High-temperature-resistant heat shrinkage silicon rubber and EVA rubber plastic blending closed hole molding pressing high-temperature secondary foaming material and preparation method thereof

A secondary foaming and silicone rubber technology, applied in the field of foaming materials, can solve the problems of easy foaming and low foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

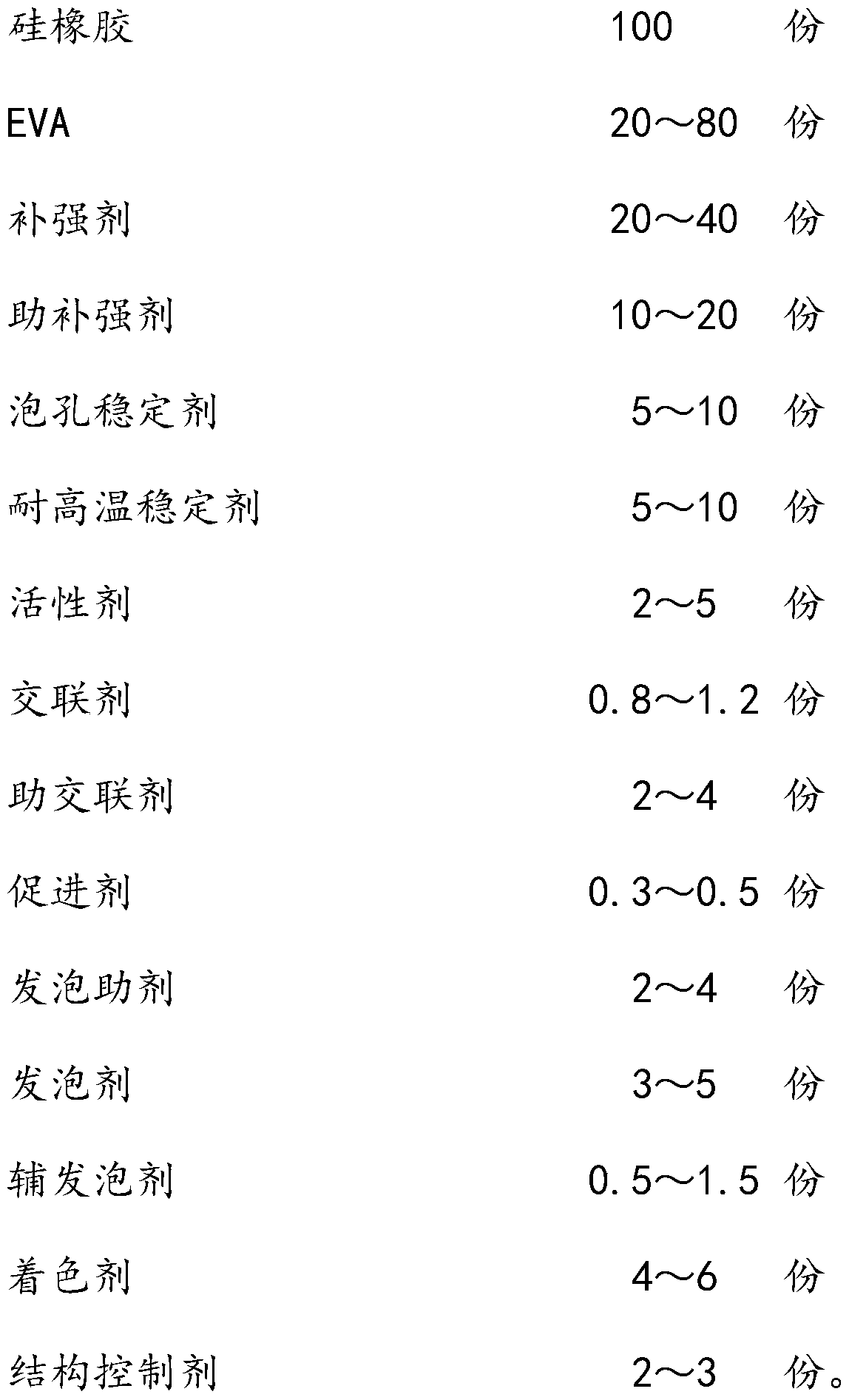

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of high-temperature heat-shrinkable silicone rubber and EVA rubber-plastic blended closed-cell molded high-temperature secondary foaming material:

[0050] (1) EVA refining with internal mixer:

[0051] According to the proportion by weight, put 100 parts of EVA and 0.2 parts of stearic acid into the internal mixer, pressurize to 7 kg, knead for 15 minutes, and discharge when the temperature reaches 110 ° C ± 5 ° C;

[0052] (2) Open mill EVA open refining:

[0053]Put the plain rubber into the open mill, control the temperature at 90°C ± 5°C, turn over the 5mm material for 180 seconds, and cut it with a thickness of 2mm into the corresponding weight for temporary storage.

