Patents

Literature

39results about How to "Not demanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of saccharomyces cerevisiae and lactobacillus acidophilus composite microbe preparation used for feed

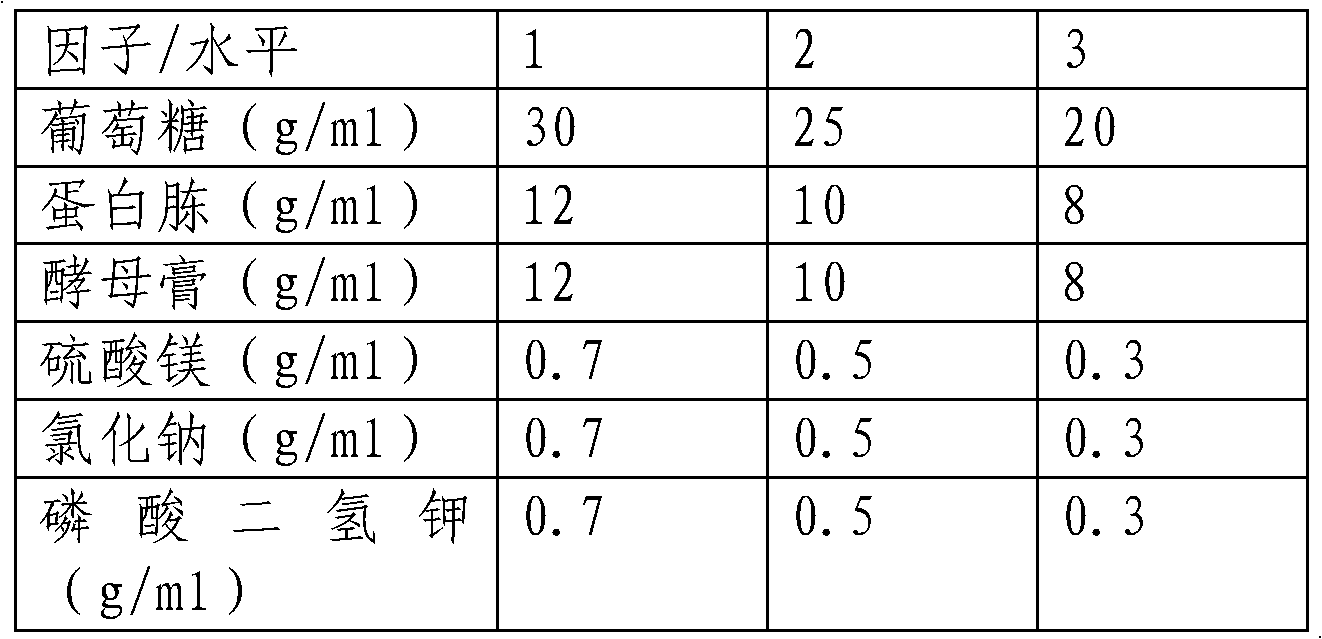

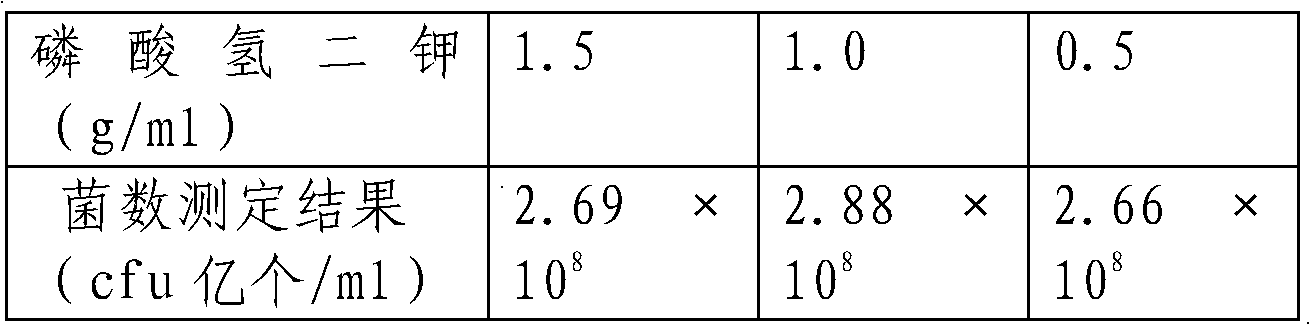

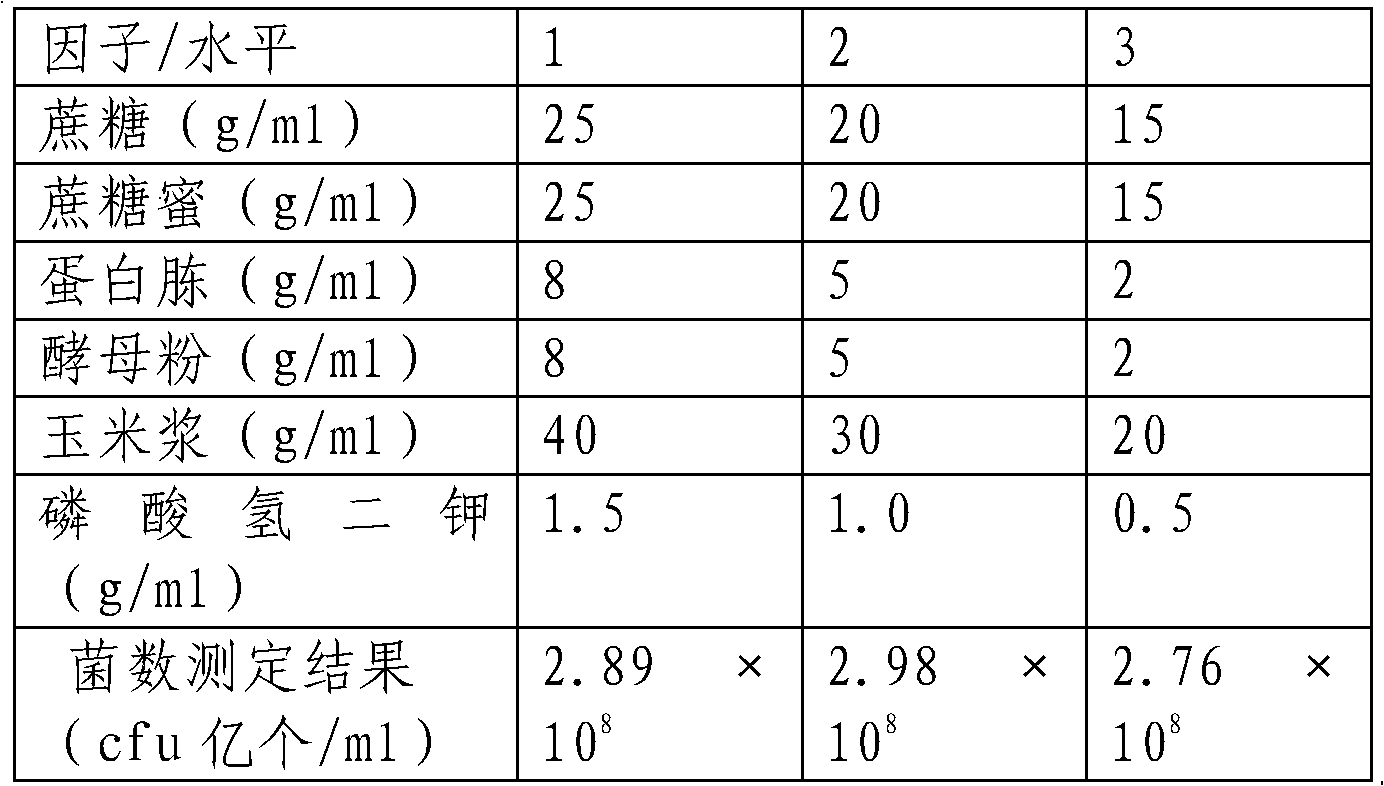

The invention relates to a microbe preparation, and concretely relates to a production method of a saccharomyces cerevisiae and lactobacillus acidophilus composite microbe preparation used for feed, the production method is characterized in that concentrated saccharomyces cerevisiae mother liquor containing saccharomyces cerevisiae greater than or equal to 50 hundreds million / ml and the concentrated lactobacillus acidophilus mother liquor with high density containing lactobacillus acidophilus greater than or equal to 100 hundreds million / ml are mixed according to 1:1 with the volume ratio, and the composite microbe preparation product containing saccharomyces cerevisiae greater than or equal to 50 hundreds million / ml and containing lactobacillus acidophilus greater than or equal to 100 hundreds million / ml. The saccharomyces cerevisiae and lactobacillus acidophilus composite microbe preparation takes glucose, cane sugar, cane sugar honey and corn steep liquor as main fermentation raw materials, the fermental cultivation can be carried out at 30-34 DEG C, the product bacteria number is high, the quality is good, pH value is between 5.0-6.6, and the quality guarantee period is 18 monthes. The saccharomyces cerevisiae and lactobacillus acidophilus composite microbe preparation used for feed has simple production technology and good product application effect, can purify the culture environment, and can be used in the culture industries such as aquatic product and livestock and poultry.

Owner:辽宁威兰生物技术有限责任公司

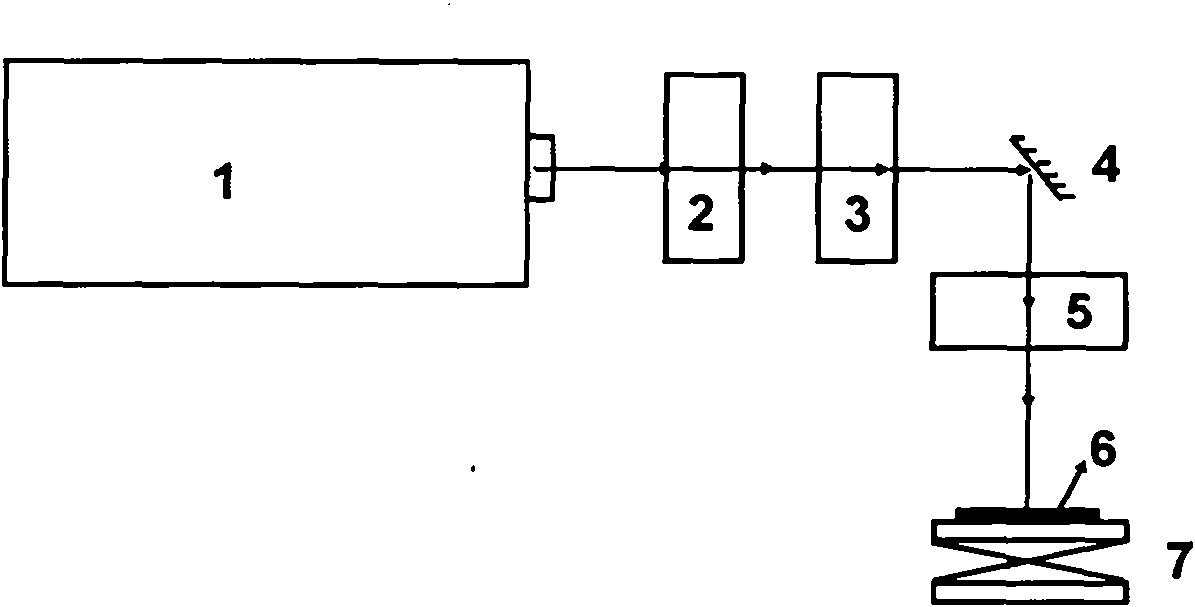

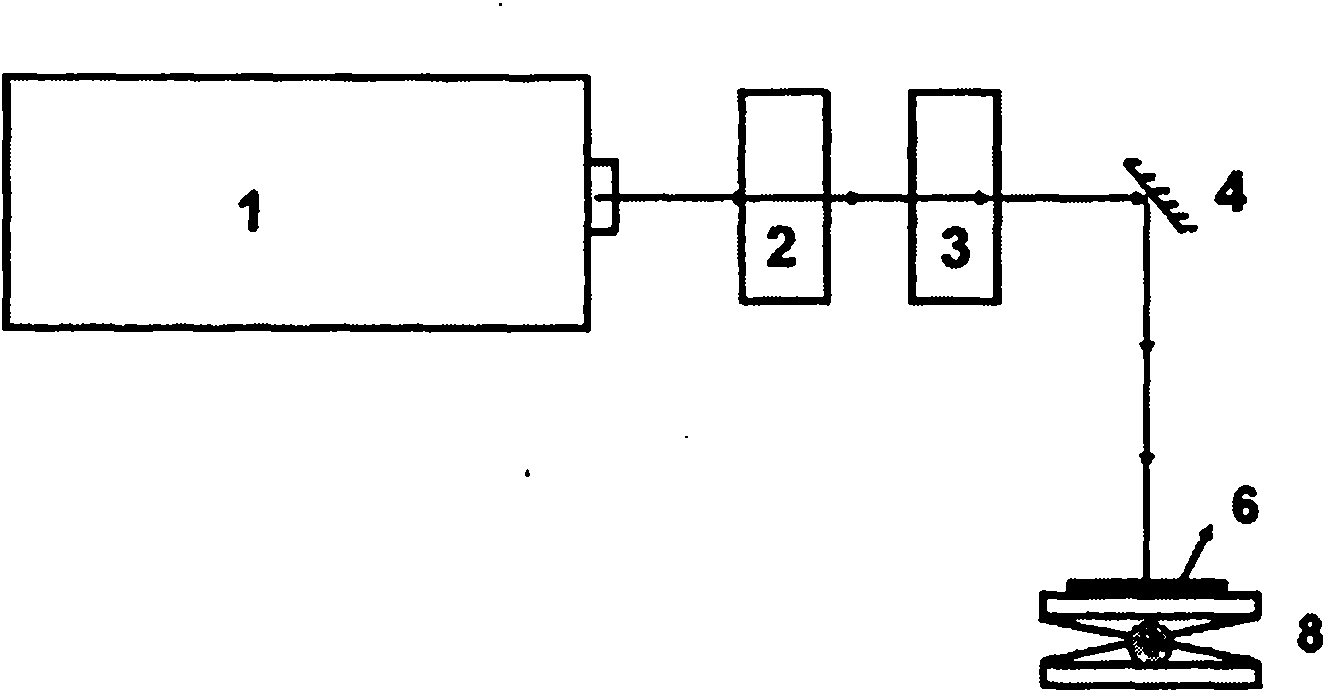

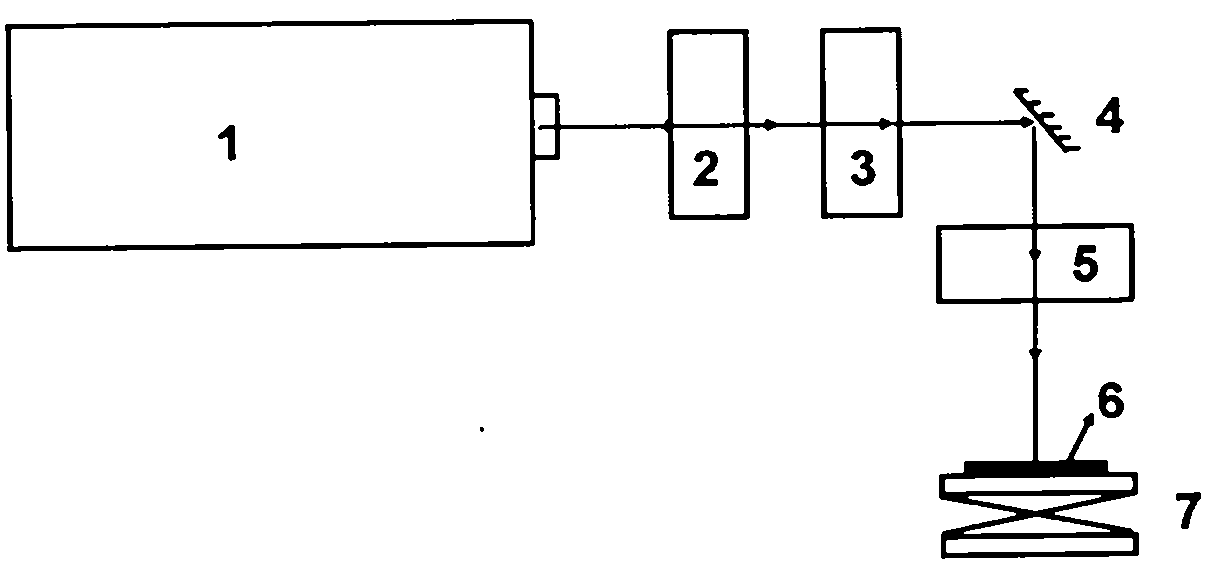

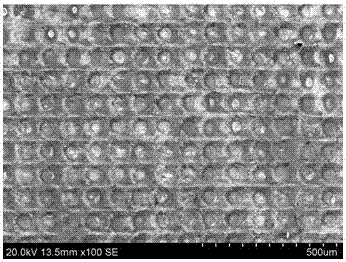

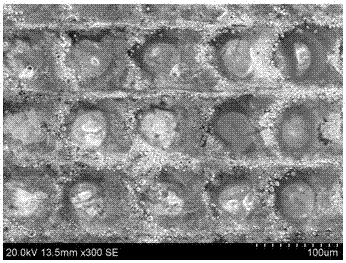

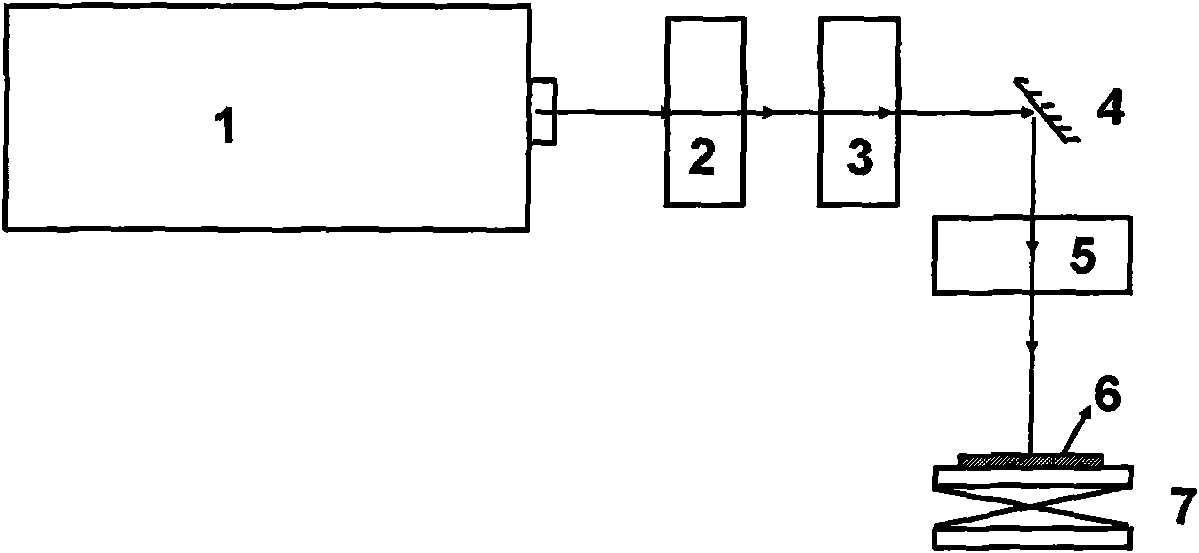

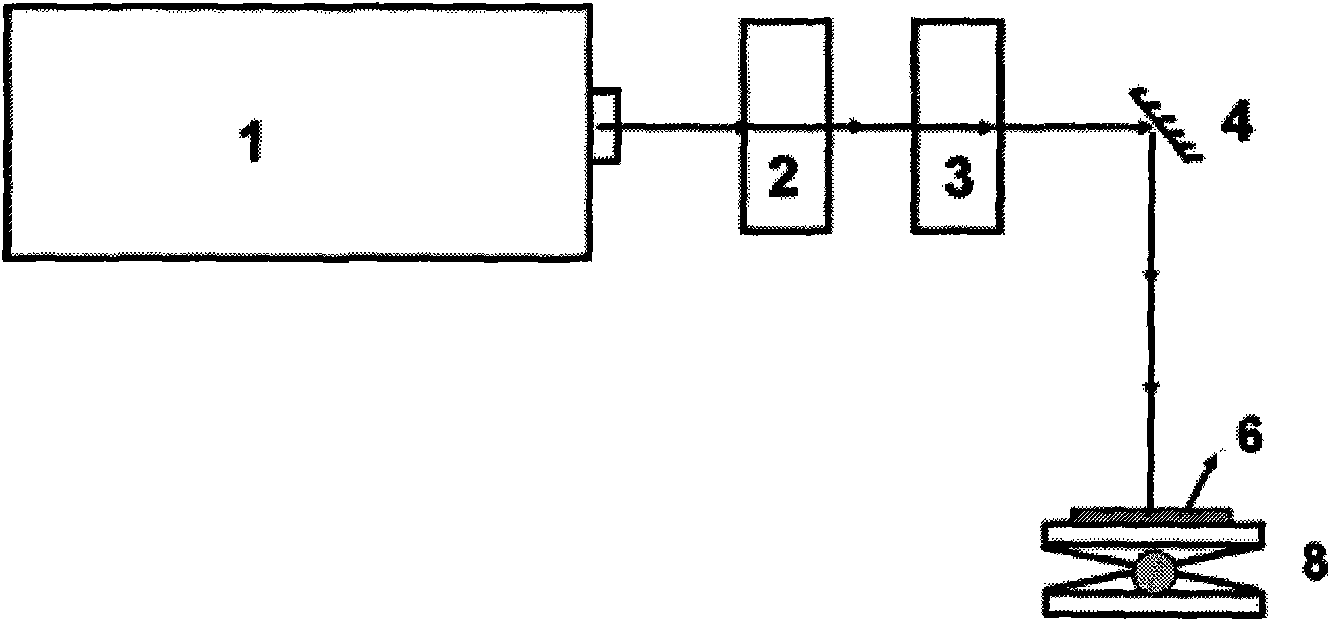

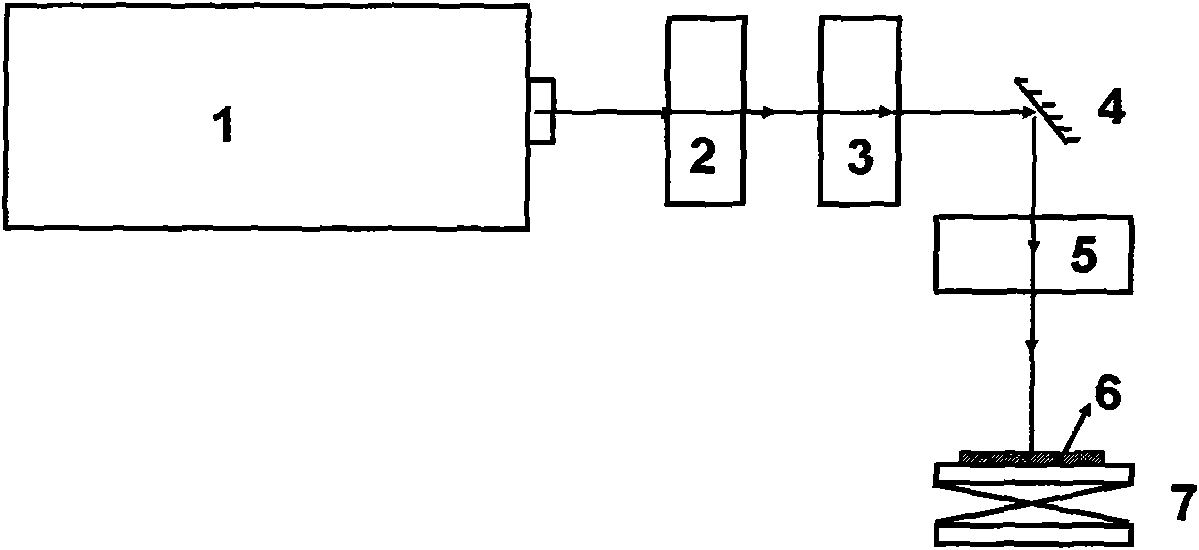

LED large-area controllable surface coarsening and etching method based on laser

InactiveCN101866996AImprove light extraction efficiencySimple production processSemiconductor devicesGalvanometerHigh power lasers

The invention relates to an LED large-area controllable surface coarsening and etching method based on a laser, belonging to the technical field of an LED. The method utilizes semiconductor material for carrying out strong absorption generating gasification on high-power laser with the wavelength less than the band edge absorption wavelength of the semiconductor material, thus realizing surface coarsening for the semiconductor material on the surface of the LED. A high-speed galvanometer or a precise displacement platform is used for controlling the laser processing area or pattern, and can be used for controlling the laser power and the processing line width and depth of focus level adjustment. The LED large-area controllable surface coarsening and etching method can be applied to surface coarsening and etching of the GaAs-based LED and the GaN-based LED of various structures. The laser takes the wavelength less than the band edge absorption wavelength of the processed semiconductor material as reference. The method has the advantages of wide applicable material, rapid processing speed, large area, low cost, good coarsening effect, low damage for the semiconductor material, high controllability of system processing parameters and the like, can effectively solve the problem of p-GaN layer coarsening, and has great application potential in the production of the high-brightness LED.

