High-fluidity TPV material and preparing method thereof

A high-fluidity, raw material technology, applied in the field of TPV materials, can solve the problems of lack of improvement in fluidity, reduced mechanical properties of products, equipment energy consumption, and large wear, etc., to improve permanent deformation resistance and processing. The effect of reducing the effect of fluidity deterioration and the effect of sufficient blending process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

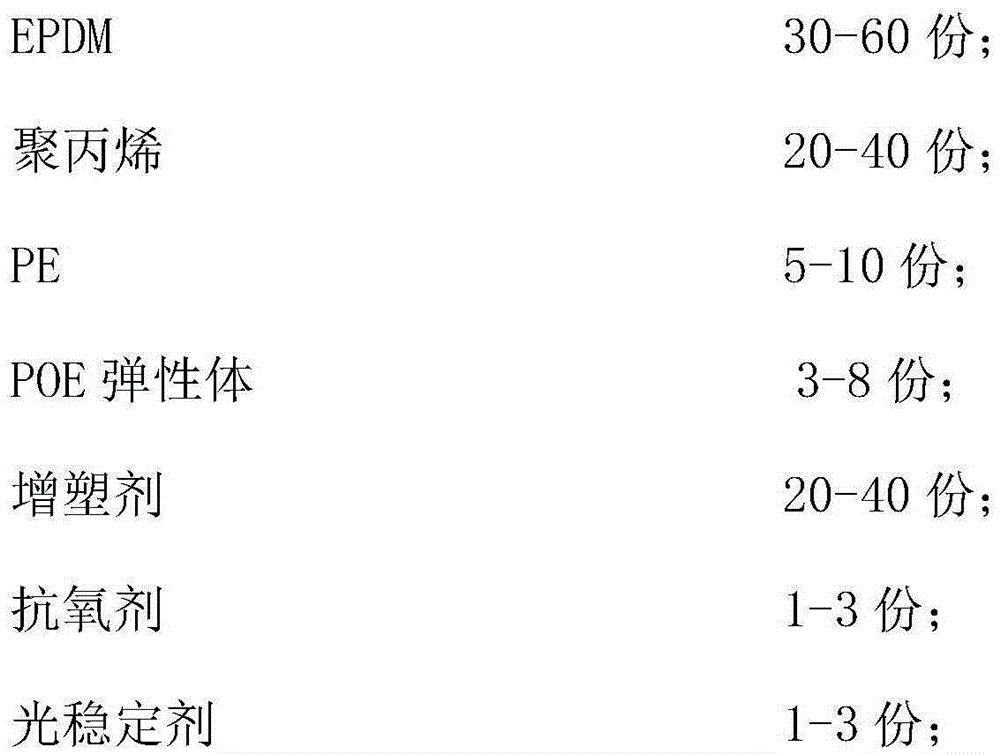

[0023] A kind of high fluidity TPV material, its raw material comprises by weight:

[0024]

[0025] The preparation of the high-fluidity TPV material includes: adding EPDM, polypropylene, POE elastomer, antioxidant, and light stabilizer to a kneader for mixing, then sending it into a twin-screw extruder for the first plasticizing, cutting After granulation, the first semi-finished granules are obtained; after the first semi-finished granules are mixed with PE, internal lubricant, and plasticizer, they are sent to the twin-screw extruder for the second plasticizing, and the second semi-finished granules are obtained after pelletizing ; After mixing the second semi-finished particle with the crosslinking agent, send it into the twin-screw extruder for the third mixing, and obtain the high fluidity TPV material after pelletizing; the processing in the first plasticizing process The temperature is 160°C, and the screw speed is 400r / min; the processing temperature in the second...

Embodiment 2

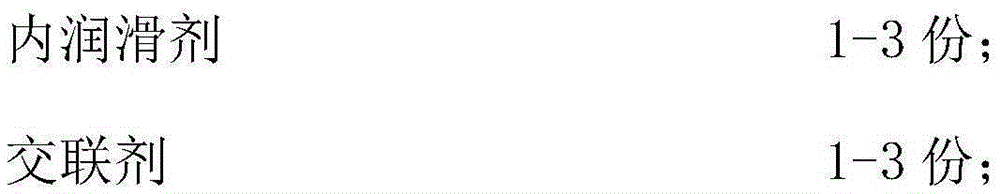

[0028] A kind of high fluidity TPV material, its raw material comprises by weight:

[0029]

[0030]

[0031]The preparation of the high-fluidity TPV material includes: adding EPDM, polypropylene, POE elastomer, antioxidant, and light stabilizer to a kneader for mixing, then sending it into a twin-screw extruder for the first plasticizing, cutting After granulation, the first semi-finished granules are obtained; after the first semi-finished granules are mixed with PE, internal lubricant, and plasticizer, they are sent to the twin-screw extruder for the second plasticizing, and the second semi-finished granules are obtained after pelletizing ; After mixing the second semi-finished particle with the crosslinking agent, send it into the twin-screw extruder for the third mixing, and obtain the high fluidity TPV material after pelletizing; the processing in the first plasticizing process The temperature is 190°C, and the screw speed is 200r / min; the processing temperature in...