[0054] (3) Internal mixer mixing:

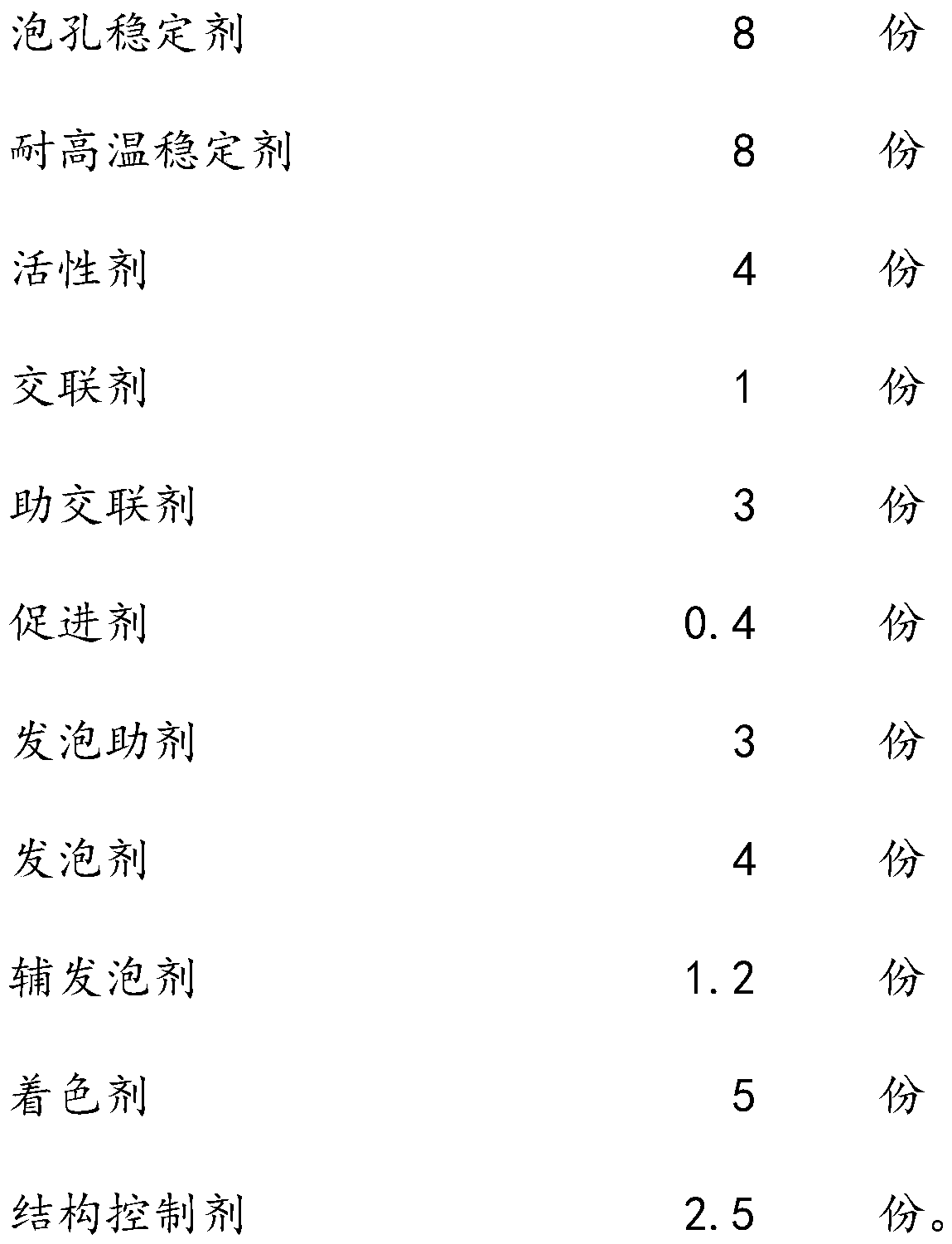

[0055] a. According to the formula weight parts, silicone rubber, 50 parts of EVA obtained in step (2), 9 parts of reinforcing agent, 15 parts of auxiliary reinforcing agent, 8 parts of cell stabilizer, 8 parts of high temperature resistant ...

Embodiment 2

[0069] A preparation method of high-temperature heat-shrinkable silicone rubber and EVA rubber-plastic blended closed-cell molded high-temperature secondary foaming material:

[0070] (1) EVA refining with internal mixer:

[0071] According to the proportion by weight, put 100 parts of EVA and 0.2 parts of stearic acid into the internal mixer, pressurize to 7 kg, knead for 15 minutes, and discharge when the temperature reaches 110 ° C ± 5 ° C;

[0072] (2) Open mill EVA open refining:

[0073] Put the plain rubber into the open mill, control the temperature at 90°C ± 5°C, turn over the 5mm material for 180 seconds, and cut it with a thickness of 2mm into the corresponding weight for temporary storage.

[0074] (3) Internal mixer mixing:

[0075] a. According to the formula weight parts, silicone rubber, 20 parts of EVA obtained in step (2), 10 parts of reinforcing agent, 10 parts of auxiliary reinforcing agent, 10 parts of cell stabilizer, 5 parts of high temperature resista...

Embodiment 3

[0089] A preparation method of high-temperature heat-shrinkable silicone rubber and EVA rubber-plastic blended closed-cell molded high-temperature secondary foaming material:

[0090] (1) EVA refining with internal mixer:

[0091] According to the proportion by weight, put 100 parts of EVA and 0.2 parts of stearic acid into the internal mixer, pressurize to 7 kg, knead for 15 minutes, and discharge when the temperature reaches 110 ° C ± 5 ° C;

[0092] (2) Open mill EVA open refining:

[0093] Put the plain rubber into the open mill, control the temperature at 90°C ± 5°C, turn over the 5mm material for 180 seconds, and cut it with a thickness of 2mm into the corresponding weight for temporary storage.

[0094] (3) Internal mixer mixing:

[0095] a. According to the formula weight parts, silicone rubber, 80 parts of EVA obtained in step (2), 5 parts of reinforcing agent, 20 parts of auxiliary reinforcing agent, 5 parts of cell stabilizer, 10 parts of high temperature resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com