Owner:SHANDONG UNIV

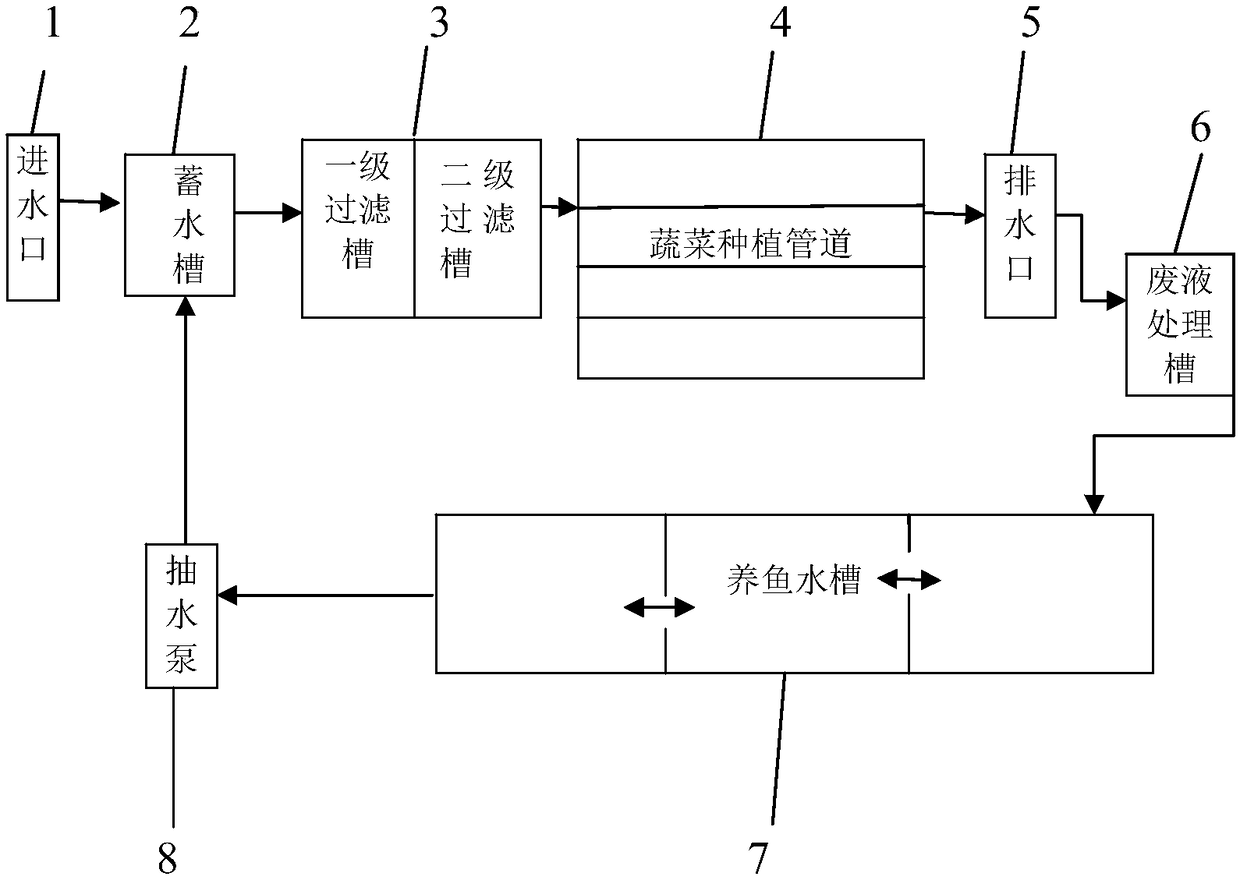

Fish and vegetable symbiotic system and application thereof

InactiveCN108812496ANot demandingReduce wasteWater/sewage treatment by irradiationWater contaminantsWater storage tankWater resources

The invention discloses a fish and vegetable symbiotic system and application thereof. The fish and vegetable symbiotic system includes a water inlet, a water storage tank, at least one filter tank, avegetable planting pipeline, a drainage port, a waste liquid treating tank and a fish framing water tank which are all connected in sequence; the fish framing water tank is lower than the position ofthe waste liquid treating tank. By adopting the fish and vegetable symbiotic system, firstly, vegetables are planted in the vegetable planting pipeline, and fish are farmed in the fish framing watertank; then, water in the fish framing water tank is transported into the water storage tank, and after being filtered by the filter tanks, the water is transported to the vegetable planting pipeline;finally, the water is transported to the waste liquid treating tank, and after being treated, the water is transported back to the fish framing water tank. In this way, water current circulation is formed, the eutrophic water can be converted into water suitable for survival of aquatic organisms, meanwhile, nutrient substances in the eutrophic water are used as plant fertilizer, therefore, waste of water resources is reduced, and the cost can be reduced.

Owner:SOUTH CHINA AGRI UNIV

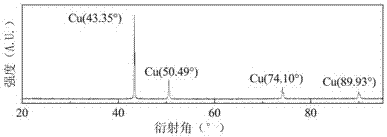

Method for preparing oxide dispersion strengthened copper composite material

The invention relates to a method for preparing an oxide dispersion strengthened copper composite material, and belongs to the field of preparation of copper alloy materials. The method is as follows:firstly reducing Cu powder; alloying element powder, to be more specific, thoroughly mixing the reduced Cu powder with an appropriate amount of Y powder to obtain a Cu powder and Y powder mixture, then packaging the Cu powder and Y powder mixture and grinding balls in a stainless steel ball mill tank, and performing ball milling under an inert gas atmosphere; after the ball milling, annealing alloyed alloy powder by a muffle furnace, and sintering the annealed alloy powder into a block by a discharge plasma sintering furnace, and then rolling the block into a desiring thickness; and finally using a muffle furnace to perform heat treatment on the rolled copper alloy, and cooling in the furnace to obtain the oxide dispersion strengthened copper composite material. The oxide dispersion strengthened copper composite material prepared by the method has uniform distribution of nano-oxide particles with an average size of 5-6 nm, the powder production rate is over 95%, and the process is simple and easy to operate.

Owner:UNIV OF SCI & TECH BEIJING

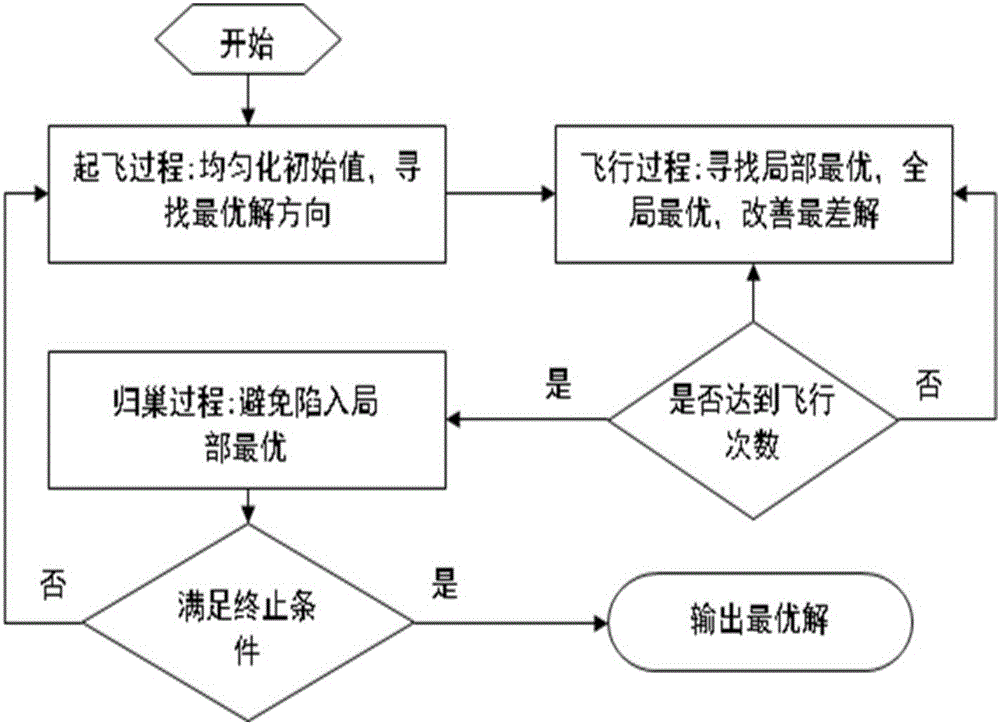

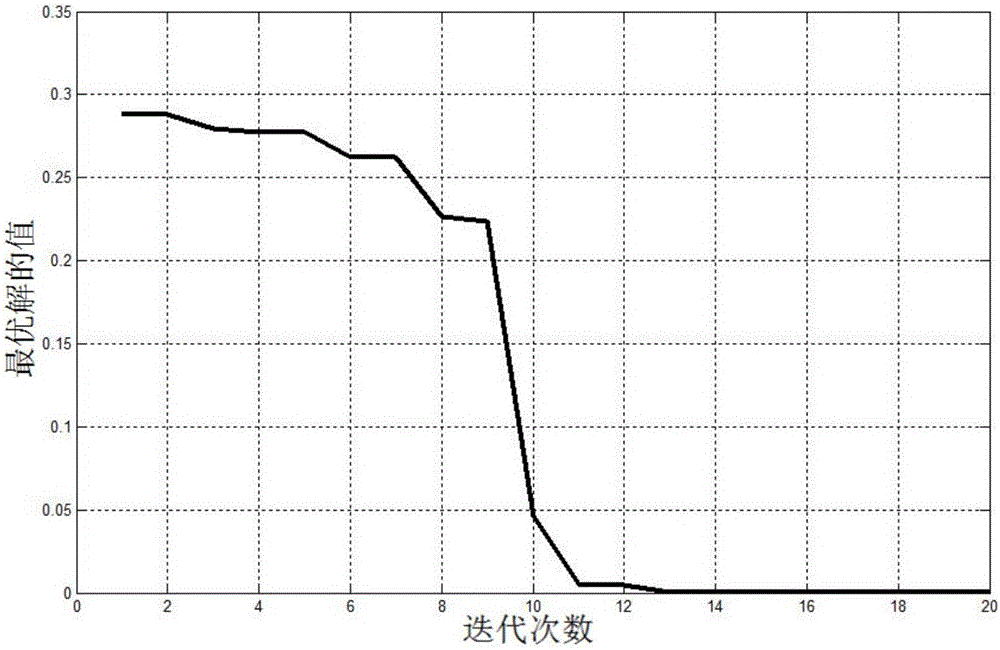

Novel swarm intelligent optimization algorithm-pigeon swarm algorithm

InactiveCN105930307ANot demandingStrong global convergenceBiological modelsComplex mathematical operationsLocal optimumPeak value

The invention belongs to the field of optimization algorithms and provides a novel swarm intelligent optimization algorithm-pigeon swarm algorithm. The algorithm comprises a takeoff process, a flight process and a homing process. The takeoff process comprises an initialization sub-process, a soaring sub-process and a rising sub-process, which are used for initializing a pigeon swarm position, a flight speed and an optimal solution direction; the flight process comprises a flat flight sub-process, a turning sub-process and a chasing sub-process, which are used for searching for a local optimal solution and a global optimal solution and improving a global worst solution; and the homing process prevents the algorithm from falling into the local optimal solution. The algorithm has the following characteristics: 1) the algorithm has low requirement on the property of a target function, and a function expression or an expression form that is not a function form can be accepted; 2) the algorithm has the characteristics of relatively high global convergence, low algorithm cycle frequency and high convergence speed for a low-dimensional function; and 3) the algorithm has relatively high global convergence, relatively low cycle frequency and relatively high stability for a high-dimensional, multi-peak-value and complex problem.

Owner:DALIAN UNIV OF TECH

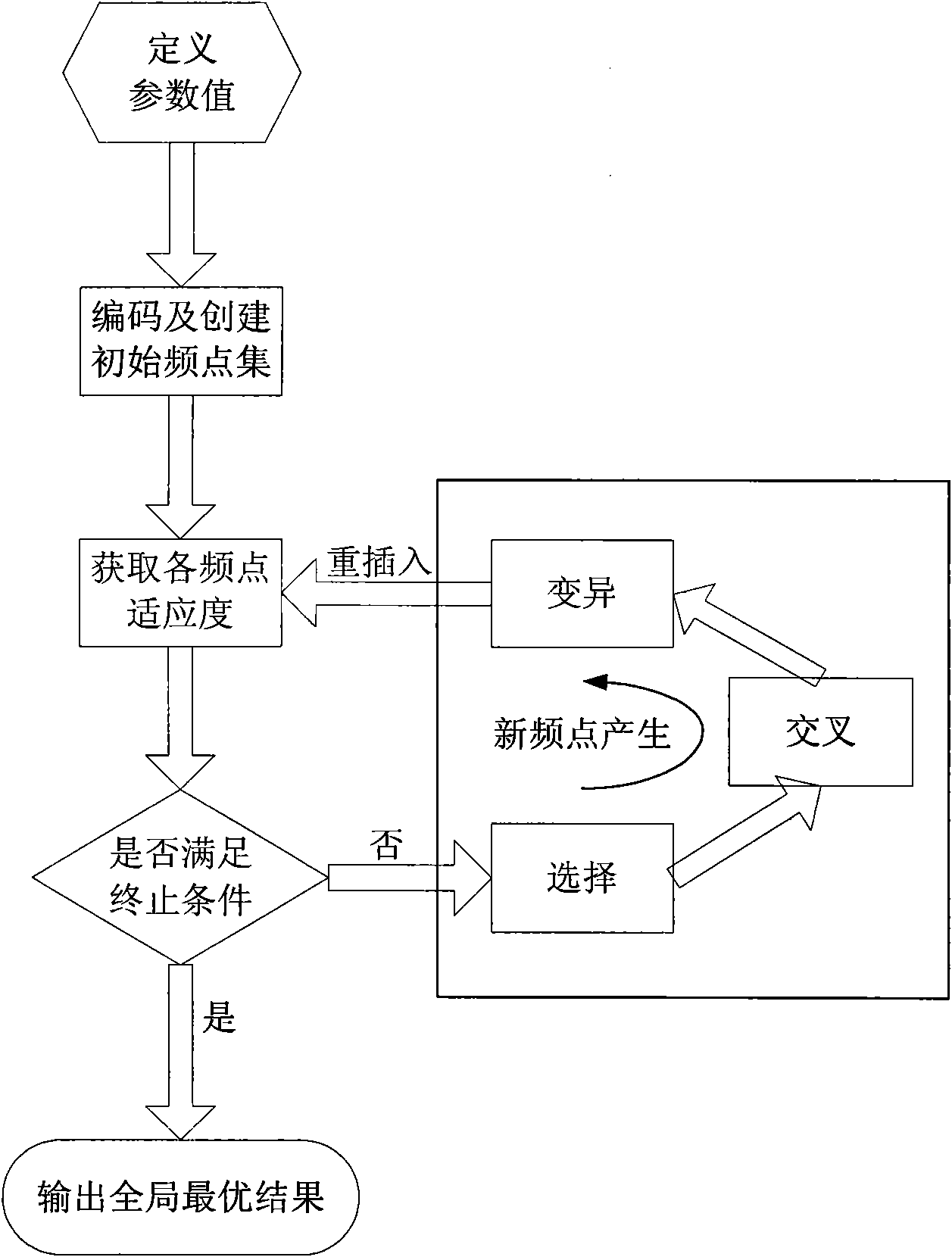

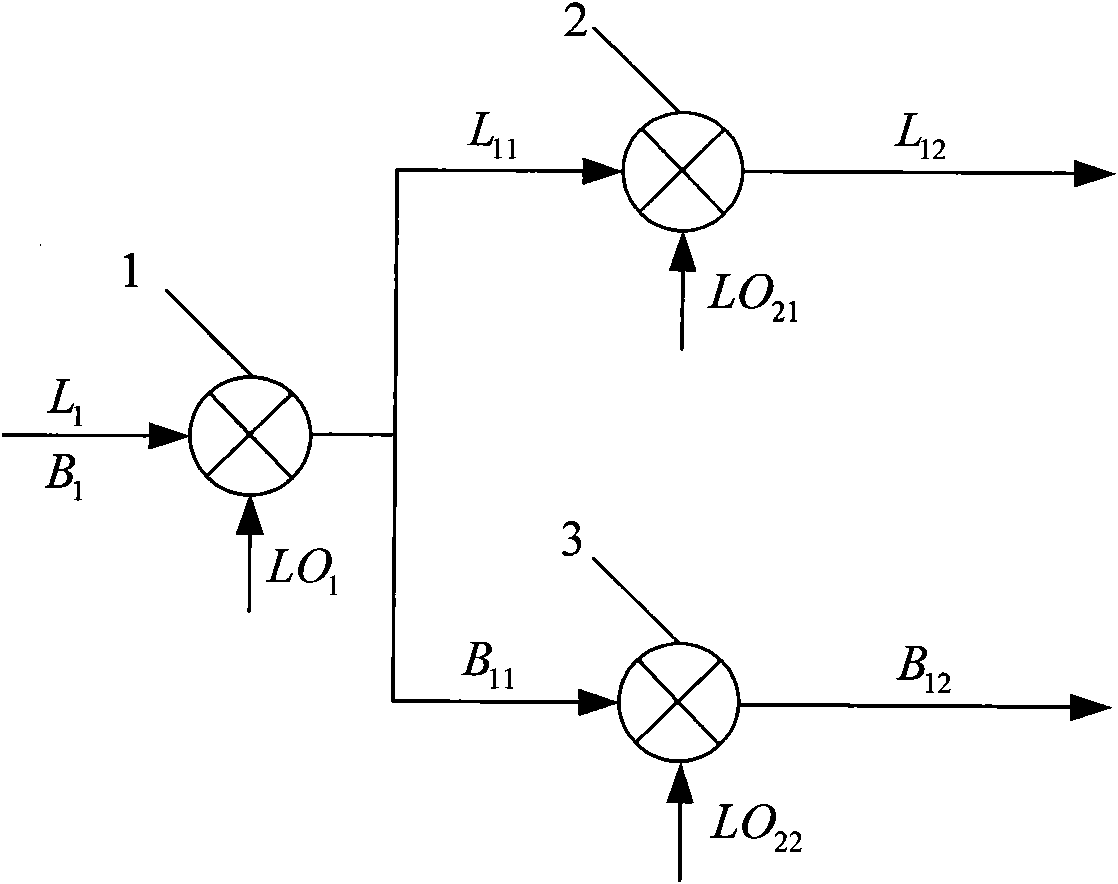

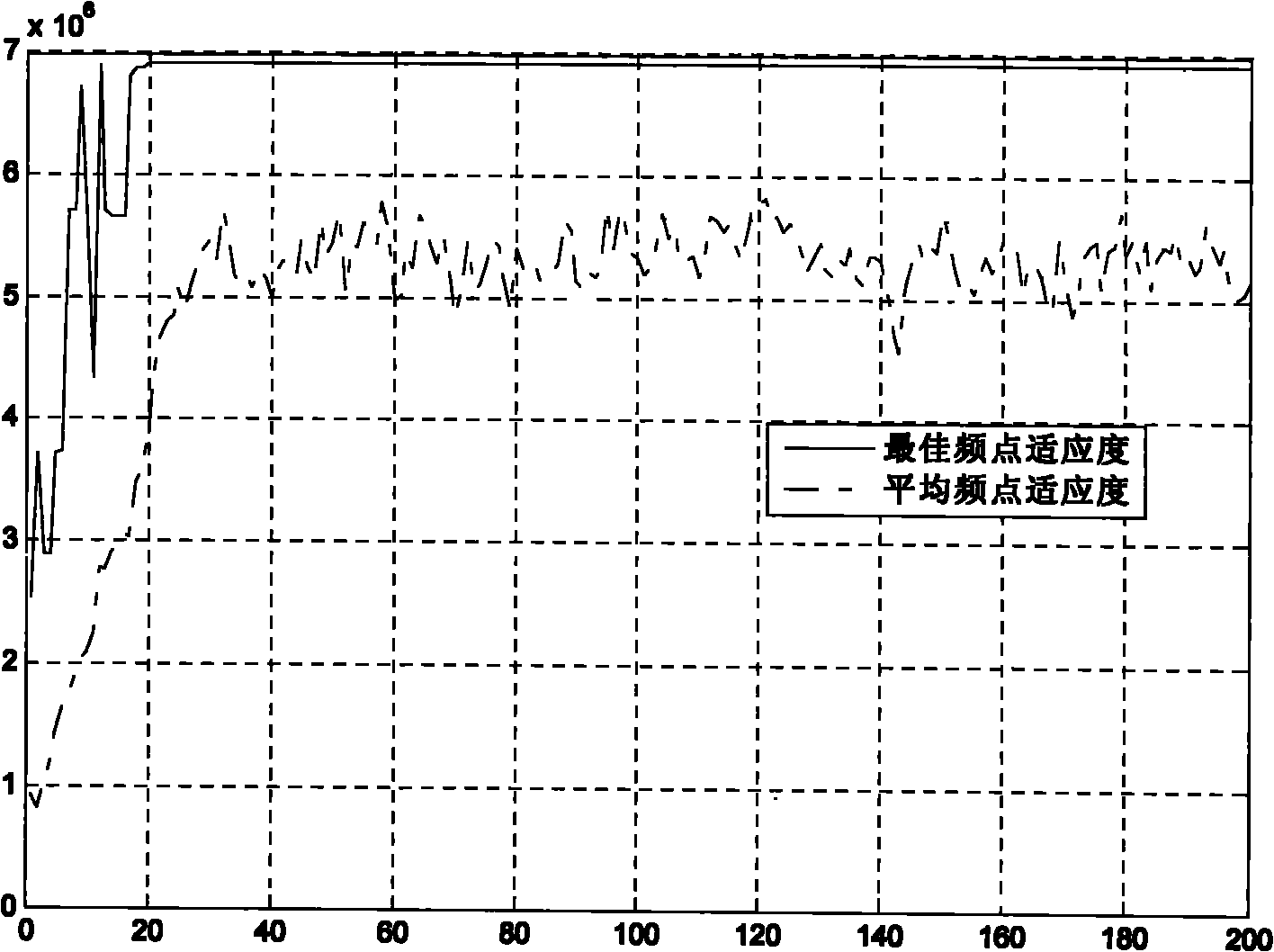

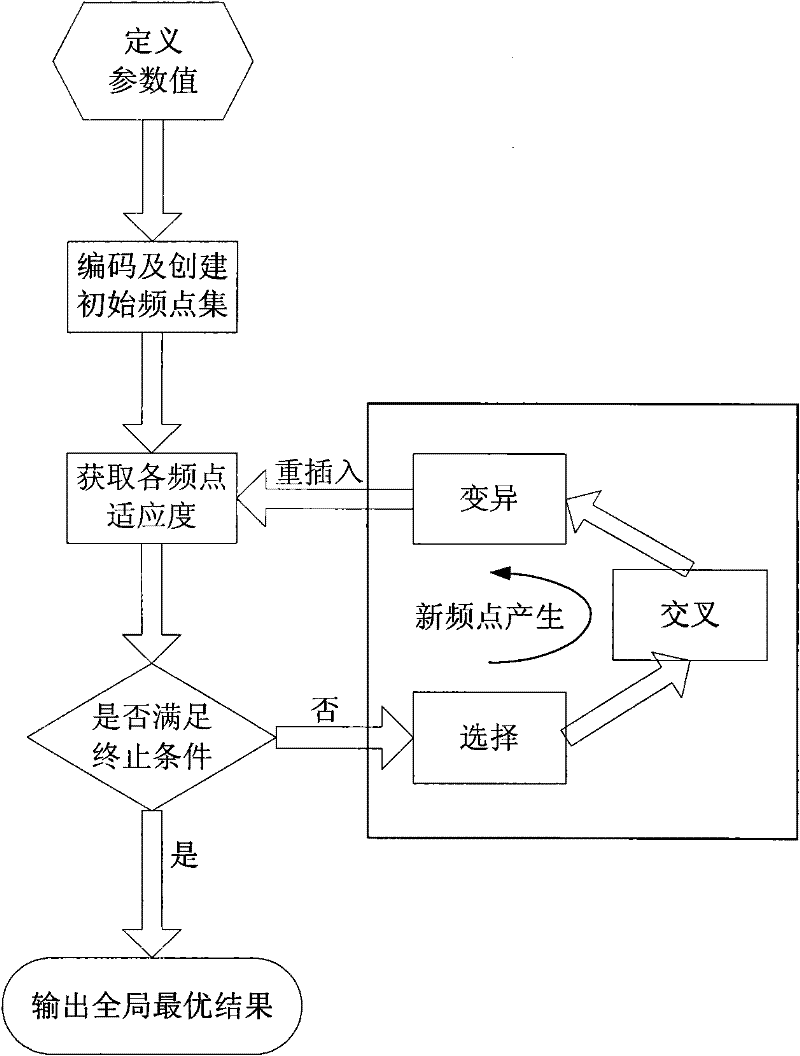

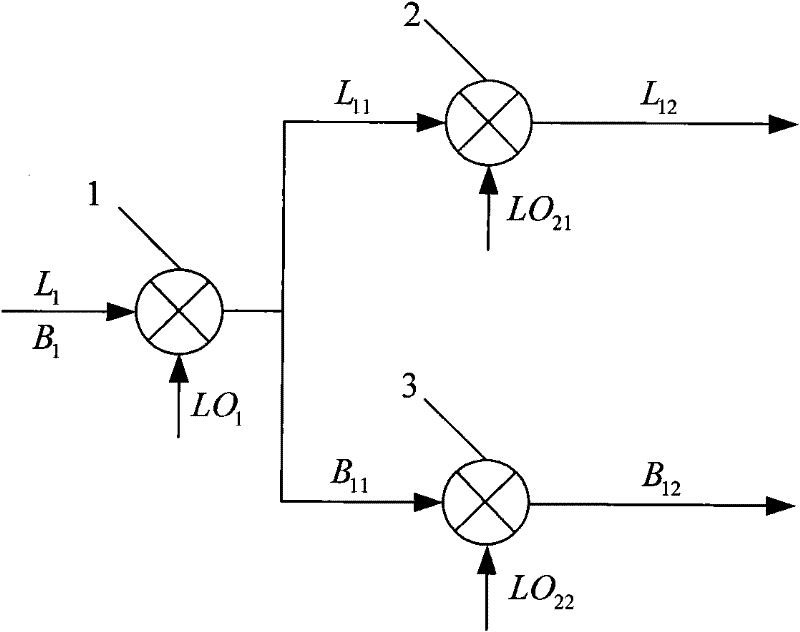

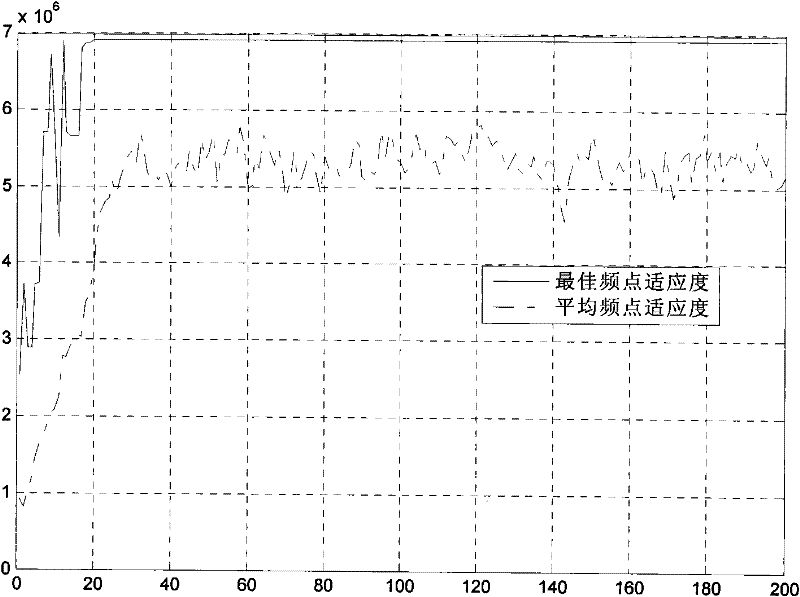

Multisystem compatible receiver frequency point selecting method

ActiveCN101776765AEnsure Global Optimal ResultsImprove computing efficiencySatellite radio beaconingComputer scienceOptimization problem

