Patents

Literature

77results about How to "Improve hole reaming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

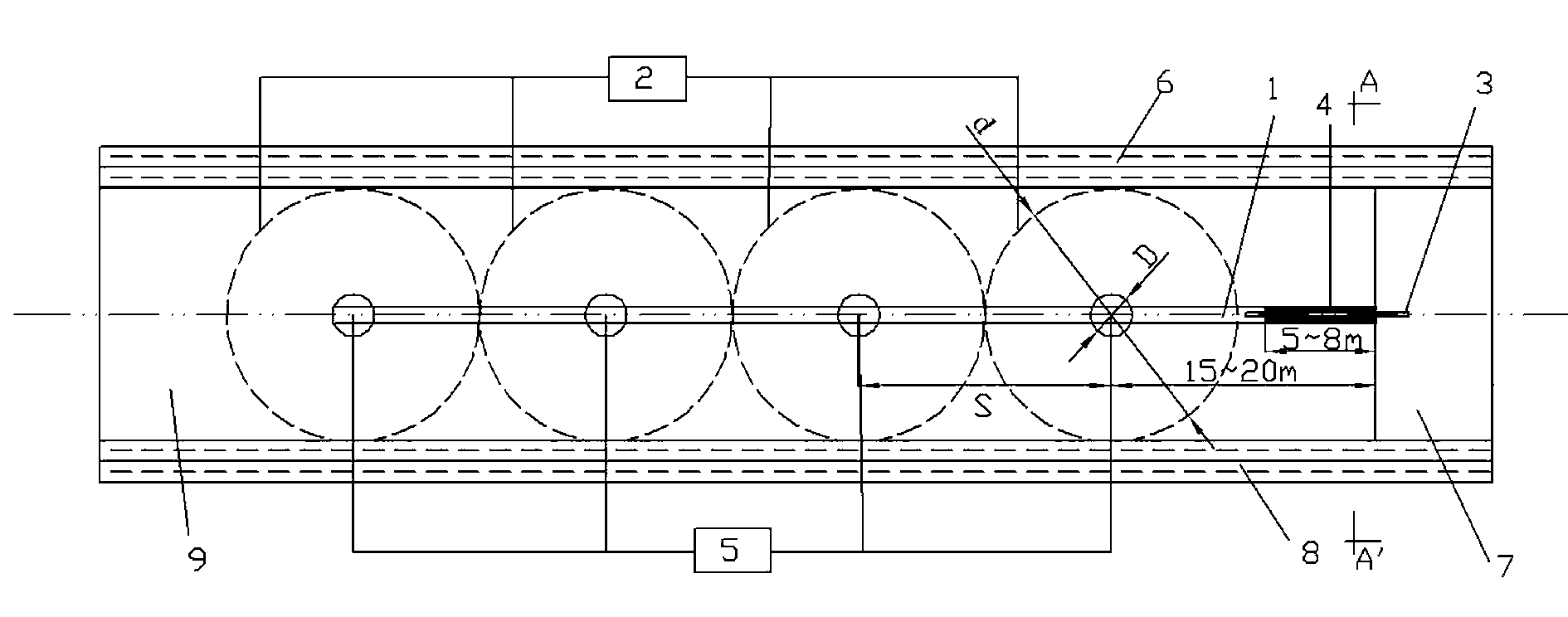

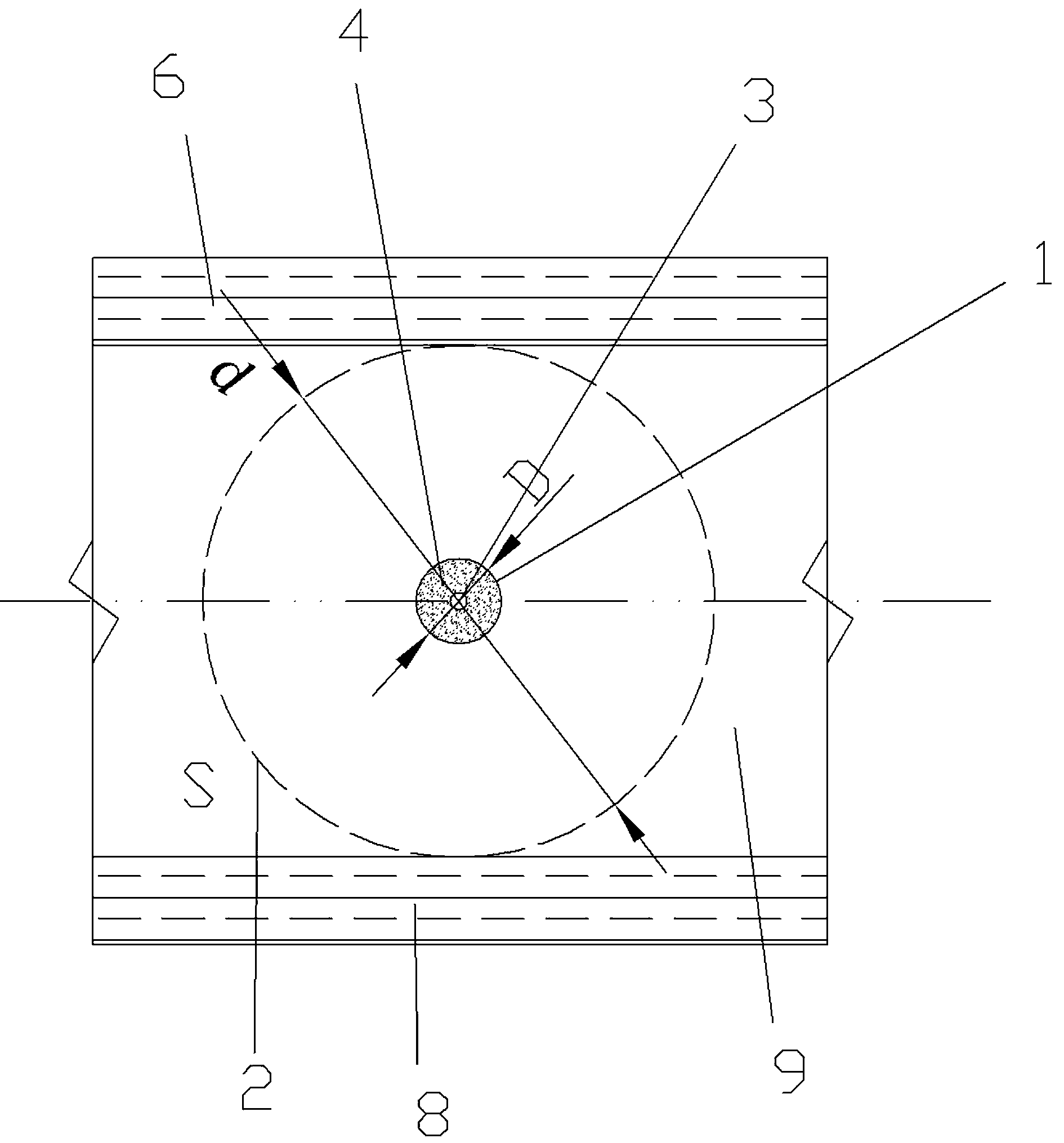

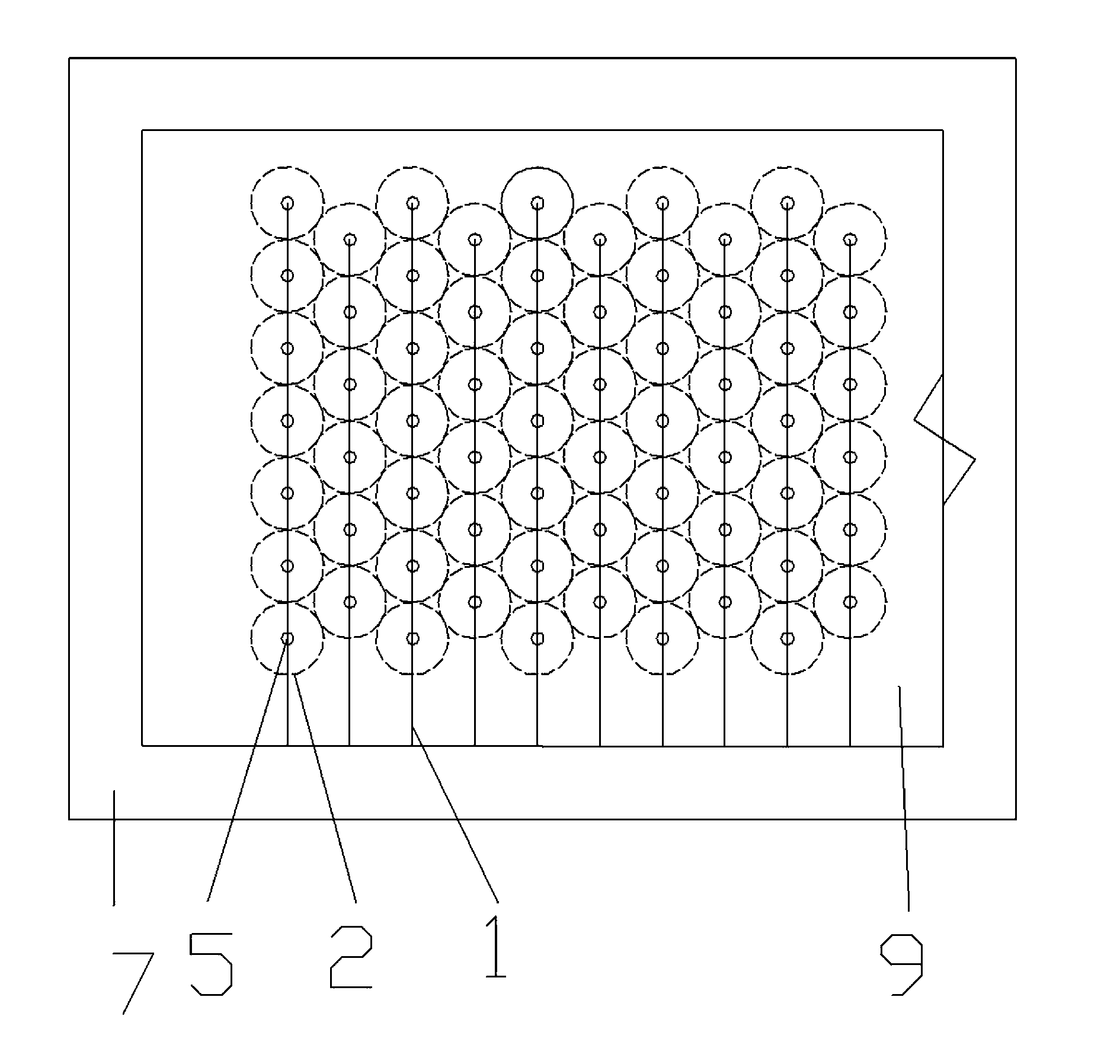

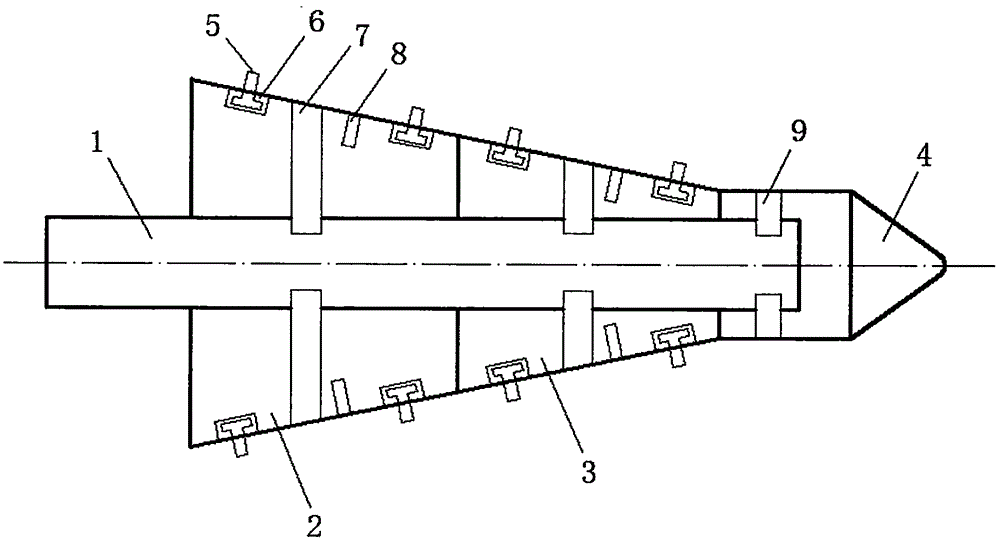

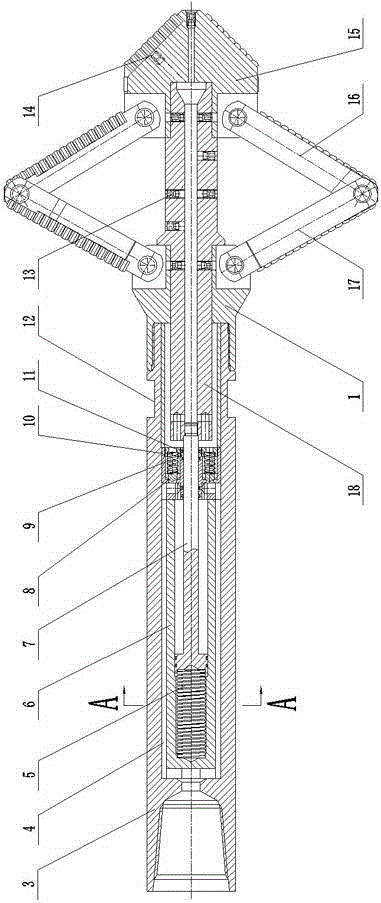

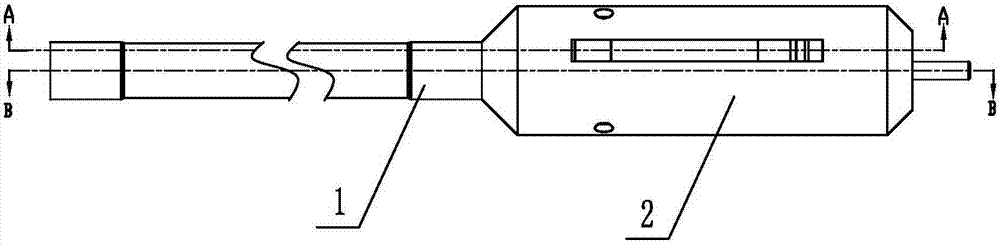

Method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building

ActiveCN103061798AImprove drilling single-hole drainage production capacityImprove extraction efficiencyDrill bitsGas removalDrill siteCoal

The invention relates to a method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building and a hydraulic mechanical drill with the diameter changed and enlarged while drilling. A coal bed bedding long borehole is combined with a cave building technology, and the permeability of low-permeable coal reservoirs and the coal bed borehole extraction capacity are improved. A hole is opened at 1 / 3 coal thickness or 1.5m upwards away from the coal heading floor on the extracting drill site coal wall of an underground coal mine along with the coal bed, the hydraulic mechanical drill with the diameter changed and enlarged while drilling performs cave building on the borehole from inside to outside successively after the borehole reaches the preset depth, and the cave diameters and distances can be calculated through formulas. Coal bed stresses around the cave are released and coal bed prior cracks are widened and lengthened after the caves are completed, tensional and shear failures occur to the coal bed, novel cracks are produced, and accordingly, the coal bed crack connectivity is increased, the permeability is improved, the coal bed methane can be depressurized and desorbed rapidly, the coal bed methane extracting efficiency is improved dramatically, and the coal bed methane extracting time is shortened.

Owner:ZHONGBEI UNIV +1

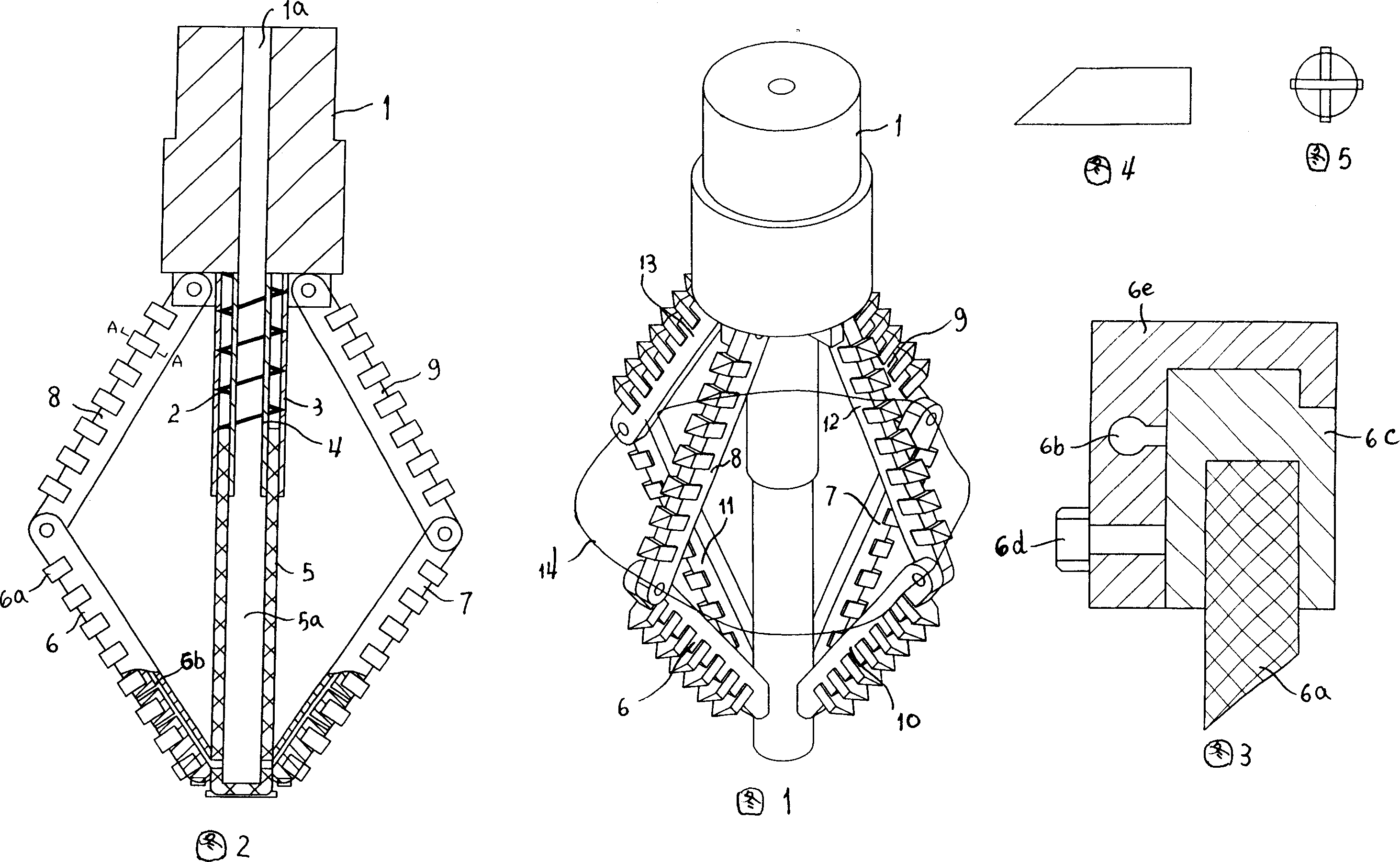

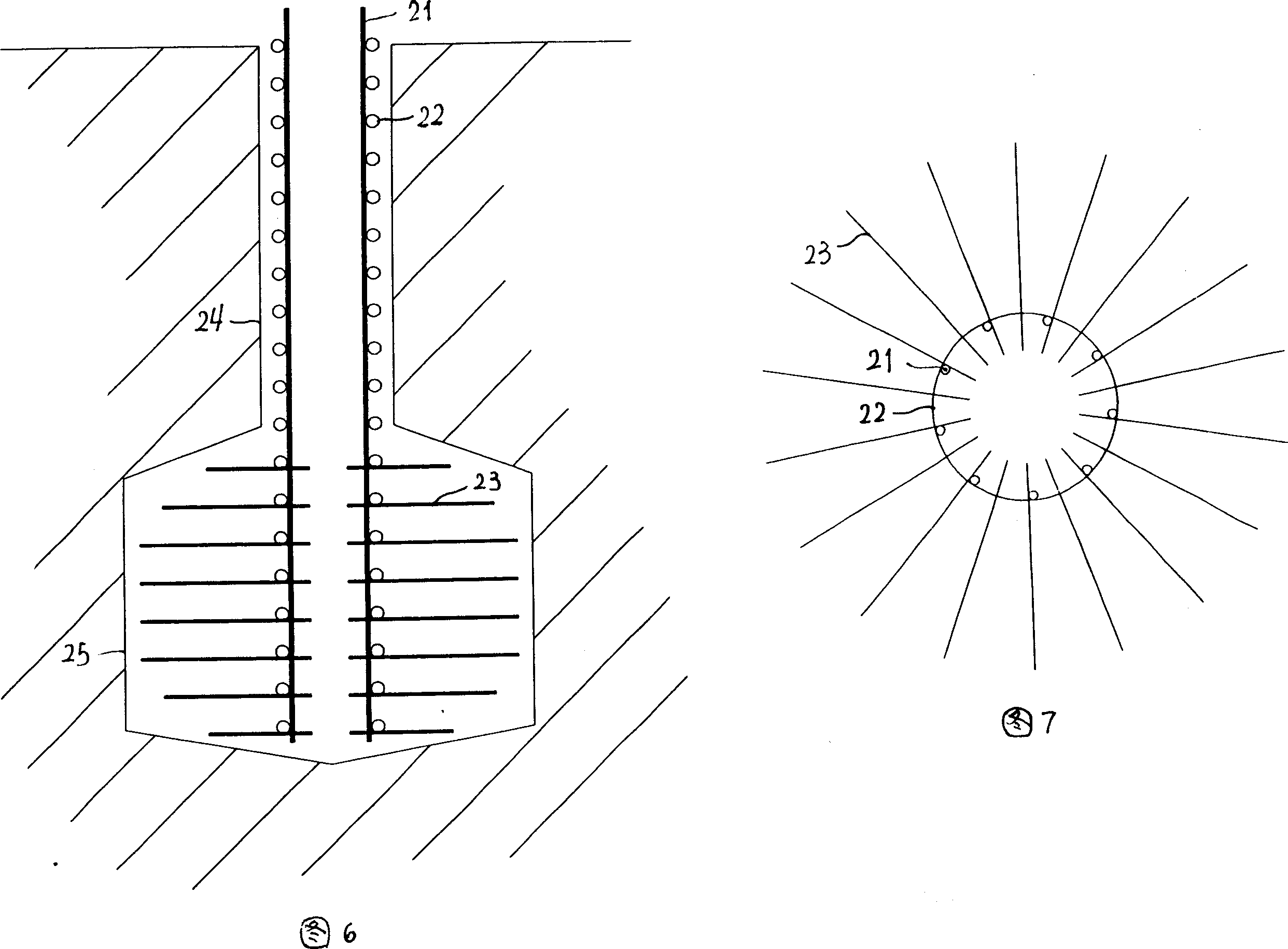

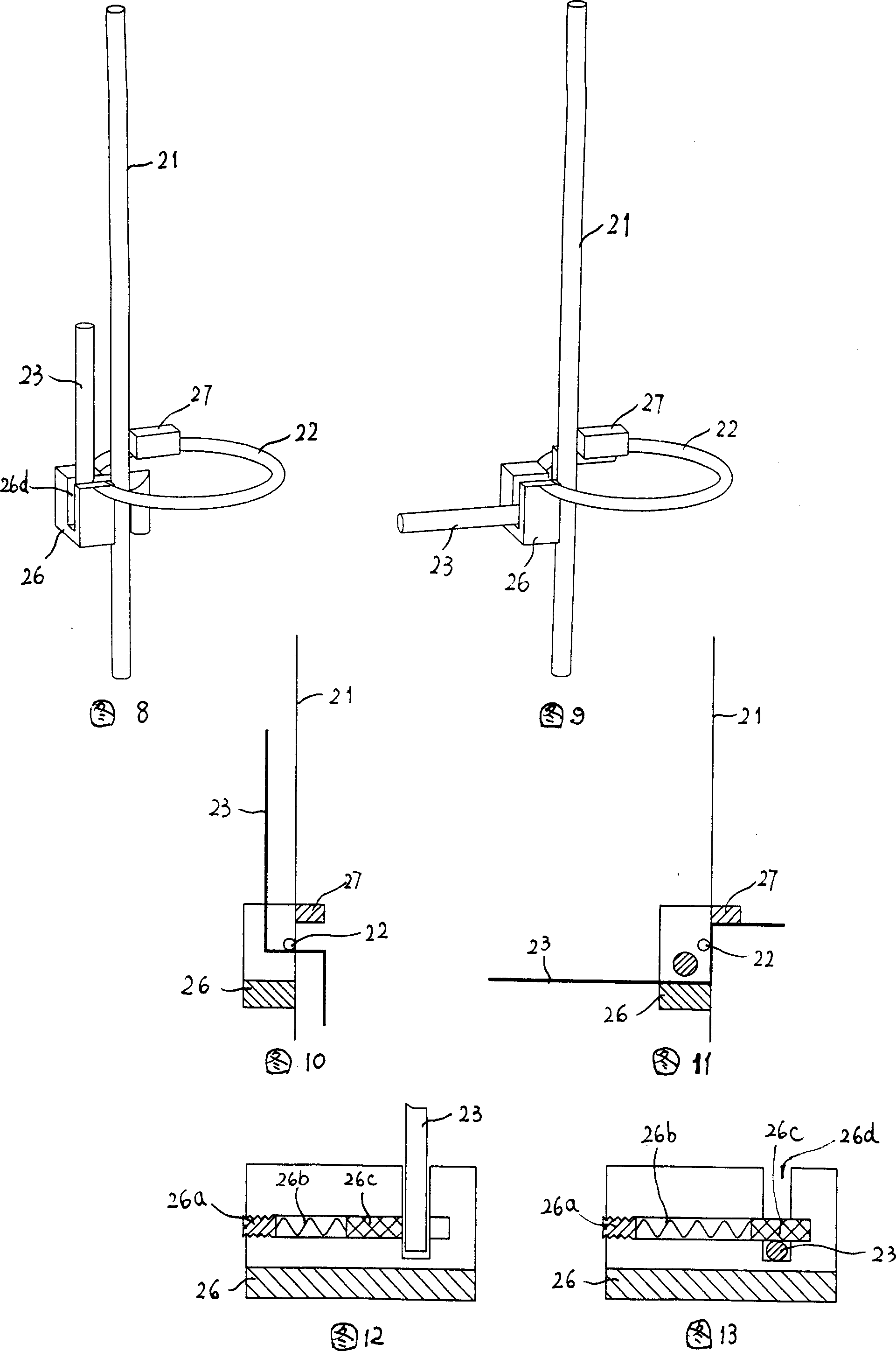

Filling pile construction method for machine drill end oversize reaming and its special apparatus

The present invention discloses construction process and special appliances for forming filling pile with reamed end. The construction process includes the following steps: boring to set depth with conventional pile work borer; reaming with reaming bit to form cylinder or frustum in the pile bottom; setting the reinforcing cage gravitationally or by means of external force; and pouring concrete to form the filling pile. The special appliances include one reaming bit capable of forming oversized pouring end, and one reinforcing cage capable of being drawn in and drawn off. The filling pile with reamed end has great stressed area in the pile bottom, great bearing capacity and high anti-seismic capacity.

