Ground drilling sectional type grouting device

A segmented grouting technology, which is applied to drilling equipment and methods, drilling equipment, drilling pipes, etc., can solve problems such as insufficient grouting pressure, endangering the life safety of staff, and rising of grout, so as to improve the sealing performance and firmness, improve the plugging effect, and improve the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

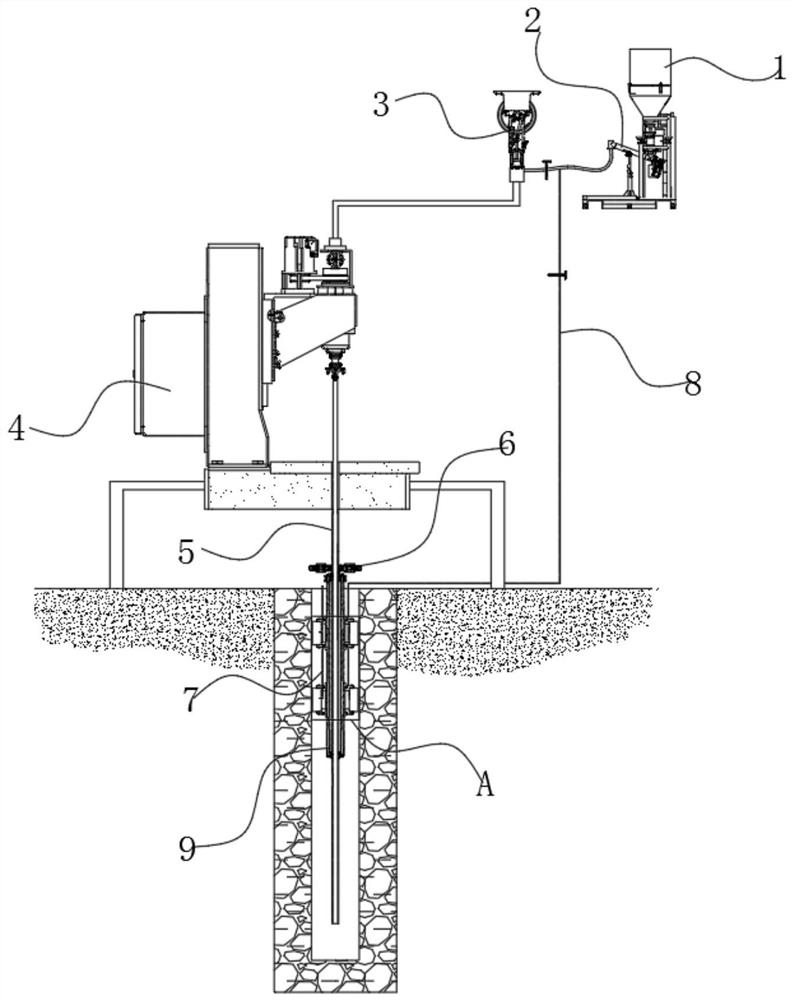

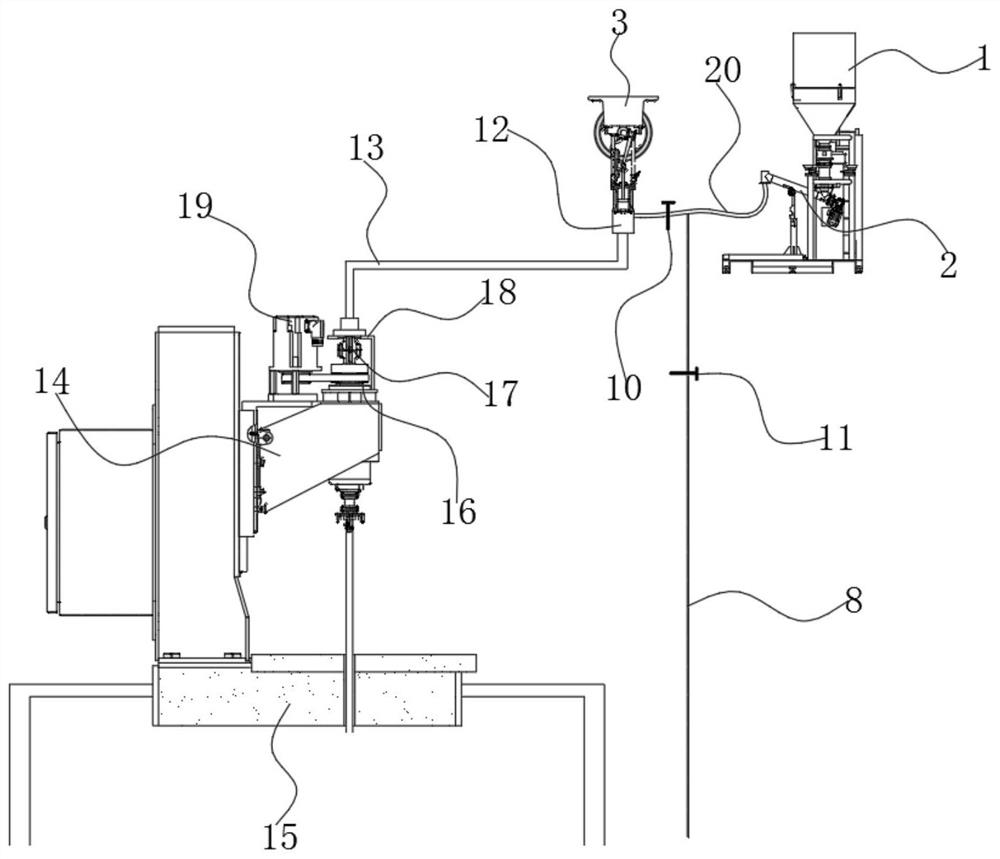

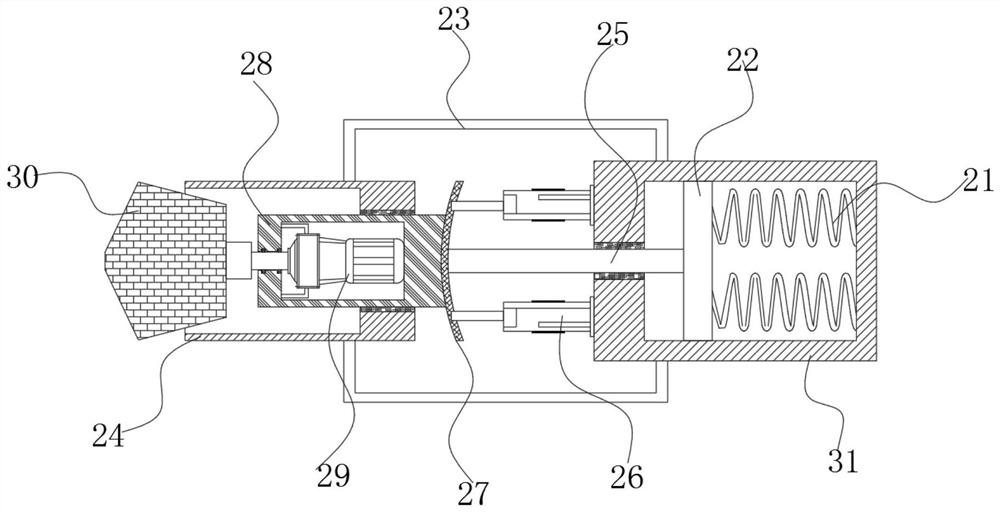

[0033] see Figure 1~5 , in an embodiment of the present invention, a ground drilling segmented grouting equipment, which includes a grout tank 1, a grouting main pipe 5, a reaming assembly 6, a liquid injection pipe 7, a low-pressure grouting pipe 8, an upper support plug component 32 and the lower support plugging component 33, wherein, the grouting main pipe 5 and the low-pressure grouting pipe 8 are both supplied with grout by the grout tank 1;

[0034] The grouting main pipe 5 is rotatably arranged in the centering sleeve 9, and the upper support block assembly 32 and the lower support block assembly 33 are arranged on the outer circumference of the centering sleeve 9, which are used to set the centering sleeve The cylinder 9 is supported in the inner wall of the borehole, that is to say, the upper support plugging assembly 32 and the lower support plugging assembly 33 are supported and attached to the inner wall of the borehole at the initial stage. After the hole is rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com