The invention discloses a multisystem compatible receiver frequency point selecting method which comprises the following steps: firstly, defining a parameter value, coding and establishing an initial frequency point set, then acquiring the fitness of each frequency point, judging whether a termination condition is met, and finally outputting a global optimal result. The invention has low requirements on the problem property and high computing efficiency, can solve a complicated optimization problem at limited cost, is suitable for a condition with large computing amount, has better global search performance, enables the process of solving the problem to be conveniently parallelized, and improves the processing efficiency. The invention can be used in the field of satellite navigation and communication, especially is suitable for the design of a satellite navigation multisystem compatible receiver, and has good application prospects in the aspects of military and civil use.

Owner:BEIHANG UNIV

Method for manufacturing hydrophobic surface through laser selective molten metal nanoparticle solution additive manufacturing in air environment

ActiveCN106894017ANot demandingLower requirementAdditive manufacturing apparatusTransportation and packagingSelective laser meltingNanoparticle

The invention discloses a method for manufacturing a hydrophobic surface through laser selective molten metal nanoparticle solution additive manufacturing in air environment, and belongs to the technical field of hydrophobic surface preparation. The method comprises the steps that a metal nanometer mixed solution is prepared; a stainless steel substrate is cleaned; the stainless steel substrate is placed near the focal distance position of a selective laser melting manufacturing device; laser scanning is carried out, and nanometer metal powder and the stainless steel substrate are molten together; the obtained surface hydrophobic structure is cleaned; and an ethanol solution of trifluorooctyl triethoxysilane is used for modifying the surface hydrophobic structure. The method has the advantages that the strength is high, stability is high, flexibility is extremely high, operation is convenient, the requirements for equipment are low, the manufacturing cost is low, and the requirements for base materials are low; and the method can be implemented in air and has low environment requirements.

Owner:HARBIN INST OF TECH

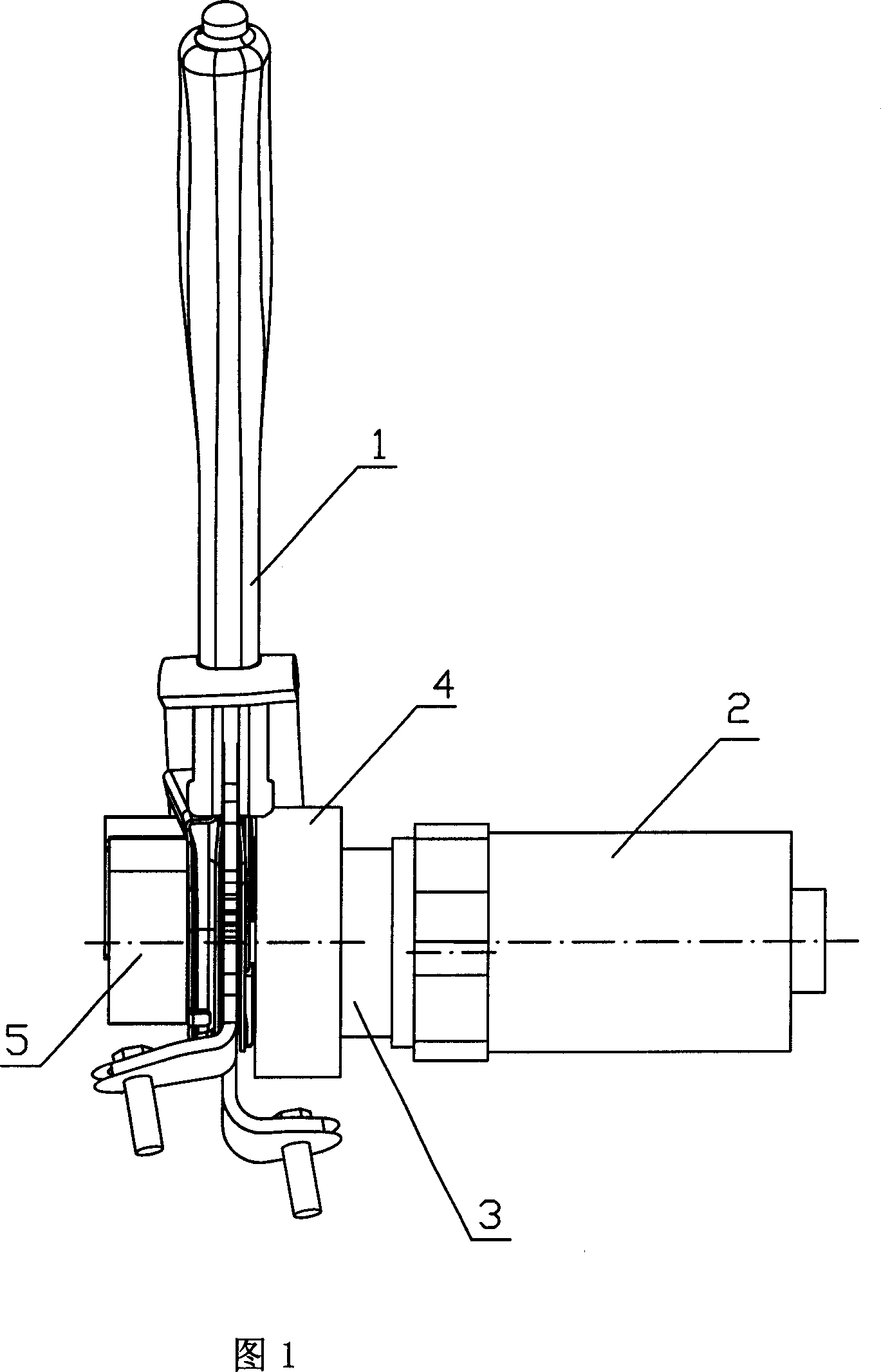

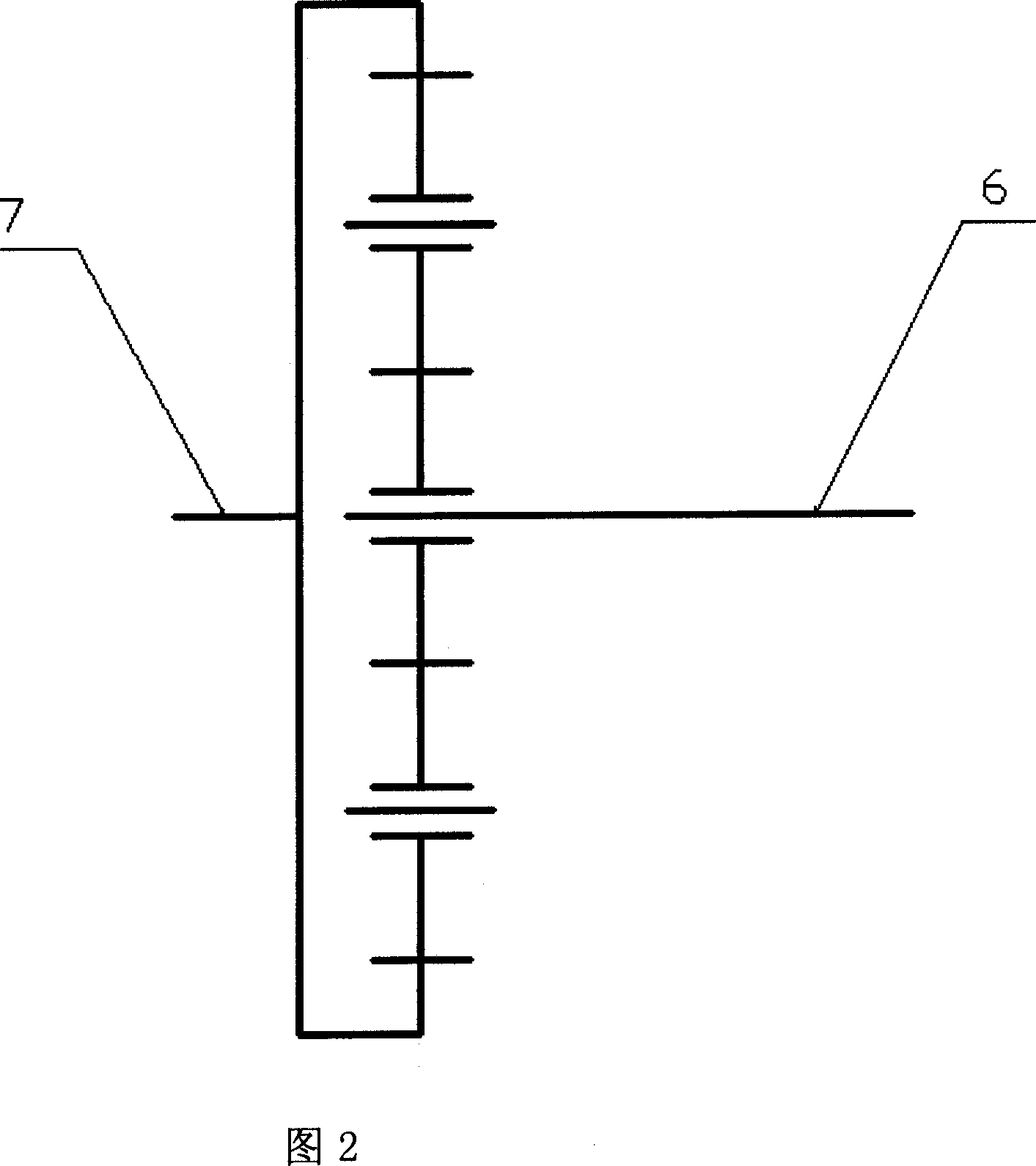

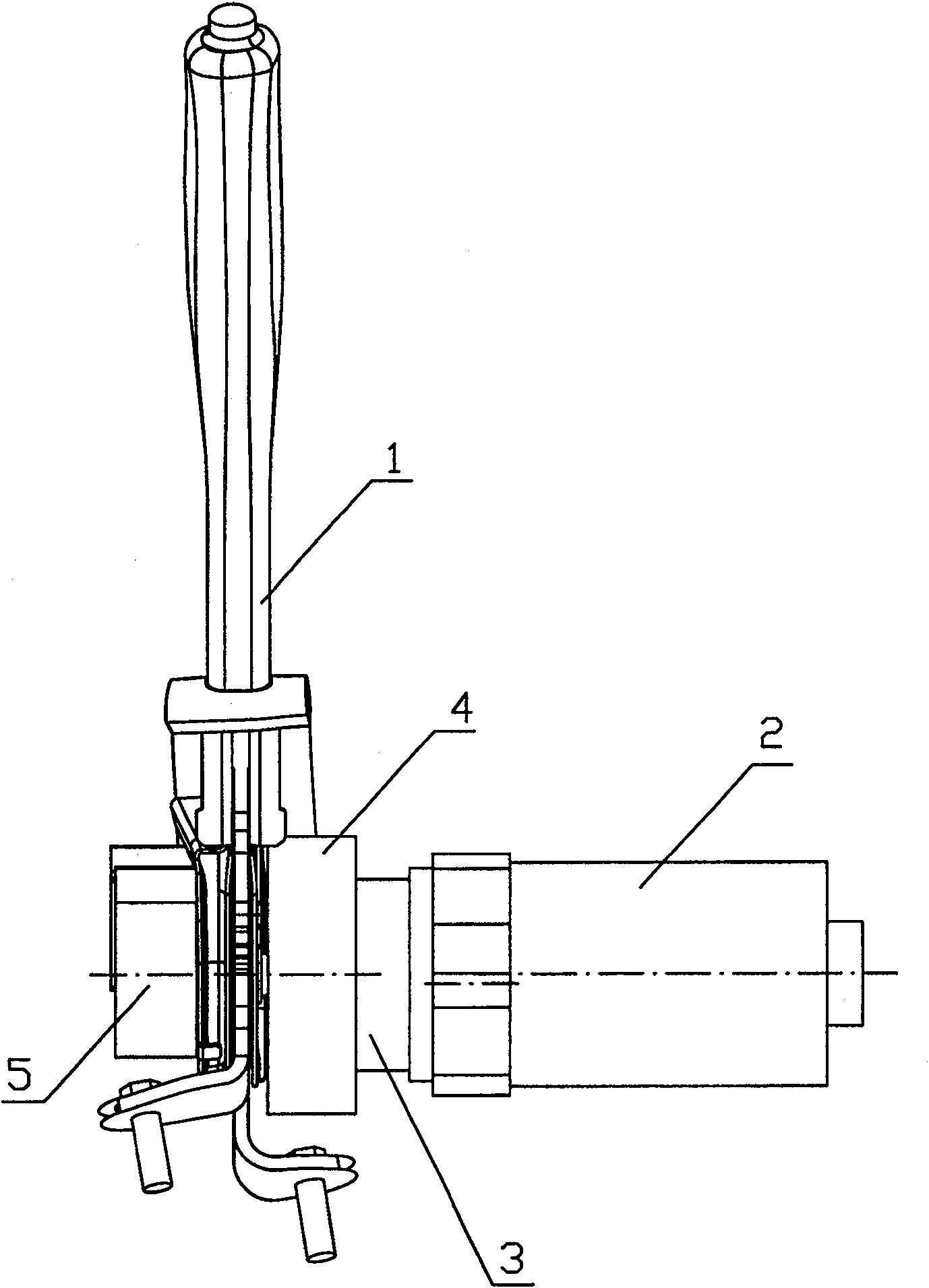

Electric booster device for automobile parking braking

InactiveCN101081616ANot demandingEliminate Braking HazardsBraking action transmissionElectricityCoupling

The present invention is one electric stopping brake assistor for hand stopping brake system of automobile with braking handle. The electric stopping brake assistor consists of an assisting motor, a clutch, a planetary speed reducing mechanism, an angle sensor, and an electronic control unit with built-in first set angle and second set angle. The assisting motor has its output shaft connected through the clutch to the planetary speed reducing mechanism; the planetary speed reducing mechanism has its output shaft connected through a coupling to the rotation shaft of the braking handle in the hand stopping brake system and one angle sensor connected for detecting the rotation angle of the handle, and the assisting motor and the angle sensor are connected electrically to the electronic control unit. The electric stopping brake assistor has simple structure and capacity of assisting the driver's stopping.

Owner:BYD CO LTD

Coarsening and etching method of large-area controllable surface of SiC substrate light emitting diode (LED) based on laser

InactiveCN102110749ANot demandingImprove light extraction efficiencySemiconductor devicesWire widthEtching

The invention provides a coarsening and etching method of a large-area controllable surface of a SiC substrate light emitting diode (LED) based on a laser, belonging to the technical field of LED. The surfaces of the SiC substrate and an LED semiconductor material can be coarsened by utilizing that the semiconductor material highly absorbs high-power laser with a wavelength smaller than the absorption wavelength of the band edge of the semiconductor material to perform gasification. An area and a pattern coarsened and etched by the laser are controlled by a high speed scanner or a precise displacement stage; and the wire width and depth of coarsening and etching are regulated by controlling power and focusing degree of the laser. The method can be applied to coarsening and etching of the surface of the SiC substrate GaN-based LED with various structures. The laser is selected on the basis that the wavelength of the laser is smaller than the absorption wavelength of the band edge of the coarsened and etched semiconductor. The method has the advantages of wide application materials, high coarsening and etching speed, large coarsening and etching area, low cost, good coarsening effect, small damage on the semiconductor material and high controllability of coarsening and etching parameters of the system; and by using the method, the problem of coarsening the p-GaN layer and the SiC substrate can be effectively solved. Thus, the method has a great application potential in high-brightness LED production.

Owner:SHANDONG UNIV

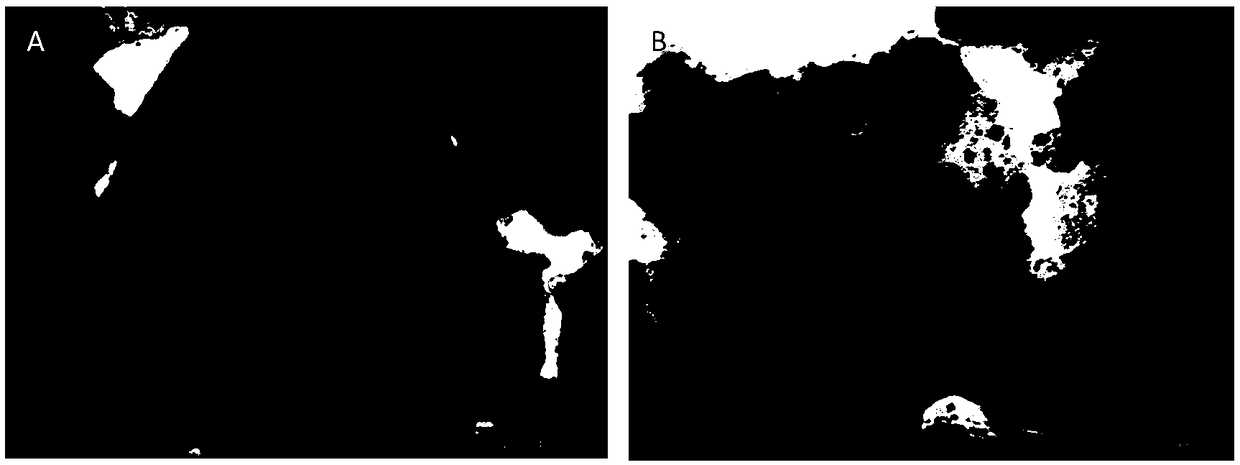

Method for accurately determining surface roughness through adopting amorphous alloy

InactiveCN102967279ANot demandingLow light transmittanceUsing optical meansPlastic materialsSurface roughness

The invention discloses a method for determining the surface roughness of an impression material through adopting a bulk amorphous alloy new material. The bulk amorphous alloy has the thermoplastic forming capability within the supercooling liquid phase interval, so that low-temperature impression treatment can be realized through utilizing the characteristic, and the material is a plastic material completely during impression and is changed into a rigid material with high strength after the impression. Consequently, compared with the traditional material, the bulk amorphous alloy impression material can high precisely reproduce the surface appearances of samples, and the impression can be stored for a long time stably; and moreover, the method is simple and convenient to operate, does not generate pollution, meets the requirements of social sustainable development and has a wide application prospect.