Owner:中国安能集团第三工程局有限公司

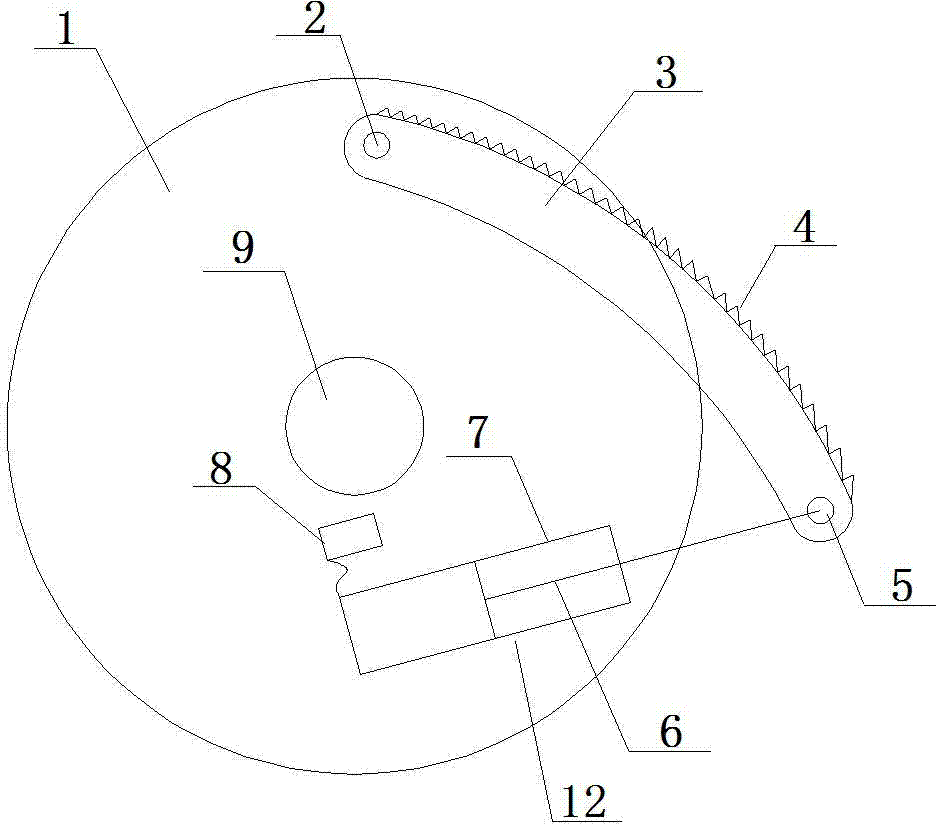

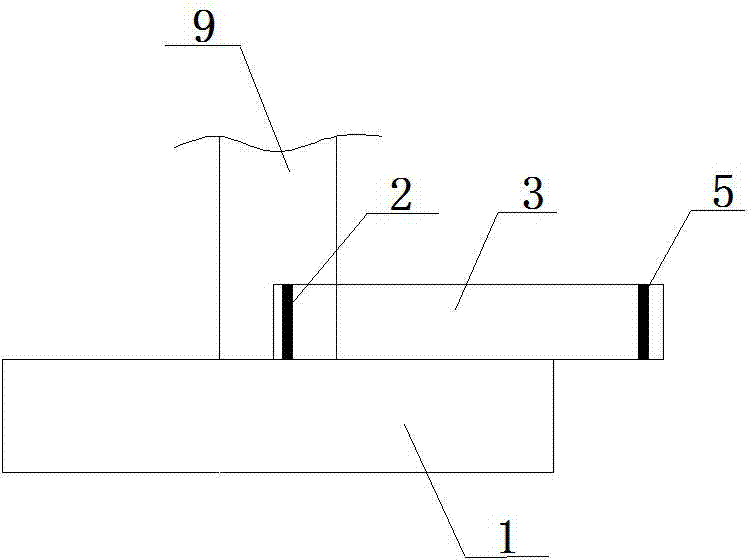

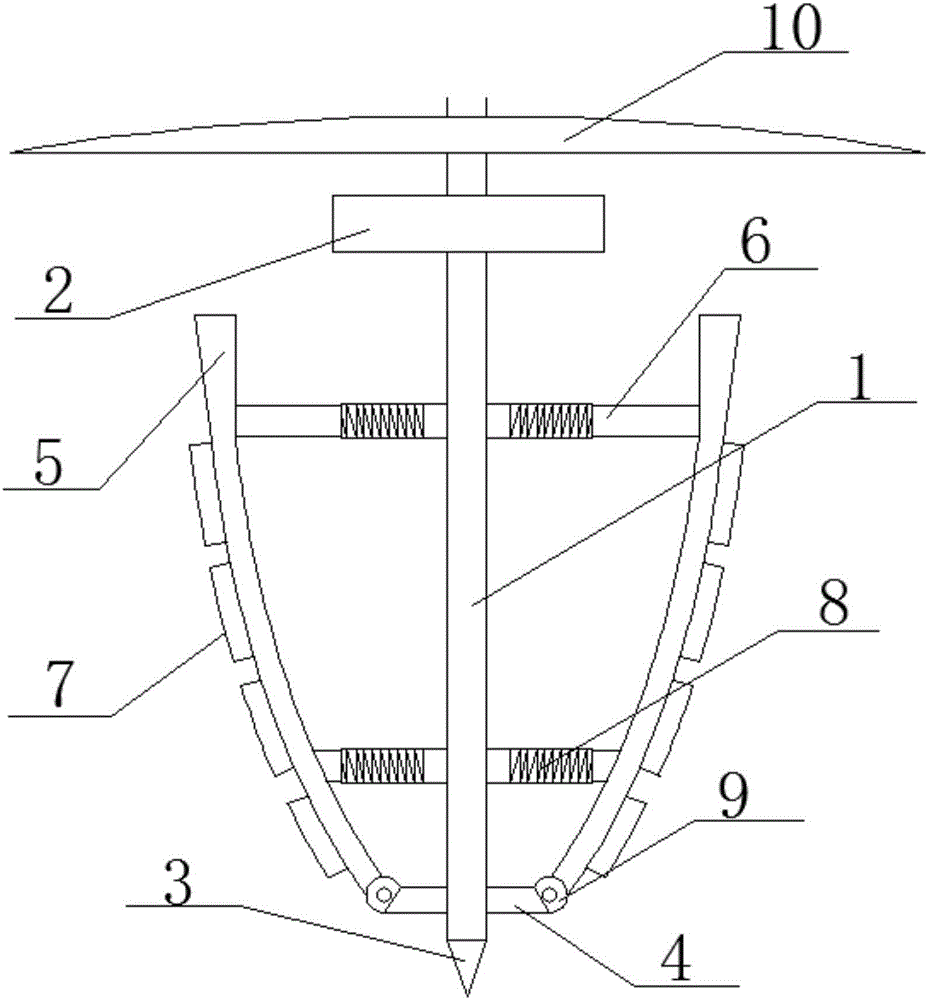

Transverse-broaching device

The invention discloses a transverse-broaching device. The transverse-broaching device is provided with a rotating shaft, and is characterized in that the transverse-broaching device further comprises a rotating table, an earth cutting arm and a telescopic arm, the rotating table is driven by the rotating shaft to rotate, the outer contour of the earth cutting arm is an arc, the fixed end of the earth cutting arm is hinged and fixed to the rotating table through a hinge shaft, the other end of the earth cutting arm is hinged to the telescopic end of the telescopic arm through a hinge shaft, and the fixed end of the telescopic arm is fixedly connected with the rotating table. The transverse-broaching device has the advantages that the transverse-broaching device is simple in structure and capable of carrying out transverse broaching on any position of a pile body, the earth cutting arm can be driven by the telescopic arm to unfold outwards at any time so as to adjust and enlarge radii as required, and the earth cutting arm is stable in stressed structure, not prone to damage and high in broaching efficiency.

Owner:CHINA RAILWAY 24TH BUREAU GRP +1

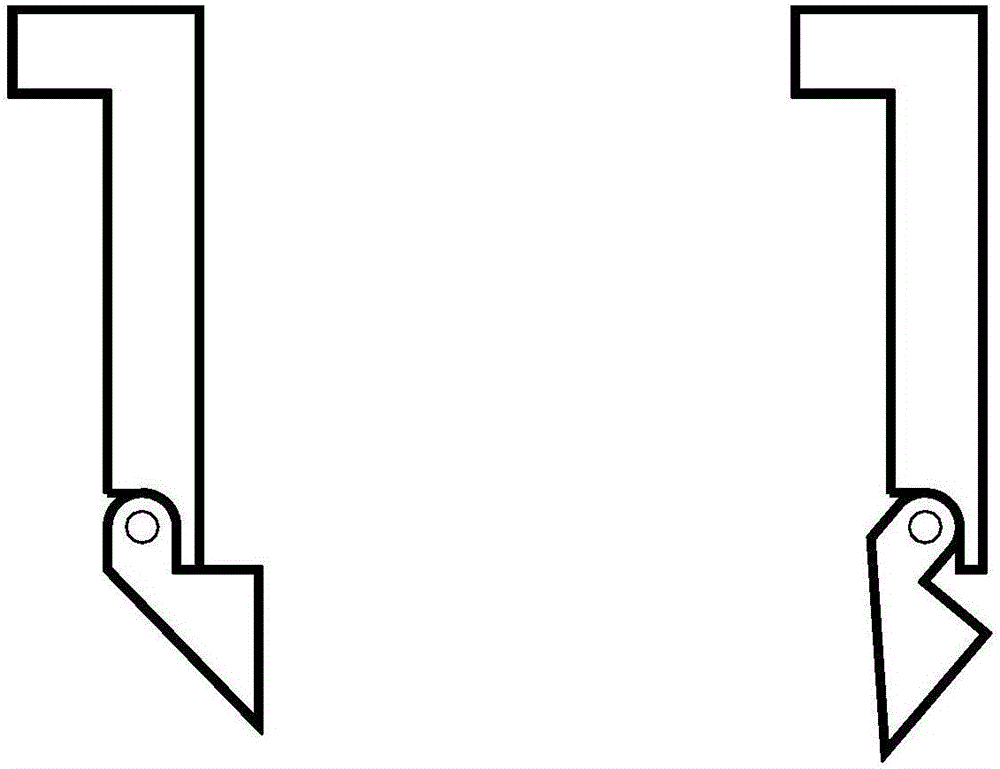

Chambering method of chambering equipment on construction site

InactiveCN106869797AImprove stabilityReduce the reducing rangeDrill bitsDrilling without earth removalEngineeringChamber method

The invention discloses a hole reaming method for hole reaming equipment on a construction site. A connecting rod is gradually lowered under the action of a power mechanism, the connecting arm rotates around the pin shaft 2 and the pin shaft 1, and the scraping mechanism rotates around the connecting pin, so that The connecting arm is horizontal, and the reaming equipment rotates around its axis, so that the scraping teeth scrape the wall of the original pile hole. After the scraping mechanism is expanded to the maximum state, the hole formed by scraping is formed; the connecting rod is gradually raised by the action of the power mechanism. The connecting arm rotates around pin 2 and pin 1, and the scraping mechanism rotates around the connecting pin, so that the connecting arm tilts from the horizontal state, and the scraping mechanism shrinks to the minimum state; the reaming equipment is pulled out along the original pile hole to the hole outside. The diameter of the hole expanded by this reaming method is high in longitudinal depth, and the diameter reduction range at the bottom of the hole and the original diameter of the pile hole is reduced, so that the bearing force after grouting is increased, the stability of the upper building can be maintained, and the reaming efficiency is high. And it can protect the security of the equipment.

Owner:CHINA MCC5 GROUP CORP

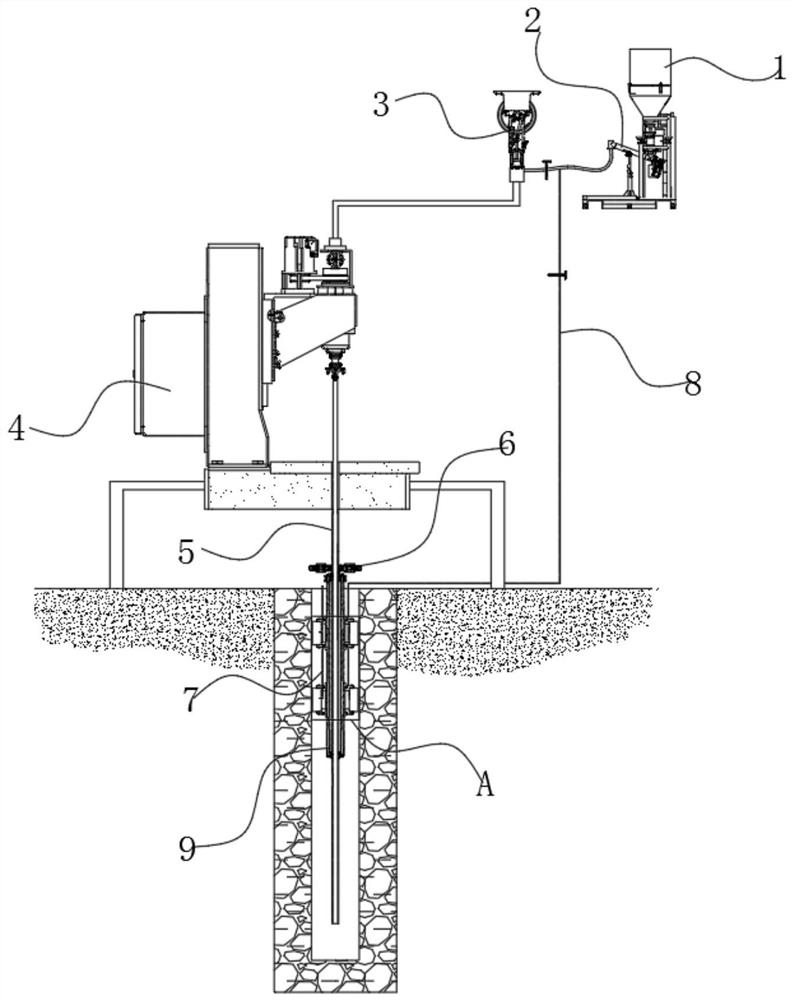

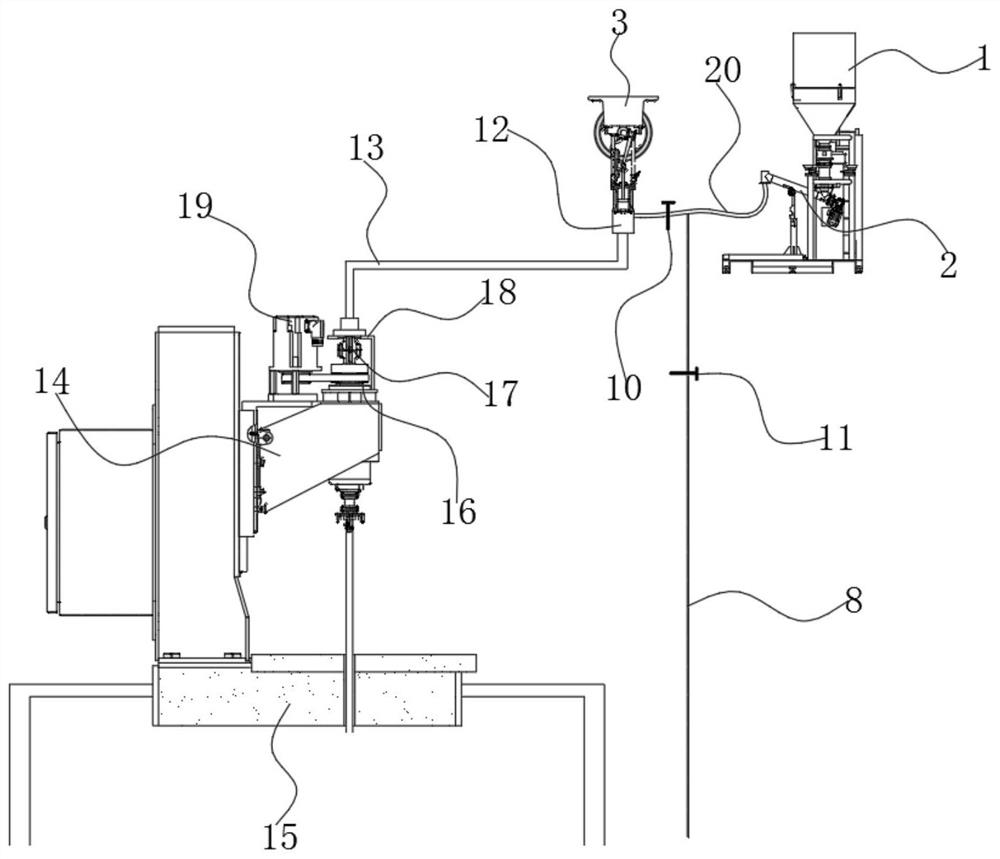

Ground drilling sectional type grouting device

The invention discloses a ground drilling sectional type grouting device. The ground drilling sectional type grouting device comprises a slurry tank, a grouting main pipe, a reaming assembly, a liquidinjection pipe, a low-pressure grouting pipe, an upper supporting and blocking assembly and a lower supporting and blocking assembly, wherein the slurry tank supplies slurry to the grouting main pipeand the low-pressure grouting pipe, the grouting main pipe is rotationally arranged in a centralizing sleeve, and the upper supporting and blocking assembly and the lower supporting and blocking assembly are arranged on the outer circumference of the centralizing sleeve; the reaming assembly is further arranged on the grouting main pipe, and the reaming assembly can be driven to rotate for reaming by driving the grouting main pipe to rotate; after reaming, liquid is injected into the upper supporting and blocking assembly and the lower supporting and blocking assembly through the liquid injection pipe so that the upper supporting and blocking assembly and the lower supporting and blocking assembly can expand and be correspondingly embedded into reamed holes, and the low-pressure groutingpipe can inject slurry into the space between the upper supporting and blocking assembly and the lower supporting and blocking assembly so as to form a sealed hole; and then the grouting main pipe injects slurry into the bottom of the sealed hole, and sectional type grouting is achieved.

Owner:北京大地高科地质勘查有限公司

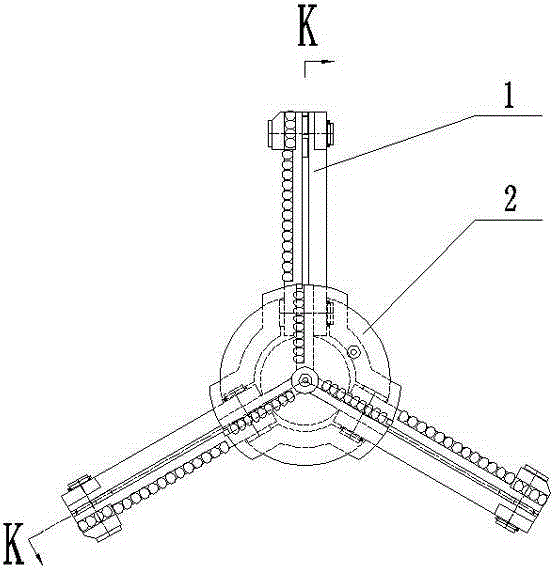

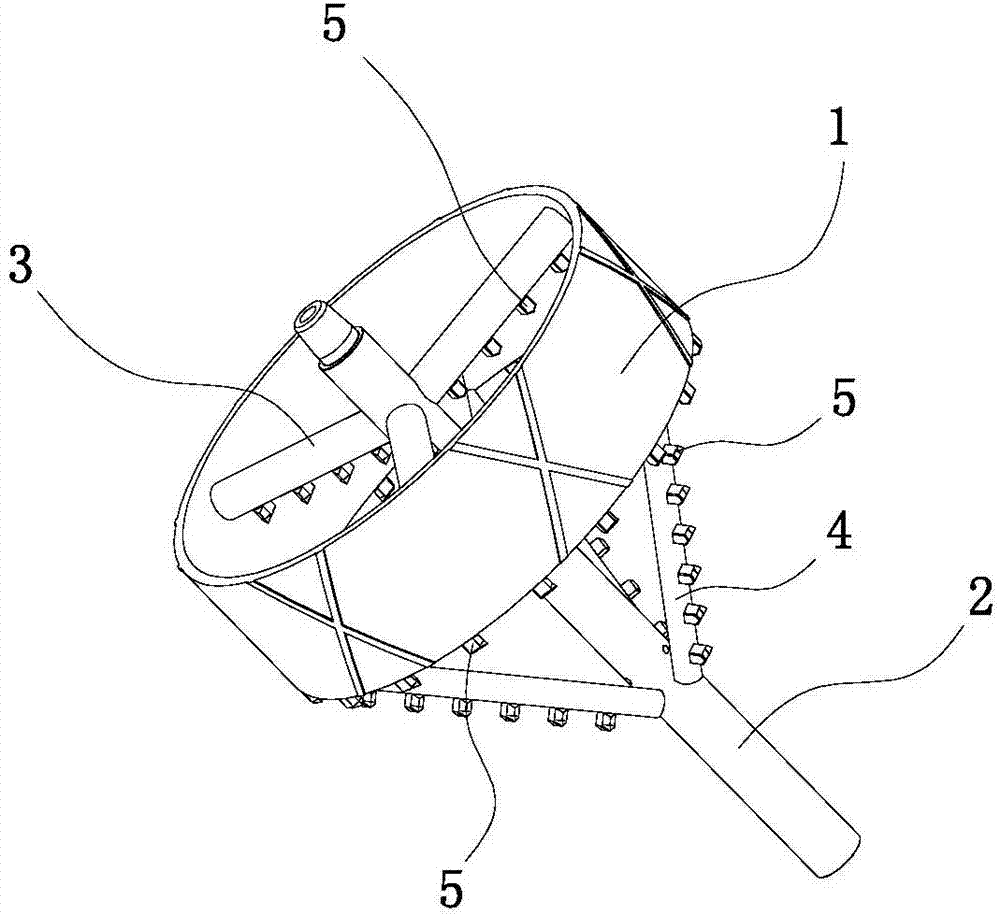

Multifunctional reamer for geological prospecting

InactiveCN106194032AImprove hole reaming efficiencyReaming speed is fastDrilling rodsDrilling casingsReamerEngineering

The invention discloses a multifunctional reamer for geological prospecting. The reamer comprises a drill pipe, a drill bit, three spiral reamer plates and a fixing band; an impactor is fixed on the upper portion of the drill pipe, the fixing band is fixed on the lower portion, close to the drill bit, of the drill pipe, three rotating shafts are uniformly fixed on the edge of the fixing band, each spiral reamer plate is rotatably connected with the fixing band through the corresponding rotating shaft, the portions, close to the fixing band, of the upper portion and the lower portion of the internal surface of each spiral reamer plate are connected with the drill pipe through telescopic cross rods, a compression spring is installed in each telescopic cross rod, protruding blocks are uniformly welded to the outer surface of each spiral reamer plate, and a dust cover is rotatably connected to the portion, above the impactor, of the drill pipe through a thread. According to the multifunctional reamer for geological prospecting, the structure is simple, the reaming effect is rapid and significant, time and labor are saved, the functions of achieving reaming and discharging mud and gravel to prevent blocking and dust are achieved simultaneously, and the multifunctional reamer is worthy of popularization.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

