030] The raw materials of the composite filler include: alkali-free ultra-fine glass fiber cotton, nano-silicon carbide, and modified expanded vermiculite, wherein the weight ratio of alkali-free ultra-fine glass fiber cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com