Method for preparing oxide dispersion strengthened copper composite material

A dispersion-strengthened copper and composite material technology, which is applied in the field of copper alloy material preparation, can solve the problems of easy segregation, Y incorporation, uneven distribution of dispersed phase, etc., and achieve the effect of loose conditions, easy operation and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

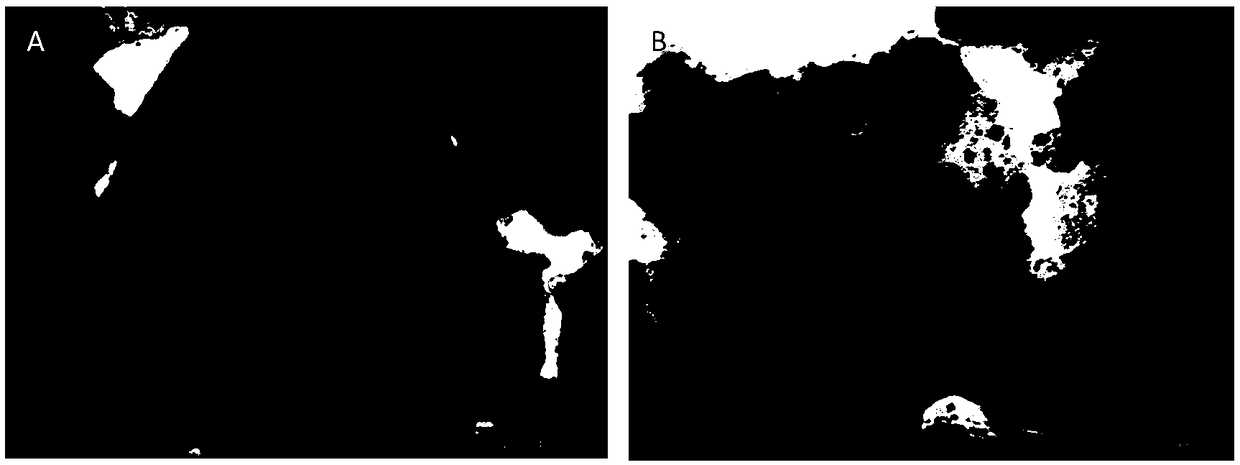

Image

Examples

Embodiment 1

[0018] 1. Weigh 74.4g of Cu powder, place it in a hydrogen reduction furnace, and reduce it at 400°C for 1 hour.

[0019] 2. Fully mix the reduced Cu powder and 0.8wt% Y powder, and then package them together with the grinding balls in a ball mill jar, the ball-to-material ratio is 10:1, and add 6wt% ethanol as a process control agent, and then ball mill The tank is fixed in a planetary ball mill, and ball milled at a speed of 350rpm for 50h.

[0020] 3. Under vacuum conditions, the alloy powder obtained after mechanical alloying was annealed at 300° C. for 5 hours in a muffle furnace.

[0021] 4. The alloy powder obtained after ball milling is placed in a mold, and sintered and formed in a spark plasma sintering furnace under the conditions of 850°C, 50MPa, and 8min.

[0022] 5. Roll the copper alloy block obtained by sintering to 10% of the original thickness.

[0023] 6. Under an inert atmosphere, heat-treat the rolled copper alloy plate at 750°C, hold for 12 hours, and c...

Embodiment 2

[0025] 1. Weigh 74.25g of Cu powder, place it in a hydrogen reduction furnace, and reduce it at 450°C for 0.5h.

[0026] 2. Fully mix the reduced Cu powder and 1wt% Y powder, and then package them together with the grinding balls in a ball milling tank. The ball-to-material ratio is 10:1, and add 6wt% ethanol as a process control agent, and then ball milling tank Fix it in a planetary ball mill and ball mill for 60 hours at a speed of 300rpm.

[0027] 3. Under vacuum conditions, the alloy powder obtained after mechanical alloying was annealed at 350° C. for 4.5 hours in a muffle furnace.

[0028] 4. The alloy powder obtained after ball milling is placed in a mold, and sintered and formed in a spark plasma sintering furnace under the conditions of 900°C, 50MPa, and 5min.

[0029] 5. Roll the copper alloy block obtained by sintering to 50% of the original thickness.

[0030] 6. Under an inert atmosphere, heat-treat the rolled copper alloy plate under the conditions of 675°C, h...

Embodiment 3

[0033] 1. Weigh 49.25g of Cu powder, place it in a hydrogen reduction furnace, and reduce it at 450°C for 0.5h.

[0034] 2. Fully mix the reduced Cu powder and 1.5wt% Y powder, and then package them together with the grinding balls in a ball mill jar, the ball-to-material ratio is 15:1, and add 6wt% ethanol as a process control agent, and then ball mill The tank is fixed in a planetary ball mill, and ball milled at a speed of 300rpm for 50h.

[0035] 3. Under vacuum conditions, the alloy powder obtained after mechanical alloying was annealed at 400° C. for 4 hours in a muffle furnace.

[0036] 4. The alloy powder obtained after ball milling is placed in a mold, and sintered and formed in a spark plasma sintering furnace under the conditions of 900°C, 40MPa, and 8min.

[0037] 5. Roll the sintered copper alloy block to 80% of its original thickness

[0038] 6. Under an inert atmosphere, heat-treat the rolled copper alloy plate under the conditions of 650° C., hold for 24 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com