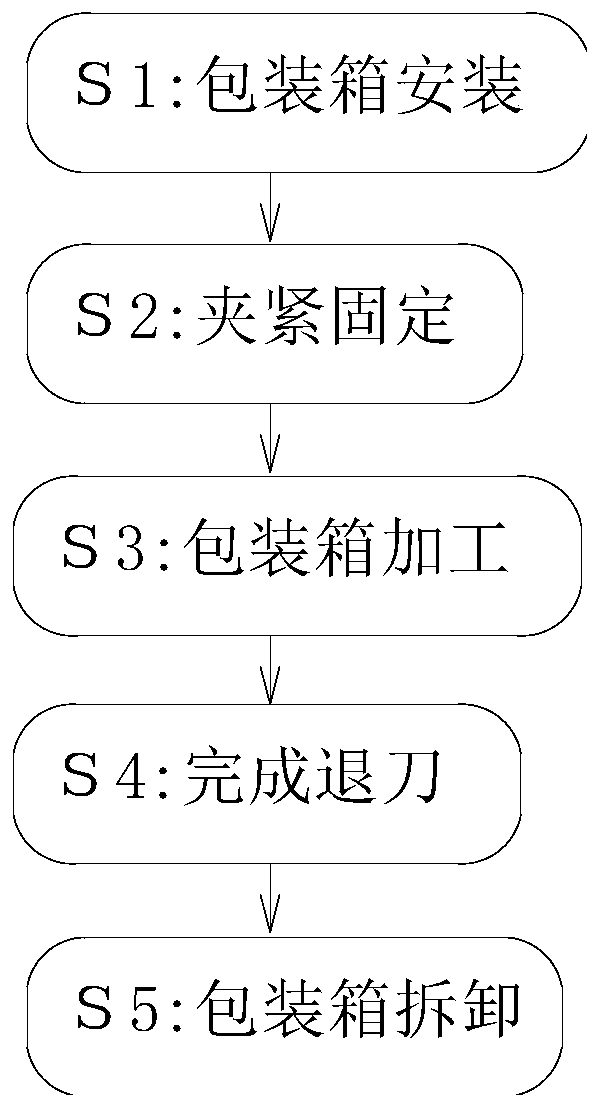

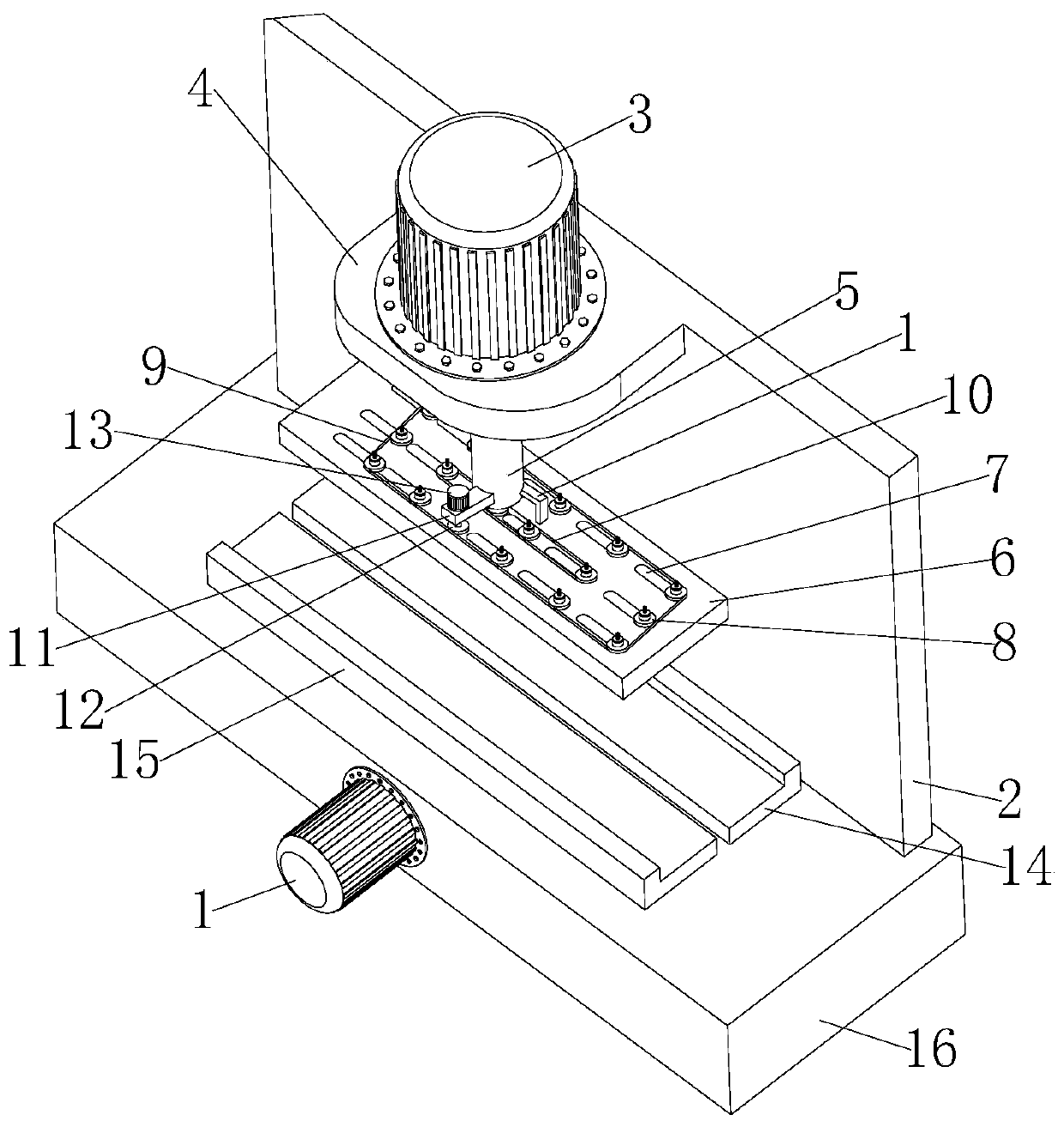

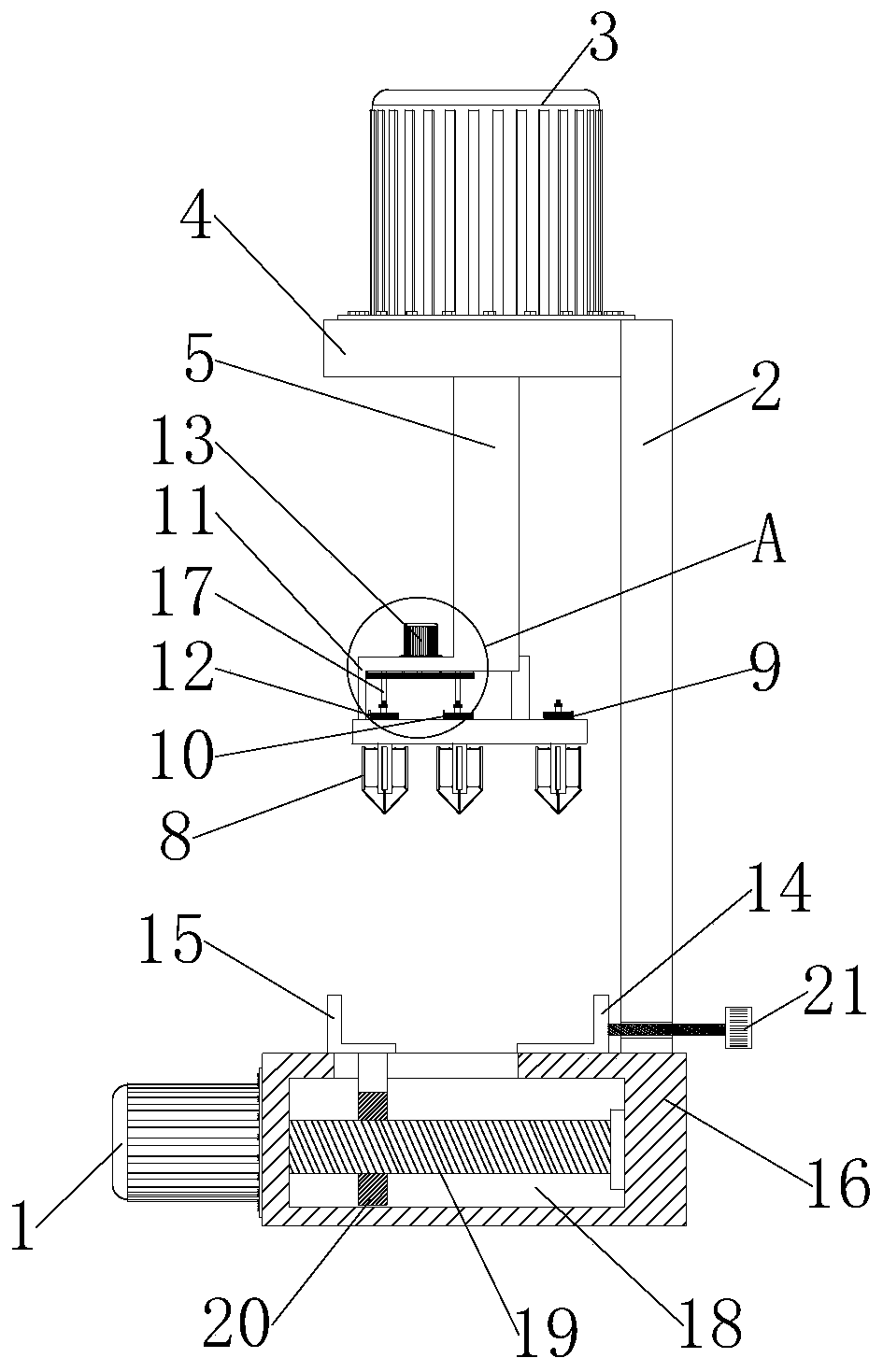

Fresh product foam plastic packaging box manufacturing and processing technology

ActiveCN111516046AImprove hole reaming efficiencyEasy to reamMetal working apparatusPlastic packagingIndustrial engineering

The invention discloses a fresh product foam plastic packaging box manufacturing and processing technology, and relates to the technical field of plastic foam processing. The fresh product foam plastic packaging box manufacturing and processing technology adopts a fresh product foam plastic packaging box manufacturing and processing device for cooperation. The fresh product foam plastic packagingbox manufacturing and processing device includes a bottom support plate which is horizontally fixed to the ground, and the top end of the bottom support plate is provided with side support ribbed plates vertically fixed to the top end of the bottom support plate. Several reaming cutters are engaged and driven through a first toothed belt and a second toothed belt and rotate synchronously in the same rotation direction, a base is vertically raised and lowered above the bottom support plate through an electric push rod, thus, the reaming cutters extend into slotted holes of a foam plastic packaging box and ream the slotted holes of the foam plastic packaging box, and the slotted holes of the foam plastic packaging box are reamed into slotted holes applicable to holding fresh fruits.

Owner:湖南君志达保温材料有限公司

Bridge ultra-large diameter pile foundation chambering construction process

The invention relates to the technical field of pile foundation construction in extra-large bridge engineering, in particular to a bridge ultra-large diameter pile foundation chambering construction process. In order to achieve the purpose, according to the technical scheme, the bridge ultra-large diameter pile foundation chambering construction process comprises the steps that firstly, a rotary drilling rig is adopted for rapidly constructing and completing a pile foundation with 1 / 2 of a diameter, and then large pile foundation equipment is used for constructing and forming holes according to the diameter of the bridge super-large-diameter pile foundation. The bridge ultra-large diameter pile foundation chambering construction process Simple method disclosed by the invention is simple instructure, scientific in design and convenient to use, firstly, the rotary drilling rig is adopted for quickly constructing the pile foundation with 1 / 2 of the diameter, then the large pile foundation equipment is used for constructing and forming the hole according to the diameter of the super-large pile foundation of a bridge, reaming efficiency is improved, potential safety hazards are reduced, construction progress and safety requirements are effectively met, meanwhile, requirements of construction equipment can be lowered, and construction cost is reduced.

Owner:云南路桥股份有限公司

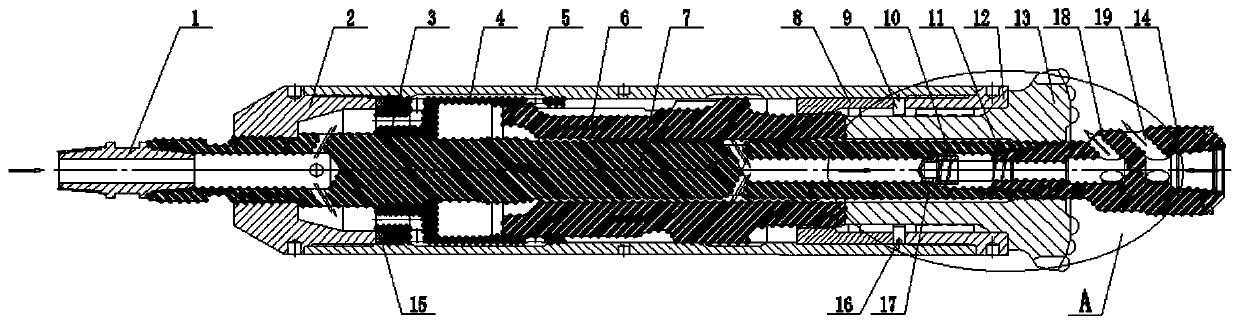

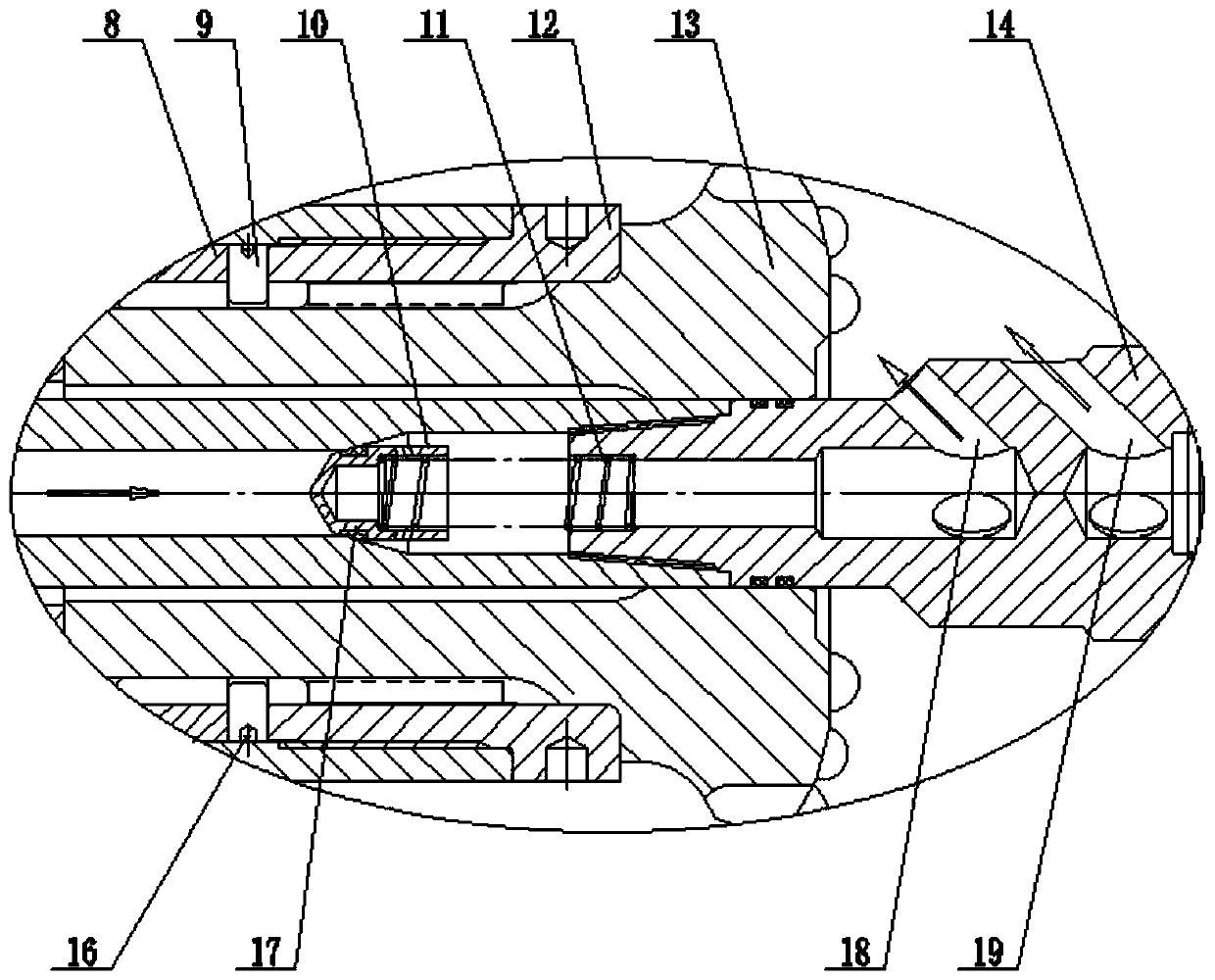

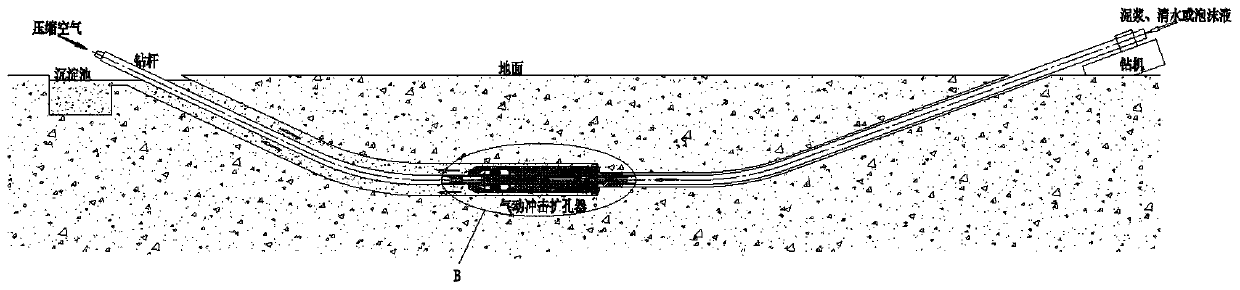

Pneumatic impact reamer and reaming construction process

PendingCN110410010AIncrease carrying capacityImprove hole cleaning effectDrill bitsDrilling rodsUpper jointEngineering

The invention discloses a pneumatic impact reamer and a reaming construction process. The pneumatic impact reamer comprises an upper joint, an upper end cover, a central spindle, an outer cylinder, apunch hammer and a drill. The upper joint belongs to a switching buckle type upper joint. The upper joint is connected with the central spindle. The upper end cover is in threaded connection with thecentral spindle and the outer cylinder. A supporting sleeve and a bushing are sleeved with the outer cylinder in sequence. The punch hammer is sleeved with the bushing, the outer cylinder and a spacersleeve. The drill is fixedly mounted in the outer cylinder through a spline sleeve. A centralizing joint is arranged at the end, far away from the upper joint, of the drill. The centralizing joint isprovided with a plurality of air guide holes and liquid guide holes. According to the pneumatic impact reamer and the reaming construction process provided by the invention, compared with a bundled impact reamer, the pneumatic impact reamer is simpler in structure, free of welded components, integrally more resistant to impact and more reliable in operation; the pneumatic impact reamer is much larger than the bundled impact reamer through the effective impacting mass of the punch hammer, can reach higher impacting energy and has much higher rock breaking efficiency.

Owner:九江廊威工程机械有限公司

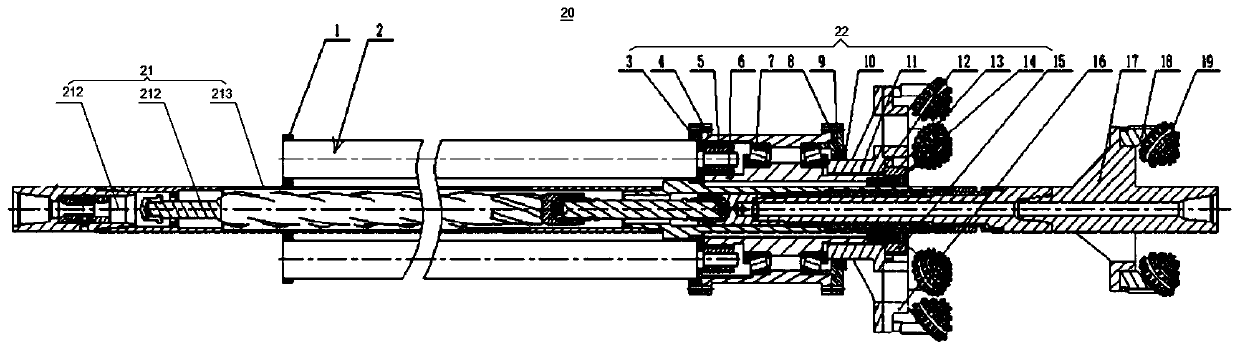

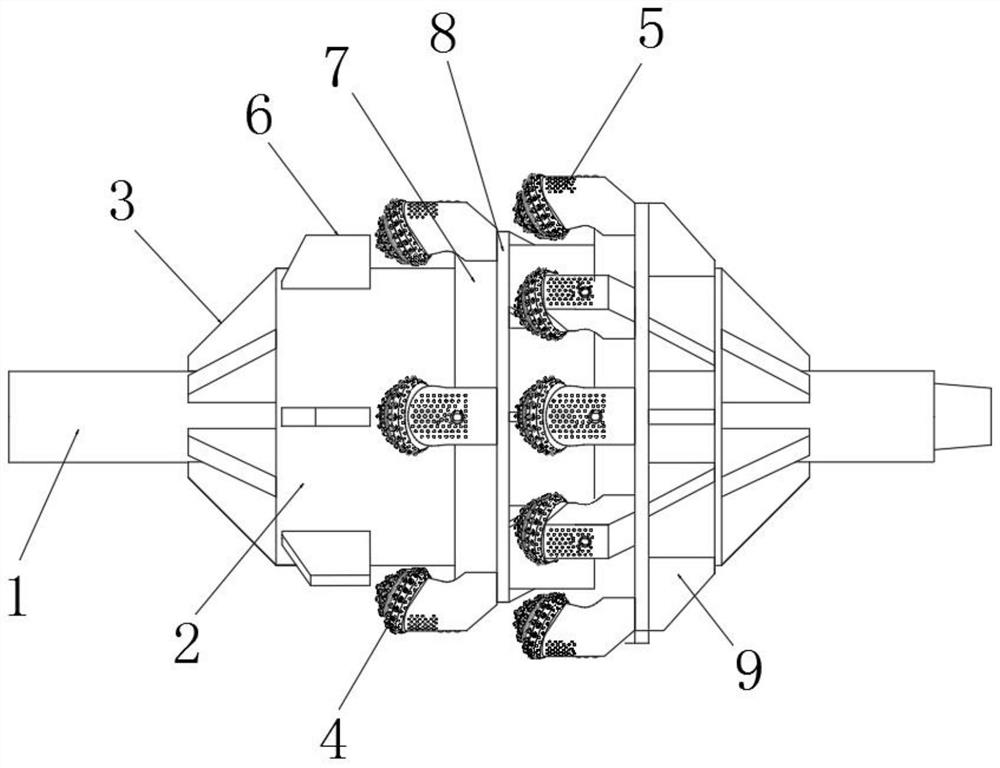

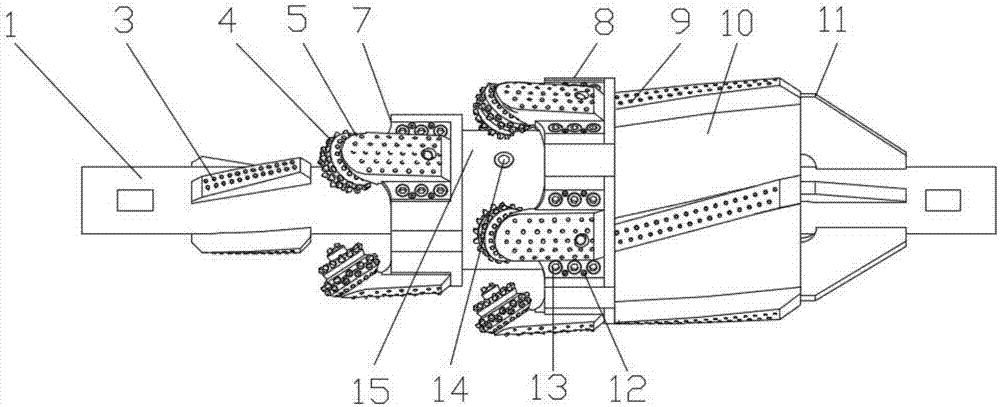

Two-stage dynamic hole expanding drilling tool

PendingCN110439466AImprove hole reaming efficiencyShorten construction timeDirectional drillingBorehole drivesDrive shaftEngineering

The invention discloses a two-stage dynamic hole expanding drilling tool, and relates to the technical field of horizontal directional drilling. The two-stage dynamic hole expanding drilling tool includes a screw motor assembly, a submersible motor assembly, a reducer, a primary cutterhead assembly and a secondary cutterhead assembly, the screw motor assembly includes a screw motor shell, a screwmotor and a transmission shaft, and the reducer includes a reducer shell, a gear set, a gear shaft, a first bearing set, an output spline sleeve and a second bearing set. The primary cutterhead assembly and the secondary cutterhead assembly are adopted, the primary cutterhead assembly and the secondary cutterhead assembly are powered by the screw motor assembly and the submersible motor assembly correspondingly, the hole expanding efficiency of the drilling tool is improved by two power sources, the single-pass hole expanding diameter of the double cutterhead plate assemblies is increased, theconstruction time is shortened, and the construction cost is saved. Hereby the technical problems that the single-pass hole expanding diameter is small due to the limitation of drilling torque in theprocess of water directional drilling in the prior art and many times of hole expanding need to be conducted to reach the expected borehole diameter are solved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hole drilling and expanding integrated device

InactiveCN105756561AImprove hole reaming efficiencyReduce construction costsDrill bitsDrilling machines and methodsDrive shaftDrill bit

Owner:WUHAN UNIV OF SCI & TECH

Combined type reaming method and device

PendingCN111779453APromote fragmentationIncreased Stretch StiffnessDrill bitsDrilling rodsMining engineeringStructural engineering

The invention relates to a combined type reaming method and device in the technical field of coal mine drilling. On the basis of common drilling, flexible combined reaming is conducted in the mode that hydraulic reaming and mechanical flexible reaming are combined through the combined type reaming device. The combined type reaming device comprises a drill rod, a hydraulic cutting head and a flexible reaming drill bit, wherein the flexible reaming drill bit comprises a reaming base and a flail chain or a flail cable; the flail chain or the flail cable is made of high-strength abrasion-resistantmetal materials; a high-pressure hose is arranged in the flail chain or the flail cable in a penetrating mode; and a high-pressure water jet orifice is formed in the end, away from the reaming base,of the high-pressure hose. According to the combined type reaming method and device, coal mine gas extraction drilling is rapidly and efficiently reamed in the mode that hydraulic cutting and flexiblemechanical reaming are combined, and the device is simple in structure, high in reliability, good in abrasion resistance and stability, capable of facilitating drill retreating and suitable for application and popularization.