Owner:NANJING UNIV OF SCI & TECH

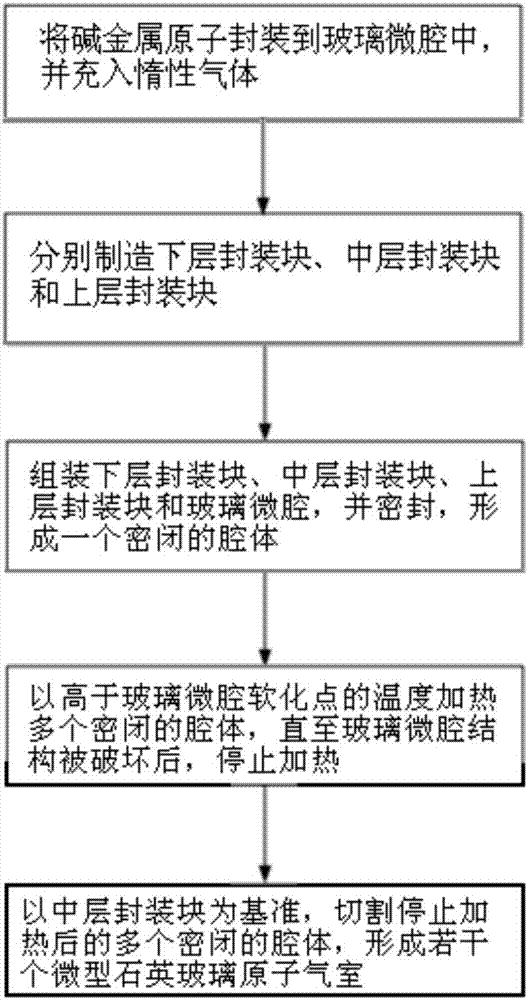

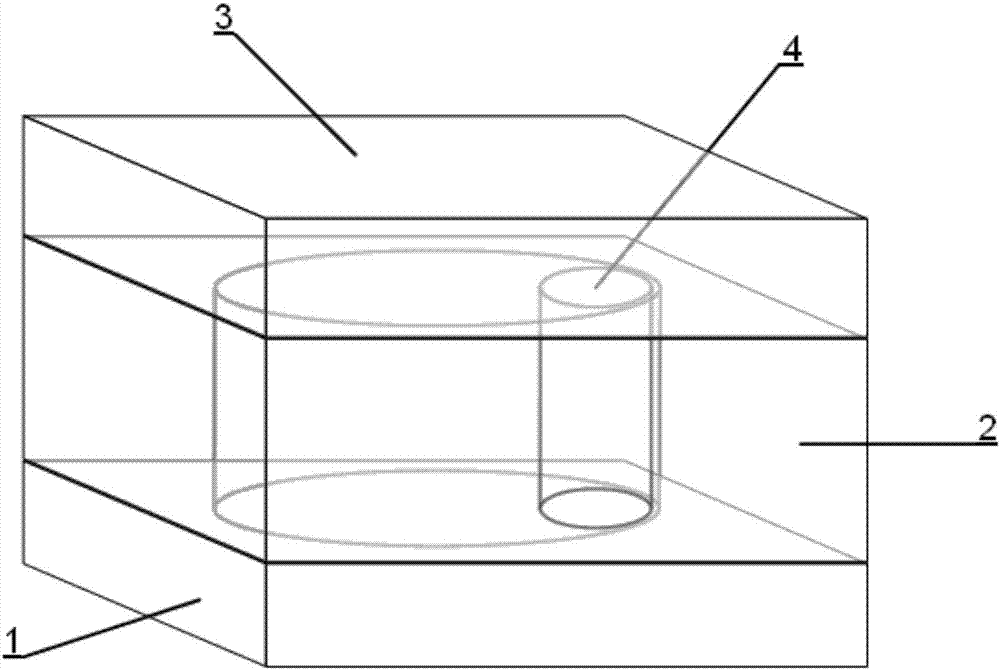

Manufacturing method for mini quartz glass atomic gas chamber

ActiveCN107311103AImprove chamber purityNot demandingPrecision positioning equipmentDecorative surface effectsEngineeringGas chamber

The invention discloses a manufacturing method for a mini quartz glass atomic gas chamber. The method comprises the following steps of encapsulating alkali-metal atoms into a glass micro-cavity and filling inert gas; manufacturing a lower-layer encapsulation block, a middle-layer encapsulation block and an upper-layer encapsulation block; assembling the lower-layer encapsulation block, the middle-layer encapsulation block, the upper-layer encapsulation block and the glass micro-cavity and sealing to form a closed cavity; heating a plurality of closed cavities at the temperature higher than the softening point of the glass micro-cavity and stopping heating until the glass micro-cavity structure is destroyed; and cutting the closed cavities after stopping heating based on the middle-layer encapsulation block in order to form the mini quartz glass atomic gas chamber. Through setting of the glass micro-cavity, the degree of purity of the atomic gas chamber is guaranteed, the problems of large difficulty of the conventional mini atomic gas chamber manufacturing process and poor degree of purity of the cavity are solved; through simultaneous heating of the closed cavities, the mass production of the atomic gas chamber is realized, and the defects of high requirements and difficulty in mass production of the conventional mini atomic gas chamber manufacturing equipment are made up.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

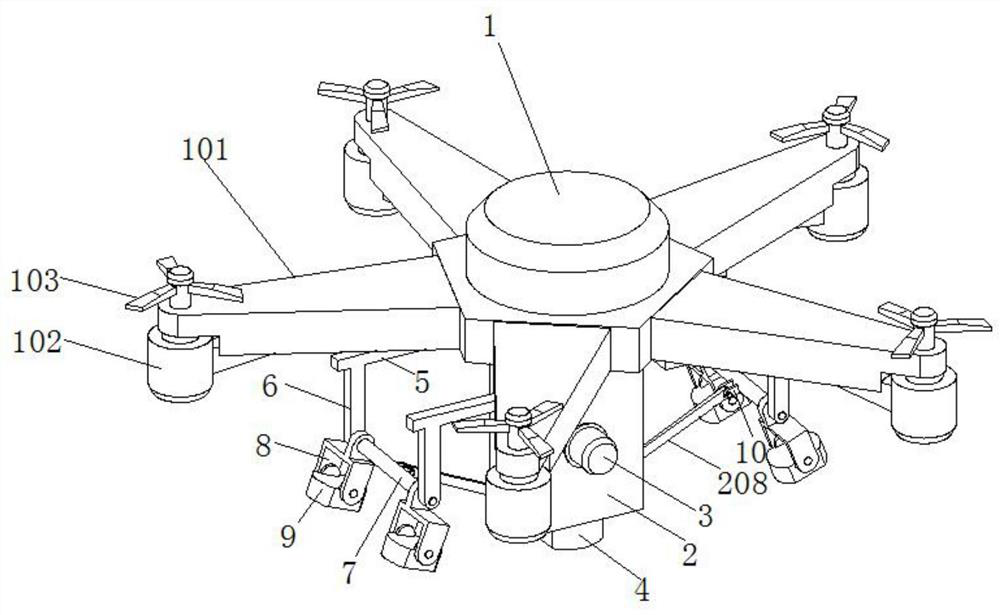

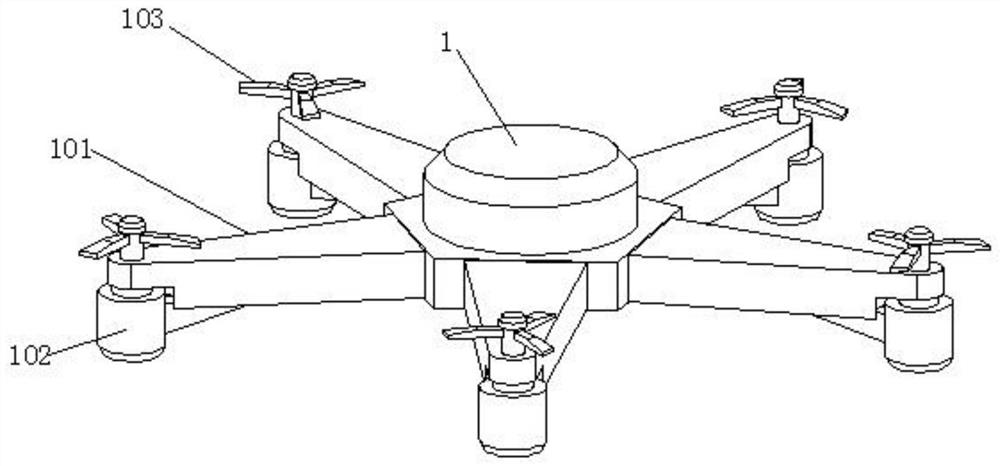

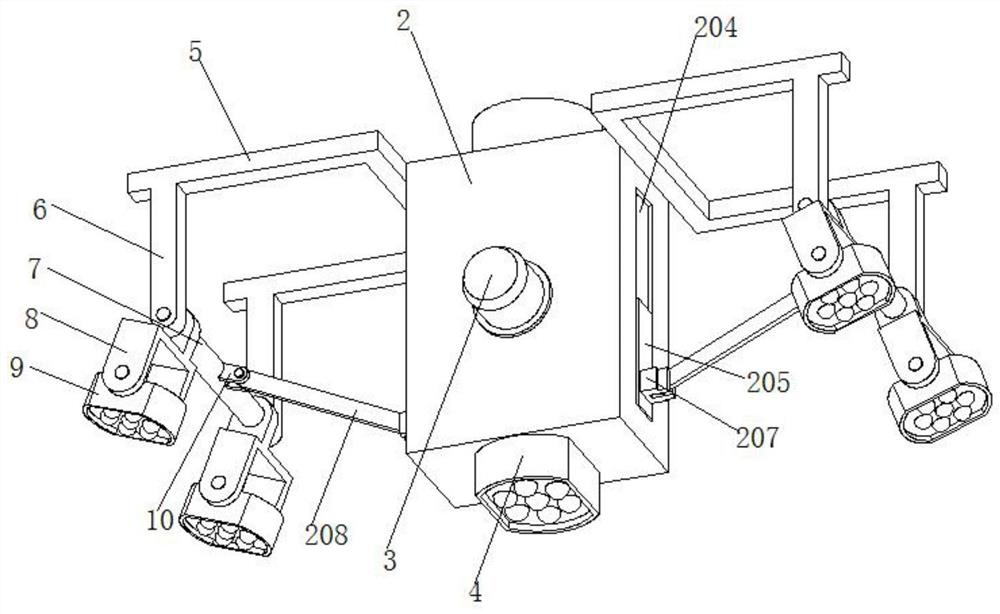

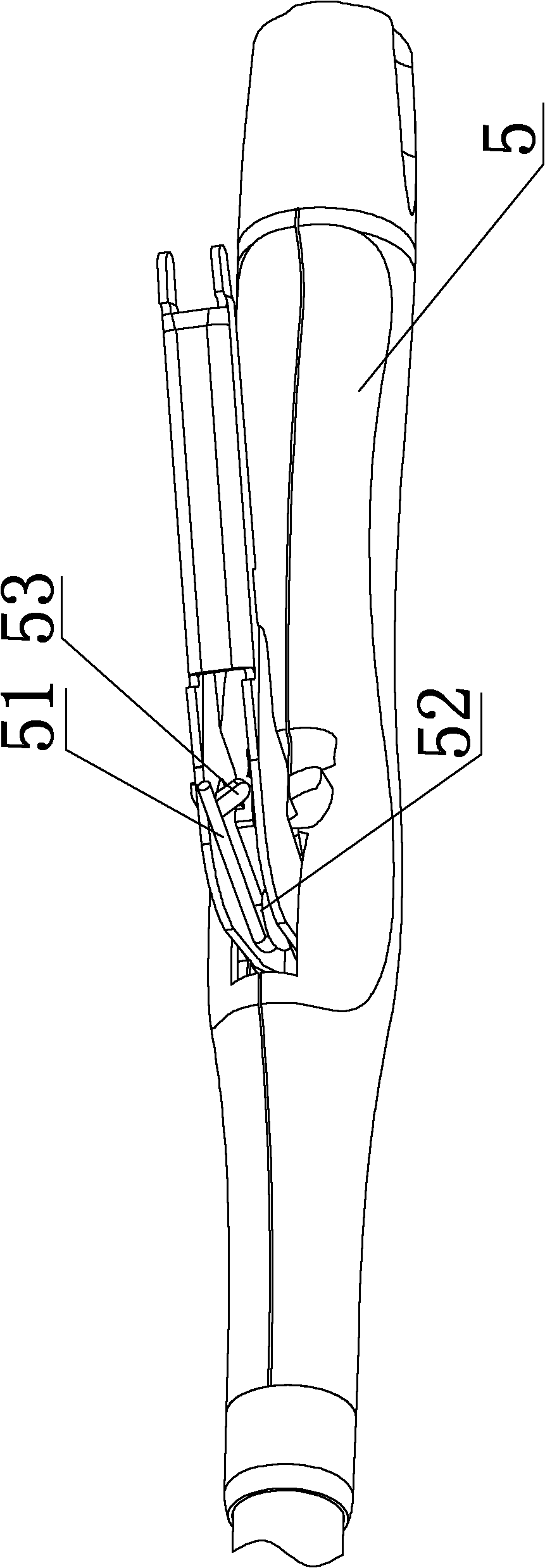

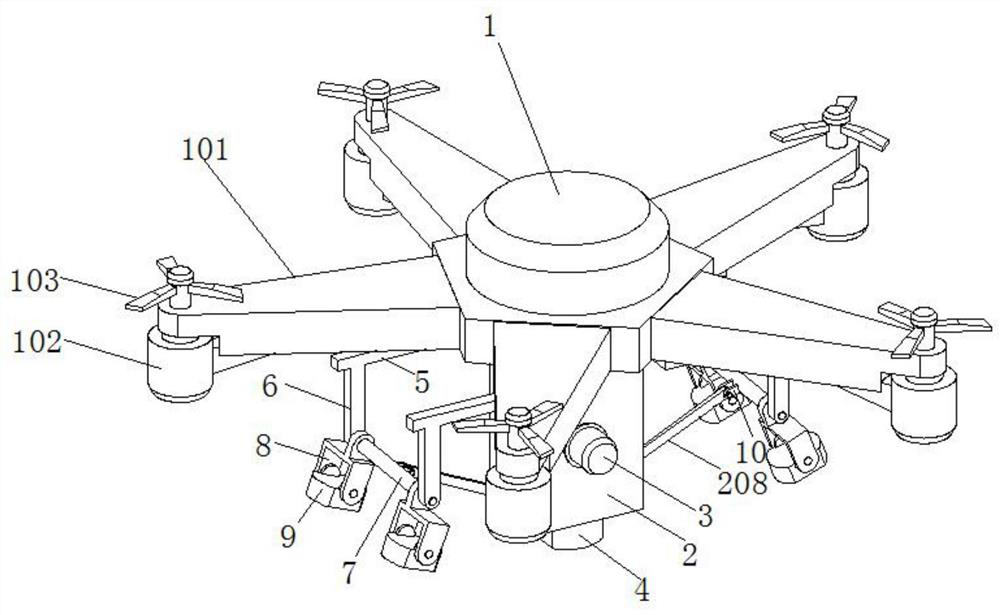

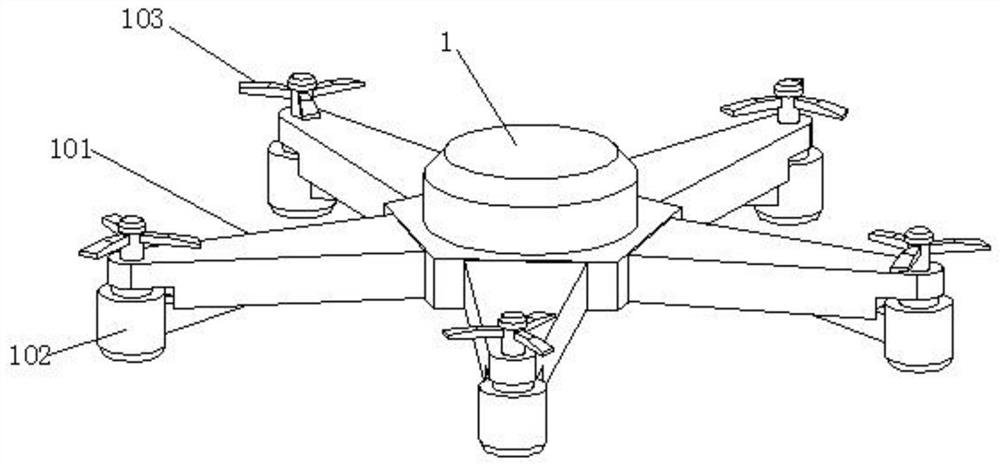

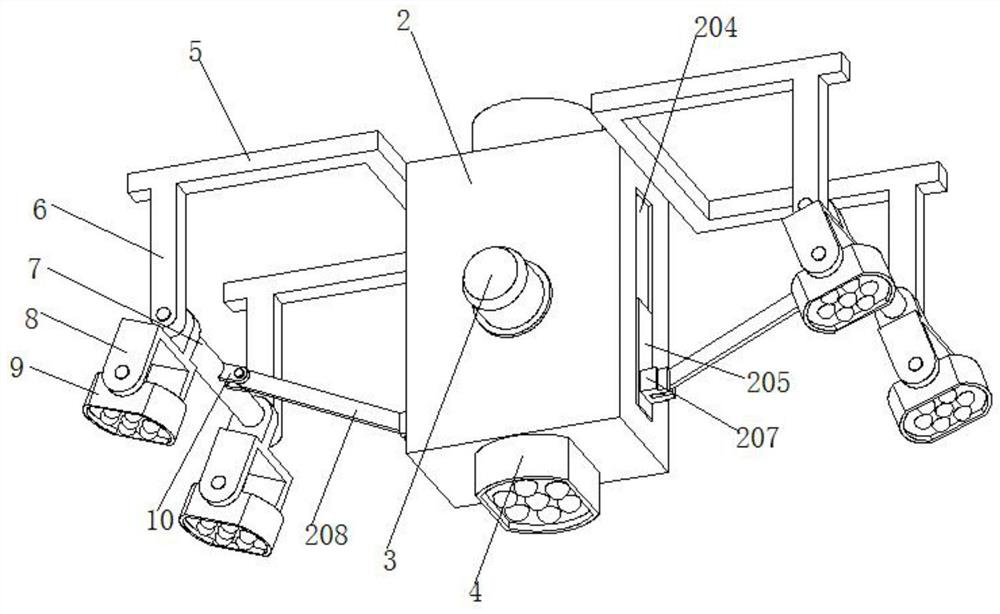

High-precision full-frame oblique photogrammetry device for unmanned aerial vehicle

ActiveCN111959770AReduce loadNot demandingPicture taking arrangementsAlighting gearGear wheelUncrewed vehicle

The invention relates to the technical field of unmanned aerial vehicle oblique photography detection, and particularly discloses an unmanned aerial vehicle high-precision full-frame oblique photogrammetry device. The device comprises an unmanned aerial vehicle body. A plurality of rotor arms are uniformly connected to the unmanned aerial vehicle body; a driving motor is fixed on a lower surface of an outer end part of each rotor arm; and propellers are arranged at an upper end, penetrating through the rotor arms, of an output shaft of the driving motor, a rectangular block is connected to thecenter of the lower surface of the unmanned aerial vehicle body, an adjusting motor is fixedly arranged on the front side surface of the rectangular block, a rotating cavity is formed in the rectangular block, and a large gear is arranged in the middle of the rotating cavity. According to the device, a photographing angle and a wide angle can be adjusted in real time in actual use; and the shooting angles of the four second high-definition cameras can be adjusted at the same time through one adjusting motor, one adjusting motor does not need to be arranged at the end of each second high-definition camera, equipment cost is greatly reduced, and more importantly, a load capacity of the whole unmanned aerial vehicle is effectively decreased.

Owner:HENAN UNIVERSITY

Oil sludge cleaning agent, and preparation method and application thereof

InactiveCN111575122AHigh oil washing rateLow sludge propertiesInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsInorganic saltsPhosphate

The invention belongs to the technical field of oil sludge cleaning, and particularly relates to an oil sludge cleaning agent and a preparation method and application thereof. The oil sludge cleaningagent comprises the following components in percentage by mass: 5 to 20% of phosphate, 5 to 20% of inorganic salt, 10 to 20% of silicate, 2 to 5% of alkali, 2 to 4% of cocoanut fatty acid diethanolamide, 2 to 4% of nonylphenol polyoxyethylene ether, 2 to 4% of fatty alcohol-polyoxyethylene ether phosphate and 2 to 4% of oil stain removing agent, with the balance being water. The oil sludge cleaning agent disclosed by the invention is high in oil washing rate, relatively low in requirement on the properties of oil sludge and wide in application scope.

Owner:新疆博云时代环保科技有限公司

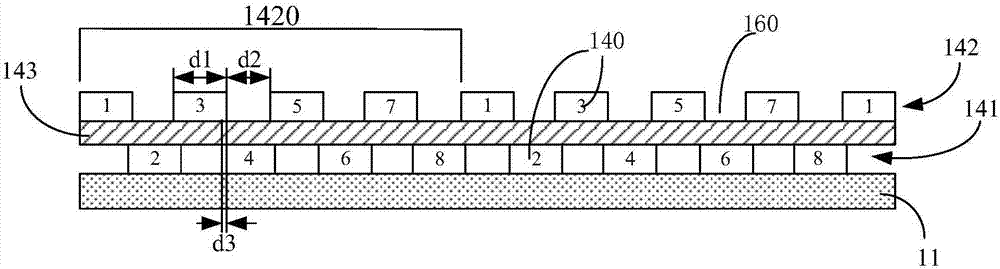

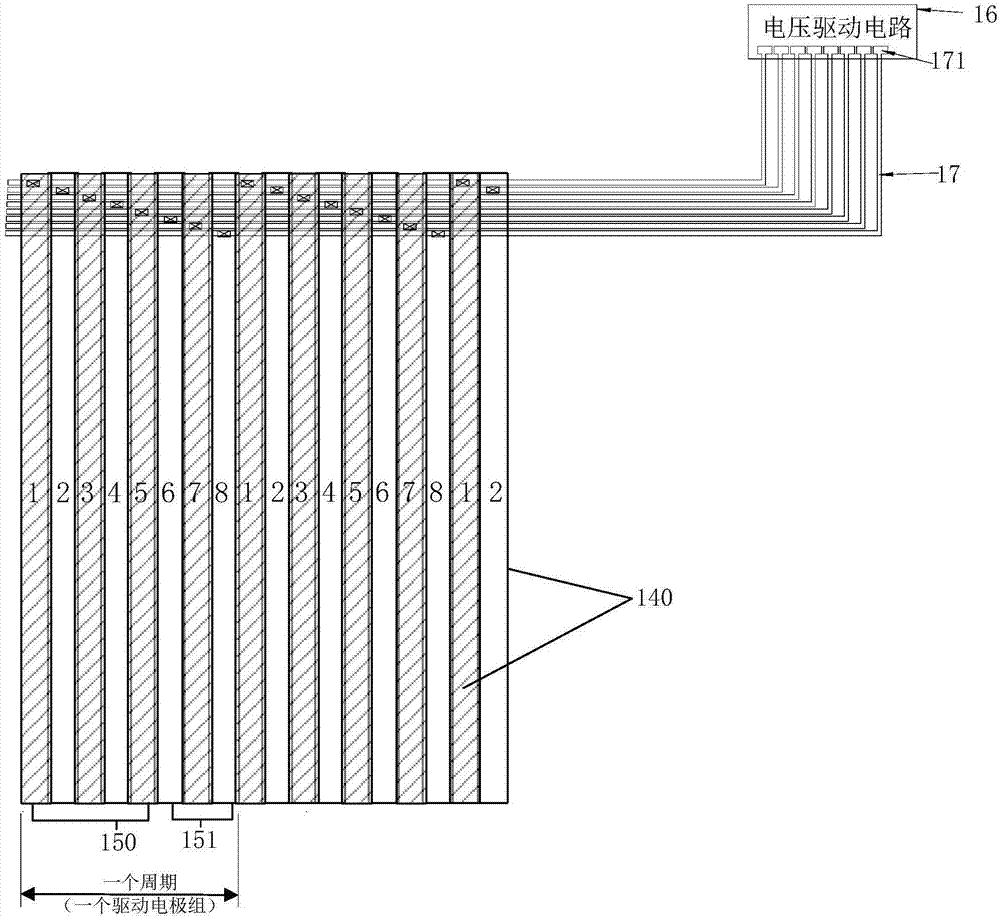

Liquid crystal parallax barrier and stereo display device and correction method thereof

InactiveCN107577092AReduce the effect of spectroscopic effectsNot dependentNon-linear opticsOptical elementsParallax barrierCorrection method

The invention relates to the technical field of stereo display, and discloses a liquid crystal parallax barrier and a stereo display device and a correction method thereof. A first electrode structureis arranged on the side, opposite to a liquid crystal layer, of a first substrate of the liquid crystal parallax barrier, the first electrode structure comprises multiple driving electrode sets whichare arranged in a periodic mode, each driving electrode set comprises at least two driving electrode layers, each driving electrode layer comprises multiple driving electrodes which are arranged at intervals, a gap portion is arranged between each two adjacent driving electrodes, and the driving electrodes and the gap portions of each two adjacent driving electrode layers are oppositely arranged;the driving electrodes which apply the first preset driving voltage in each driving electrode set form a shading portion, the driving electrodes which apply the second preset driving voltage in eachdriving electrode set form a photic portion, and when the driving electrodes which apply the first preset driving voltage and the driving electrodes which apply the second preset driving voltage change, the positions of the shading portions and the photic portions change correspondingly, so that over dependency and excessive demands on the laminating accuracy can be effectively avoided.

