Method for manufacturing hydrophobic surface through laser selective molten metal nanoparticle solution additive manufacturing in air environment

An air environment, additive manufacturing technology, applied in metal material coating process, additive manufacturing, additive processing, etc., can solve the problems of low hydrophobic surface strength, difficult mass production and application, weak non-covalent bonds, etc. Achieve the effect of low property requirements, high controllability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific Embodiment 1: A method for additively manufacturing a hydrophobic surface by laser selective melting of a metal nanoparticle solution in an air environment. The method for preparing a hydrophobic surface in this embodiment is to first configure a metal nano-mixed solution, and evenly coat the surface of the metal substrate with After laying a layer, selective laser sintering is used to obtain a surface structure with hydrophobic properties on the surface; the specific steps of the method are as follows:

[0024] Step 1: Prepare metal nano-mixed solution, disperse 20.8wt% polyvinylpyrrolidone (viscosity K30, relative molecular mass Mr 10000) and 46.2wt% nano-metal powder (particle diameter less than 100nm) in 33wt% solvent, ultrasonic Evenly dispersed;

[0025] Step 2: Ultrasonic cleaning of the stainless steel substrate with absolute ethanol, acetone, sodium hydroxide solution and secondary water in sequence and drying in the air;

[0026] Step 3: Evenly coat ...

specific Embodiment approach 2

[0030] Specific embodiment 2: The method of laser selective melting of metal nanoparticles solution additive manufacturing hydrophobic surface described in specific embodiment 1 in the air environment, in step 1, the nano metal powder is copper, gold, silver, titanium or nickel metal, Or one of the oxides of the above metals.

specific Embodiment approach 3

[0031] Embodiment 3: In Embodiment 1 or 2, the method for additively manufacturing a hydrophobic surface by laser selective melting of metal nanoparticle solution in an air environment, in step 1, the solvent is ethylene glycol, ethanol or glycerol.

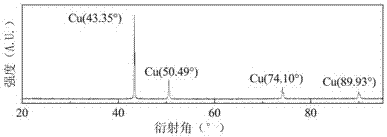

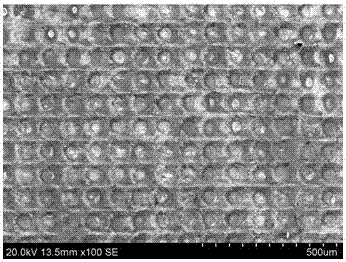

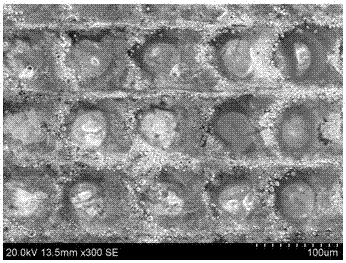

[0032] The principle of the present invention is (taking copper metal as an example): copper nanoparticles have a low melting point due to the size effect, and the copper nanoparticles are dispersed in ethylene glycol under the action of polyvinylpyrrolidone dispersant to form a solution. Prevents agglomeration and precipitation of copper nanoparticles. The copper nanometer mixed solution is evenly spread on the surface of the substrate. Under the action of the laser, the metal particles absorb heat and melt and combine with the stainless steel substrate to create a certain micron-scale structure. Due to the high proportion of copper nano powder in the mixed solution, copper nanoparticles adhere to the surface after melting and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com