Owner:HENAN POLYTECHNIC UNIV

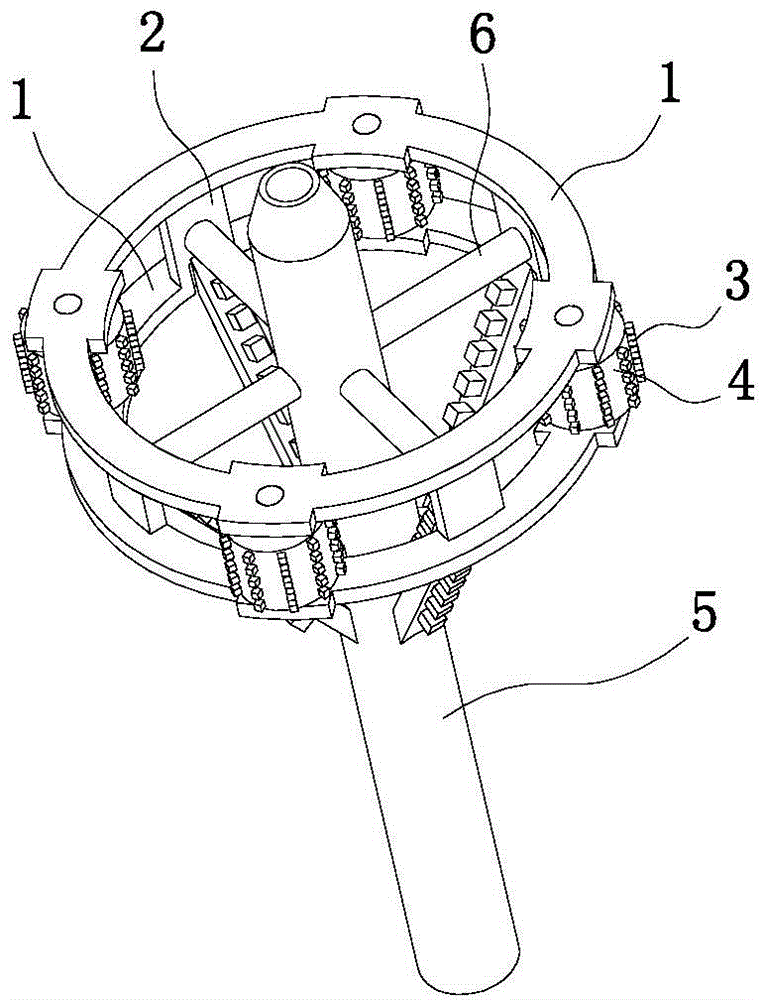

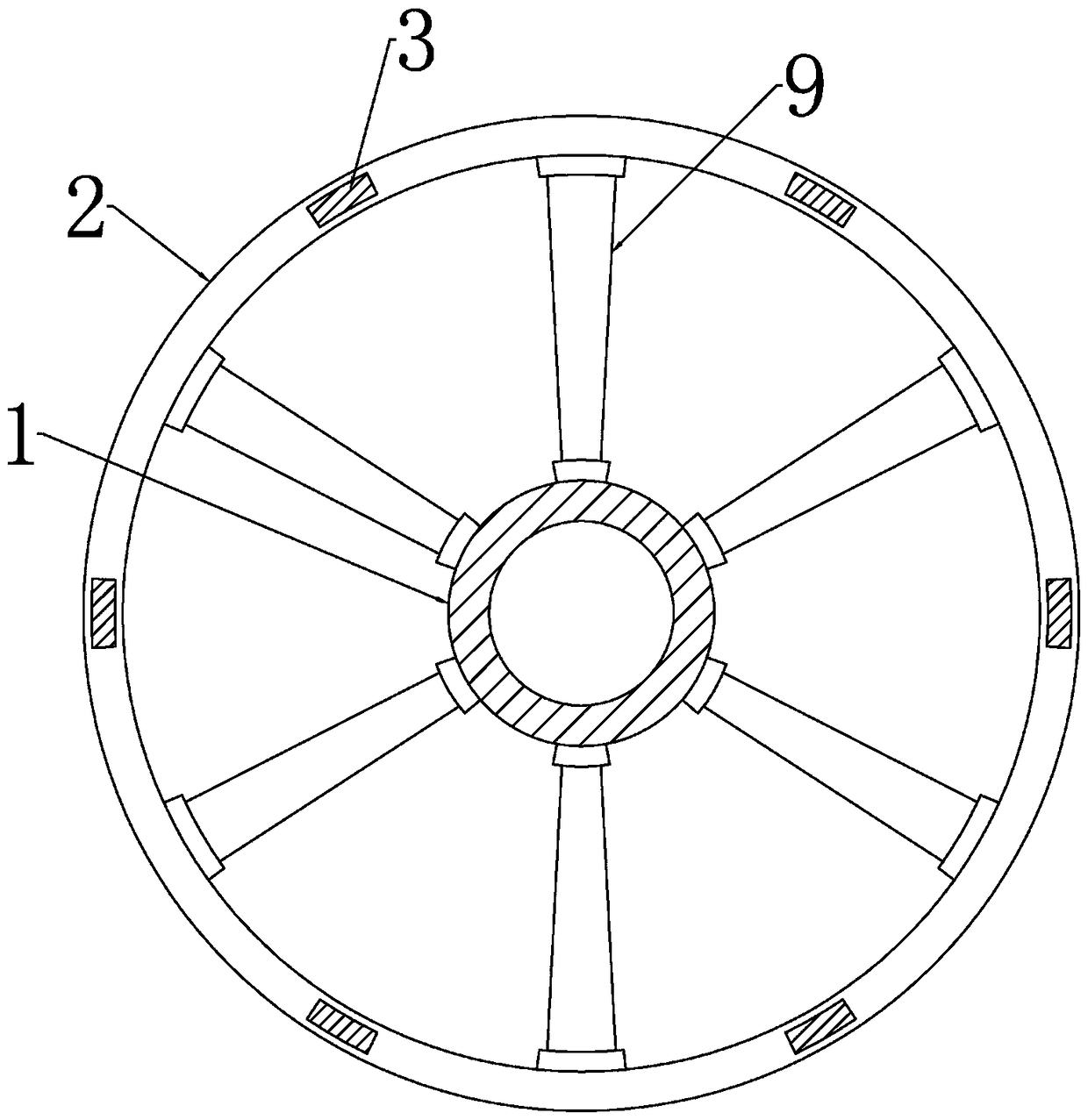

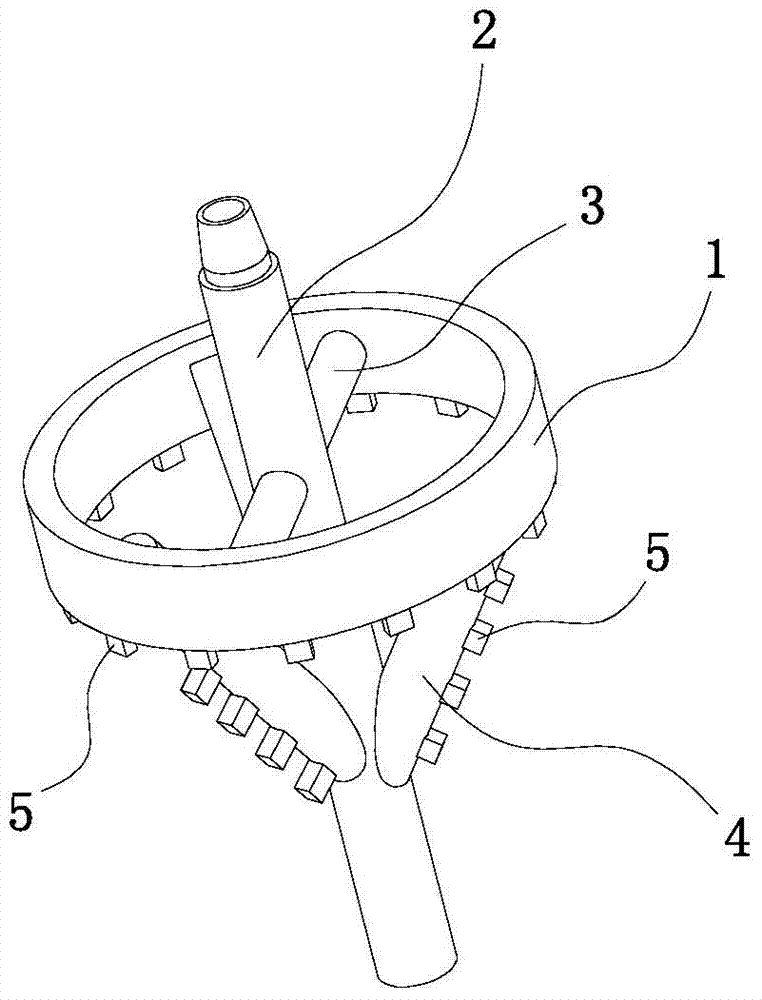

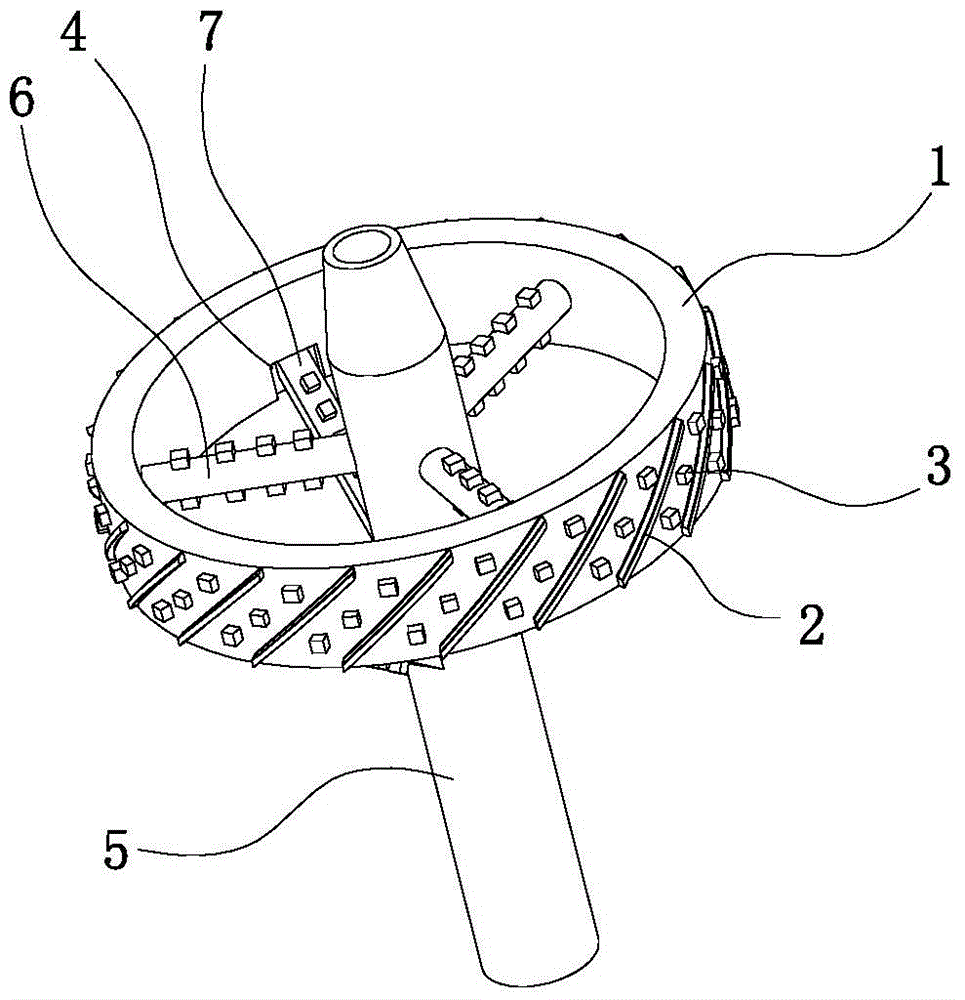

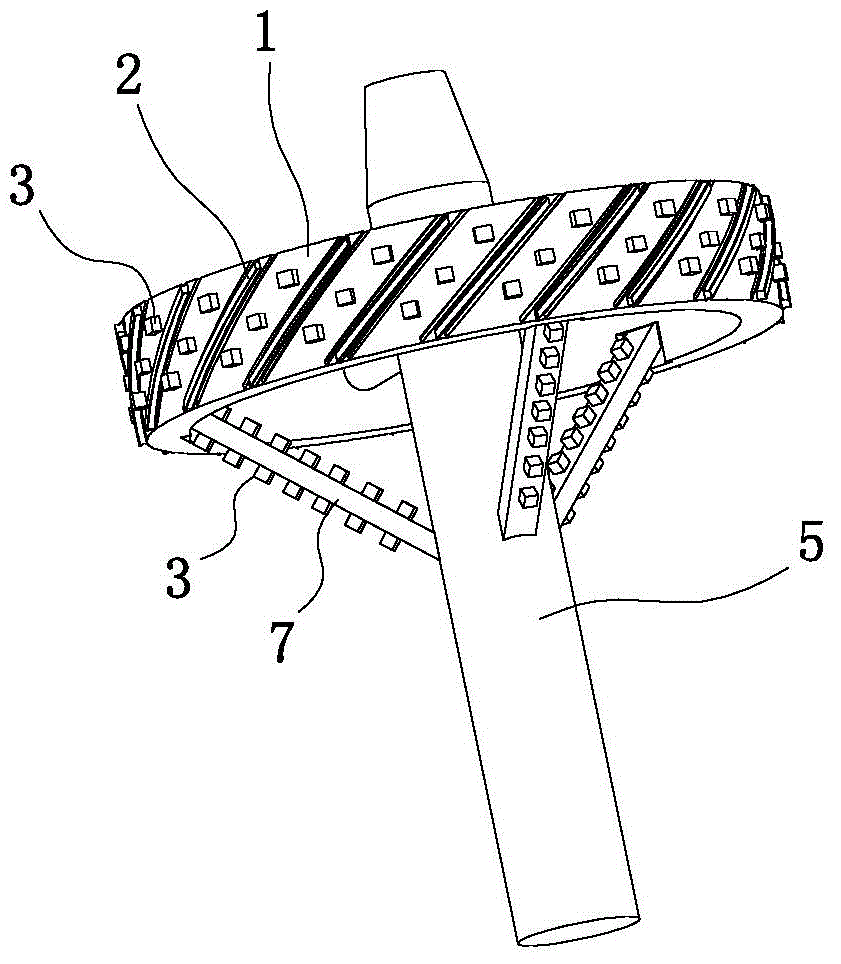

Novel reamer

ActiveCN104563881AIncrease frictionImprove hole reaming efficiencyDrilling machines and methodsEngineeringReamer

The invention relates to a novel reamer. The novel reamer comprises a waistband body, the center of the waistband body is fixedly connected with a drill rod by the aid of a crossbar, a plurality of reaming rods are fixedly connected between the waistband body and the drill rod and are symmetrically arranged relative to the center of the drill rod, the drill rod, the reaming rods and the crossbar are of hollow structures, and the waistband body comprises two waistband rings arranged at intervals from top to bottom. A plurality of support plates are connected between the inner side walls of the lower ends of the support plates are provided with welding grooves, the upper ends of the reaming rods are fixedly welded in the welding grooves, and the sections of the reaming rods are of square structures. A plurality of reamed hole drums symmetrically arranged relative to the center of the waistband body are rotationally connected between the upper and lower waistband rings, alloy blocks are uniformly distributed on the outer walls of the reamed hole drums as well as the outer walls of the reaming rods.

Owner:临沭县济才人力资源服务有限公司

Drilling device for drilled grouting pile

InactiveCN108533182AEasy to assemble and disassembleImprove cutting performanceEarth drilling toolsDrill bitsEngineeringDrill bit

The invention discloses a drilling device for a drilled grouting pile. The drilling device comprises a hollow drill rod, a trapezoidal reaming rack and a drill bit, wherein a hollow screw is arrangedat the upper end of the drill bit; internal threads are arranged at the lower end of the hollow drill rod; external threads of the hollow screw are matched with the internal threads of the hollow drill bit; the drill bit is screwed at the lower end of the hollow drill bit; the trapezoidal reaming rack is of a structure with a large upper end and a small lower end and fixedly sleeves the hollow drill bit above the drill bit; a plurality of tilt blades are arranged on the inclined plane of the trapezoidal reaming rack in the height direction of the inclined plane; a spray head is arranged on theinclined plane between two adjacent tilt blades; an infusion chamber communicated with the spray heads is arranged inside the trapezoidal reaming rack; a drill rod side hole communicated with the infusion chamber is formed in the side wall of the hollow drill rod. According to the drilling device disclosed by the invention, the drill bit is in threaded connection with the hollow drill rod, so asto facilitate disassembly and assembly; the trapezoidal reaming rack is arranged, and the tilt blades and the spray heads are arranged on the incline plane of the trapezoidal reaming rack, so that reaming and flushing can be simultaneously realized, and reaming efficiency is improved.

Owner:李晓

Pipe expander

InactiveCN107127265AEasy to adjustImprove efficiencyMetal-working feeding devicesPositioning devicesEngineeringIntermediate pressure

The invention discloses a pipe expander, which includes a clamp, a bow frame, a top pressure screw, a pipe expansion cone and a handle. The bow frame is installed on both sides of the fixture, and a top pressure screw is installed on the bow frame. Cone head, the upper end of the top pressure screw protrudes from the bow frame to connect with the handle, a row of middle holes for clamping the metal pipe is set in the middle of the fixture, and a fine-tuning mechanism is set at the connection between the bow frame and the fixture for fine-tuning the top of the bow frame The concentricity of the pressure screw and the middle hole. The pipe expander of the present invention uses the top pressure screw to press and expand the cone to expand the metal pipe clamped in the center hole. In order to adjust the position of the pipe expander, the concentricity between the top pressure screw and the middle hole is ensured. Set the fine-tuning mechanism at the connection between the bow frame and the fixture. Before processing, first press the expander cone to the upper edge of the metal pipe to correct the concentricity of the top pressure screw and the middle hole. When there is a deviation, adjust the fine-tuning mechanism until The top pressure screw is concentric with the middle hole.

Owner:句容新禾五金电器有限公司

Process method for treating and thinning middle-high voltage anode aluminum foil

ActiveCN112863879AAvoid uneven thicknessLarge specific surface areaElectrolytic capacitorsO-Phosphoric AcidHigh voltage

The invention discloses a process method for treating and thinning a middle-high voltage anode aluminum foil. The method comprises the steps of pretreatment, first-stage hole forming corrosion, middle treatment corrosion, second-stage hole expanding corrosion, post-treatment and the like, and comprises the following steps: soaking aluminum foil in a mixed solution of hydrochloric acid and sulfuric acid, applying current to the mixed solution of hydrochloric acid and sulfuric acid to carry out direct-current hole-forming corrosion and carry out first-stage direct-current hole-forming corrosion, soaking the aluminum foil in a mixed solution of silicon hydrofluoric acid and phosphoric acid, then applying current to the aluminum foil in a nitric acid solution to carry out second-stage direct-current hole-forming corrosion, repeating the processes of intermediate treatment corrosion and second-stage hole-forming corrosion many times, soaking the aluminum foil in the nitric acid solution for post-treatment, finally cleaning the aluminum foil with tap water, cleaning the aluminum foil with pure water, and then drying and rolling the aluminum foil to obtain the corroded foil. The method can effectively remove the porous layer on the surface of the finished corrosion foil, reduces the residual thickness of the corrosion foil, does not reduce the specific volume, and improves the specific volume of the corrosion foil in unit thickness.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