Owner:SUPERD CO LTD

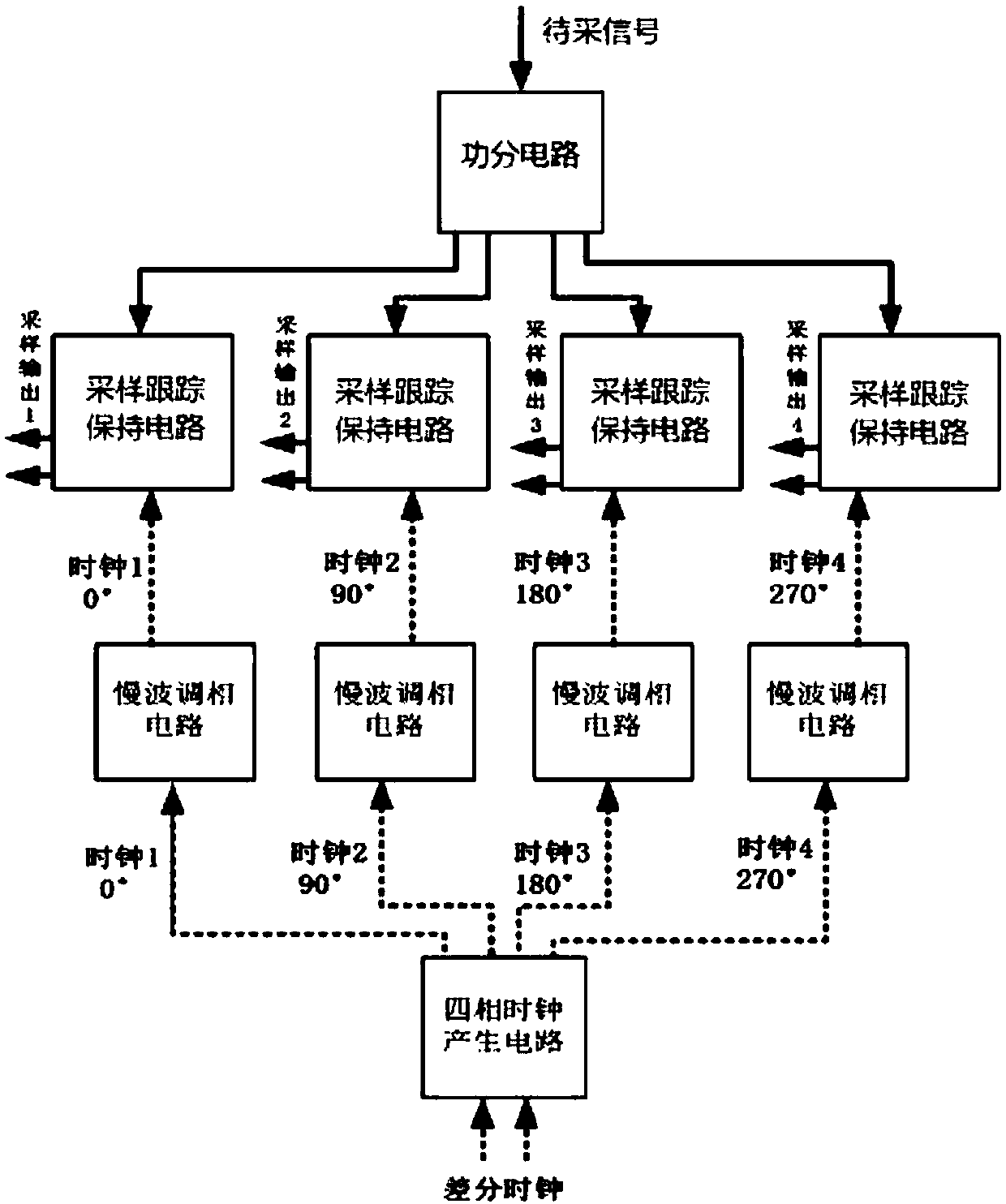

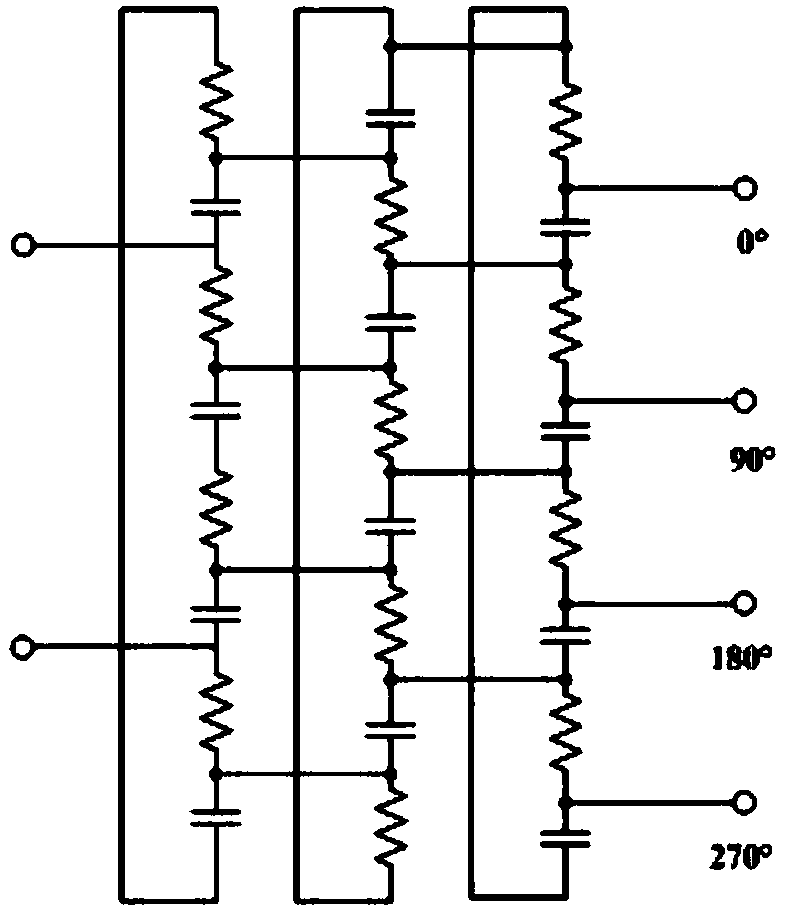

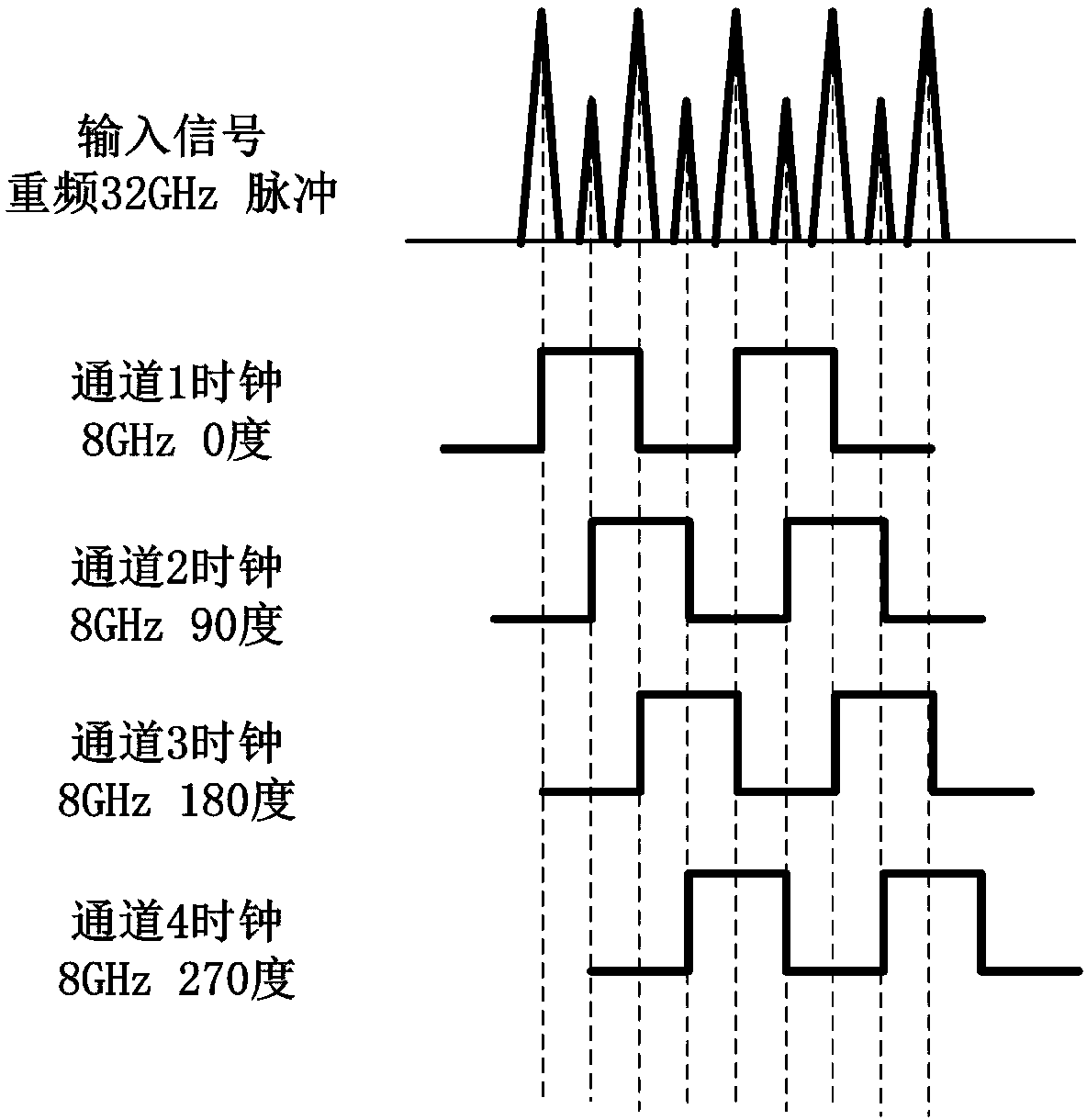

Multi-channel sampling-tracking-holding equipment and signal sampling method

InactiveCN107911118ANot demandingIncrease sampling rateAnalogue-digital convertersEngineeringAnalog-to-digital converter

The invention discloses a multi-channel sampling-tracking-holding equipment, comprising a power division circuit, a multi-channel sampling-tracking-holding circuit and a multi-phase clock generation circuit, wherein the power division circuit is provided with one input end and multiple output ends; the multi-channel sampling-tracking-holding circuit is provided with multiple channels, each channelis provided with a sub-sampling-tracking-holding circuit, and each output end of the power division circuit is separately connected with one sub-sampling-tracking-holding circuit; and the multi-phaseclock generation circuit is simultaneously connected with each sub-sampling-tracking-holding circuit, and clock signals transmitted to the adjacent two sub-sampling-tracking-holding circuits have equal intervals. According to the scheme of the invention, the high-frequency sampling of an original high-speed signal can be realized without increasing the external sampling clock frequency of a chipor without using an external sampling clock of the chip, and high requirements for a subsequently-connected analog-to-digital converter cannot be generated.

Owner:成都中宇微芯科技有限公司

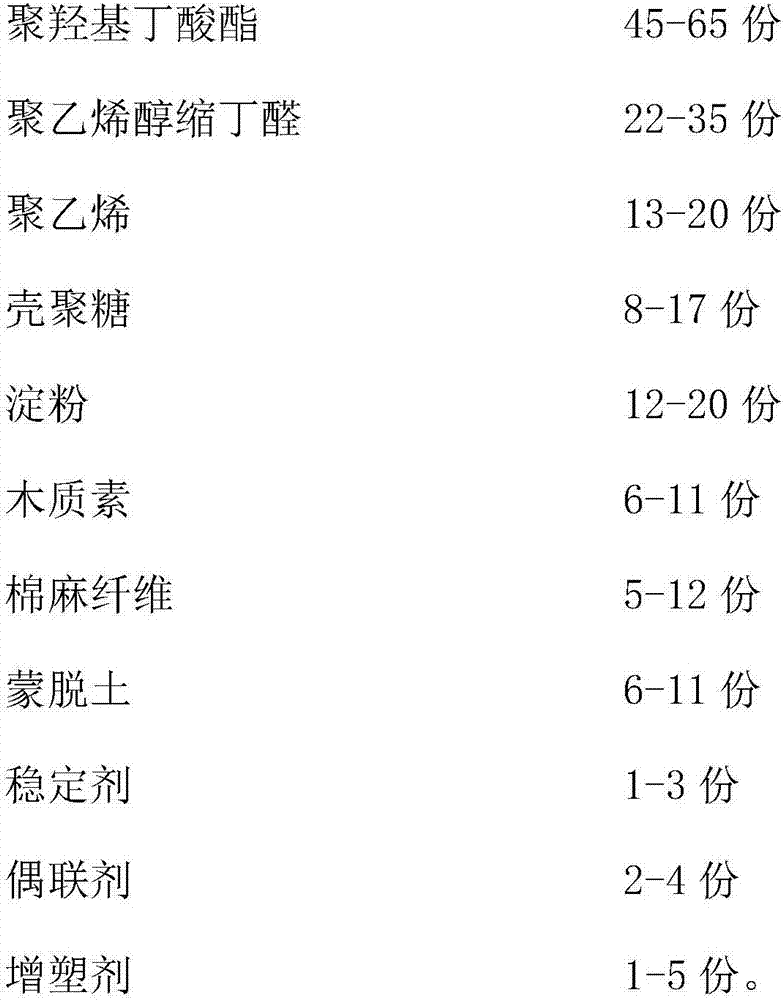

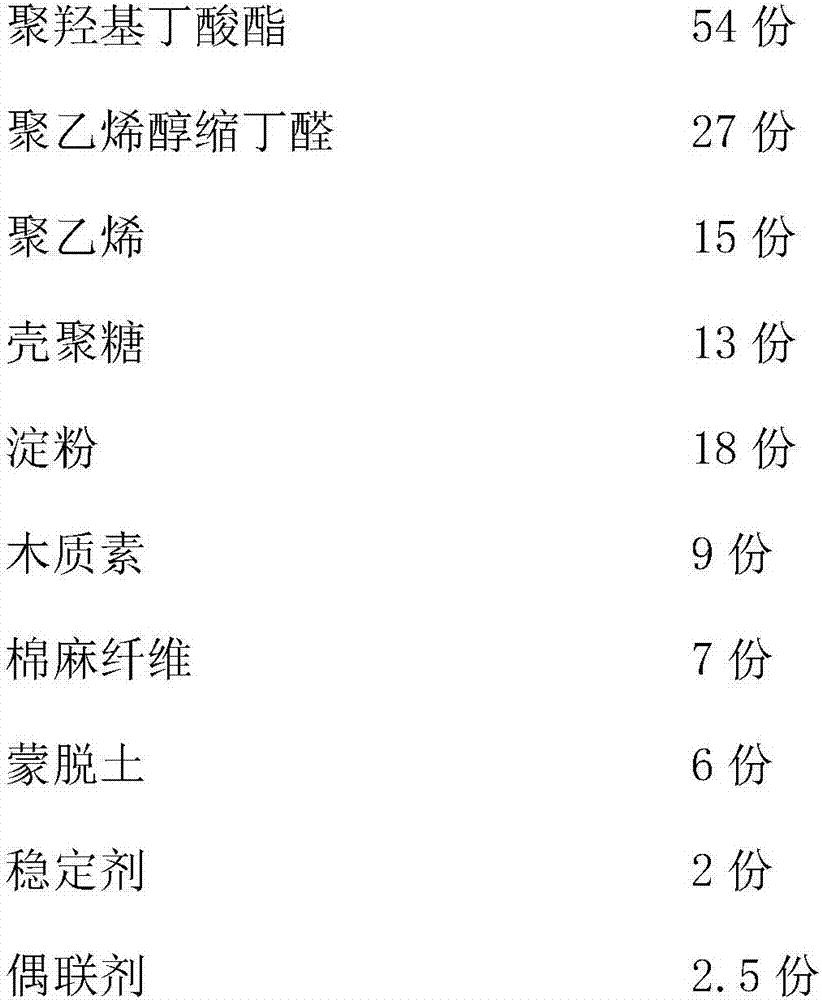

Plastic packaging bag

The invention relates to a plastic packaging bag and belongs to the field of processing of plastic products. The plastic packaging bag is prepared from raw materials in parts by weight as follows: 45-65 parts of polyhydroxybutyrate, 22-35 parts of polyvinyl butyral, 13-20 parts of polyethylene, 8-17 parts of chitosan, 12-20 parts of starch, 6-11 parts of lignin, 5-12 parts of cotton-linen fiber, 6-11 parts of montmorillonoid, 1-3 parts of a stabilizer, 2-4 parts of a coupling agent and 1-5 parts of a plasticizer. The plastic packaging bag is mainly prepared from bio-degradable polyhydroxybutyrate and polyvinyl butyral matched with chitosan, lignin, cotton-linen fiber and montmorillonoid, the toughness of the plastic packaging bag is guaranteed, the plastic packaging bag has a good degradation effect and influence on surrounding environment is reduced. The processing process is simple, convenient and low in manufacturing cost and has good economic benefits.

Owner:闫博

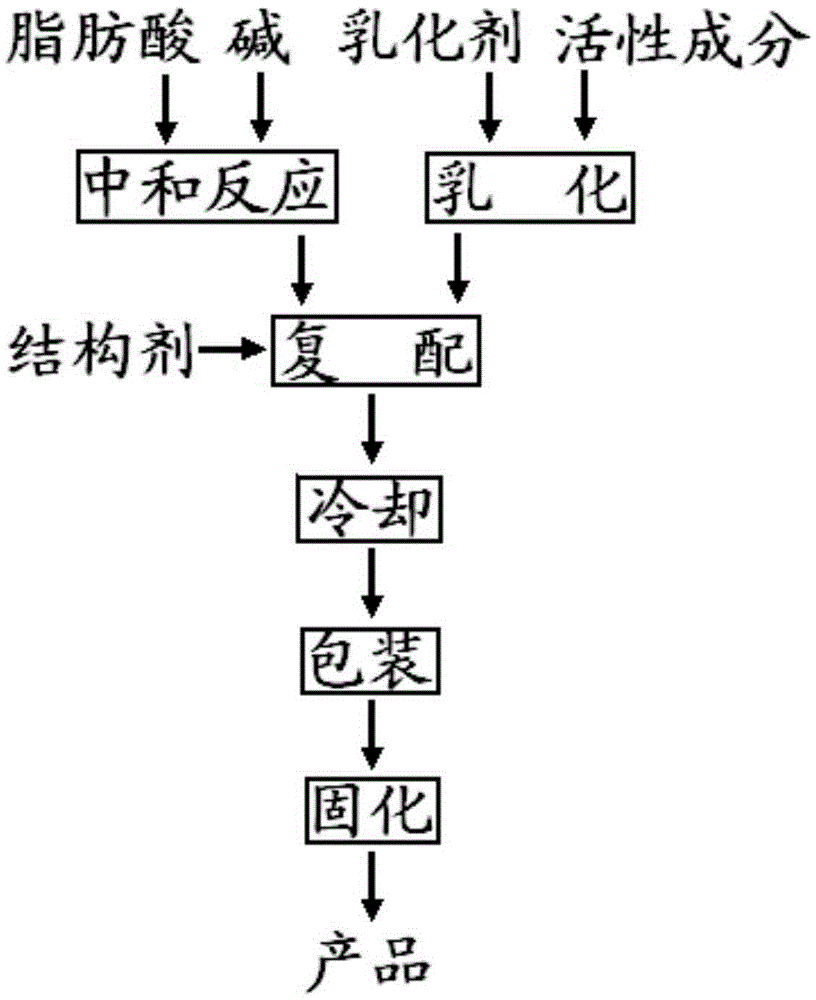

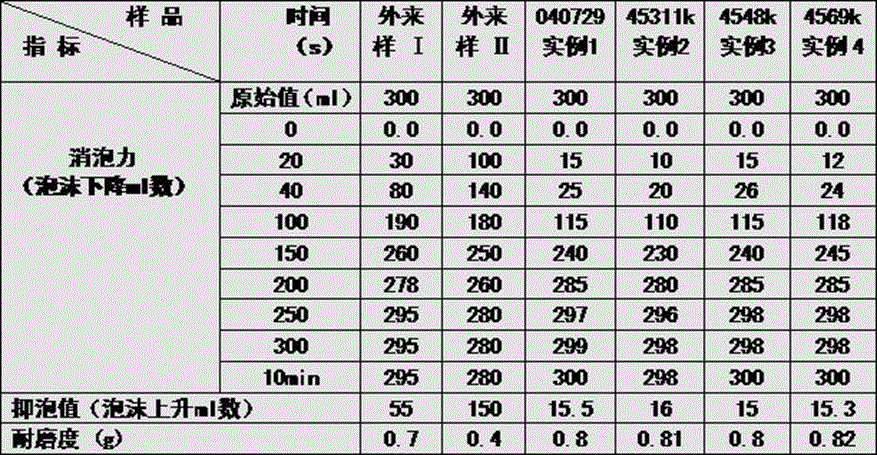

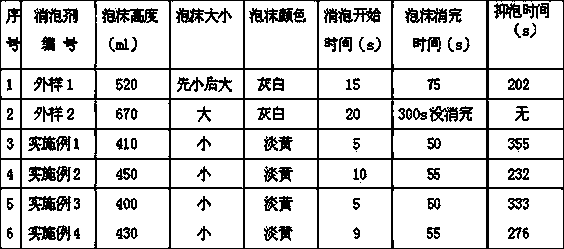

A block solid defoamer and preparation method thereof

InactiveCN103550961BImprove compatibilityNo pollutionFoam dispersion/preventionPapermakingBULK ACTIVE INGREDIENT

The invention discloses a block solid defoamer and its preparation method. The components and parts by weight include: 10-90 parts of fatty acid salt, 1-20 parts of active ingredient, 0-10 parts of emulsifier, and 10 parts of structuring agent. ~90 parts, appropriate amount of acid-base regulator. The preparation is to first neutralize the fatty acid mixed in proportion with sodium hydroxide solution to form fatty acid salt, then emulsify the active ingredient with an emulsifier, compound the active ingredient with fatty acid salt and structuring agent, mix well, and properly Add an acid-base regulator, and after cooling, discharge the material into plastic bags, and further cool and shape it to obtain a solid block product. The invention has the advantages of simple production process, convenient operation, high safety, non-toxicity, non-corrosion, good environmental compatibility and no environmental pollution. The product has low surface tension, fast dispersion in water, fast defoaming, long antifoaming time, less dosage, wide source of raw materials, high cost performance, not only used in papermaking and sewage treatment industries, but also in petroleum, mineral processing, chemical and other industries.

Owner:南宁春城助剂有限责任公司

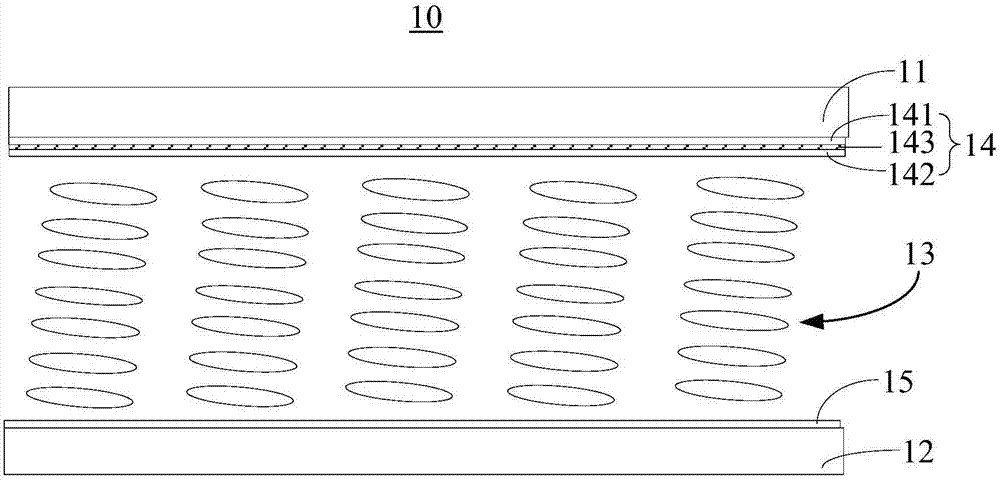

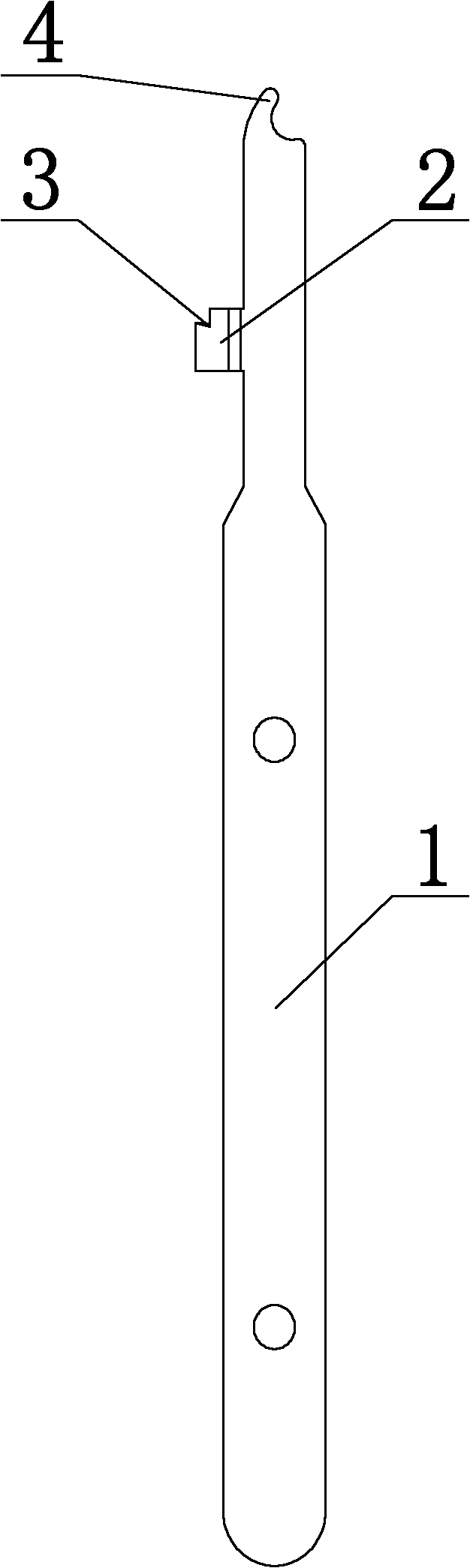

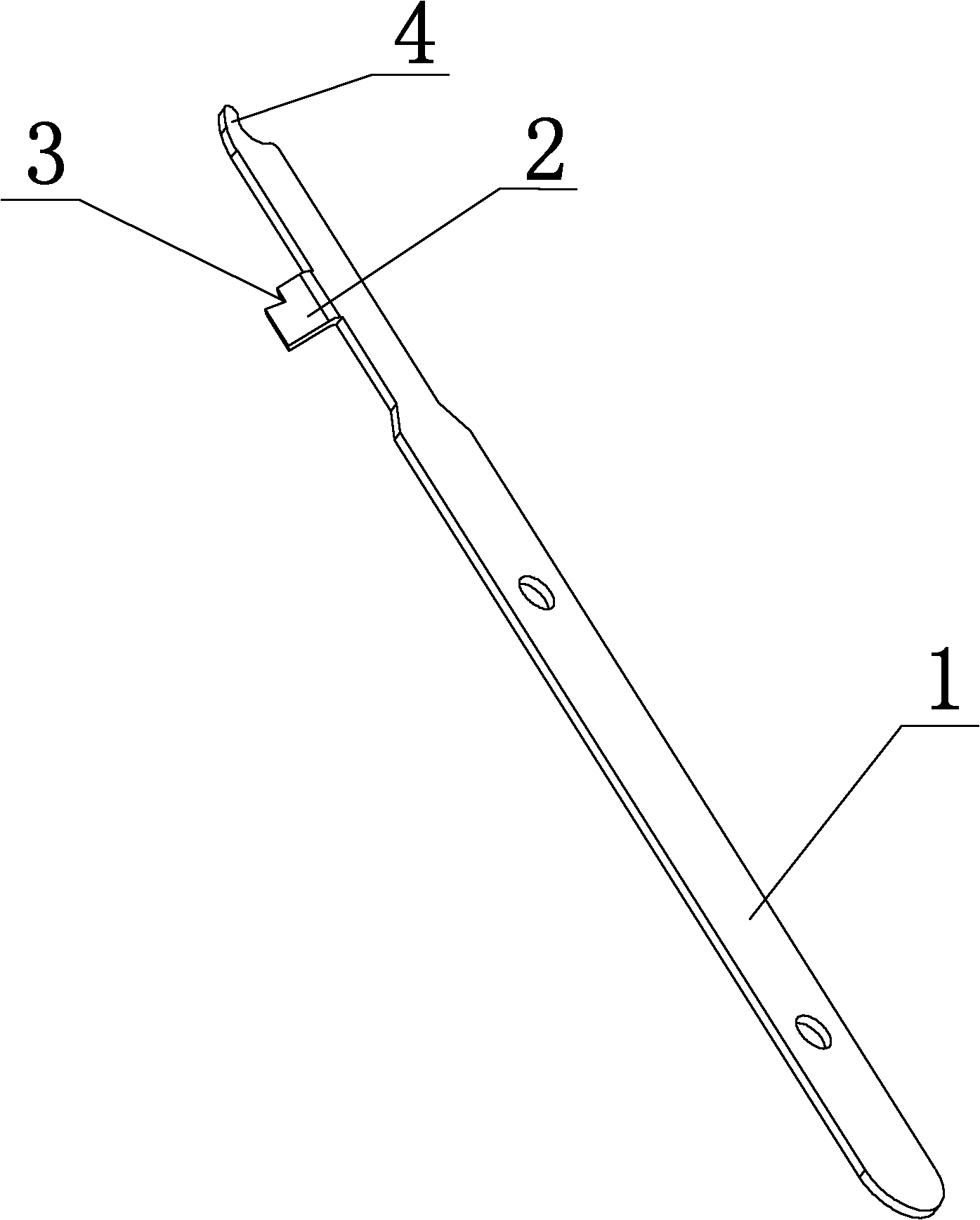

Spring mounting tool

InactiveCN102371571ANot demandingGood labor saving effectMetal-working hand toolsEngineeringMechanical engineering

The invention relates to a spring mounting tool, which comprises a strip-type handle, wherein a bulge is arranged on the circumferential surface of the strip-type handle; and a notch is formed in the bulge and is formed on one surface, which faces the top end of the strip-type handle, on the upper side of the bulge. The invention provides a spring mounting tool capable of mounting a restoring spring of a movable handle safely and easily, and the injury of operators or the rejection of products is avoided effectively.

