Degradable vegetable fiber environmental-protection composite material capable of being subjected to extrusion or plastic suction thermal molding

A plant fiber and composite material technology, applied in the field of degradable plant fiber environmental protection composite materials, can solve the problems of natural environment destruction, aggravated resource shortage, environmental pollution, etc., to improve mechanical properties, promote degradation efficiency, and improve dispersion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

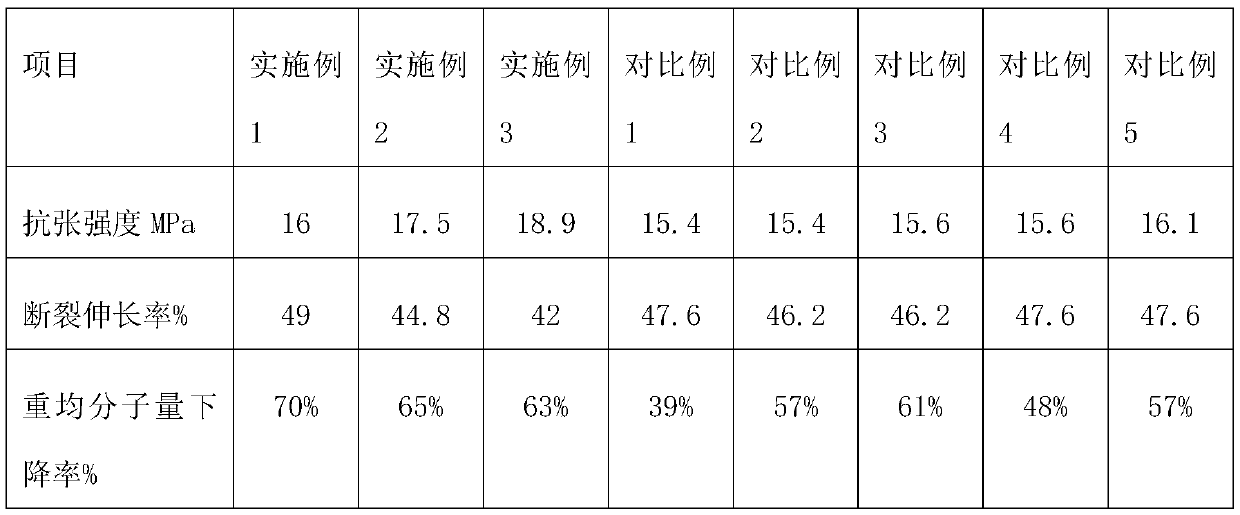

Examples

Embodiment 1

[0027] A preparation method of degradable plant fiber environmental protection composite material that can be processed by thermoforming such as extrusion or blister, is characterized in that it includes the following steps:

[0028] (1) After the chaff is pulverized by a mill, it is vibrated and screened to get a fiber powder with a particle size of 200 meshes, and the cellulose powder is stirred and incubated in acetic anhydride for 2 hours at 120 ° C under an atmospheric pressure of 4 kg. , cooled and filtered, directly dried without washing.

[0029] (2) Then in parts by mass, 40 parts of modified plant fiber powder, 60 parts of thermoplastic resin, 1.5 parts of compatibilizer, 0.9 part of coupling agent, 0.5 part of lubricant, 1 part of heat stabilizer, 2 parts of filler, pigment 2 parts, 1 part of other additives, mixed with a vertical mixer, initially stirred at a high speed of 25rpm / min for 7.5min, and then stirred at a low speed of 7.5rpm / min for 3-5min; the thermopla...

Embodiment 2

[0032] Same as Example 1, except by mass, 50 parts of modified plant fiber powder, 50 parts of thermoplastic resin, 1.5 parts of compatibilizer, 0.9 part of coupling agent, 0.5 part of lubricant, 1 part of thermal stabilizer, 2 parts of filler 1 part, 2 parts of pigment, 1 part of other additives. The other additives are metal stearic acid, ethylene-ketone-containing monomer copolymer (1:1) mixture.

Embodiment 3

[0034] Same as Example 1, except by mass, 60 parts of modified plant fiber powder, 40 parts of thermoplastic resin, 1.5 parts of compatibilizer, 0.9 part of coupling agent, 0.5 part of lubricant, 1 part of thermal stabilizer, 2 parts of filler 1 part, 2 parts of pigment, 1 part of other additives. The other additives are metal stearic acid, ethylene carbon monoxide copolymer (1:1) mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com