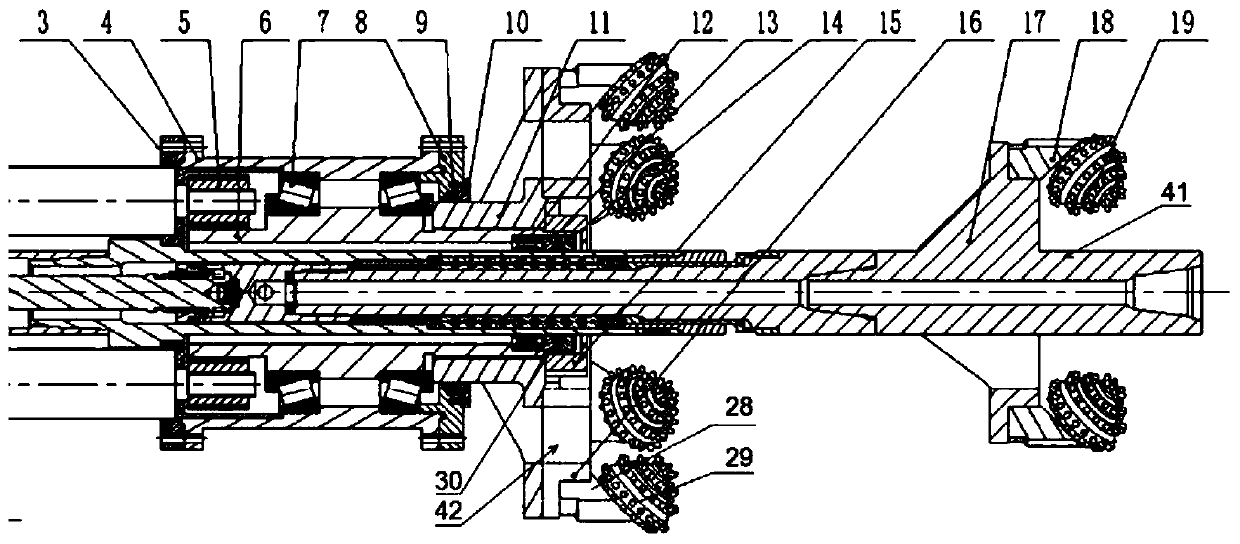

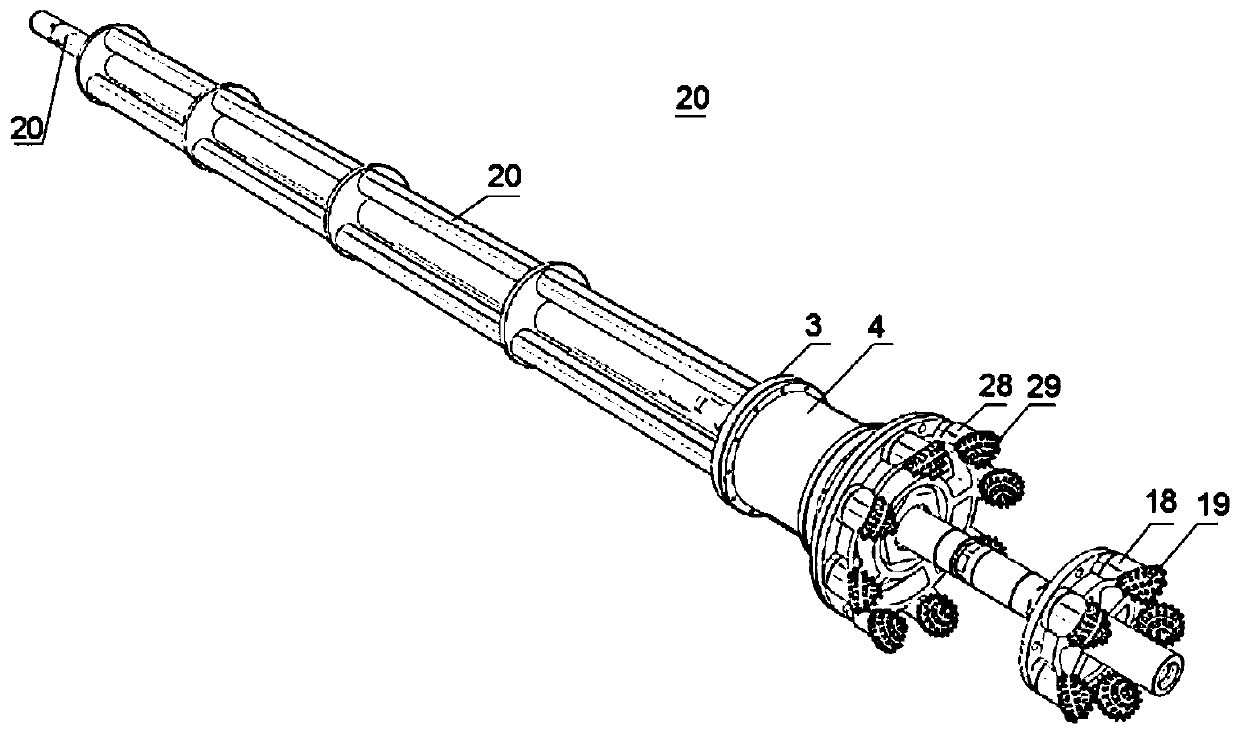

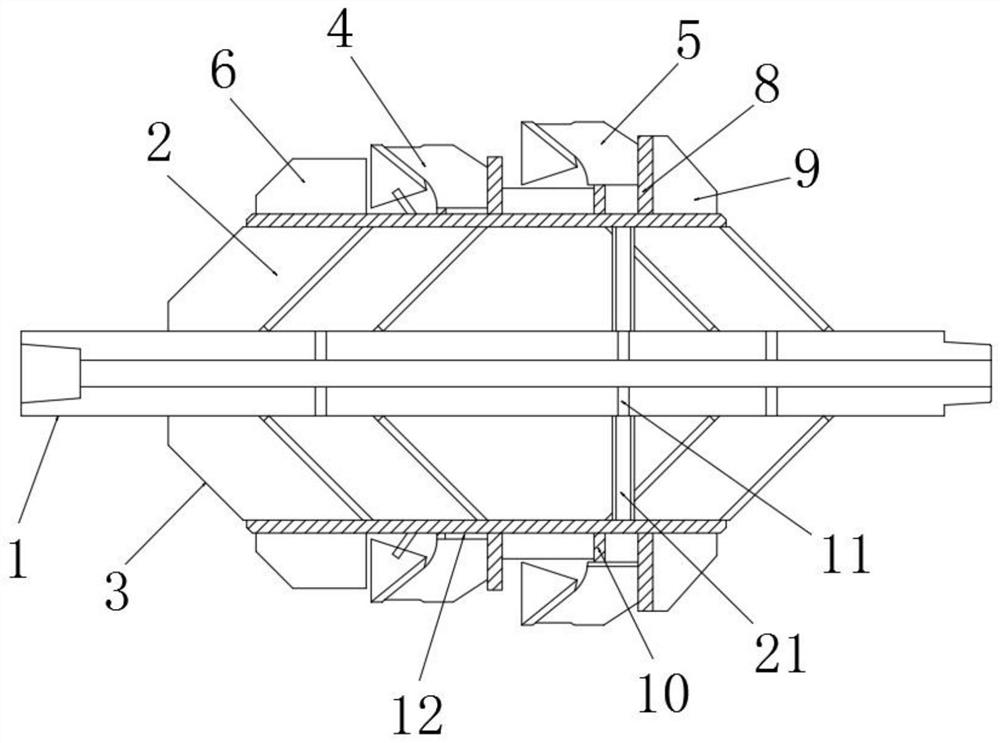

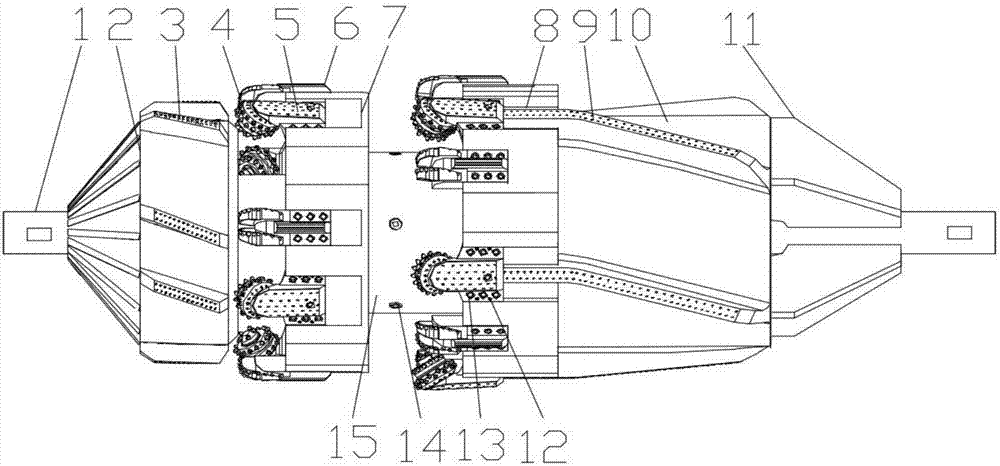

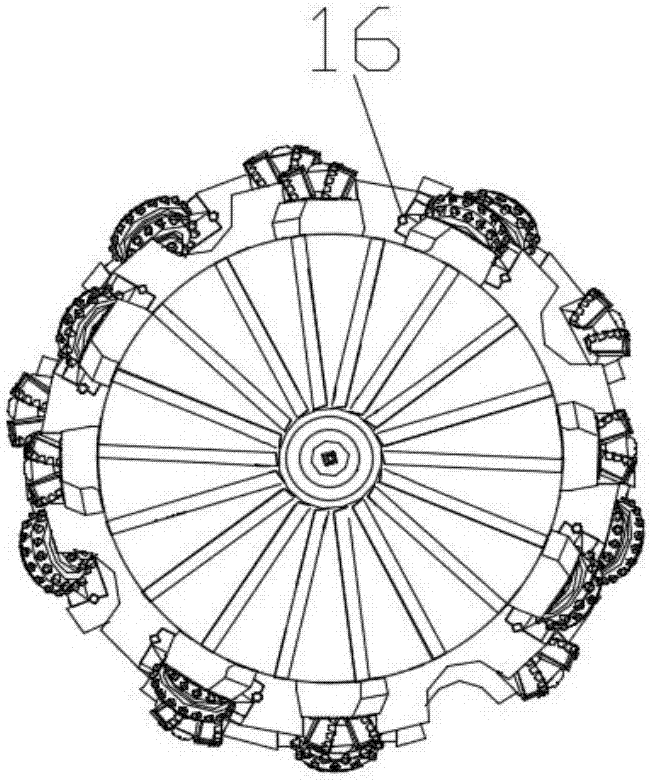

Centralizing and cutting integrated two-stage cone reamer

PendingCN113279696AEffective combinationReduce weightDrill bitsDrilling rodsEngineeringStructural engineering

The invention discloses a centralizing and cutting integrated two-stage cone reamer, and relates to the technical field of horizontal directional drilling construction rock reaming. The centralizing and cutting integrated two-stage cone reamer comprises a reamer body; a mandrel is arranged at the axis of the reamer body; a first-stage centralizing cone set and a second-stage cutting cone set are arranged on the reamer body; the first-stage centralizing cone set is used for centralizing; the second-stage cutting cone set is used for cutting; and each of the first-stage centralizing cone set and the second-stage cutting cone set consists of a plurality of cones. Through the arrangement of the first-stage centralizing cone set and the second-stage cutting cone set, reaming cutting can be achieved, the reamer can be centralized, effective combination of the reamer and a centralizer is achieved, the weight of a reaming drilling tool is reduced, the drilling torque is reduced, and the footage drilling efficiency is improved; and according to the design, the centralizing cones has a cutting capacity and can smoothly enter guiding holes in a stratum with both a soft part and a hard part, and the design has the advantages of light weight, compact structure and high reaming efficiency.

Owner:天津博为中天钻具有限公司

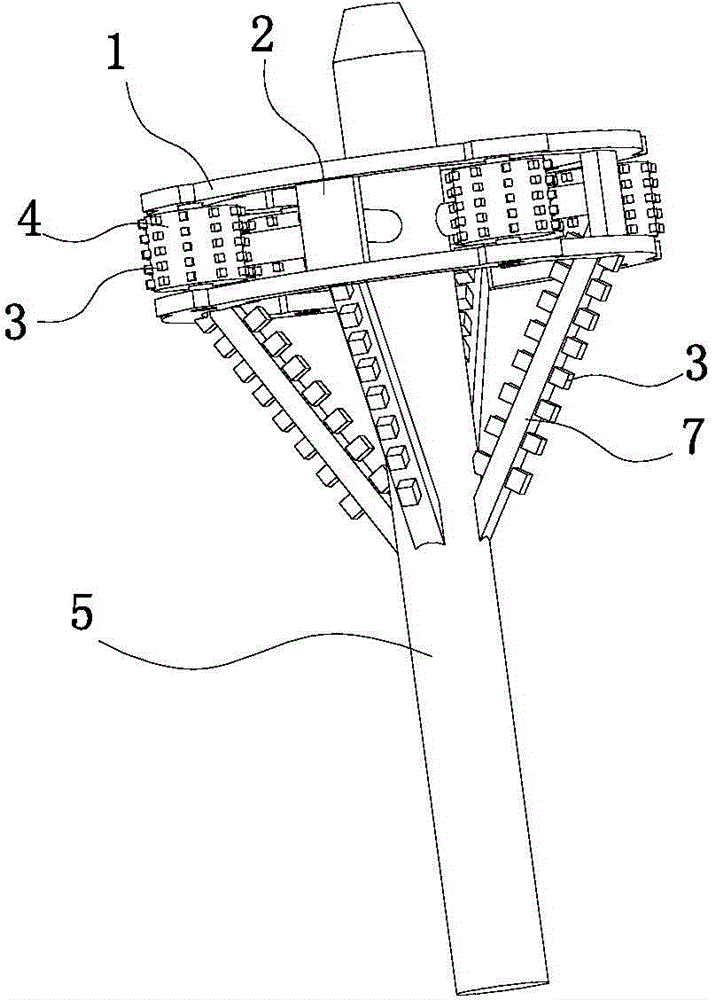

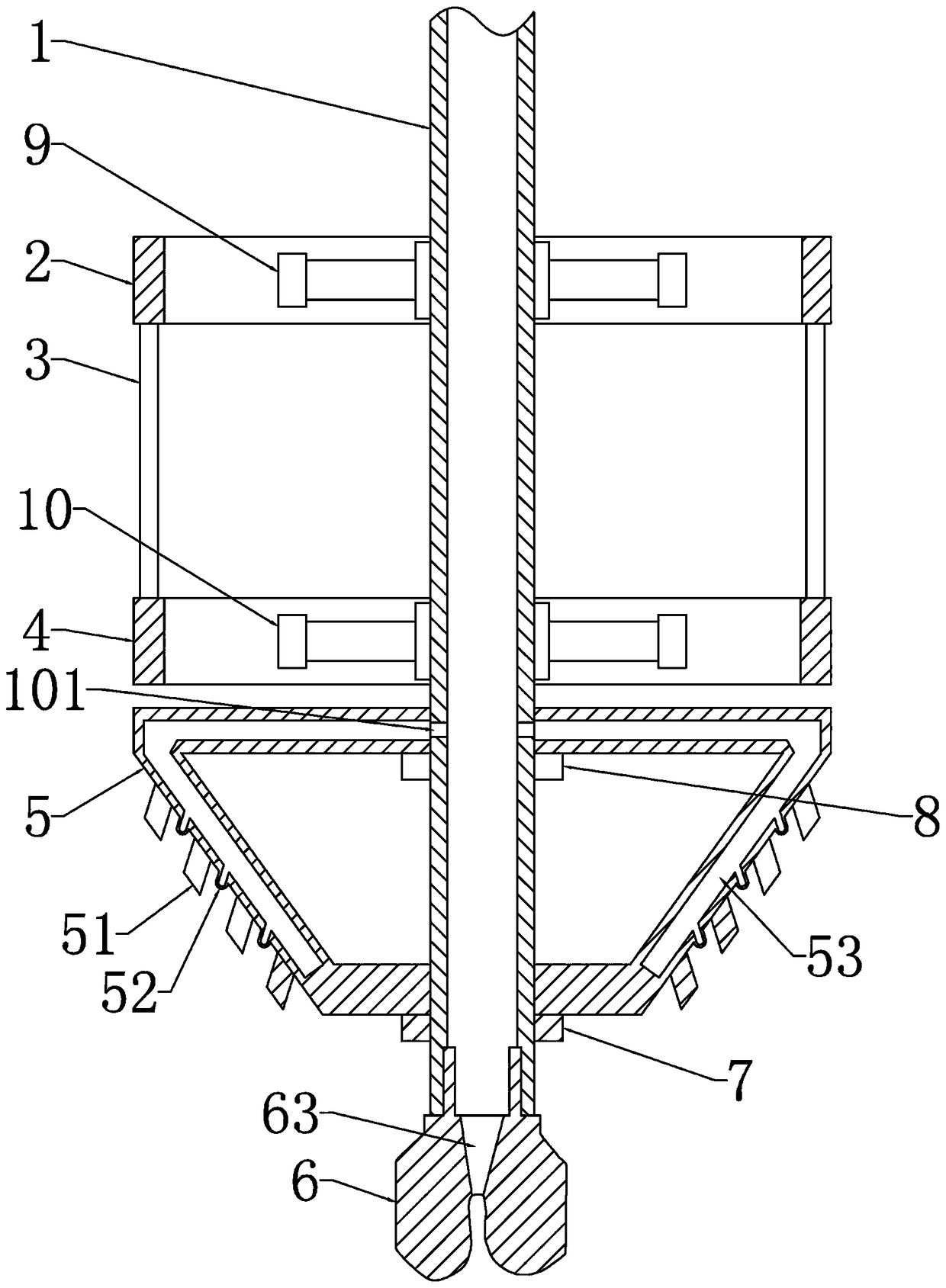

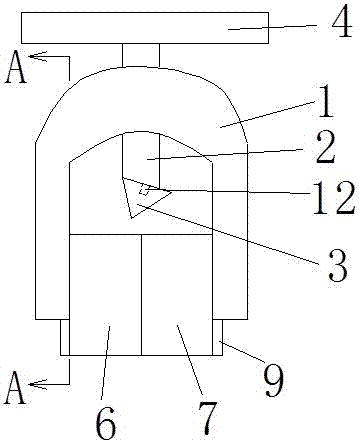

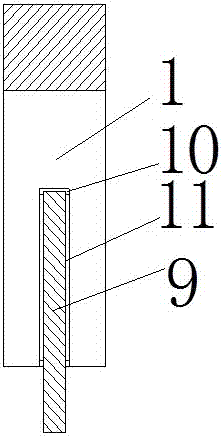

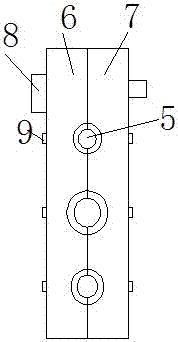

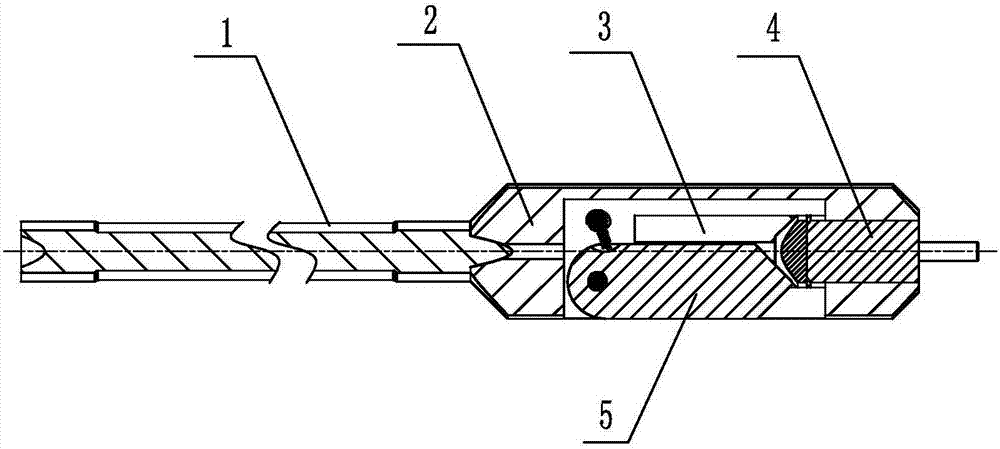

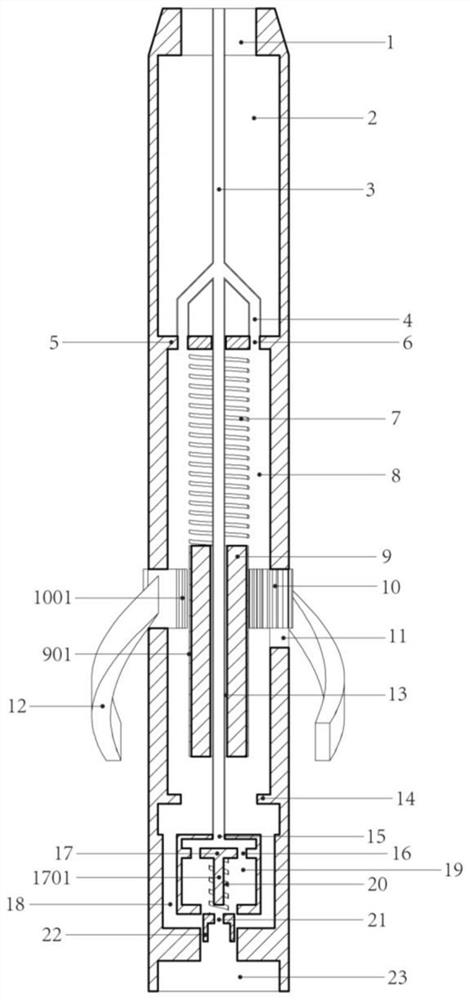

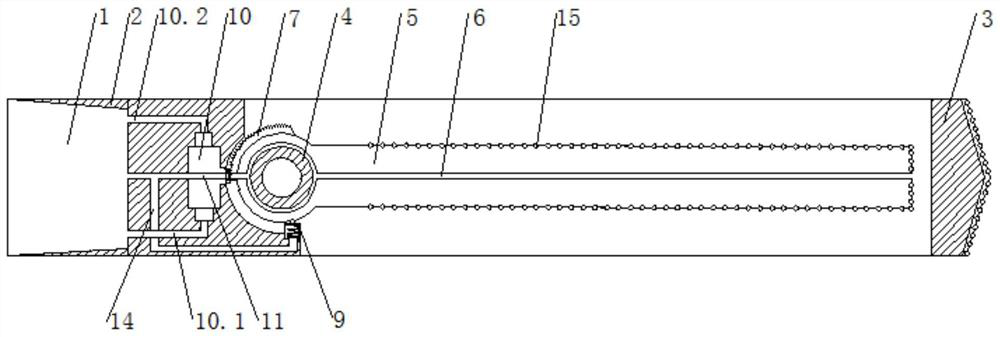

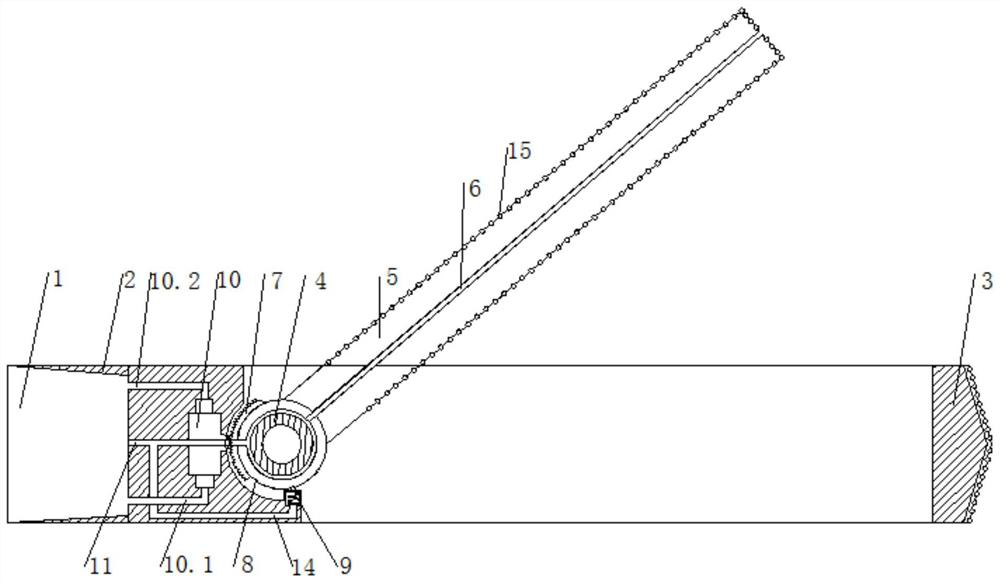

Hole reaming and borehole enlarging device for exploitation of coalbed methane exploitation hole bottom

ActiveCN105178862AReduces failure to open and retract properlyImprove hole reaming efficiencyDrilling machines and methodsDrill bitEngineering

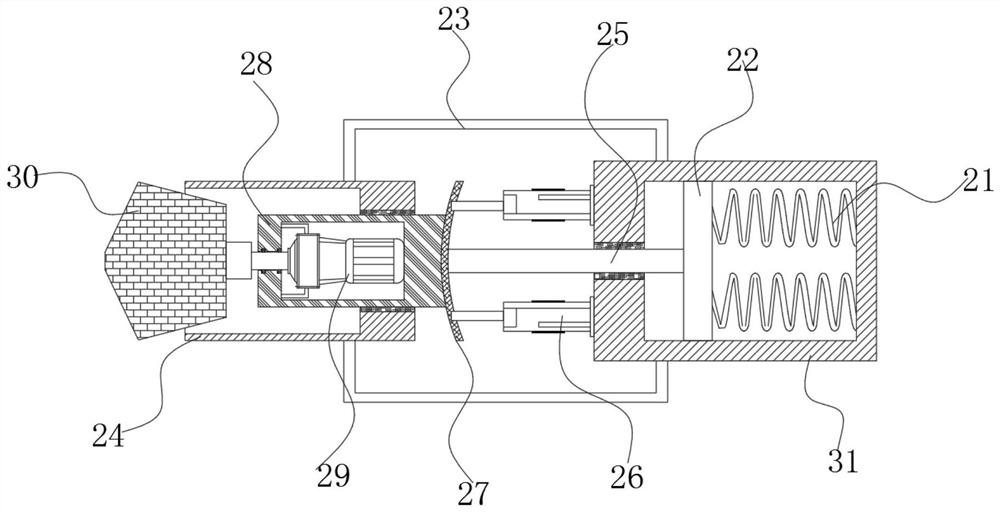

A hole reaming and borehole enlarging device for exploitation of a coalbed methane exploitation hole bottom comprises a connecting drill pipe, wherein a hole reaming drill bit is arranged at the lower end of the connecting drill pipe; an inner cavity of the connecting drill pipe serves as a flushing fluid flowing duct; a flushing fluid counterbalance valve is mounted in the flushing fluid flowing duct; a borehole enlarging oil cylinder is arranged in the flushing fluid flowing duct; the hole reaming drill bit comprises a cutting head and a guiding sleeve which is fixedly connected with the connecting drill pipe; a guiding rod which moves in the up-down direction is mounted in the guiding sleeve; and a plurality of cutting wings for hole reaming operation are uniformly distributed between the guiding sleeve outside the guiding rod and the cutting head in the peripheral direction. The hole reaming and borehole enlarging device is simple and reliable in structure, good in stability and high in safety, completely meets construction requirements of coalbed methane borehole enlarging wells, and has an excellent market prospect.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

An anchoring method for a bolt

The anchoring method of the anchor rod of the present invention relates to the technical field of building construction, comprising the following steps: (1) first drilling a pre-drilled hole with the same diameter; The reaming head extends into the pre-drilled hole; (3) Control the anchor drilling machine to pull the inner rod so that the knife plate protrudes from the knife plate receiving groove outside the jacket, and the fluid is pressed into the liquid guide between the inner and outer rods through the pump (4) Control the inner and outer rods to rotate together through the anchor drilling rig, and pull the inner and outer rods forward at the same time, so that the knife plate rotates to cut a hole larger than the diameter of the pre-drilled hole; (5) Push the inner rod backward to turn the inner rod When the rod is pushed back to make the cone block of the reaming head abut against the front end of the guide sleeve, the knife plate will be retracted into the knife plate receiving groove in the outer casing under the action of the spring, and the reaming head in the hole will be brought together as a whole. Out of the hole, complete the hole reaming; (6) Put the prefabricated anchor rod into the expanded hole, and pour the anchoring agent in the hole, and the anchoring agent will be completed after the anchoring agent solidifies.