Owner:江苏瑞安贝医疗器械有限公司

A UAV high-precision full-frame tilt photogrammetry device

ActiveCN111959770BReduce loadNot demandingPicture taking arrangementsAlighting gearGear wheelElectric machinery

The invention relates to the technical field of unmanned aerial vehicle tilt photography detection, and specifically discloses a high-precision full-frame tilt photogrammetry device for unmanned aerial vehicles; it includes a drone body, and a number of rotor arms are uniformly connected to the drone body, each The lower surface of the outer end of the rotorcraft arm is fixed with a drive motor, and the output shaft of the drive motor passes through the upper end of the rotorcraft arm to be provided with a propeller. The center of the lower surface of the drone body is connected with a rectangular block, and the front side of the rectangular block is fixed. There is an adjusting motor, a rotating chamber is arranged inside the rectangular block, and a large gear is arranged in the middle of the rotating chamber; the device of the present invention can perform real-time adjustment of the photography angle and wide angle in actual use; and it can be realized simultaneously by an adjusting motor The adjustment of the shooting angles of the four second high-definition cameras does not require an adjustment motor at the end of each second high-definition camera, which greatly reduces the cost of equipment, and more importantly, effectively reduces the load of the entire drone.

Owner:HENAN UNIVERSITY

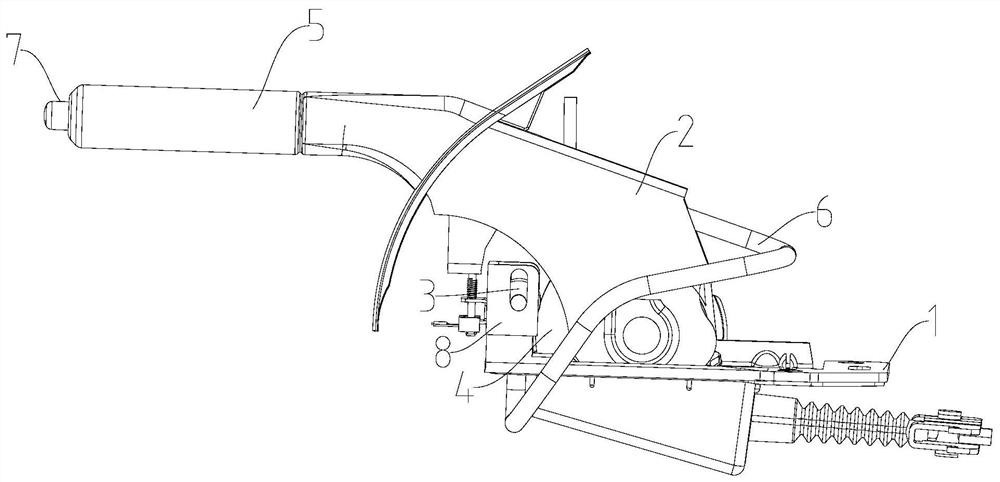

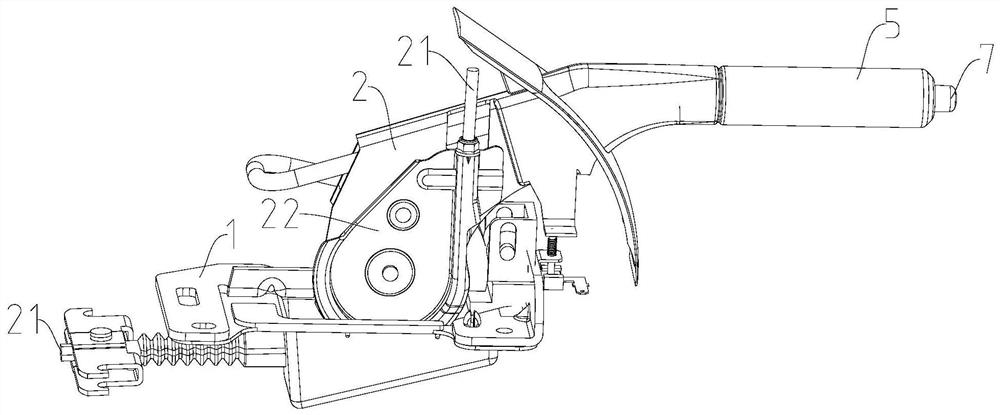

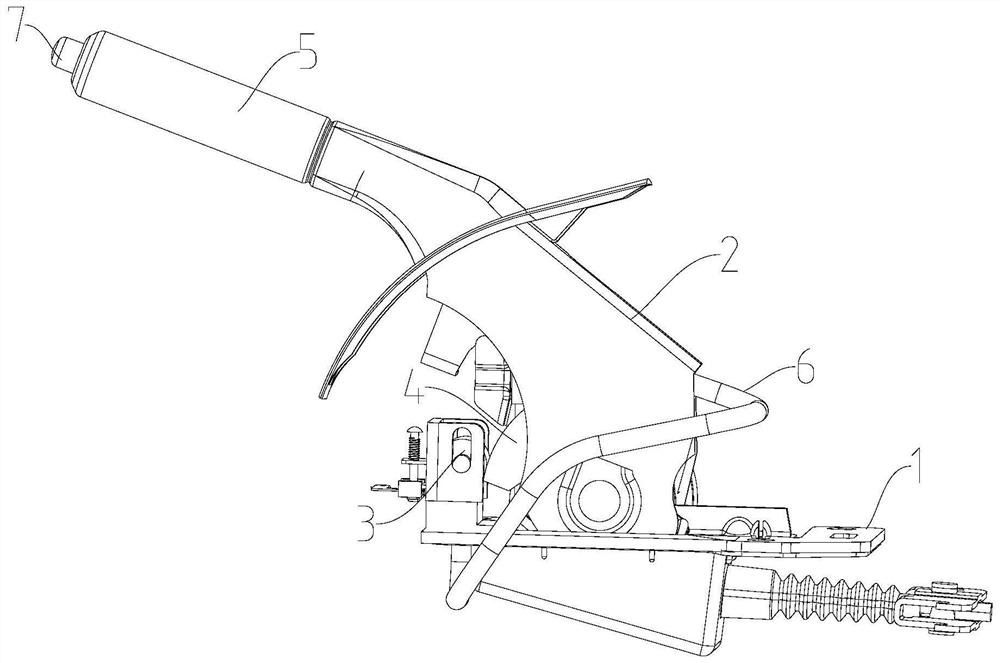

Parking brake lever assembly, auxiliary brake and vehicle

ActiveCN110857081BAchieve lockingAchieve separationHand actuated initiationsDriver/operatorControl arm

The invention relates to a parking braking handle assembly, an auxiliary brake and a vehicle. The parking braking handle assembly comprises a base, a control arm, a pin roller and a parking handle; the control arm is rotationally connected onto the base; a friction wheel is formed on the control arm; the pin roller is arranged on the base in an up-and-down movement manner; the parking handle is connected with the control arm; a pull wire for driving the pin roller to move upwards is arranged in the parking handle; the first end of the pull wire is connected with a button at one end of the parking handle; the second end is fixed below the pin roller in an up-and-down movement manner; when the parking handle is pulled up, the friction wheel abuts against the pin roller, and the parking handle is locked; when one end of the pull wire moves upwards and drives the pin roller to move upwards, the friction wheel is separated from the pin roller, and the parking handle is unlocked. According to the parking braking handle assembly, the parking handle can be locked in any position, the requirement for the strength of a driver is not high in the switching process between the locking state andthe unlocking state, abnormal sounds and impact sounds can be avoided, the parking braking handle assembly is convenient to operate, and the driving comfort is improved.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

Defoamer for wet-process phosphoric acid production and production method thereof

InactiveCN102600646BQuality is not affectedGood dispersionFoam dispersion/preventionCarboxylic saltPhosphoric acid

The invention discloses a defoamer for wet-process phosphoric acid production, which is characterized by consisting of the following components in parts by weight: 30-100 parts of mineral oil, 1-30 parts of ethers, 1-20 parts of carboxylates, 1-10 parts of an emulsifier and 1-10 parts of an inorganic salt. A preparation method of the defoamer for wet-process phosphoric acid production comprises the steps of pre-emulsifying the ethers and the carboxylates by using the compound emulsifier; then mixing with the mineral oil and the inorganic salt; and finally emulsifying, grinding, homogenizing and thinning to obtain the defoamer for wet-process phosphoric acid production. According to the invention, the production process of the product is simple, the production control is simple and convenient and the conditions are not overcritical; the product does not influence the qualities of phosphoric acid products, has good environmental compatibility and does not pollute the environment; the product is low in surface tension, quick for defoaming, long in foam inhibition time and less in dosage; and the raw material sources are wide, the cost is suitable and the performance price ratio is high. The defoamer is not only suitable for wet-process phosphoric acid production, but also suitable for acidic medium defoaming and foam inhibition in the industries of spinning, printing and dyeing and the like.

Owner:南宁春城助剂有限责任公司

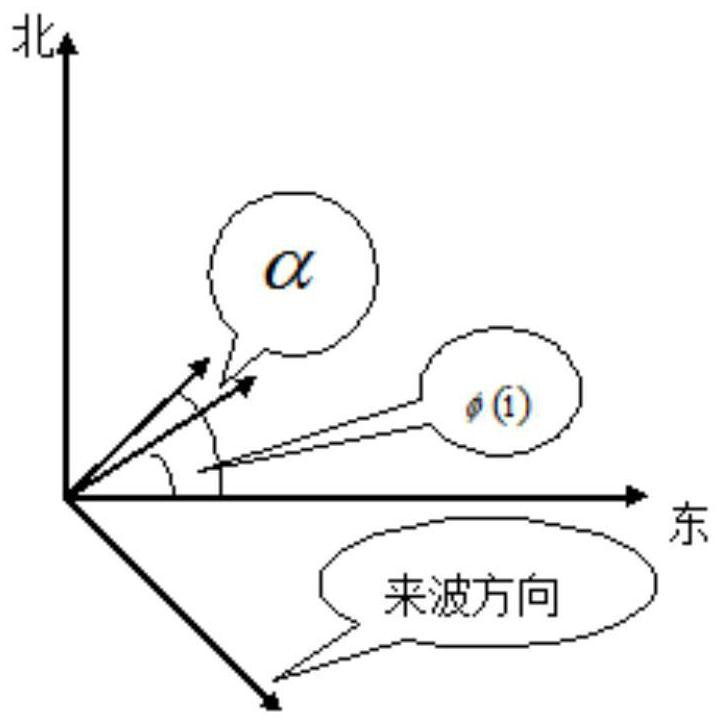

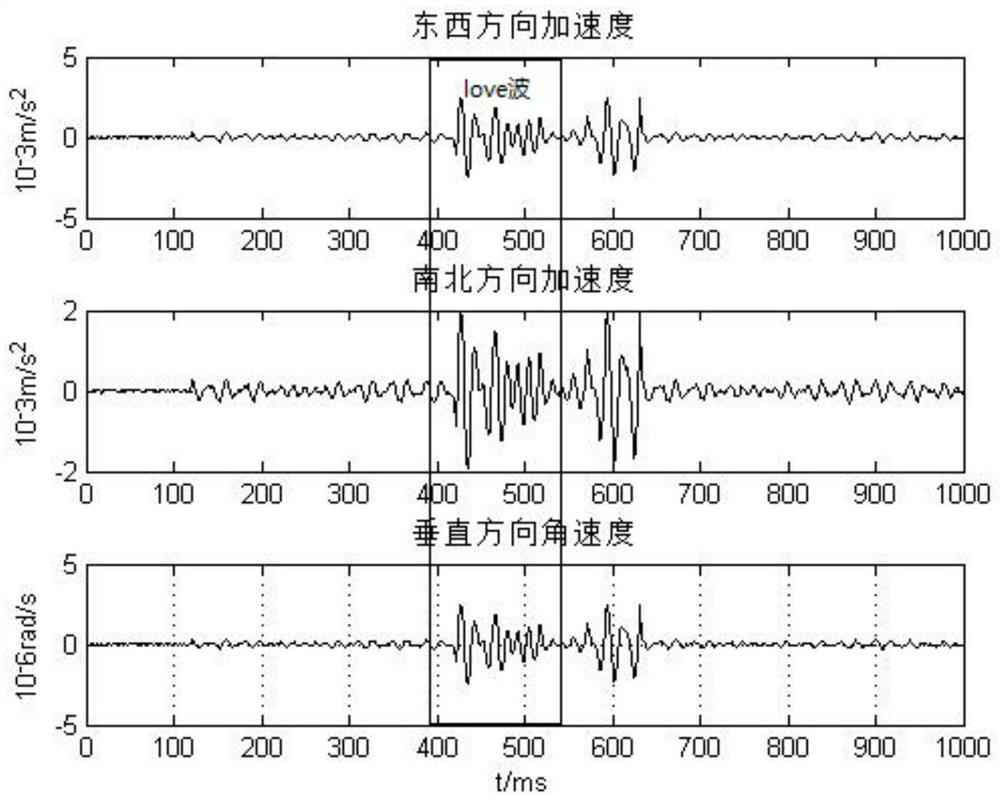

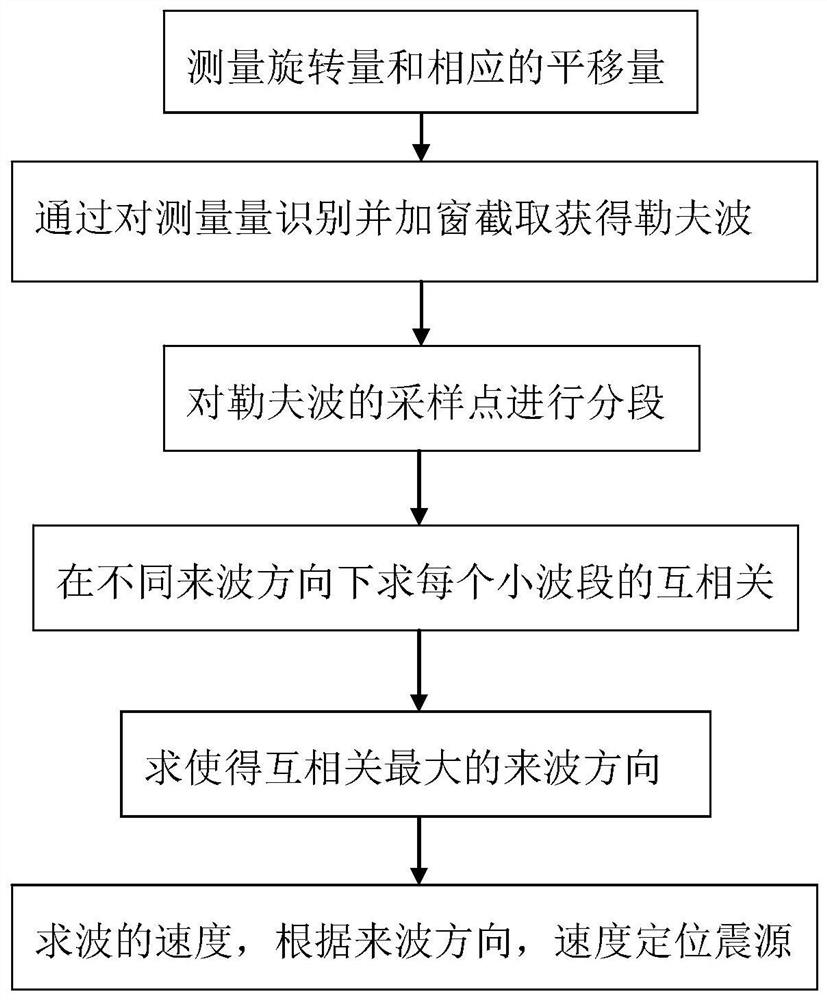

Moving vehicle tracking method for single-station earthquake rotation amount and translation amount concurrent measurement

PendingCN113503887AEasy to measureQuick measurementInstruments for road network navigationEngineeringLove wave

The invention discloses a moving vehicle tracking method based on single-station earthquake rotation amount and translation amount concurrent measurement. The method comprises the following steps: S1, measuring rotation amount and corresponding translation; S2, identifying the measurement amount and conducting windowing and intercepting to obtain a Love wave; S3, segmenting sampling points of the Love wave; S4, solving the cross-correlation of each small wave band in different incoming wave directions; S5, solving an incoming wave direction enabling the cross-correlation to be maximum; and S6, solving a wave speed, and positioning a seismic source according to the incoming wave direction and the speed. The method provided by the invention can be used for single-station measurement, is different from previous multi-station measurement and is easy to implement, in addition, translation components are easy to be greatly influenced by terrains, and the method provided by the invention has rotation measurement and translation measurement, so that the influence of the terrains on the measurement is reduced.

