Hydrophilic and oleophilic polytetrafluoroethylene micro-powder and preparation method thereof

A polytetrafluoroethylene micropowder and polytetrafluoroethylene technology are applied in the fields of hydrophilic and lipophilic polytetrafluoroethylene micropowder and its preparation, polytetrafluoroethylene micropowder and its preparation field, and can solve the problem of affecting the lipophilicity of polytetrafluoroethylene micropowder. problems such as mechanical properties, to achieve the effects of improving economic and environmental benefits, simple preparation methods and high grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

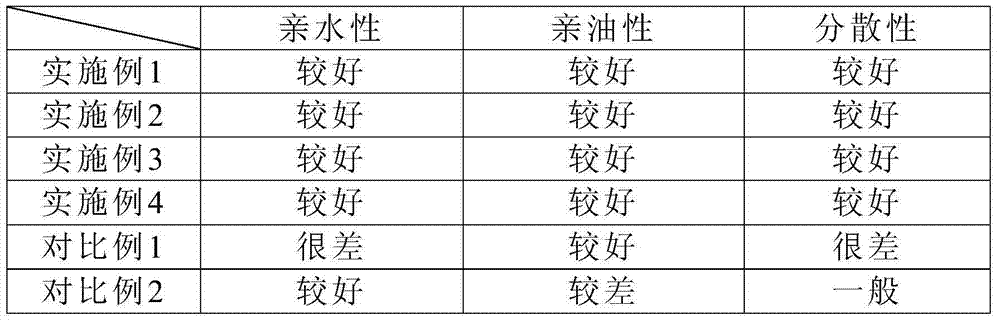

Examples

Embodiment 1

[0036] Wash and dry the oil stains on the waste polytetrafluoroethylene scraps, use a crusher to primary crush the large pieces of waste polytetrafluoroethylene scraps, put them into polyethylene plastic bags, and remove them. Gas, airtight. Afterwards, the plastic bag containing the discarded polytetrafluoroethylene scraps was irradiated and pulverized by an electron beam generated by an accelerator, and then unpacked and degassed in a fume hood to obtain polytetrafluoroethylene micropowder.

[0037] Prepare methanol and water as a solvent in a ratio of 1:2, then add 15 parts of polytetrafluoroethylene micropowder with a particle size of 2 μm obtained above into the prepared solvent, and then add 5 parts of anionic surfactant dodecane Sodium sulfate, 25 parts of water-soluble monomer acrylic acid, 40 parts of oil-soluble monomer styrene, 1 part of concentrated H 2 SO 4 1. 1 part of inorganic compound polymerization inhibitor ferrous ammonium sulfate, mix evenly, and stir wa...

Embodiment 2

[0039] Wash and dry the oil stains on the waste polytetrafluoroethylene scraps, use a crusher to primary crush the large pieces of waste polytetrafluoroethylene scraps, put them into polyethylene plastic bags, and remove them. Gas, airtight. Afterwards, the plastic bag containing the discarded polytetrafluoroethylene scraps was irradiated and pulverized by an electron beam generated by an accelerator, and then unpacked and degassed in a fume hood to obtain polytetrafluoroethylene micropowder.

[0040] Prepare methanol and water as a solvent in a ratio of 1:4, then add 25 parts of polytetrafluoroethylene micropowder with a particle size of 1 μm obtained above into the prepared solvent, and then add 8 parts of anionic surfactant dodecane Sodium sulfonate, 35 parts of water-soluble monomer acrylic acid, 60 parts of oil-soluble monomer styrene, 2 parts of concentrated H 2 SO 4 1. 2 parts of inorganic compound polymerization inhibitor ferrous ammonium sulfate, mix evenly, and sti...

Embodiment 3

[0042] Wash and dry the oil stains on the waste polytetrafluoroethylene scraps, use a crusher to primary crush the large pieces of waste polytetrafluoroethylene scraps, put them into polyethylene plastic bags, and remove them. Gas, airtight. Afterwards, the plastic bag containing the discarded polytetrafluoroethylene scraps was irradiated and pulverized by an electron beam generated by an accelerator, and then unpacked and degassed in a fume hood to obtain polytetrafluoroethylene micropowder.

[0043] Prepare ethanol and water as a solvent in a ratio of 1:4, then add 25 parts of polytetrafluoroethylene micropowder with a particle size of 2 μm obtained above into the prepared solvent, and then add 8 parts of nonionic surfactant fatty acid glycerin Ester, 35 parts of water-soluble monomer sulfonic acid group, 60 parts of oil-soluble monomer N-alkylacrylamide, 1 part of concentrated H 2 SO 4 , 2 parts of hydroquinone, a phenolic polymerization inhibitor, mix well, and stir the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com