Owner:广西建工集团第二安装建设有限公司

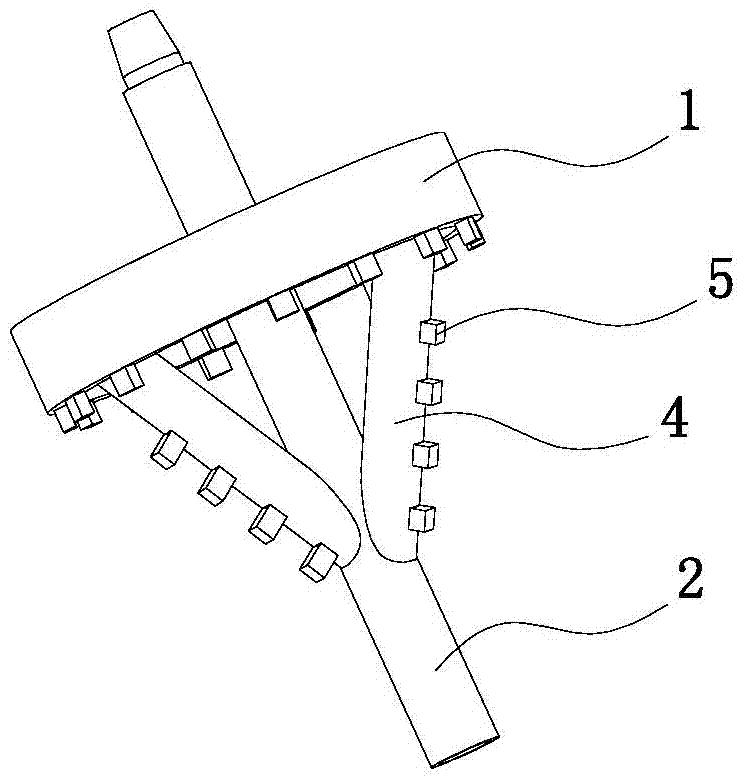

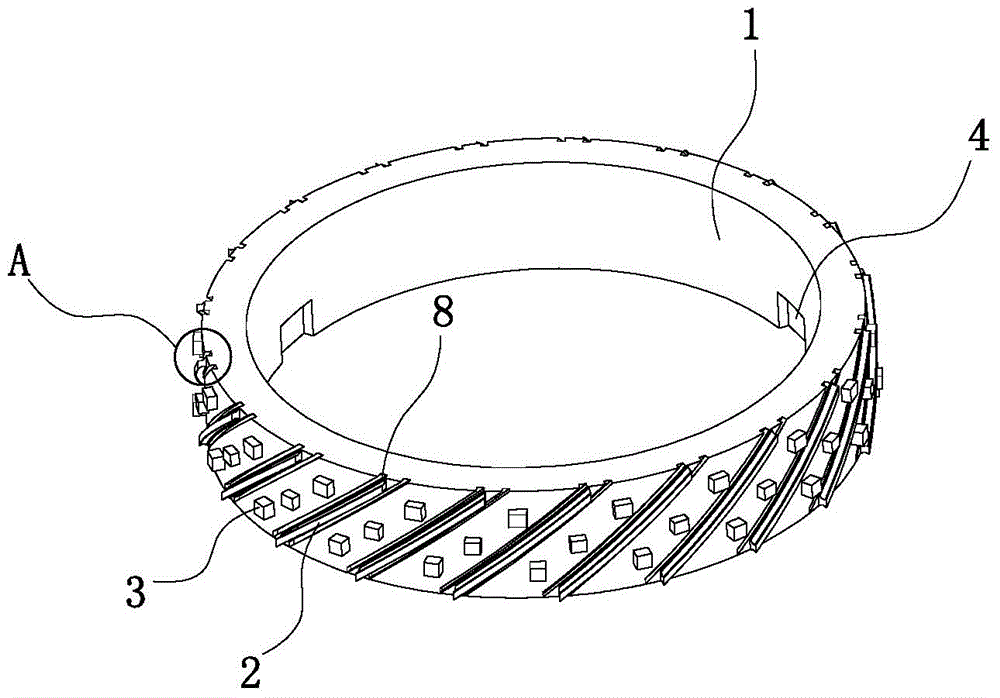

Cutting type reamer

ActiveCN104265176ARealize secondary mixingAchieve shreddingDrilling machines and methodsSingle supportCrushed stone

The invention relates to a cutting type reamer which comprises a waist band and a drill rod. The drill rod is supported by cross rods to be fixedly connected to the center of the waist band, a plurality of reaming rods are fixedly connected between the inner wall of the waist band and the outer wall of the drill rod, a plurality of alloy blocks are evenly distributed on the lower end face of the waist band and the outer walls of the reaming rods, the reaming rods are symmetrically arranged relative to the center of the drill rod, the drill rod and the reaming rods are of a hollow structure and are communicated, the cross rods are of an upper-layer and lower-layer structure, the cross rods of the upper layer and the lower layer are arranged in a staggered mode, the cross rods of each layer are symmetrically arranged relative to the central axis of the drill rod, and a plurality of alloy blocks are fixedly connected with the lower side walls of the cross rods. The cross rods are of a hollow structure, and are communicated with a central through hole of the drill rod. The cross rods of the dual-layer structure are additionally arranged, the alloy blocks are arranged and combined with the reaming rods, secondary stirring and smashing on soil and broken stone are achieved, large soil and broken stone are avoided, and compared with original single-support cross rods, reaming efficiency is greatly improved.

Owner:WUXI ZHONGDI DRILLING EQUIP

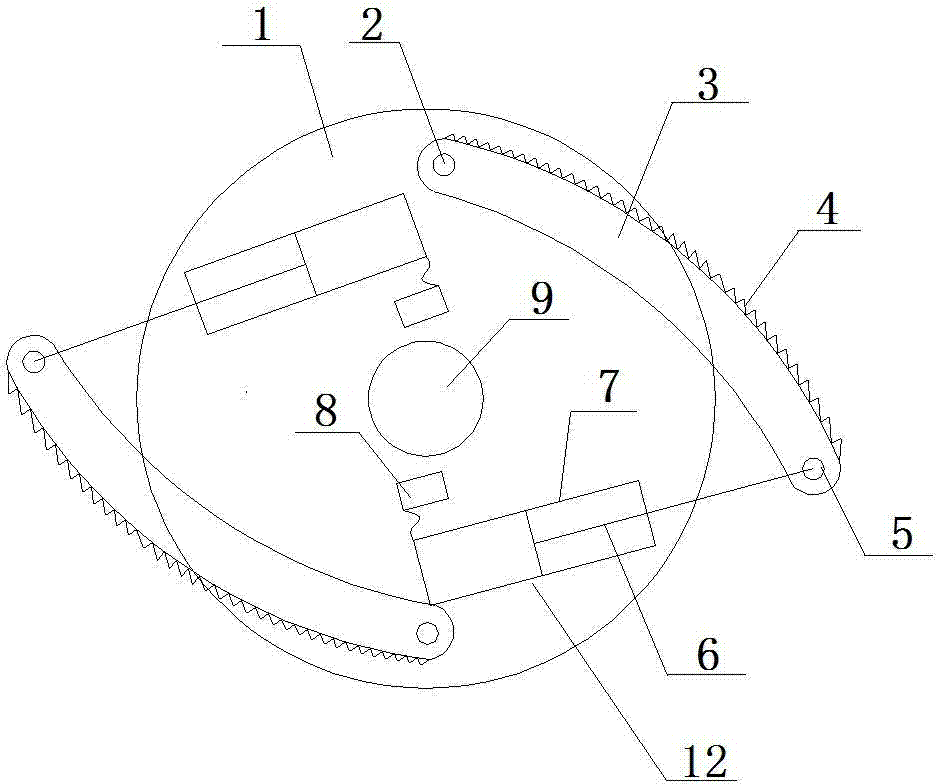

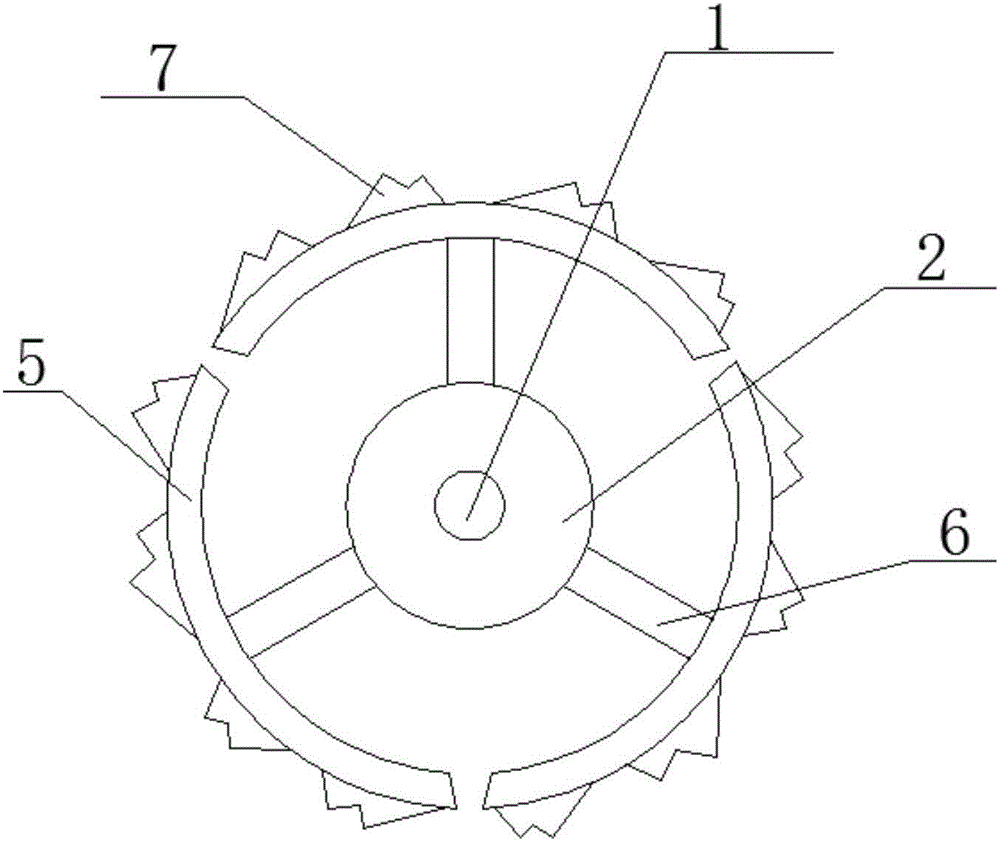

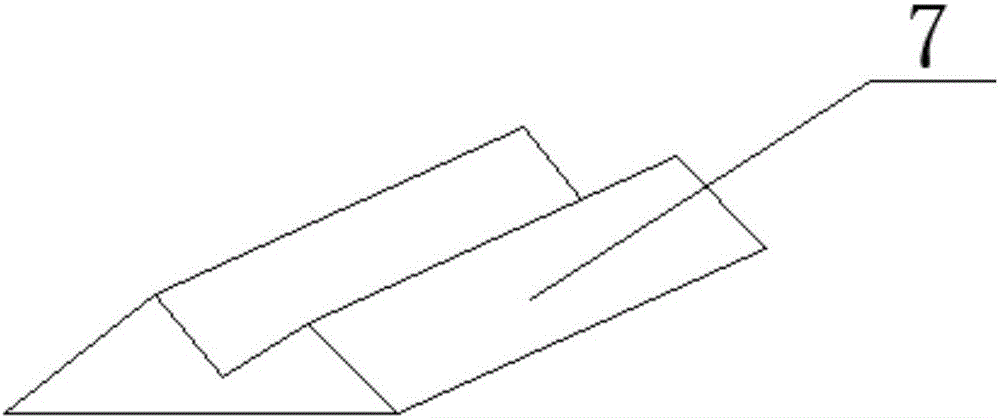

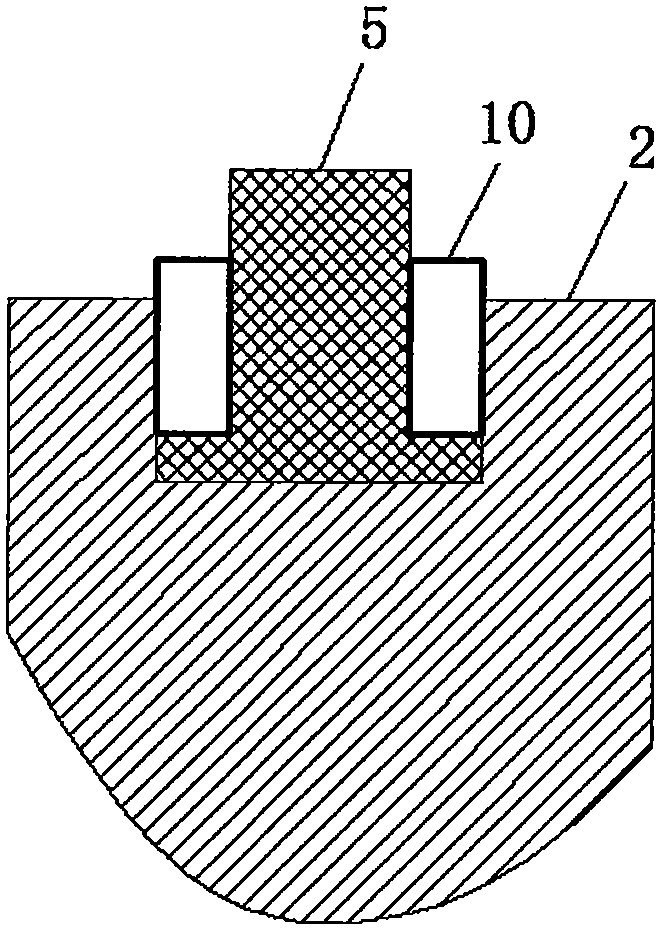

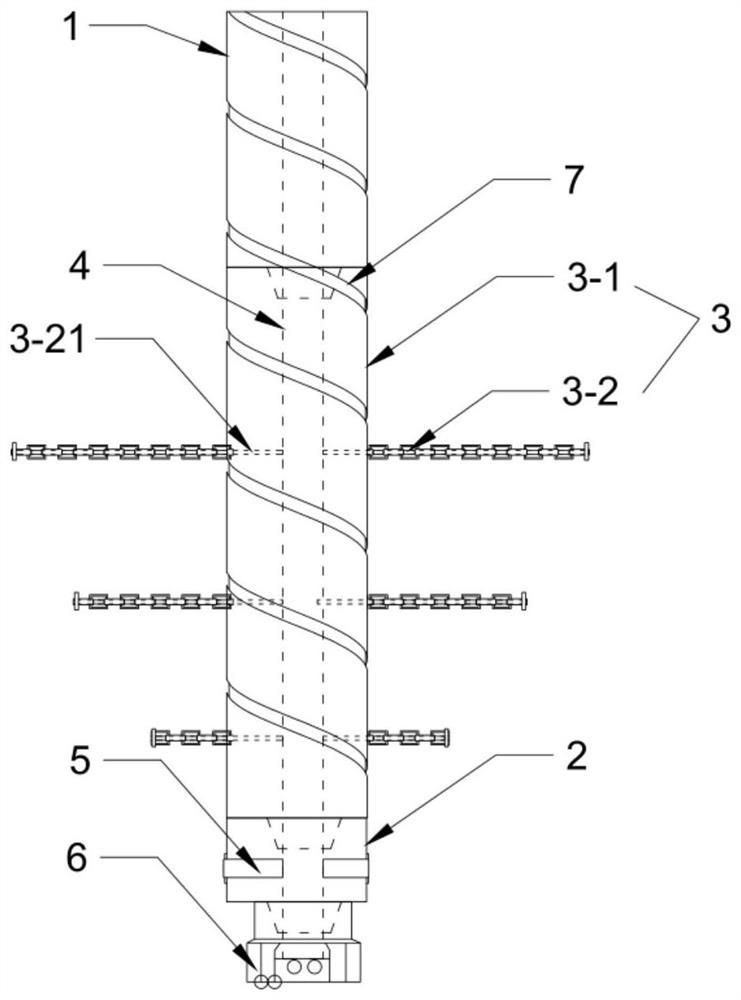

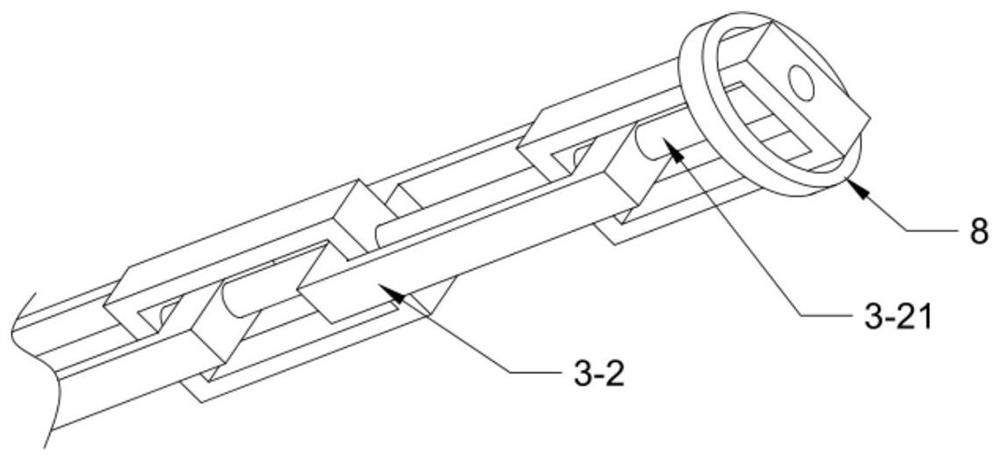

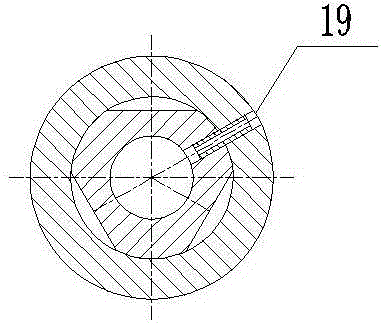

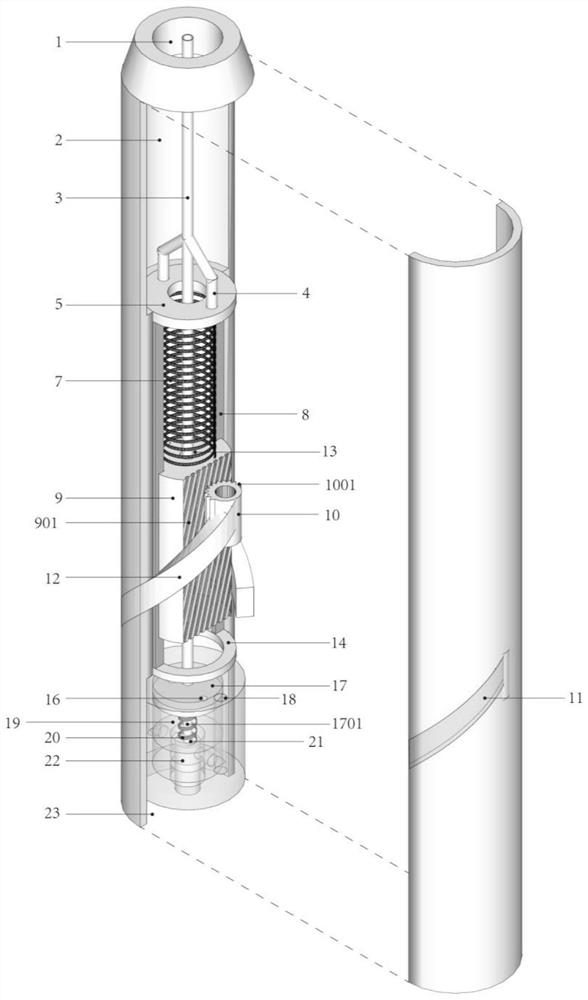

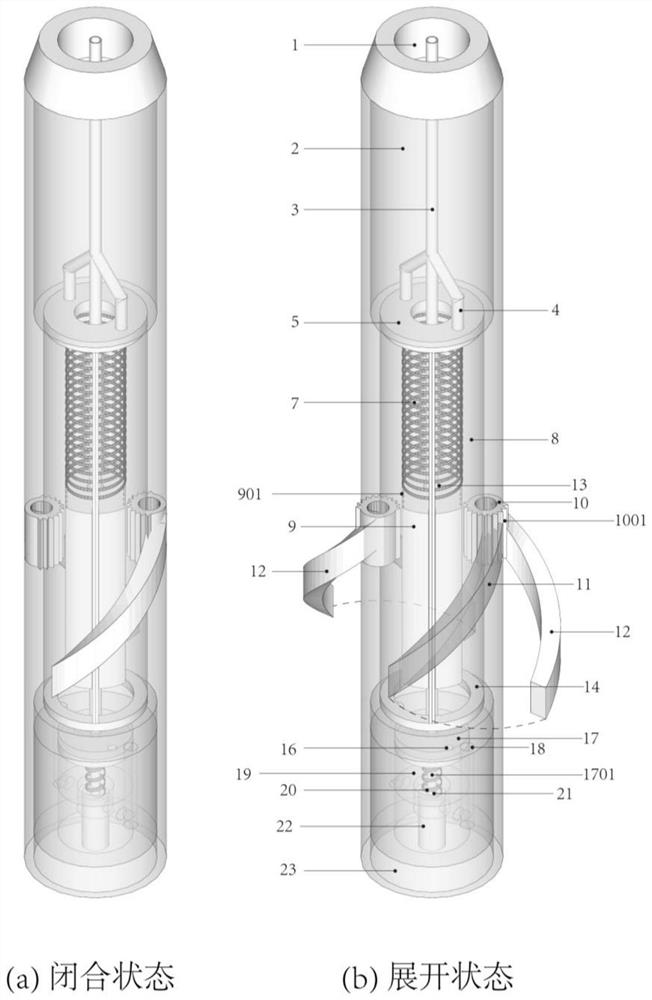

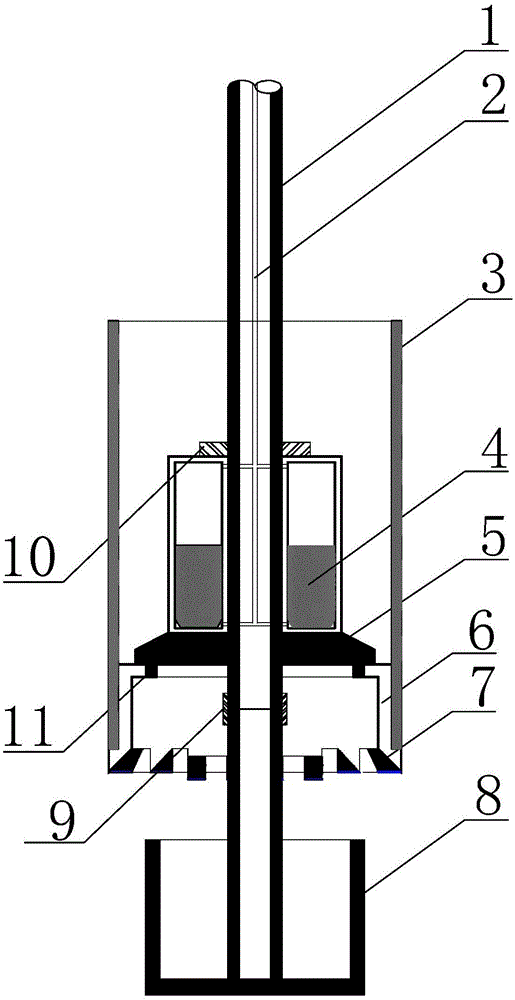

Coal mine underground spiral hydraulic mechanical reaming device

PendingCN111622675AImprove breathabilityImprove the extraction effectGas removalDrilling machines and methodsGear driveGear wheel

The invention relates to a coal mine underground spiral hydraulic mechanical reaming device. The device comprises a drill bit cavity, a cutter arm cavity and a water valve cavity, wherein a power driving device is arranged in the cutter arm cavity, and a high-low pressure cooling water switching device and a spiral cutter arm device are arranged in the water valve cavity. A pair of spiral cutter arms is arranged on the outer side of the cutter arm cavity, cutter arm gear bodies for machining helical teeth are installed at the roots of the spiral cutter arms, and the cutter arm gear bodies aretightly meshed with piston sliding sleeves with helical teeth machined on the same side faces through the helical teeth; a high-pressure water pipeline provides high-pressure water to push a piston tomove and drive a gear, and the spiral cutter arm can be unfolded under the combined action of helical tooth transmission power and the high-pressure water; and the high-low pressure cooling water switching device can change the water pressure in the device and the opening and closing state of the pipeline. The cutter arm structure is changed into a spiral type from a traditional right-angle type,the power supply mode is improved, the cutting efficiency and the reaming efficiency can be improved in the drilling and reaming project, the reaming construction period is shortened, and the gas extraction effect is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Reverse circulation channel-type double stage reamer

The invention provides a reverse circulation channel-type double stage reamer comprising a reverse circulation assembly. The reverse circulation channel-type double stage reamer is characterized in that the reverse circulation assembly comprises a mandrel whose inner portion is provided with a reverse circulation structure; both ends of the mandrel are internal thread joints; a front centralizer,a first level reaming base, a second level reaming base, a rear centralizer and a slag suction bucket are welded on the shell of the mandrel; a front spiral blade is welded on the shell of the front centralizer while a rear spiral blade is welded on the shell of the rear centralizer; the slag suction bucket is welded on the shell of the mandrel and located between the first level reaming base andthe second reaming base; the slag suction bucket is communicated with the mandrel through a slag suction pipe; a reinforcing rib is respectively welded on the shell of the mandrel and the end surfaceof the rear centralizer; tooth palms and double rows of PDC (polycrystalline diamond compact) blades are respectively fixed on the first level reaming base and the second level reaming base; the end portion of the tooth palms is connected with a cone. The reverse circulation channel-type double stage reamer has the advantages of being applicable to different geology, having large cross section insingle reaming and high reaming efficiency, and achieving the effects of quick replacement of cutting edges, reducing costs and prolonging service life.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