Owner:XIAN UNIV OF TECH

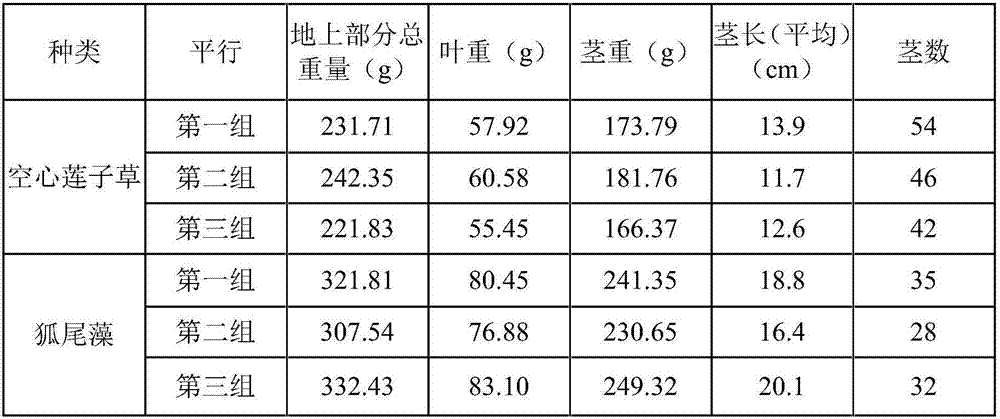

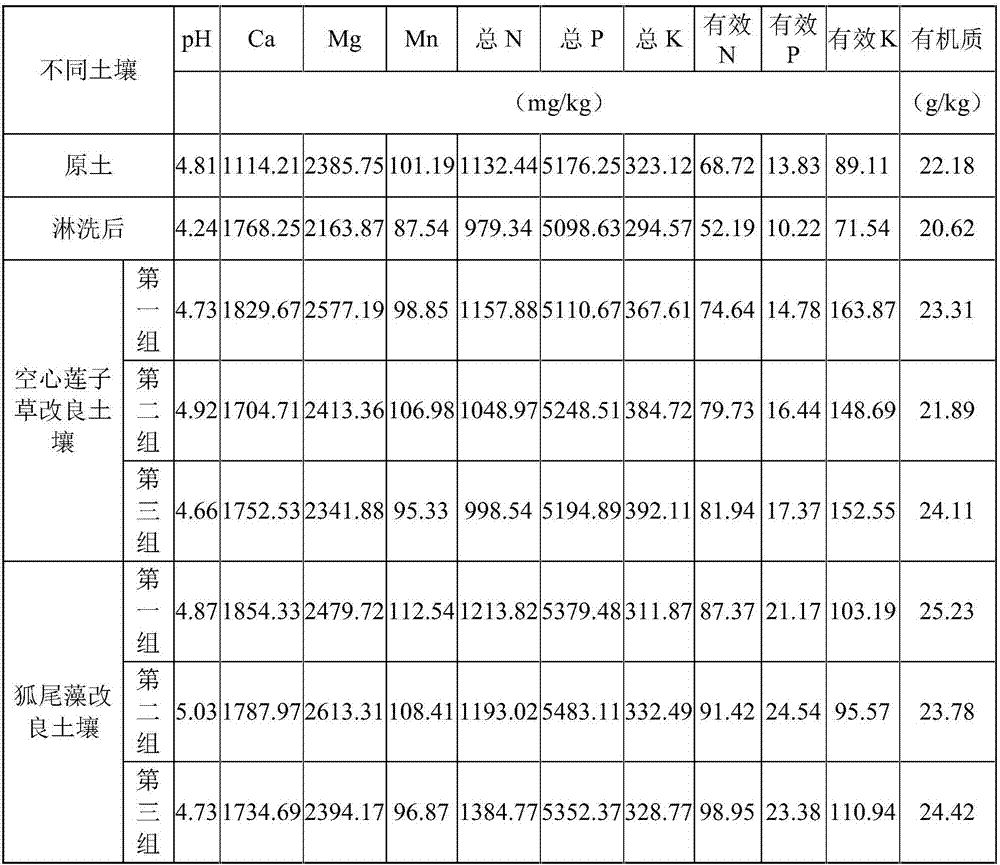

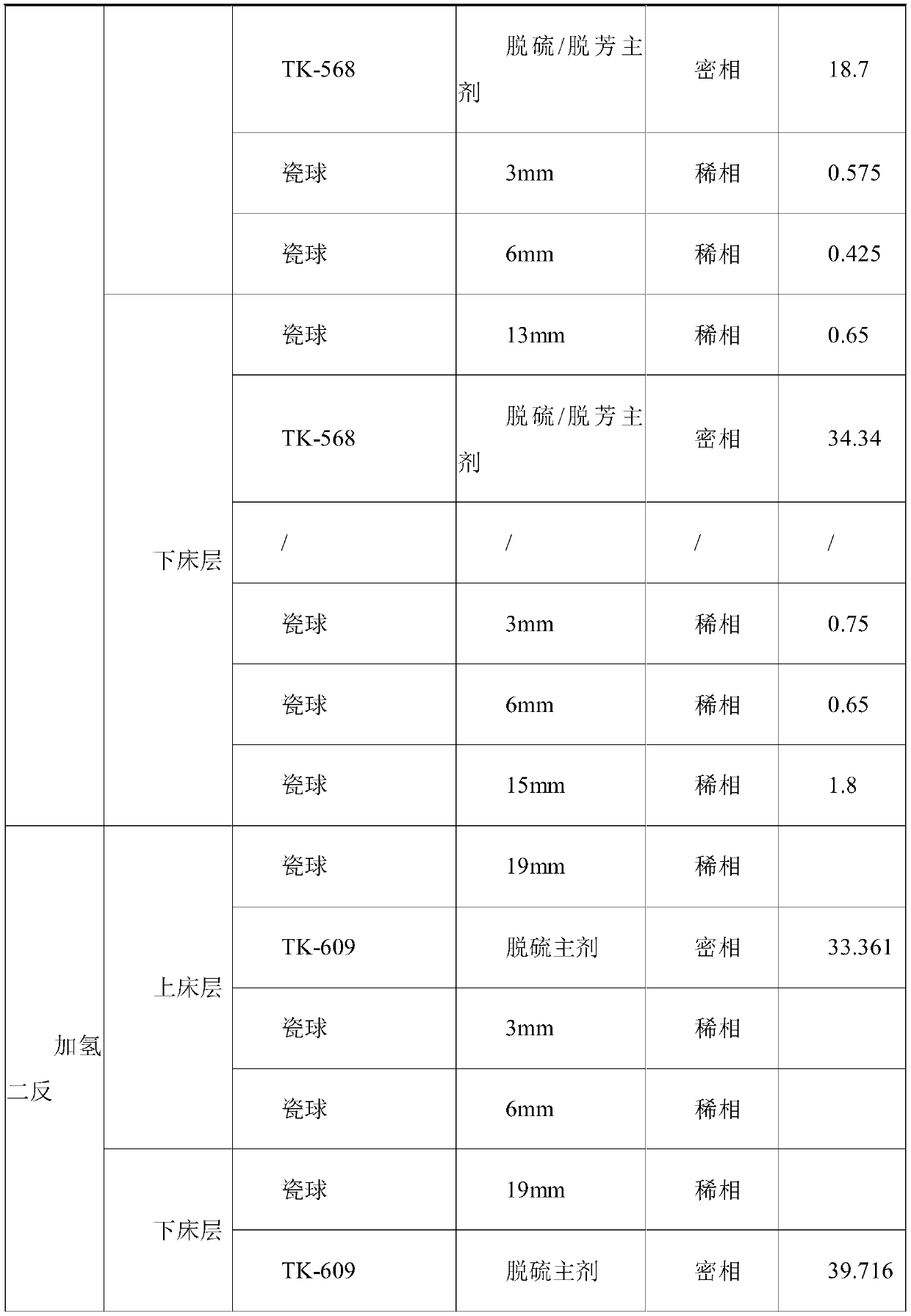

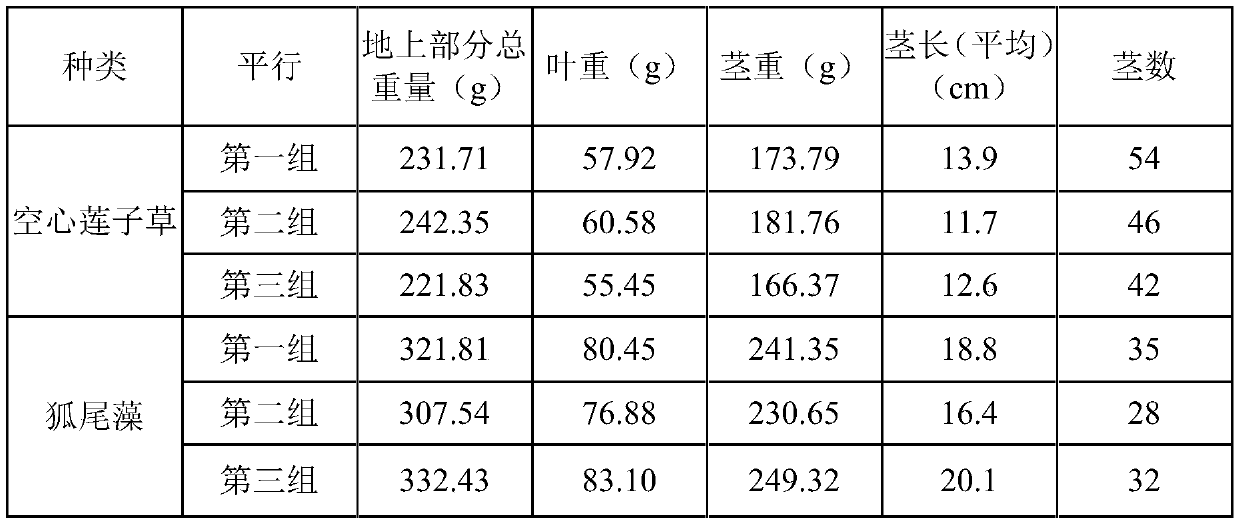

Chelating agent washed-off soil improvement method

ActiveCN107211614ALow toxicitySolve problems that are difficult to grow and surviveBio-organic fraction processingOrganic fertiliser preparationMyriophyllumAlternanthera

The invention discloses a chelating agent washed-off soil improvement method which includes the steps: planting aquatic plants into chelating agent washed-off soil; applying fertilizers for cultivation to improve chelating agent washed-off soil. The aquatic plants are alligator alternanthera herbs and / or myriophyllum spicatum. The alligator alternanthera herbs and / or myriophyllum spicatum are used for improving the chelating agent washed-off soil for the first time, degradation activity of enzyme and microorganisms in the restorable soil can be improved, chelating agents remaining in the soil can be biologically degraded, toxicity of the soil is remarkably reduced, the problem of difficulty in growth and survival of plants in the chelating agent washed-off soil is solved, and the method has the advantages of low cost, high practicability, good improvement effect and the like.

Owner:HUNAN AGRICULTURAL UNIV

Electric booster device for automobile parking braking

InactiveCN100560412CNot demandingEliminate Braking HazardsBraking action transmissionElectricityCoupling

The invention discloses an automobile parking brake electric booster suitable for a manual parking brake system provided with a brake handle, which mainly consists of a booster motor, a clutch, a planetary reduction mechanism, an angle sensor, and a The set angle is composed of the electronic control unit for the second set angle, in which the output shaft of the booster motor is connected with the input shaft of the planetary reduction mechanism through a clutch, and the output shaft of the planetary reduction mechanism is connected with the manual parking brake through a coupling The rotating shaft on the brake handle of the system is connected, and the planetary reduction mechanism is also fixedly connected with an angle sensor used to detect the rotation angle of the handle, and the booster motor and the angle sensor are electrically connected with the electronic control unit. This mechanism has a simple structure and can provide power assistance for the driver's parking brake.

Owner:BYD CO LTD

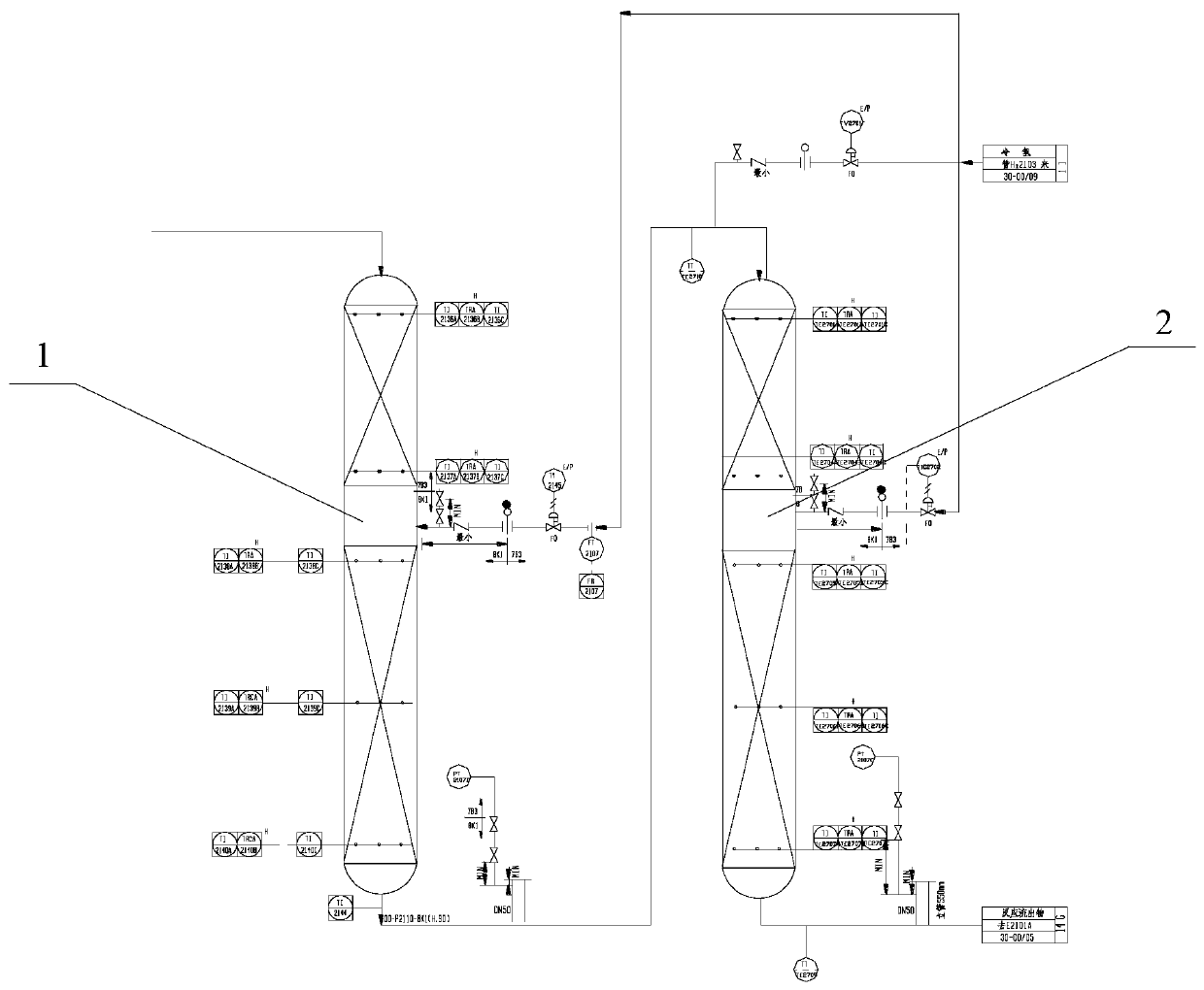

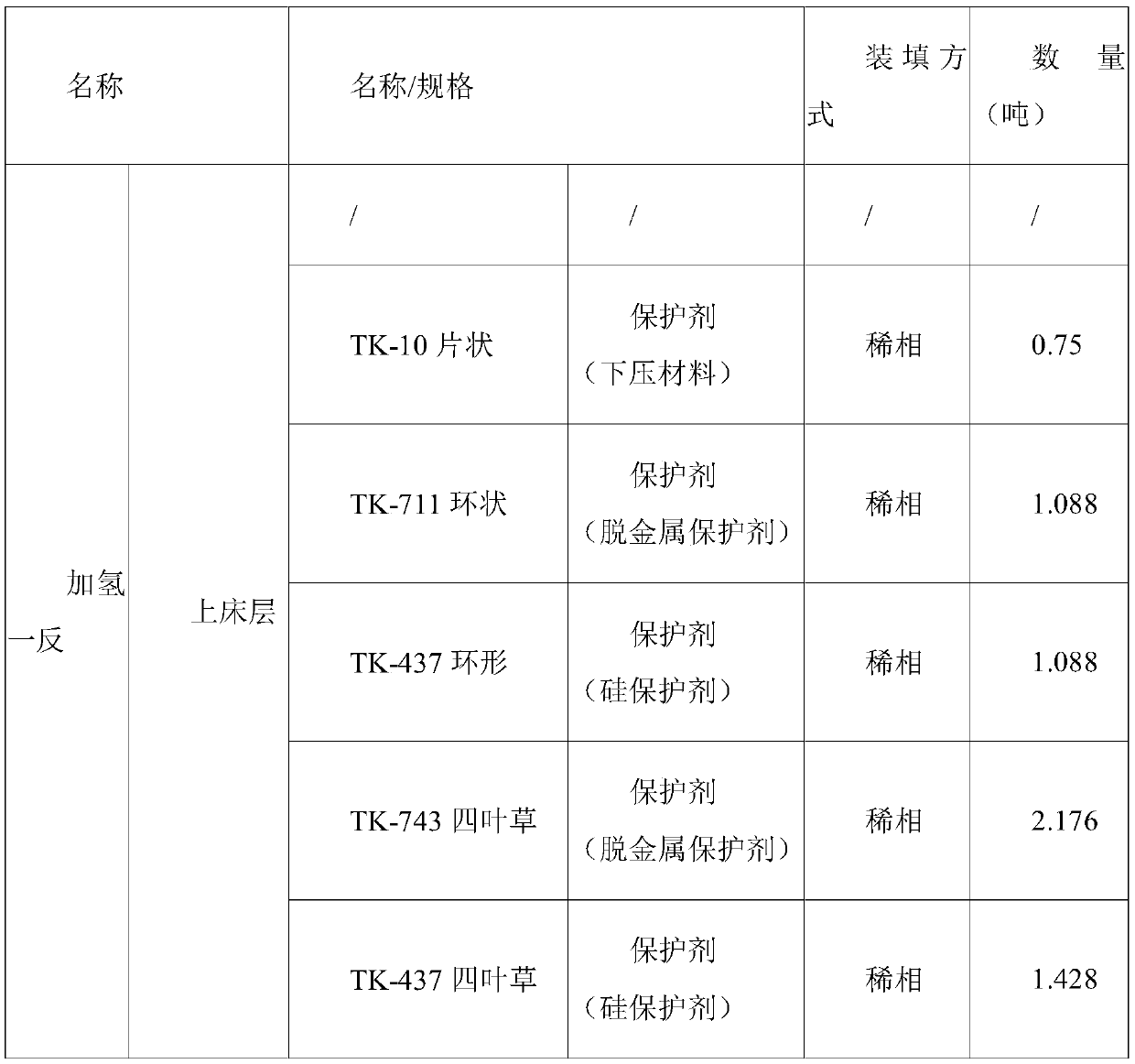

Deep desulfurization system and desulfurization method thereof

InactiveCN110144241ARealize deep desulfurizationGood product indexTreatment with hydrotreatment processesSiliconMetal

The invention discloses a deep desulfurization system, which comprises a first hydrogenation reactor and a second hydrogenation reactor which are connected through a pipeline. An upper catalyst bed ofthe first hydrogenation reactor comprises a dense-phase desulfuration / dearomatization catalyst, and a flaky compacted top catalyst, an annular demetalization protective agent, an annular silicon protective agent, a clover-shaped demetalization protective agent and a clover-shaped silicon protective agent which are dilute phases. A lower catalyst bed of the first hydrogenation reactor comprises adense-phase desulfuration / dearomatization catalyst. An upper catalyst bed of the second hydrogenation reactor comprises a dense-phase desulfurizer. A lower catalyst bed of the second hydrogenation reactor comprises a dense-phase desulfurizer. The desulphurization system of the invention has two hydrogenation reactors which are arranged in succession. Raw oil is subjected to a hydrofining reactionthrough the first hydrogenation reactor and then the product immediately enters the second hydrogenation reactor to continuously undergo hydrofining. With the cooperation of different catalyst selections, deep desulfurization is realized, and product indexes are greatly improved.

Owner:SHANDONG QINGYISHAN PETROCHEM TECH CO LTD

Method for improving chelating agent leaching soil

ActiveCN107211614BLow toxicitySolve problems that are difficult to grow and surviveBio-organic fraction processingOrganic fertiliser preparationMicroorganismMyriophyllum

The invention discloses a chelating agent washed-off soil improvement method which includes the steps: planting aquatic plants into chelating agent washed-off soil; applying fertilizers for cultivation to improve chelating agent washed-off soil. The aquatic plants are alligator alternanthera herbs and / or myriophyllum spicatum. The alligator alternanthera herbs and / or myriophyllum spicatum are used for improving the chelating agent washed-off soil for the first time, degradation activity of enzyme and microorganisms in the restorable soil can be improved, chelating agents remaining in the soil can be biologically degraded, toxicity of the soil is remarkably reduced, the problem of difficulty in growth and survival of plants in the chelating agent washed-off soil is solved, and the method has the advantages of low cost, high practicability, good improvement effect and the like.

Owner:HUNAN AGRICULTURAL UNIV

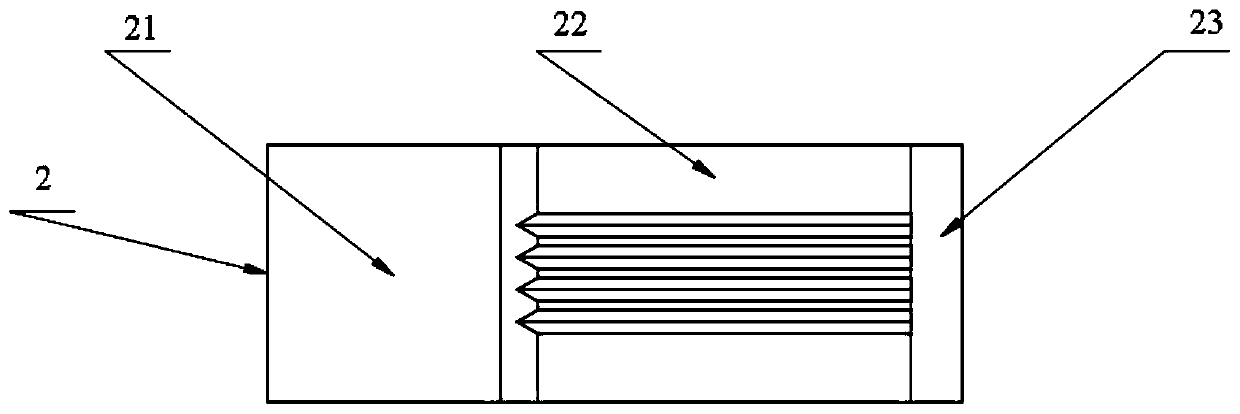

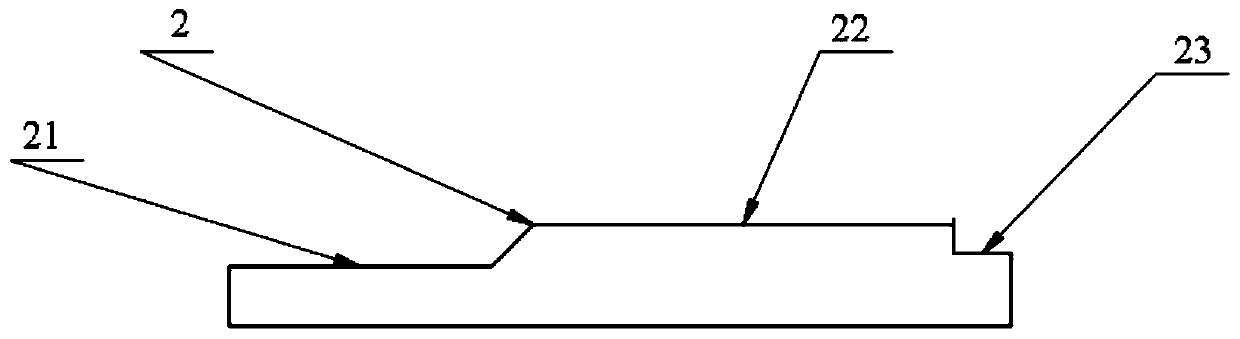

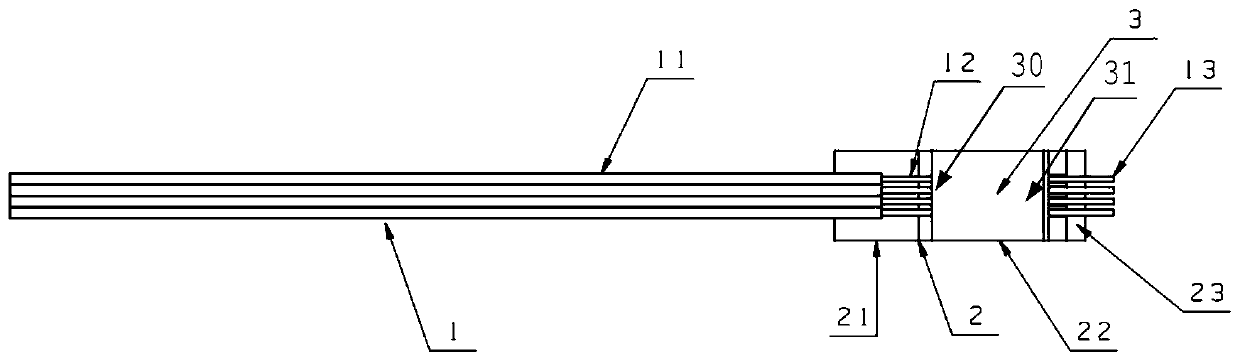

A method of fabricating an exposed optical fiber array with an inclined end face and its substrate

The invention provides a manufacturing method and a substrate of a bare type fiber array with an inclined end face; the substrate comprises a platform structure, a notch structure and a pressure disperse structure; the fiber array manufacture method comprises the following steps: 1, clearly peeling off a wrapping layer on one end of a fiber, using alcohol to clean residuals on the surface of the bare fiber, thus forming a bare fiber portion; 2, placing the bare fiber into a notch of the notch structure, and allowing the end face of the bare fiber to extend outside the pressure disperse structure. 3, using a cover plate to cover the bare fiber zone above the notch structure; 4, dripping UV solidification glue into the boundary between the notch structure and the platform structure, and using an UV lamp to solidify the UV glue; 5, carrying out angle grinding process on the end face of the solidified fiber array, thus forming an optical slope with a specific angle. The method can solve the problems that the front bare fiber is easily broken or damaged in a bare type fiber array manufacture process, thus obviously improving fiber bare type fiber array manufacture yield, reducing material waste, and reducing making cost.

Owner:武汉生一升光电科技有限公司

Multisystem compatible receiver frequency point selecting method

ActiveCN101776765BNot demandingImprove computing efficiencySatellite radio beaconingOptimization problemGlobal optimal

The invention discloses a multisystem compatible receiver frequency point selecting method which comprises the following steps: firstly, defining a parameter value, coding and establishing an initial frequency point set, then acquiring the fitness of each frequency point, judging whether a termination condition is met, and finally outputting a global optimal result. The invention has low requirements on the problem property and high computing efficiency, can solve a complicated optimization problem at limited cost, is suitable for a condition with large computing amount, has better global search performance, enables the process of solving the problem to be conveniently parallelized, and improves the processing efficiency. The invention can be used in the field of satellite navigation and communication, especially is suitable for the design of a satellite navigation multisystem compatible receiver, and has good application prospects in the aspects of military and civil use.