Embodiment 3

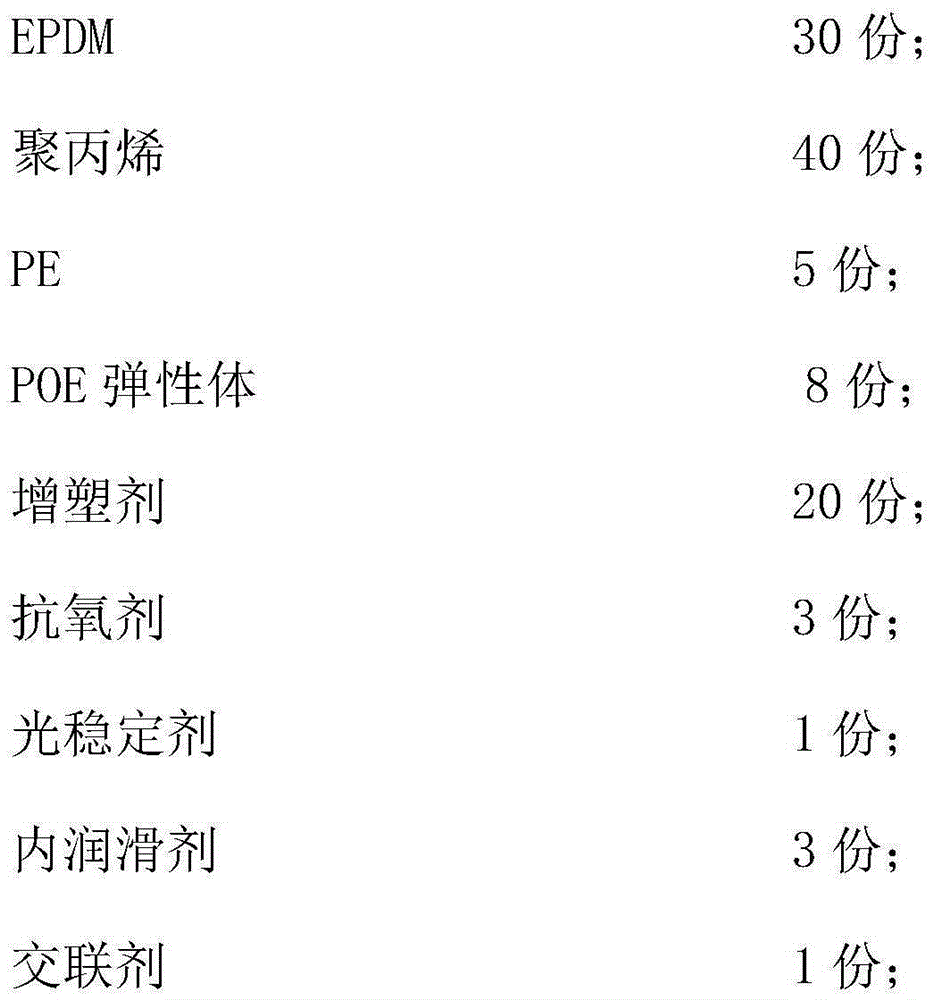

[0034] A kind of high fluidity TPV material, its raw material comprises by weight:

[0035]

[0036]

[0037] The preparation of the high-fluidity TPV material includes: adding EPDM, polypropylene, POE elastomer, antioxidant, and light stabilizer to a kneader for mixing, then sending it into a twin-screw extruder for the first plasticizing, cutting After granulation, the first semi-finished granules are obtained; after the first semi-finished granules are mixed with PE, internal lubricant, and plasticizer, they are sent to the twin-screw extruder for the second plasticizing, and the second semi-finished granules are obtained after pelletizing ; After mixing the second semi-finished particle with the crosslinking agent, send it into the twin-screw extruder for the third mixing, and obtain the high fluidity TPV material after pelletizing; the processing in the first plasticizing process The temperature is 180°C, and the screw speed is 300r / min; the processing temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com