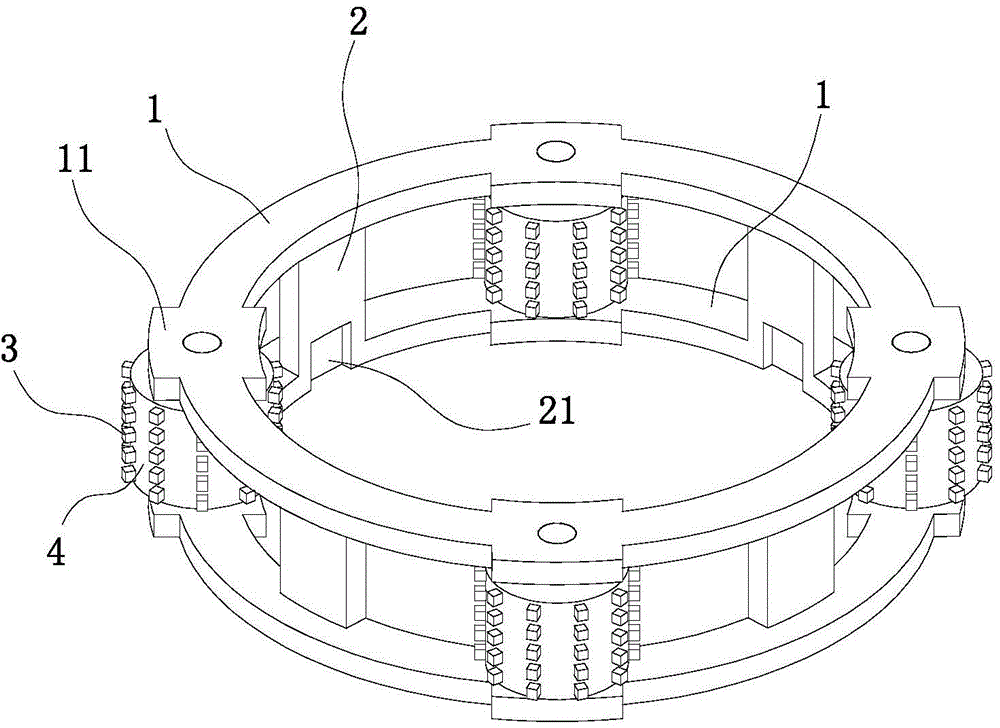

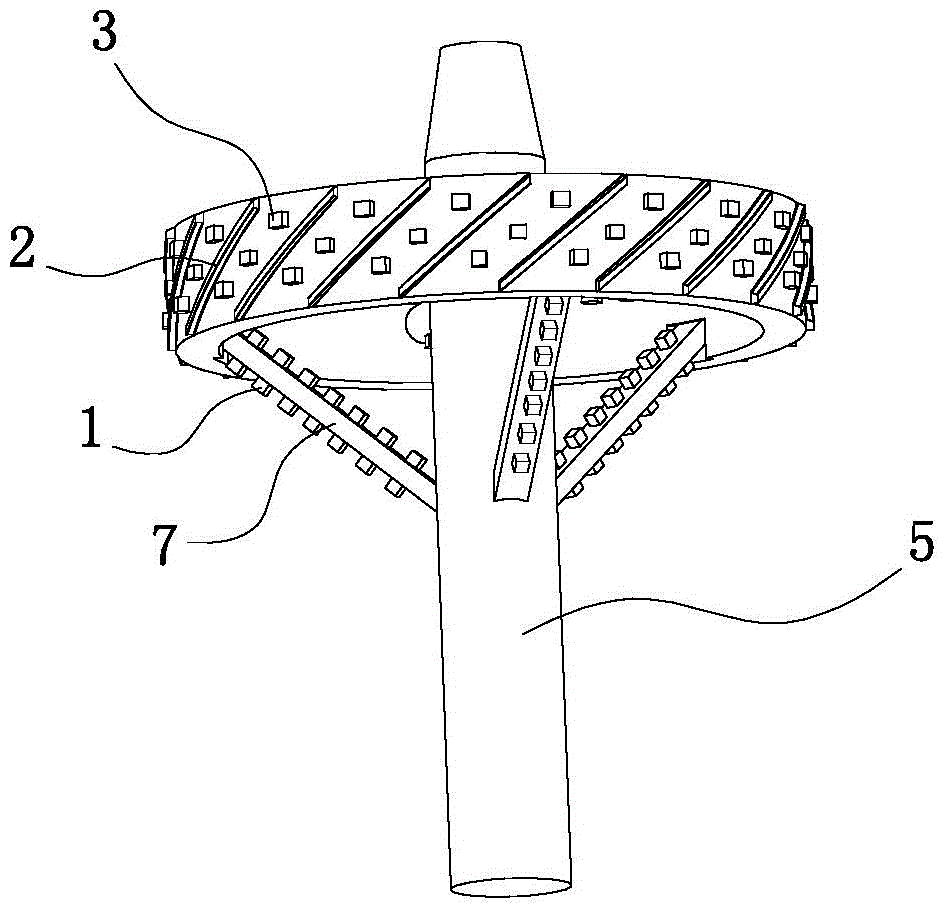

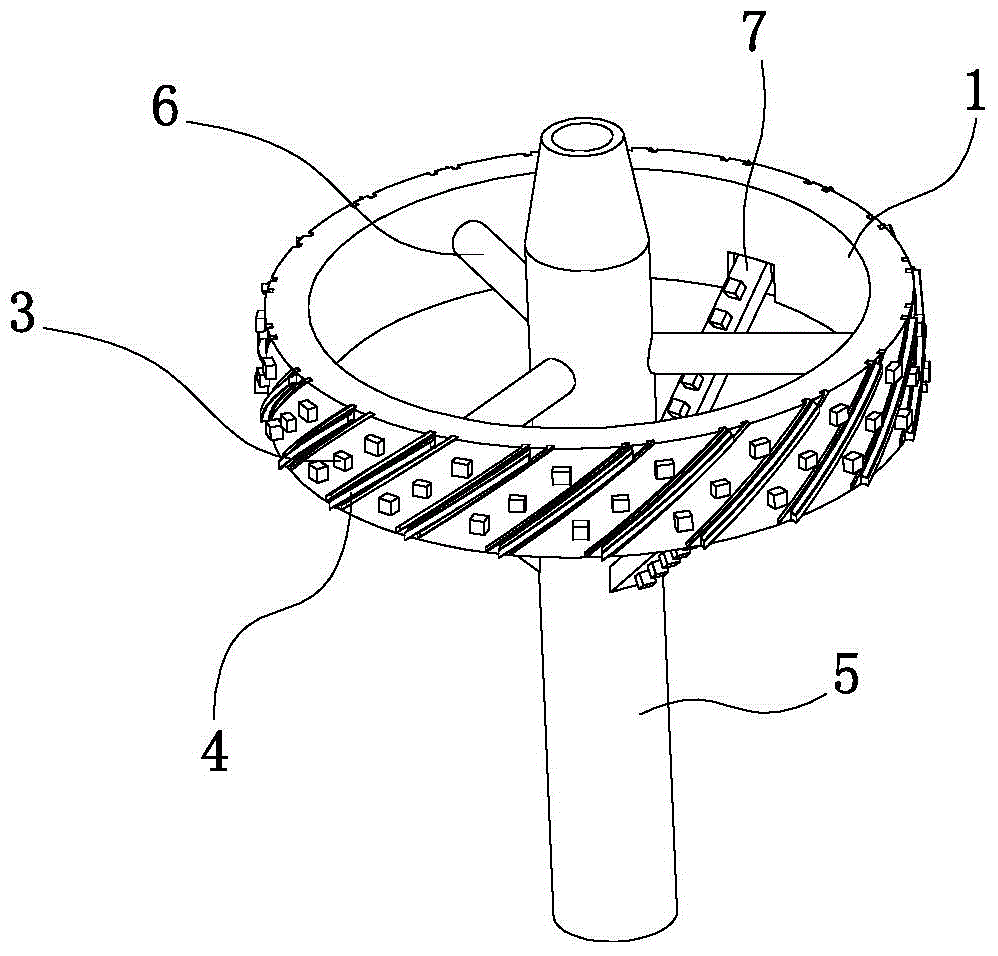

Waistband reaming type reamer

InactiveCN104563876AIncrease frictionImprove hole reaming efficiencyDrill bitsDrilling machines and methodsAlloyEngineering

The invention relates to a waistband reaming type reamer, which comprises an annular waistband, wherein the center of the waistband is fixedly connected to a drill rod through a cross rod, a plurality of reaming rods are fixedly connected between the inner wall of the waistband and the sidewall of the drill rod, the reaming rod is centrally symmetrical along the drill rod, the drill rod, the reaming rods and the cross rod are of hollow structures, a plurality of welding grooves are symmetrically formed in the inner wall of the waistband, the upper end of each reaming rod is welded in the corresponding welding groove, and the section of each reaming rod is of a square structure; a plurality of reaming strips are arranged on the outer wall of the waistband, an alloy block group is arranged between the adjacent reaming strips, and each alloy block group comprises a plurality of alloy blocks arranged along the reaming strips; the alloy blocks are uniformly arranged on the outer walls of the cross rod and the reaming rods.

Owner:WUXI GEOTEC GEOLOGICAL EQUIP

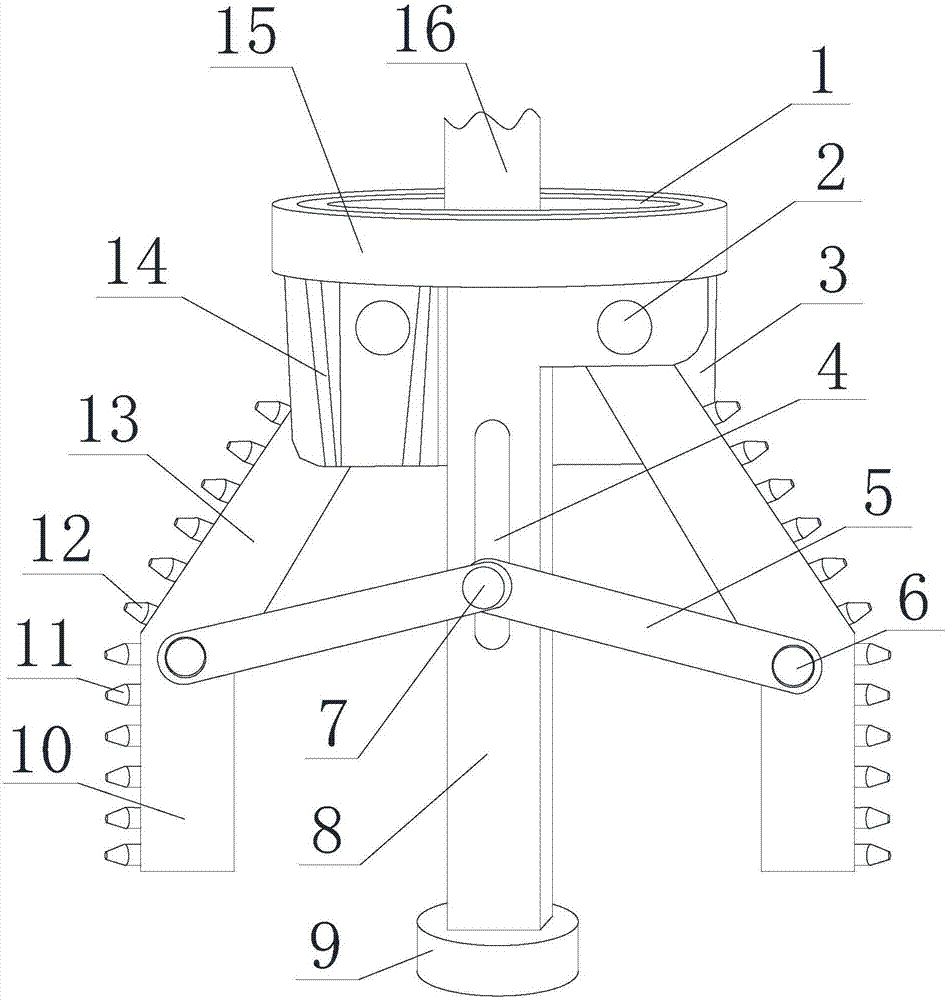

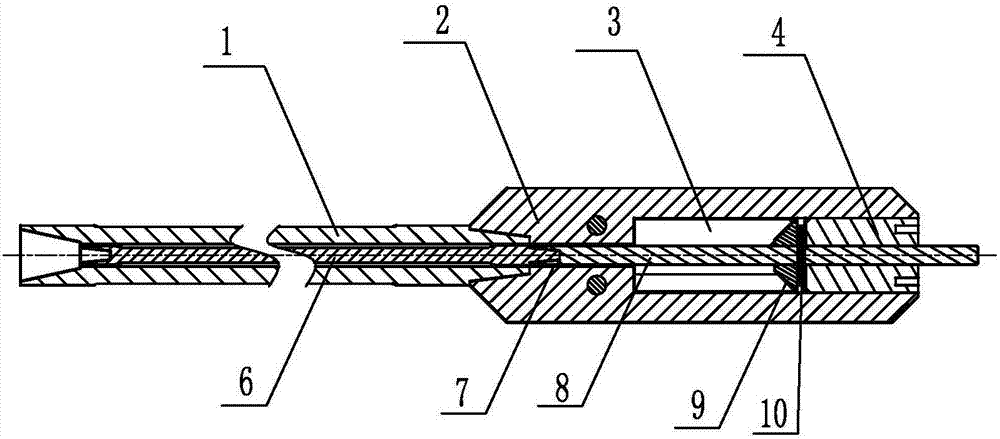

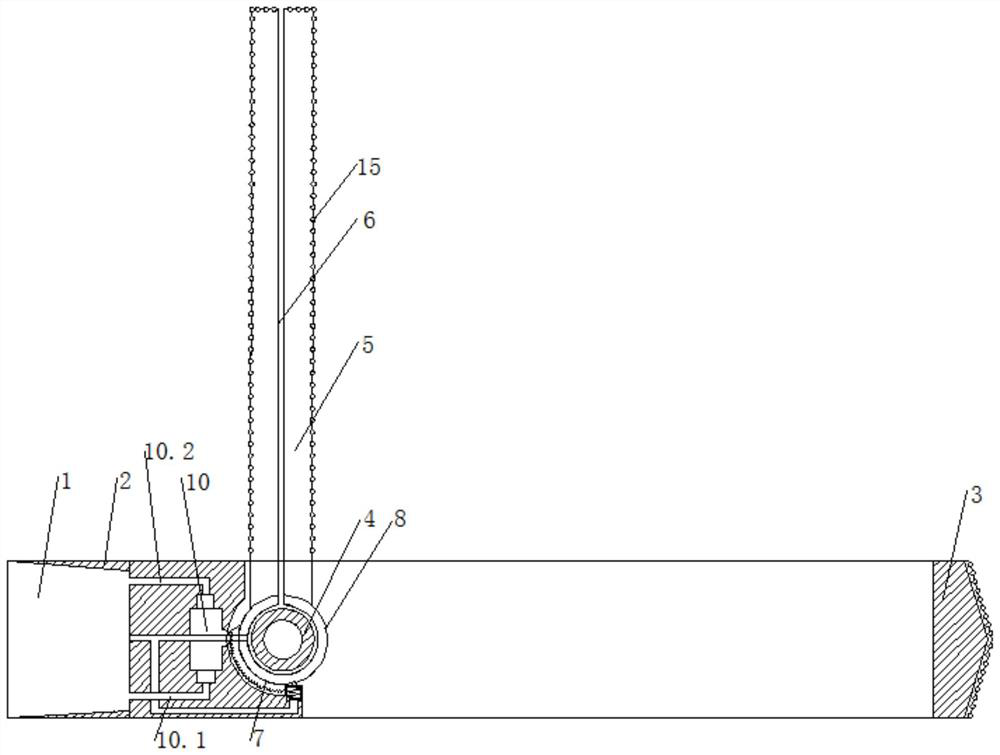

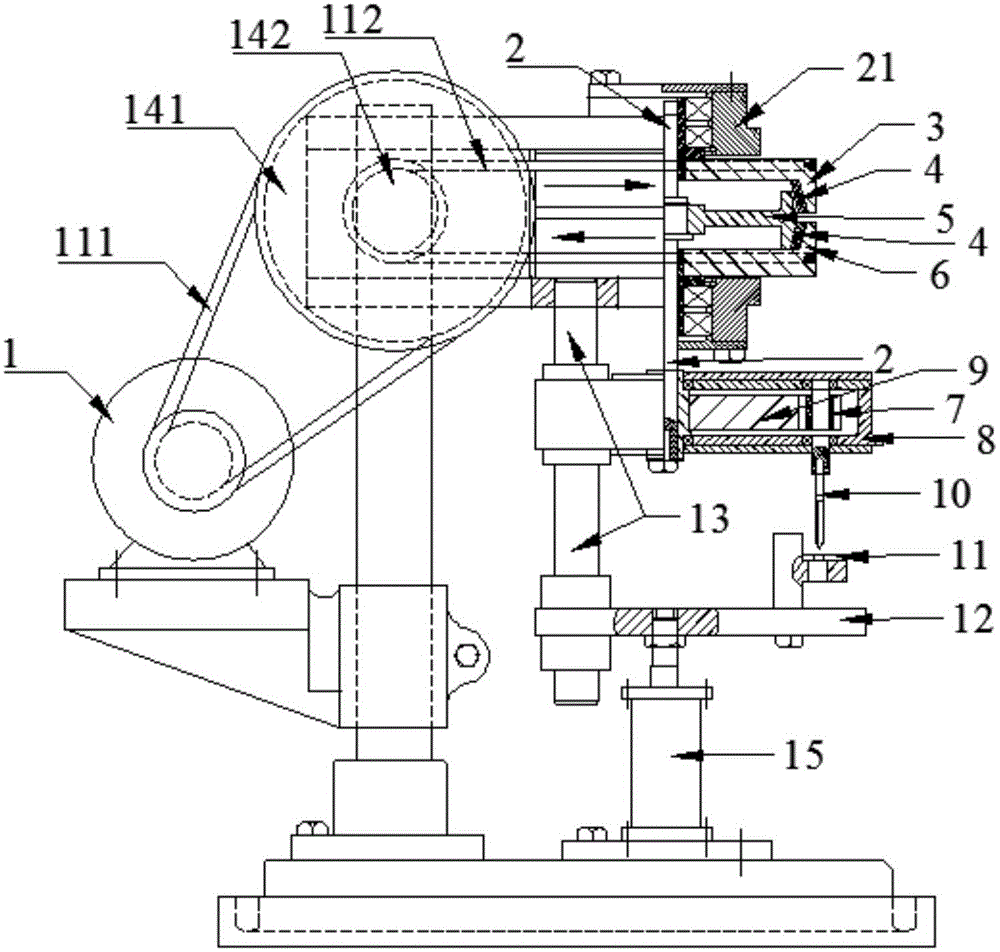

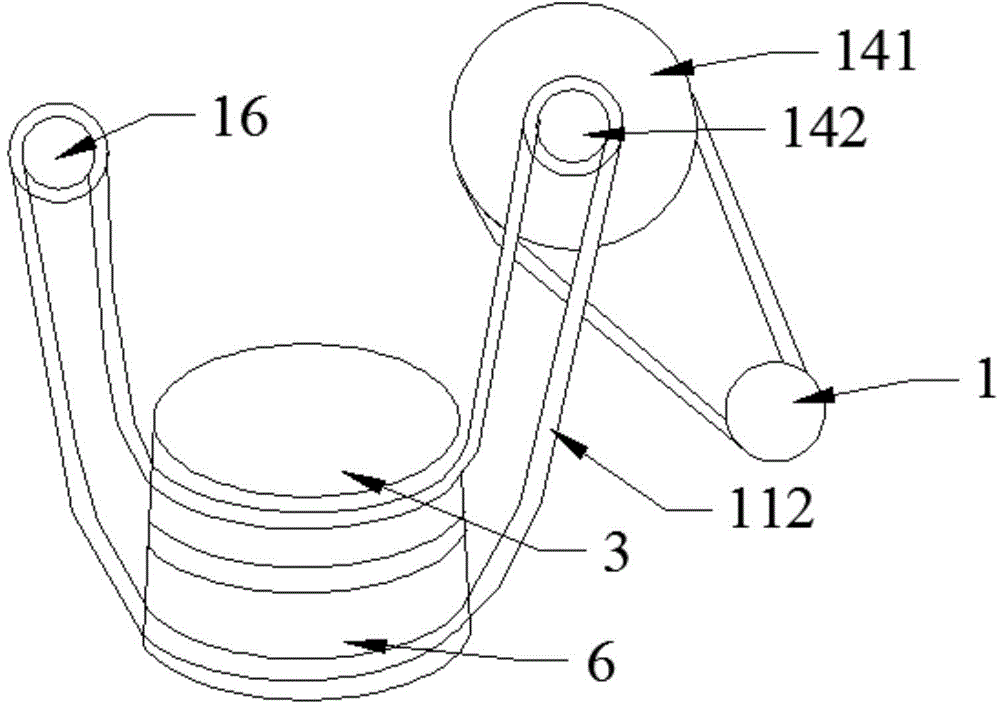

A kind of hydraulic hole reaming drilling tool and its reaming method for mechanically cavitating coal seam

ActiveCN111577142BSimple structureEasy to operateDrill bitsDrilling machines and methodsWork cycleGear wheel

The invention discloses a hydraulic expanding drill used for mechanical hole making coal bed permeability improvement and an expanding method of the hydraulic expanding drill. An expanding tool can berotationally installed on the front side of a hollow cylinder shaft, with the transverse center line of the hollow cylinder shaft as the boundary, an arc clamping tooth is arranged on one side of theouter wall of the rear end of the expanding tool, a clamping groove is formed in the other side of the outer wall of the rear end of the expanding tool, and the top end of a clamping head penetratesa clamping device to be matched with the clamping groove. A hydraulic cylinder and a gas-water channel I for compressed air and high-pressure water flow to pass are arranged in a pipeline at the rearportion of a drill body, and a gear arranged on the hydraulic cylinder is engaged with the arc tooth. One end of a gas-water branch channel III communicates with the gas-water channel I, and the otherend of the gas-water branch channel III communicates with the bottom end of the clamping device. Due to the engagement of the gear and the arc clamping tooth, the hydraulic cylinders works, the gearrotates, the arc clamping tooth is driven to rotate, and the expanding tool is opened with an angle. The hydraulic expanding drill used for mechanical hole making coal bed permeability improvement andthe expanding method of the hydraulic expanding drill are simple in structure and convenient to operate and capable of adapting to the requirements for different expanding diameters, in addition, thelength of the expanding tool does not need to be changed, the expanding efficiency is improved, and the work cycle is shortened while the workload is reduced.

Owner:CHINA UNIV OF MINING & TECH +1

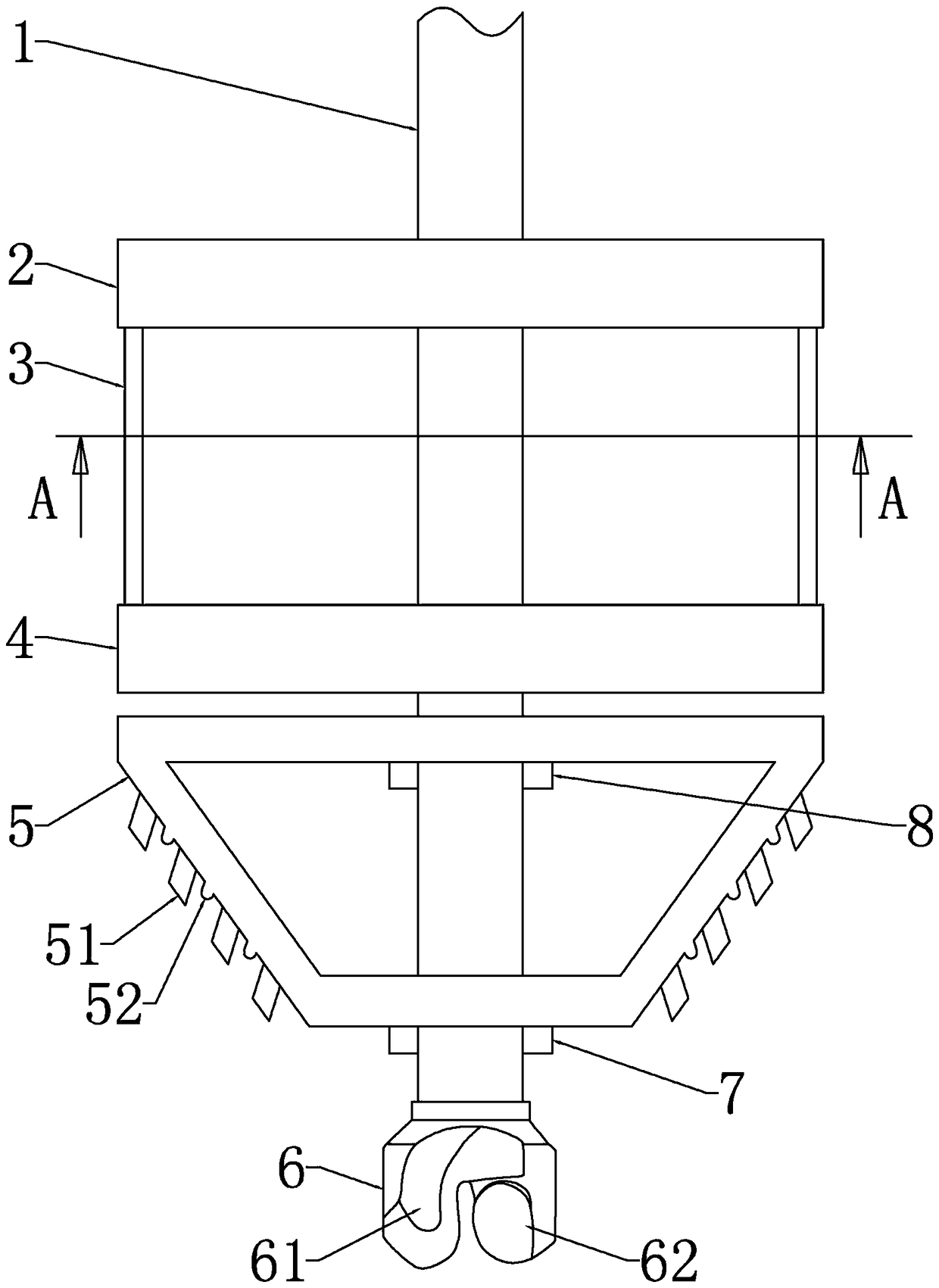

Non-circular impact-reaming device for bored pile and reaming method of non-circular impact-reaming device

ActiveCN106014262ATo achieve the purpose of reamingImprove hole reaming efficiencyDrill bitsBorehole drivesSlagEngineering

The invention discloses a non-circular impact-reaming device for a bored pile. The non-circular impact-reaming device for the bored pile comprises a control spindle. The control spindle is sequentially sleeved with a driving device, an impact energy transmitting device, a reamer and a slag discharging hopper from top to bottom. A limiting device used for fixing the reamer is further arranged below the transmitting device. A round hole is formed in the middle of the reamer. A rock / soil cutter is arranged at the bottom of the reamer. A liquid pressure inlet / outlet pipe is arranged in the control spindle, and the liquid pressure inlet / outlet pipe is connected with the driving device. According to the non-circular impact-reaming device, since the driving device is arranged, rock / soil breaking impact force can be provided for the reamer through the impact energy transmitting device, and the reaming purpose is achieved; since the round slag discharging hopper is arranged, guiding for reaming can be achieved, and reaming soil and rocks can be collected; since the slag discharging hopper is detachable, slag discharging hoppers of different types can be replaced at any time, and the reaming efficiency is improved; and since the rock / soil cutter is provided with a cutter bit which can retract inwards, a space for storing a wall protection cylinder is provided, and the rock / soil cutter can be taken out of the reaming device more conveniently.