Owner:BEIHANG UNIV

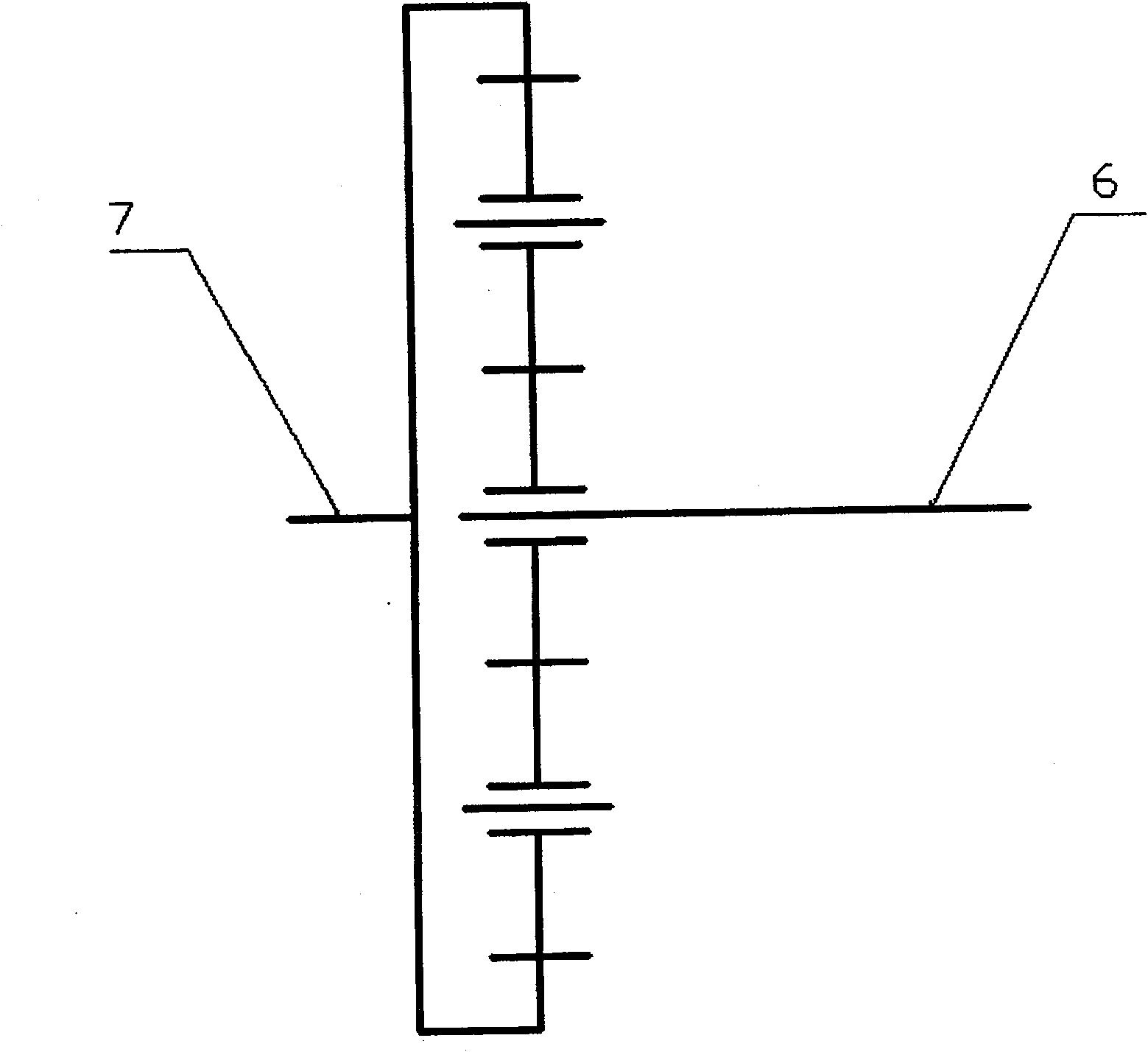

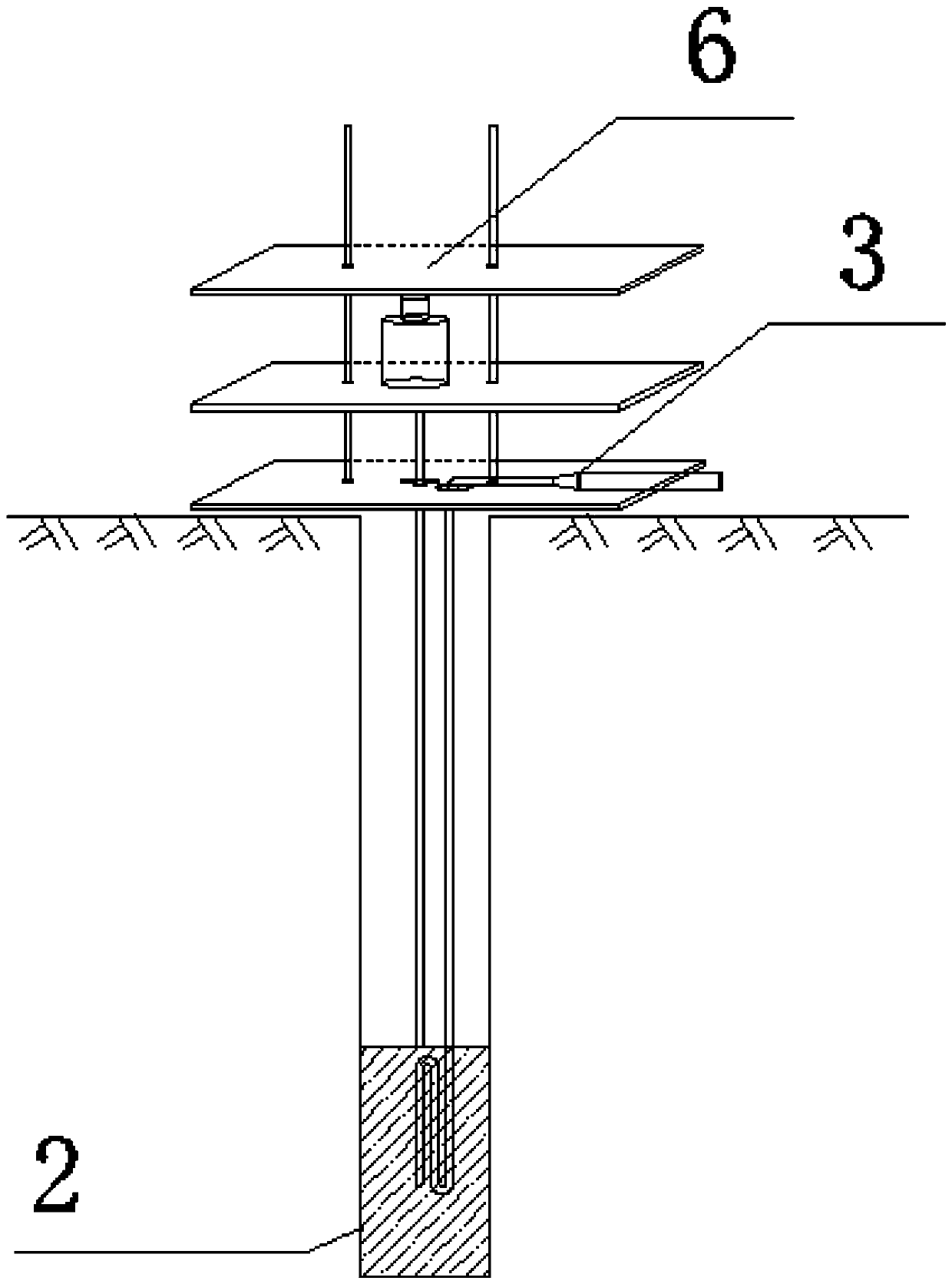

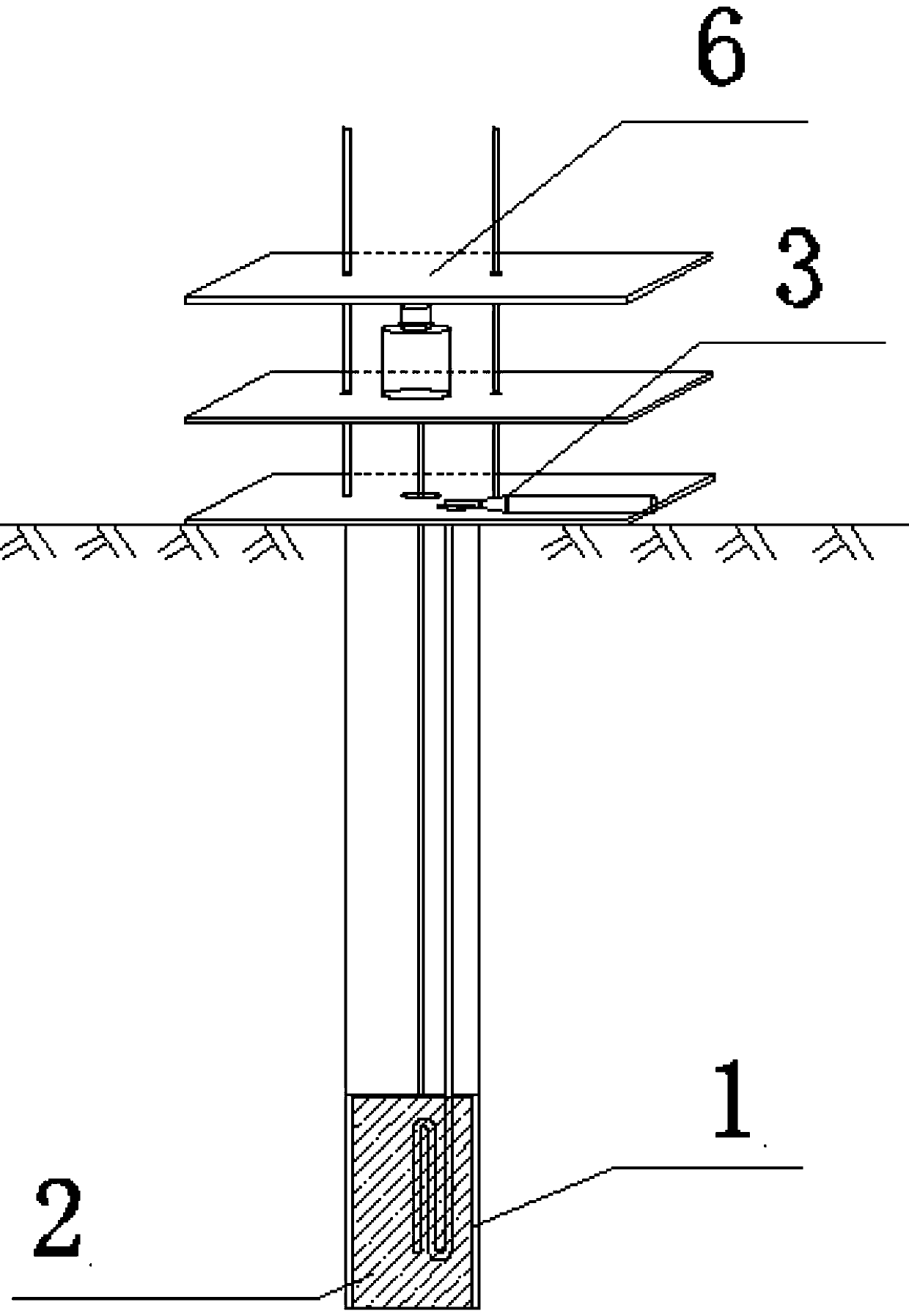

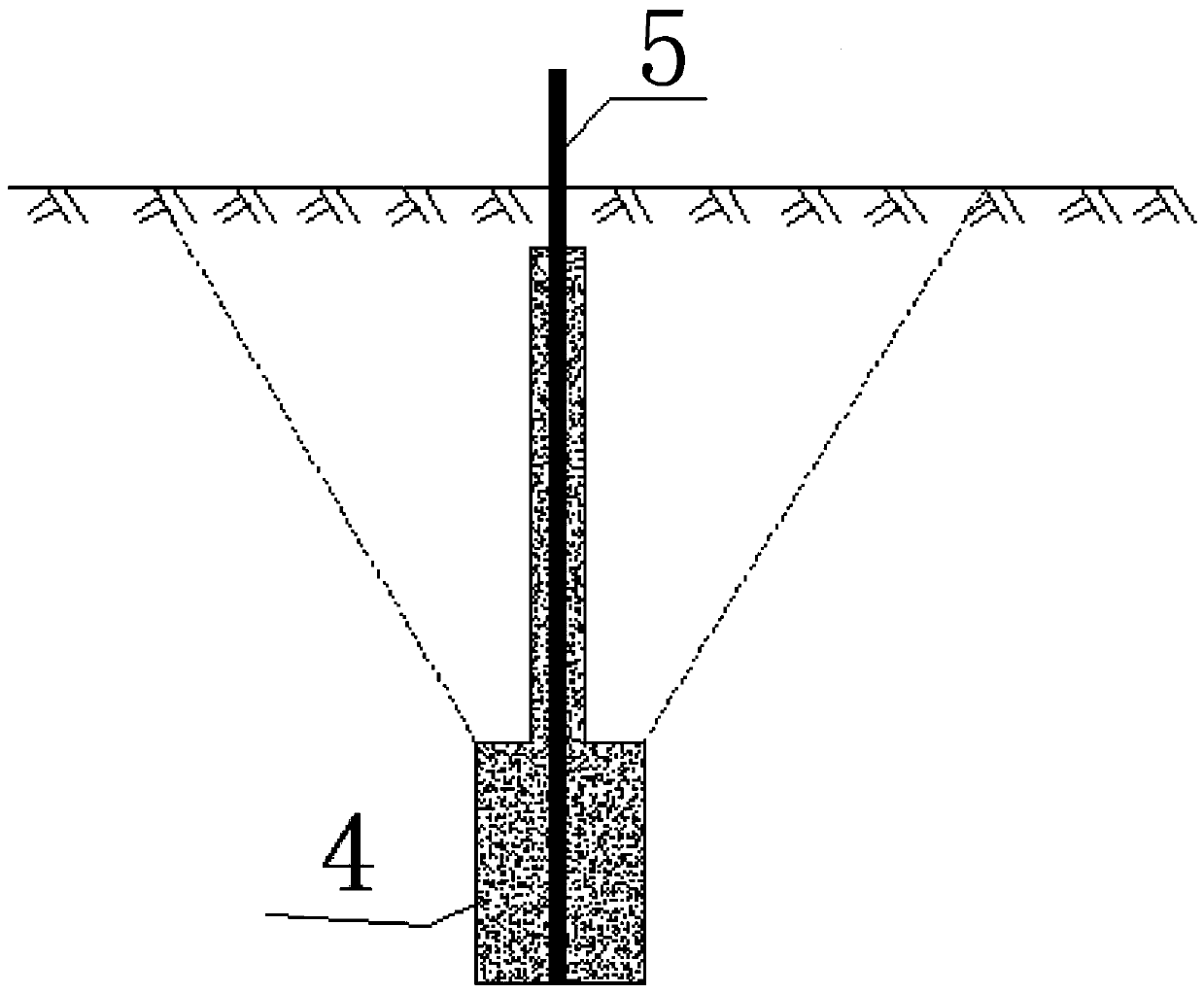

A kind of ice expansion method of rock and soil mass

ActiveCN109322622BImprove hole reaming efficiencyAvoid situations that require extensive additional equipmentAnchoring boltsDrilling machines and methodsSoil scienceSoil mass

The invention discloses an ice expansion broaching method for a rock-soil body. The ice expansion broaching method comprises the steps that the soil body needing to be broached is drilled, a columnarcapsule is put into a drilled hole, and a certain quantity of freezing media are injected into the columnar capsule; the freezing media are frozen quickly by a quick freezer, thus the freezing media at the bottom of the columnar capsule are expanded after being condensed, after volume expansion of the columnar capsule, the bottom of the drilled hole is expanded to be open, and the drilled hole isbroached; and after broaching, the freezing media are melted, and then melted waste liquid is drained out of the drilled hole. The technology is easy and convenient to operate and rapid in construction, the broaching efficiency is significantly improved, the defects that traditional broaching equipment is numerous, operation is complicated, the occupied area is large, the construction period is long, and a large quantity of manpower and material resources are spent are effectively overcome, and the economic loss is greatly reduced.

Owner:重庆高新技术产业研究院有限责任公司

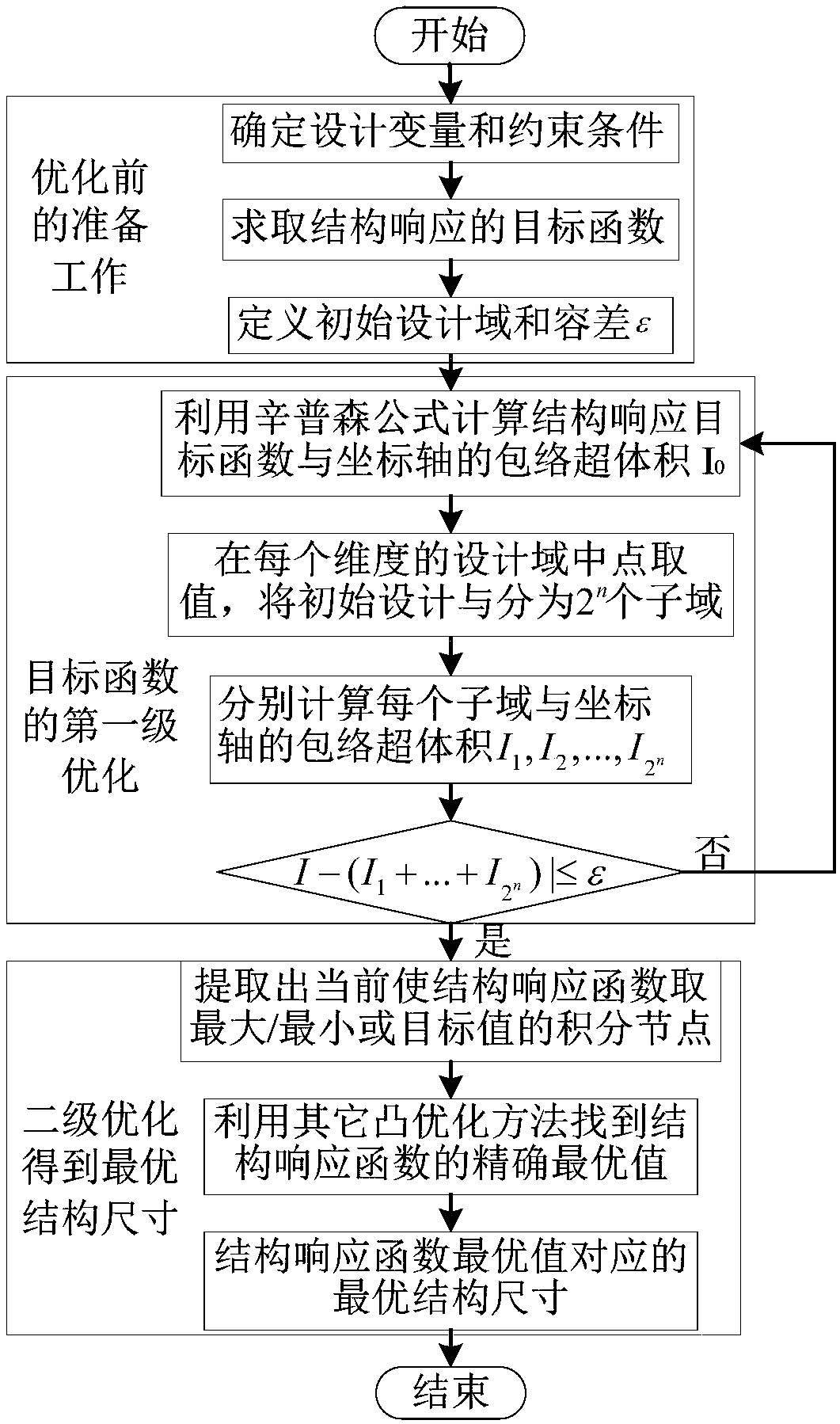

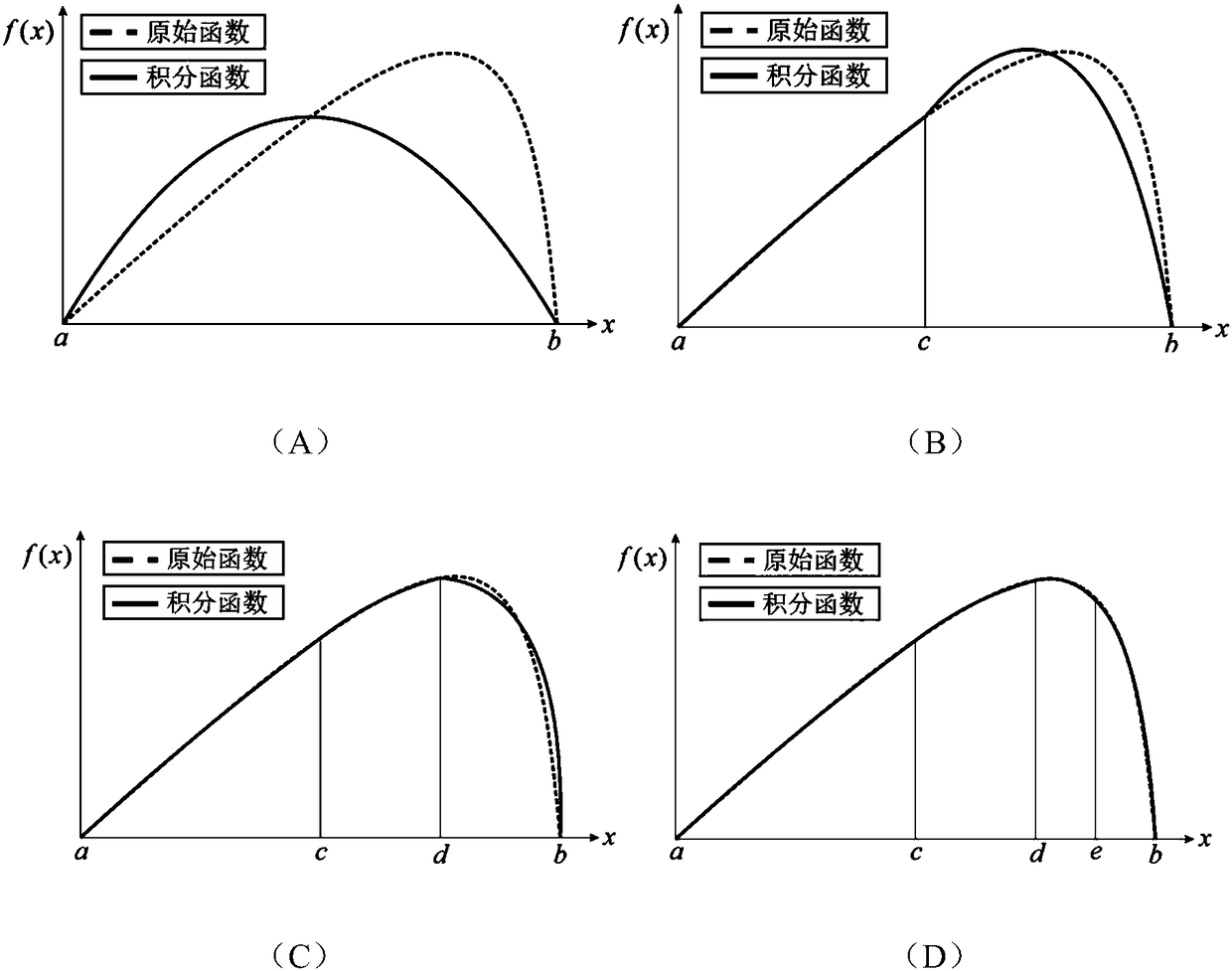

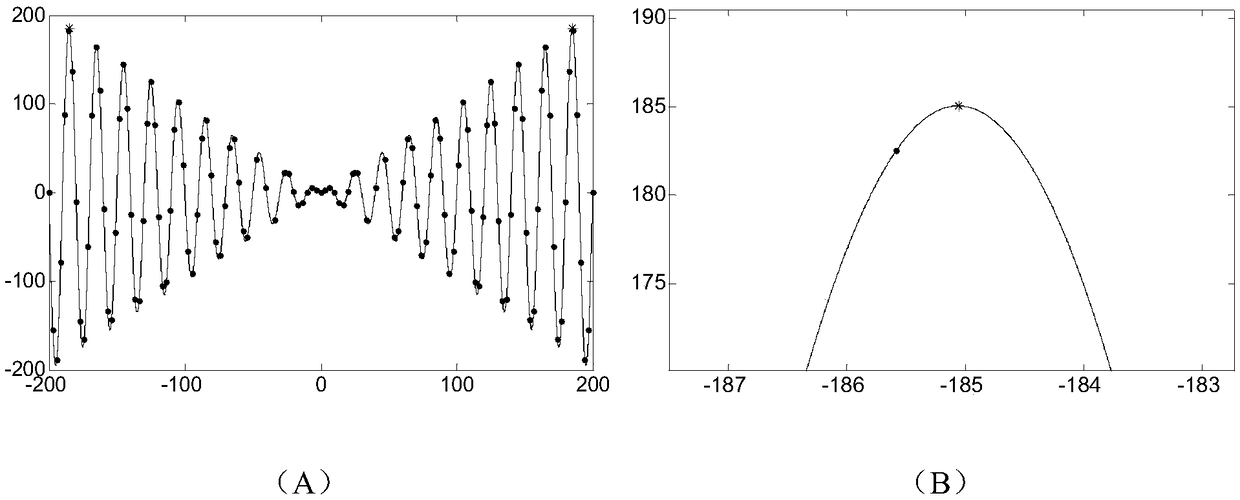

A Method for Determining Optimal Structure Size Based on Hypervolume Iterative Global Optimization Algorithm

ActiveCN107092710BNot demandingGeometric CADDesign optimisation/simulationSelf adaptiveObject function

The invention discloses a method for determining optimum structure sizes on basis of a hyper-volume iteration global optimization algorithm. According to the method, the hyper-volume iteration global optimization algorithm is utilized to optimize target functions of structure responses (such as displacement, frequency, stress and the like), so as to determine optimum structure sizes. The method can be used for the conditions that the target functions of the structure responses are continuous or discontinuous, guidable or unguidable and implicit or explicit. The optimization algorithm comprises the following steps of: firstly utilizing a self-adaptive Simpson formula to calculate hyper volumes of the target functions of the structure responses and using the hyper volumes as iterative convergence criterions; extracting integral nodes and selecting a node, the response of which is minimum or maximum or satisfies a given value as an approximate global optimum solution; and finally using other convex optimization methods to iterate the found approximate optimum solution to find a global optimum value and the obtain an optimum size of a structure.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com