Owner:叶晓明

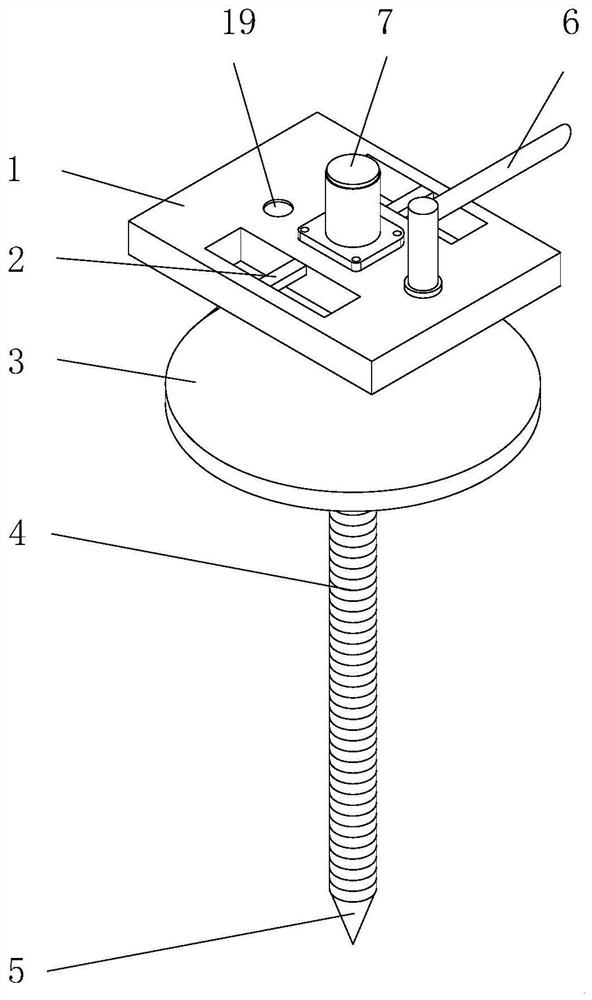

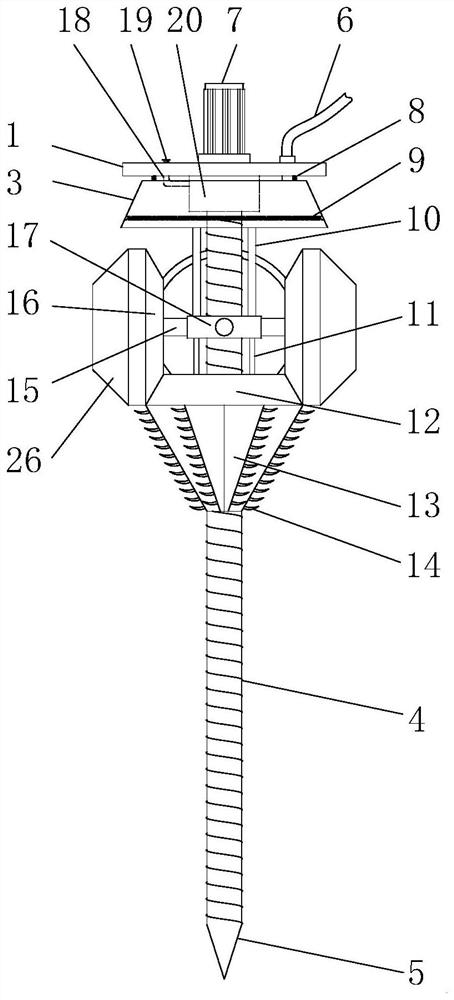

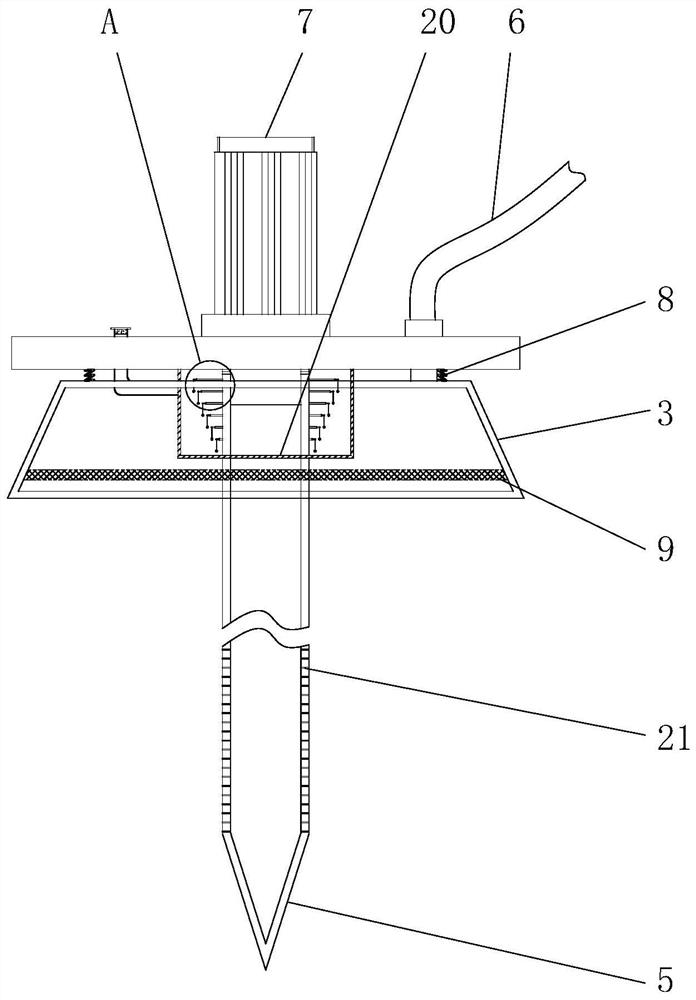

Nursery stock planting device and method capable of expanding holes directionally for landscape gardens

PendingCN113924847AImprove hole reaming efficiencyQuick clean upPlantingFurrow making/coveringDrive motorAgricultural engineering

The invention discloses a nursery stock planting device and method capable of expanding holes directionally for landscape gardens. The nursery stock planting device comprises a device plate and a driving bevel gear, wherein a driving motor is mounted above the device plate, the output end of the driving motor is connected with a guide screw rod, and a soil penetrating nail is fixed to the lower end of the guide screw rod; and the driving bevel gear is arranged outside the guide screw rod in a sleeving mode, a drilling head is fixed to the lower portion of the driving bevel gear, and a plurality of drilling teeth are evenly arranged on the surface of the drilling head. According to the nursery stock planting device and method capable of expanding holes directionally for landscape gardens, an arranged driven bevel gear can rotate in the vertical direction under the meshing action of the driving bevel gear, a side wing hole expanding head is arranged on the surface of the driven bevel gear and can be in contact with soil, meanwhile, rotating crushing teeth can quickly crush stones and the like contained in the soil, so that the hole expanding efficiency of the driven bevel gear is improved, and the phenomenon that the stones are large and are difficult to dig out is avoided.

Owner:王彩玲

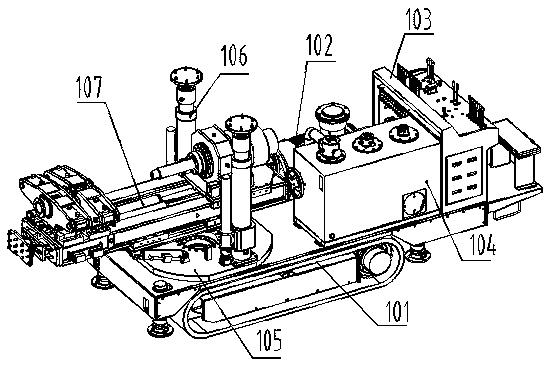

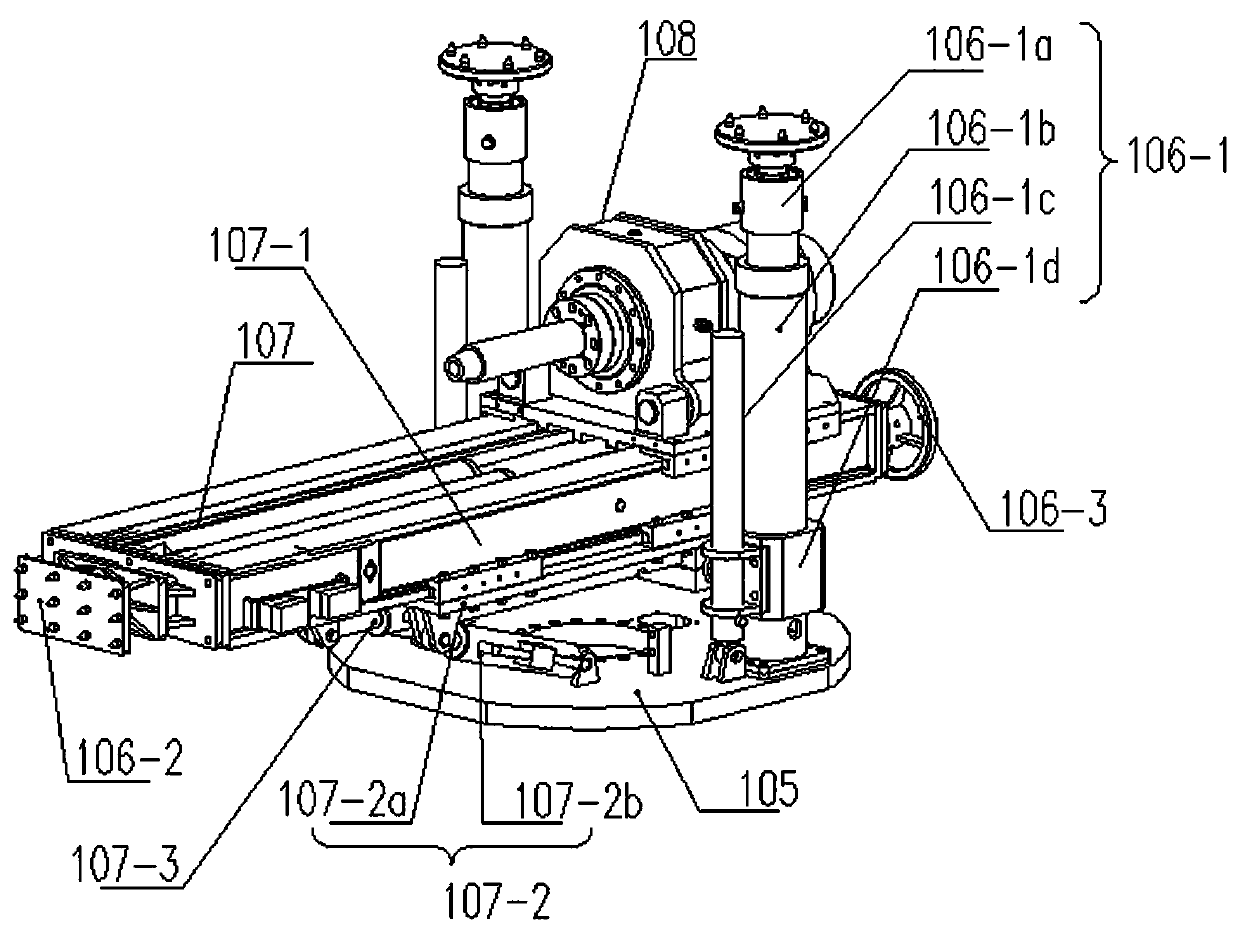

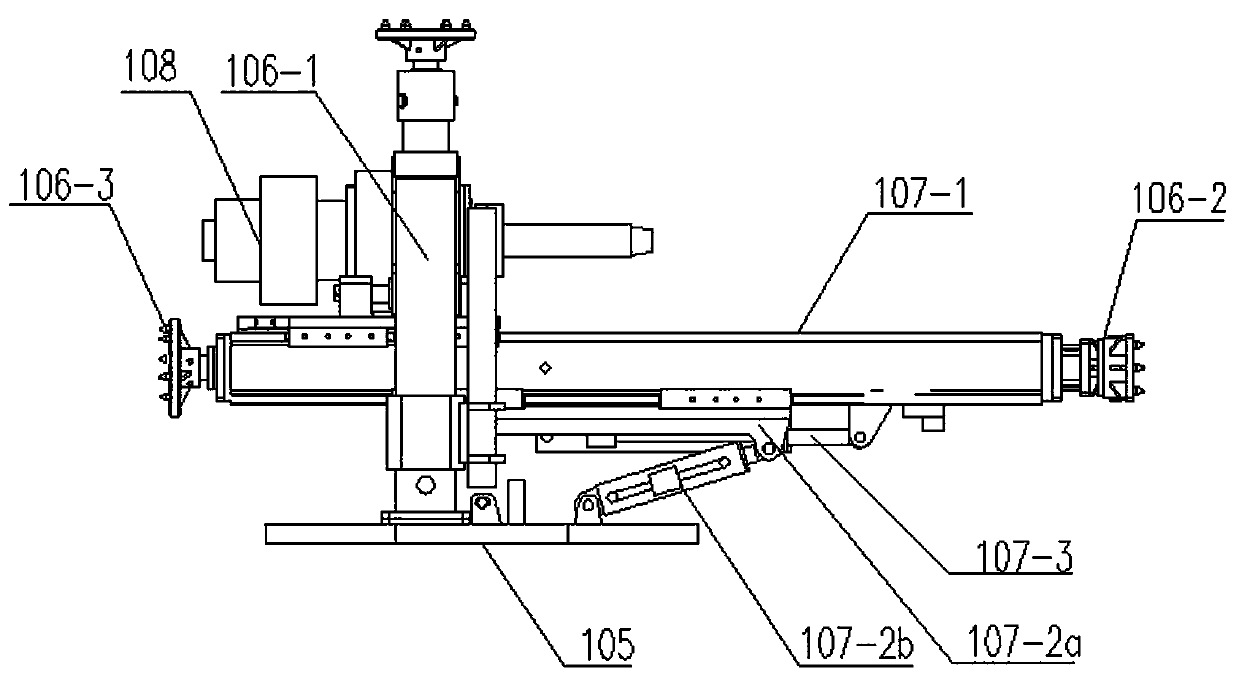

Complete equipment for transverse large-diameter hole forming in soft coal seam coal pillar area and hole forming technology

PendingCN111140170ASolve homework difficultiesSolve efficiency problemsDrill bitsDrilling rodsThermodynamicsPull force

The invention relates to complete equipment for transverse large-diameter hole forming in a soft coal seam coal pillar area and a hole forming technology. The complete equipment comprises a high-torque drilling machine, a holing drilling tool and a reaming drilling tool, wherein the high-torque drilling machine comprises a guide rail assembly, a stable drilling support assembly and a drilling androtating device; the stable drilling support assembly is installed on a large rotation plate of the high-torque drilling machine to provide support for a drilling machine in the drilling process; thedrilling and rotating device is installed on the guide rail assembly, and drives the holing drilling tool to rotate according to the drilling process to achieve high-speed drilling or driving the reaming drilling tool to rotate to achieve low-speed high-torque back reaming; the guide rail assembly is installed on the stable drilling support assembly, can adjust the drilling position and directionof the drilling and rotating device and provide required pulling force for back reaming of the drilling and rotating device. The hole forming technology comprises a holing process and a back reaming process. The problems of difficult operation, low efficiency, low hole forming rate, high labor intensity and the like in transverse large-diameter hole forming in the soft coal seam coal pillar can beeffectively solved.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD

Reaming and tapping machine

InactiveCN104148751AQuality improvementImprove hole reaming efficiencyThread cutting machinesLow frictionElectric motor

The invention provides a reaming and tapping machine. The reaming and tapping machine comprises a support, a motor, an upper friction sleeve, a lower friction sleeve, a linear guide rail pair and a friction pair spindle, wherein the rotating direction of the upper friction sleeve is opposite to the rotating direction of the lower friction sleeve; an output shaft of the motor is connected with an input shaft through a first transmission part; an output shaft coaxial with the input shaft is connected with the upper friction sleeve and the lower friction sleeve through a second transmission part and an auxiliary supporting shaft; the friction pair spindle is provided with a friction wheel located between the upper friction sleeve and the lower friction sleeve; the linear guide rail pair is provided with an output gearbox; the friction pair spindle is provided with a driving gear of the output gearbox; a plurality of satellite gears meshed with the driving gear are further arranged in the output gearbox; a shaft of each satellite gear is provided with a tool; a lifting platform is arranged below the tools; a fixing platform is arranged on the lifting platform, and the lifting platform is connected with an air cylinder. The reaming and tapping machine can conduct multi-position reaming or tapping on a workpiece to be machined simultaneously, improve the reaming or tapping efficiency and accurately determine the reaming or tapping positions in the reaming or tapping process, thereby improving the quality of the workpiece.

Owner:TIANJIN BOLIXIN HARDWARE PROD

Reamer with anti-drag reaming type belt

ActiveCN104563880AIncrease frictionImprove hole reaming efficiencyDrilling machines and methodsEngineeringReamer

The invention relates to a reamer with an anti-drag reaming type belt. The reamer comprises a belt body of an annular structure, the center of the belt body is fixedly connected with a drill rod by the aid of cross bars, multiple reaming rods are fixedly connected between the belt body and the drill rod and symmetrically arranged relative to the center of the drill rod, each of the drill rod, the reaming rods and the cross bars is of a hollow structure, multiple welding grooves are formed in the inner wall of the belt body symmetrically, the upper end of each reaming rod is welded in the corresponding welding groove, and the section of each reaming rod is of a square structure; multiple reaming strips are arranged on the outer wall of the belt body, an alloy block group is arranged between every two adjacent reaming strips, and each alloy block group comprises multipole alloy blocks arranged along the reaming strips; alloy blocks are evenly distributed on the outer walls of the cross bars and the reaming rods.

Owner:滁州正点电气有限公司

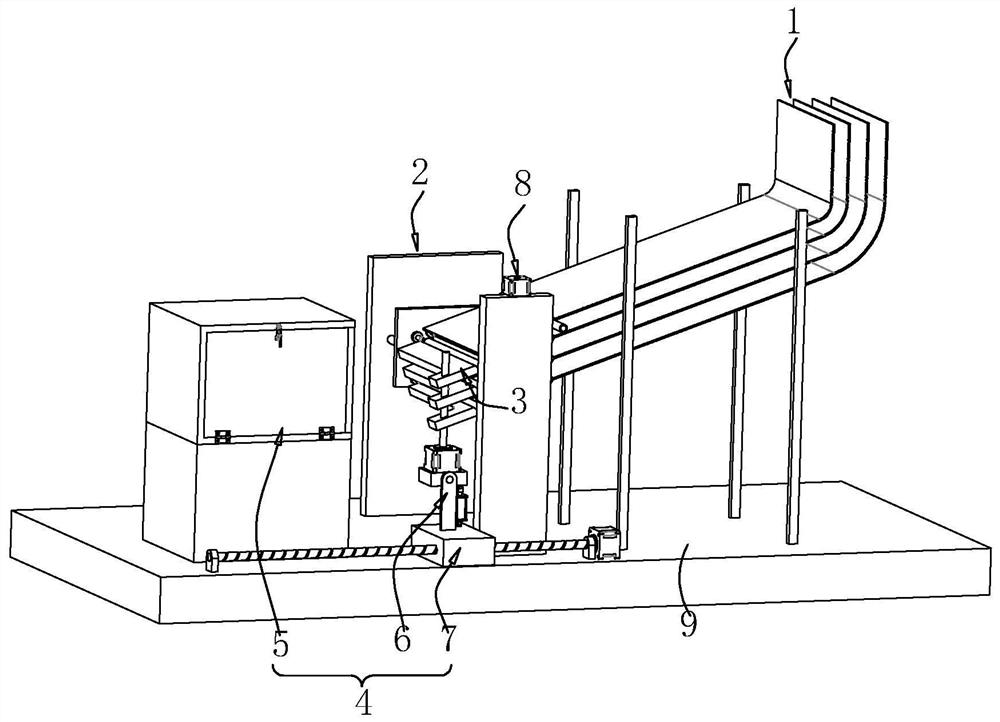

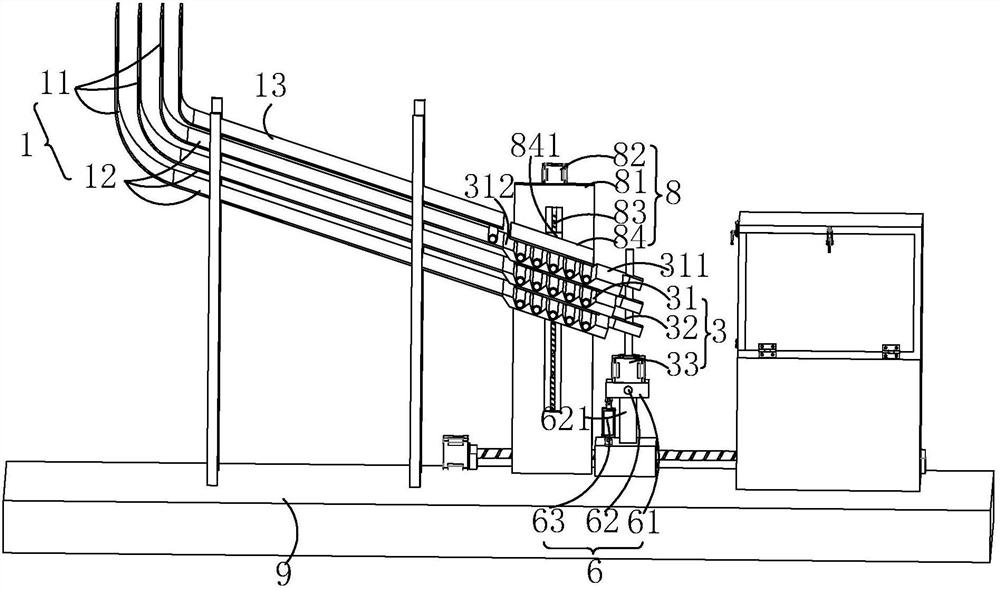

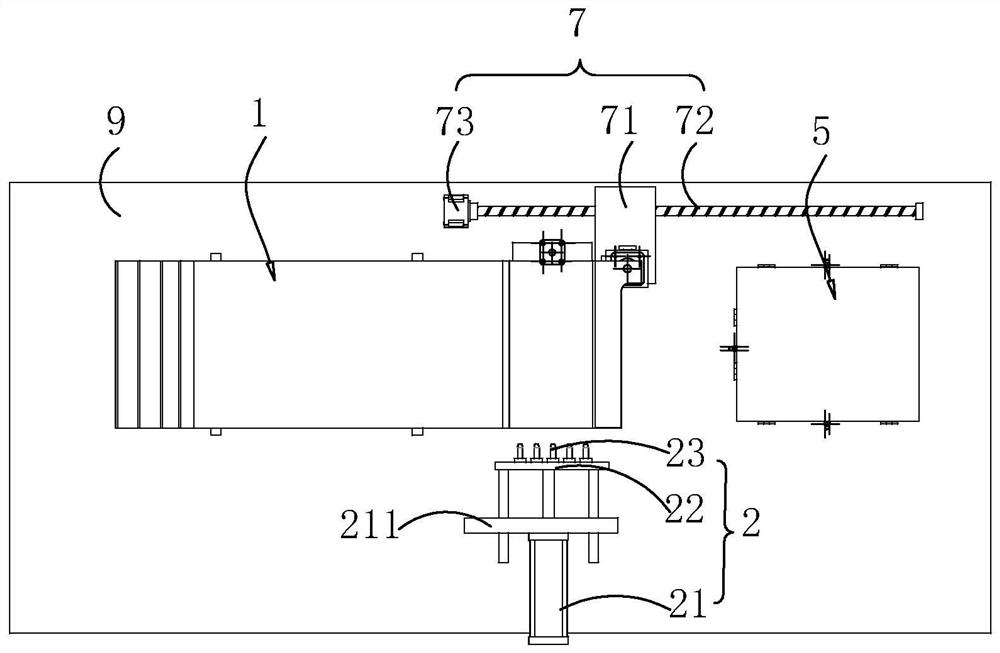

Super-automatic pipe reaming production line

ActiveCN112893664ASave labor and timeImprove hole reaming efficiencyMetal-working feeding devicesPositioning devicesElectric machineryStructural engineering

The invention relates to a super-automatic pipe reaming production line, and relates to the field of reaming machines. The super-automatic pipe reaming production line comprises a feeding assembly, a reaming assembly, a rotating assembly and a receiving device. The feeding assembly is located on one side of the reaming assembly, the receiving device is located on the other side of the reaming assembly, and the rotating assembly is located between the feeding assembly and the receiving device and is connected with the feeding assembly. The rotating assembly comprises a rotating plate, a rotating rod and a rotating motor, and the rotating plate is located between the feeding assembly and a material collecting box and connected with the feeding assembly. The rotating rod penetrates through one corner of the rotating plate and is fixedly connected with the rotating plate, and a driving shaft of the rotating motor is fixedly connected with the rotating rod. The receiving device is located on the side, away from the reaming assembly, of the rotating plate and connected with the rotating motor. The super-automatic pipe reaming production line has the advantages that full-automatic receiving and boxing of pipelines are achieved in the whole receiving process, workers do not need to count the number or box pipelines, and time and labor are saved.

Owner:苏州市吴中区木渎特种不锈钢材料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com